Carbon Monoxide - Swansea University

advertisement

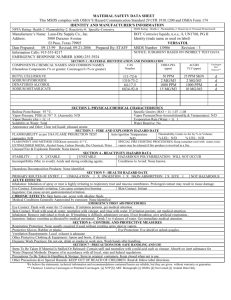

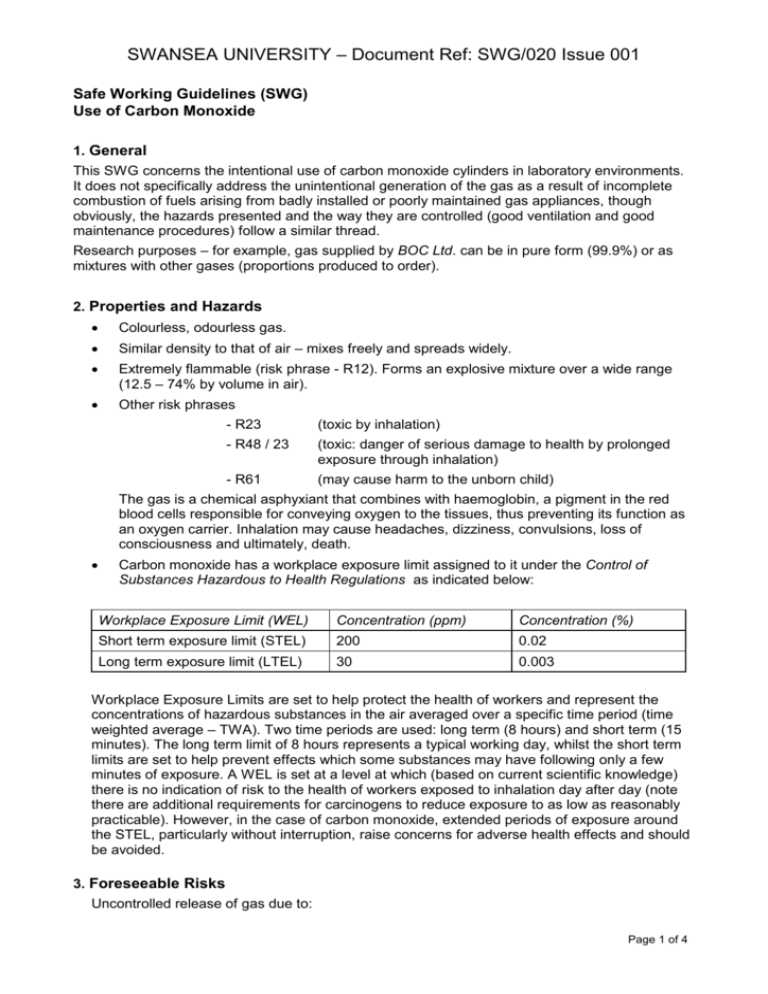

SWANSEA UNIVERSITY – Document Ref: SWG/020 Issue 001 Safe Working Guidelines (SWG) Use of Carbon Monoxide 1. General This SWG concerns the intentional use of carbon monoxide cylinders in laboratory environments. It does not specifically address the unintentional generation of the gas as a result of incomplete combustion of fuels arising from badly installed or poorly maintained gas appliances, though obviously, the hazards presented and the way they are controlled (good ventilation and good maintenance procedures) follow a similar thread. Research purposes – for example, gas supplied by BOC Ltd. can be in pure form (99.9%) or as mixtures with other gases (proportions produced to order). 2. Properties and Hazards Colourless, odourless gas. Similar density to that of air – mixes freely and spreads widely. Extremely flammable (risk phrase - R12). Forms an explosive mixture over a wide range (12.5 – 74% by volume in air). Other risk phrases - R23 (toxic by inhalation) - R48 / 23 (toxic: danger of serious damage to health by prolonged exposure through inhalation) - R61 (may cause harm to the unborn child) The gas is a chemical asphyxiant that combines with haemoglobin, a pigment in the red blood cells responsible for conveying oxygen to the tissues, thus preventing its function as an oxygen carrier. Inhalation may cause headaches, dizziness, convulsions, loss of consciousness and ultimately, death. Carbon monoxide has a workplace exposure limit assigned to it under the Control of Substances Hazardous to Health Regulations as indicated below: Workplace Exposure Limit (WEL) Concentration (ppm) Concentration (%) Short term exposure limit (STEL) 200 0.02 Long term exposure limit (LTEL) 30 0.003 Workplace Exposure Limits are set to help protect the health of workers and represent the concentrations of hazardous substances in the air averaged over a specific time period (time weighted average – TWA). Two time periods are used: long term (8 hours) and short term (15 minutes). The long term limit of 8 hours represents a typical working day, whilst the short term limits are set to help prevent effects which some substances may have following only a few minutes of exposure. A WEL is set at a level at which (based on current scientific knowledge) there is no indication of risk to the health of workers exposed to inhalation day after day (note there are additional requirements for carcinogens to reduce exposure to as low as reasonably practicable). However, in the case of carbon monoxide, extended periods of exposure around the STEL, particularly without interruption, raise concerns for adverse health effects and should be avoided. 3. Foreseeable Risks Uncontrolled release of gas due to: Page 1 of 4 regulator failure. failure of pipework or tubing connecting cylinder to other equipment. damage caused by impact e.g. falling cylinder. damage caused by fire. human error – valves left open. 4. Assessment of Potential for Gas Release It is difficult to determine exactly what rate CO would be discharged from a cylinder in the event of a hose or line break. There is also the possibility of leakage from poorly fitted regulators. As always, we have the slow release (over the course of the day or night) and rapid release or ‘worst case’ scenarios. Slow release is arguably more likely than a sudden or fast release and there is also a greater chance that a slow release would go unnoticed (a sudden failure or rapid release may well give rise to hissing, popping or other audible / visual warnings that would alert anyone in the vicinity to the fact that something was wrong). Both are considered below: Examples: Using the equation: C = L / Vn where: C = CO concentration in room L = CO release from cylinder (m3 / hour) V = room volume (m3) n = air changes per hour …….the levels of CO that could be expected in a laboratory with dimensions 6m x 4m x 3m having one air change per hour are given in the table below: Cylinder size* Standard contents* Level of CO in 72m3 room from rapid total release Level of CO in 72m3 room from slow release (8 hour) # AV 3ft. (pure CO) 1.91 m3 26500 ppm 2.65% 3300 ppm 0.33% AK 5ft. (pure CO) 7.67 m 3 106500 ppm 10.65% 13300 ppm 1.33% AV 3ft. (0.1% CO) 1.91 m3 30 ppm 0.003% 3 ppm 0.0003% AK 5ft. (0.1% CO) 7.67 m3 100 ppm 0.01% 10 ppm 0.001% * figures provided by BOC Ltd. # slow release being the rate of release which causes the cylinder to completely empty over a period of 8 hours. It can be seen that, in the event of a slow release in an open laboratory, the levels of CO that can accumulate when the pure gas is used are still way above the assigned workplace exposure limits and that even forced extraction in the region of 10-20 air changes an hour would not reduce the level below those limits. With the low concentration mixture, the potential levels are much lower risk – below the exposure limits. 