Hoping on Downstream Development of the National Seaweed

advertisement

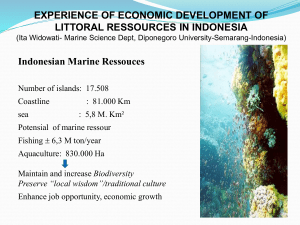

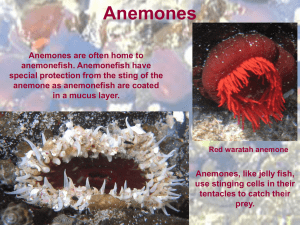

Hoping on Downstream Development of the National Seaweed Future national seaweed may change. This opportunity is open as the program in cooperation the Ministry of Industry Ministry of Maritime Affairs and Fisheries to develop downstream industries seaweed (Kompas, 6/1/2010). To support the program, an export ban has been discourse seaweed began in 2014. This plan should be pursued cautiously, because there are many problems that wait for a solution. Efforts to establish downstream industrial commodities, must be in line with the increasing prosperity of coastal communities. Seaweed is one of the mainstays of revitalization of fisheries. With a long coastline of this country, there is potential for approximately 1.1 million ha of land. Flown 20% of new land. These bright prospects for commodity markets. Because easily cultivated, their needs were great. Global needs of Eucheuma seaweeds 236 000 dry tons per year, just filled with 145 000 tons. For this type of Gracilaria, jelly-making materials, 96 000 tonnes, only produced 48 500 tons per year dry. Currently, world production of dried seaweed around 1.2 million tonnes. Approximately 50 percent of Indonesia and 35 percent from the Philippines. Indonesian seaweed exported to Danish, China, Philippines, Hong Kong, Spain, Japan and the United States, as food, drugs, and cosmetics. Still the largest export in the form of dried seaweed. Value accounted for 36% of total fisheries exports reached Rp 30 trillion. The type of seaweed Eucheuna cottonii nearly 90% are exported in the form of chips or flour, so little added value. Intermediate products are carrageenan seaweed, agar-agar, and alginate. Carrageenan, a stable maker, used in dairy products, processed meats, juices, bread products and others. In the field of non-food, carrageenan used industrial ceramic coatings, paper, textiles, biotechnology, and pharmaceutical industries, like cosmetics, sampho, and contraceptive gels. Carrageenan is relatively non toxic compared to other additives. Gelatin products used for clinical testing, molecular biology, and food industries. Water binding properties and the thermoreversible gel is important for food products. Eg bread, confectionery, dairy products, meat and fish, and beverages. Meanwhile, the alginate to stabilize or strengthen the texture of processed products, such as ice cream, juices, and pastries. Chemical and physical properties of alginate functions as elmusifier, stabilizer, coating agents, and others. Development of intermediate products of seaweed, followed by an absolute increase in power absorbed in the food industry, beverages, cosmetics in the country. If not, will be a new problem. Moreover, if the export of dried seaweed are prohibited, while in the country has not absorbed, then the coastal communities will be sacrificed. Myriad problems Although our country is potential to develop seaweed, a myriad of problems still facing. Problems in the upstream, among others: First, we do not have nationally accurate map-related territorial waters suitable for seaweed farming. Second, most seaweed seedling vegetative development results so prone to disease and less productive. We have not seriously provide separate seeds of each species and strainnya from nurseries. Third, human resources (HR) pembudida seaweed 79.05% did not complete primary school, 17.59% complete primary school, and only 0.03% of a degree. Fourth, the limited capital of cultivators. Financial institutions still consider this a high risk business. Downstream issues such as: First, the seaweed is often harvested young (less than 40 days) so the quality is bad. It also triggered a mischievous act of the mediator to meet the quota order. Secondly, the drying is dried away. From farmers, the water content of about 30-40%, exceeding the standard from 11.80 to 13.90% of dry seaweed. Third, the national downstream industries is very limited, so little added value. Fourth, government regulation has not been sharp. For example, the seaweed industry cluster programs in various provinces of sporadic and not well impressed evaluations. Some Solutions To solve the problem, it needs the synergy of the various parties to develop seaweed. In the upstream sector, need to do mapping and classification of seaweed farming in accordance carrying capacity. Knowledge and skills base of farmers cultivating and processing also needs to be improved. Therefore, the not only counseling are needed, but also adjacent. Then, facilities and infrastructure and capital cultivation farmers need to be improved, as well as institutional strengthening and empowerment of farmers to be able to synergize fairly with other business actors. In the lower reaches of the necessary development of downstream industries that enhance the value added. As an illustration, from dried seaweed valued at Rp 5000, when processed into Semi Refine carrageenan (SRC), food grade could be worth Rp. 40,000 to Rp 66 000. If processed until Refine carrageenan (RC) for drugs worth Rp 75,000 to Rp 95 000 (Basmal, 2007). We must attempt to improve the quality of Indonesian National Standard (SNI) and international certification and accreditation, so that we can compete with producers of other seaweeds, such as the Philippines, China, Korea, and Chile. Also important is to strengthen the national structure of the seaweed industry from upstream to downstream. Articles cluster seaweed needs to be strengthened in order to create fair business mechanisms between farmers, processors, and other business elements. Despite many constraints, we are optimistic we will be able to seaweed to compete at international level. Source: Opinion Sucipto, STP. MP. (UB lecturer FTP TIP) in Cash Daily Friday 8, January 2010.