5. Control Measures Control should normally be achieved by a combination of measures but follows the general hierarchy: 1. Eliminate or minimise risk of a CO release at source. 2. In the event of a release, dissipate the gas before it builds up to a dangerous concentration. Page 2 of 4 3. In the event of 1 and 2 failing, have detection systems to warn of a release before the gas accumulates to a dangerous level. Ways of eliminating or minimising risk at source Eliminate the need to use CO or substitute for a safer agent – standard elements of the COSHH hierarchy. Minimise size of cylinder – smaller cylinders in preference to larger. Inventory control - order as and when required. Do not store more than one cylinder in the laboratory. Fit safety devices such as gas fuses. These are commercially available for use with CO and affect a total shut down in the event of a hose or line break. These devices also have no auto-reset – the system must be isolated and the fault rectified before reconnection is possible. Ensure that cylinders are secure and away from sources of heat. Ensure that there is a regime in place for proper systematic checking and maintenance of regulators and associated parts. This should comprise routine simple user checks and annual maintenance checks by a competent person. Training – ensure that users are familiar with the equipment and the properties of all substances that they are handling and know what to do in an emergency. Records of training should be maintained accordingly. Dissipating the gas in the event of a release Ventilation. Ensure that CO is used in well ventilated areas. The formula in Section 4 should enable you to estimate the sort of levels that the gas could reach under particular circumstances. If pure CO is being used and the calculations suggest that the gas could not be dissipated below the exposure limits even with forced room ventilation, then total enclosure of the process / local exhaust ventilation should be considered (including use of a gas cabinet). It is also imperative that the other controls outlined in this section are in force. Eliminate all sources of ignition (including static discharges). A standard precaution for all flammable gases – this will avoid the risk of the gas igniting or exploding should it reach the explosive threshold. Detection Due to the toxicity of the gas, it is recommended that CO detectors are installed wherever the gas is used. Detectors provide evidence of the efficacy of other controls and also reassure workers. They are usually available in ranges from 0 – 2000ppm and typically have first and second stage alarm settings. The set-points should be in the vicinity of the WEL’s or lower - manufacturers will normally advise on the positioning, setting and maintenance requirements. Page 3 of 4 Other factors to consider Risks to pregnant workers: At the time of publication of this guidance, the lowest recorded feto-toxic levels of CO are significantly above the workplace exposure limits. Therefore, providing the activity has been risk assessed and controls implemented to enable exposure to be controlled below the WEL, then there is no additional risk to the foetus. To confirm that exposure is being controlled below the WEL then continuous monitoring or air sampling will be necessary. Emergency procedures: - - Be aware of fire / explosion potential – do not introduce any sources of ignition. Stop the flow of gas but only if safe to do so. Leave the area immediately if a leak is detected / suspected. If possible, increase ventilation to the area. Rescue personnel should be equipped with self-contained breathing apparatus. University staff should not attempt this unless fully maintained breathing apparatus is available and users have been specifically trained to handle the equipment. Otherwise, the emergency services should be summoned following the established procedures for the area concerned. If all of the above control measures are implemented the likelihood of an overexposure and rescue situation arising should be very low. Seek medical treatment for all cases of overexposure to the gas. Page 4 of 4