Silica Control

advertisement

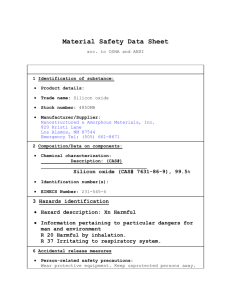

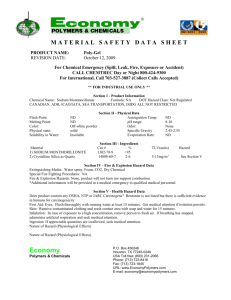

Silica Control Program Audit Why conduct an audit of your program? A periodic audit of your Silica Control Program helps to ensure that key program elements are in place and operating so your goals of controlling silica exposures and preventing silicosis are achieved. The questions in this checklist are designed as a management tool for assessing your Silica Control Program. In addition to verifying the appropriate program elements currently in place, this checklist also will help you identify weaknesses or gaps in your program and guide you in developing appropriate solutions. How to conduct an audit of your program Use this audit checklist to review your Silica Control Program as it currently operates, not as you think it should be operating or as it was originally intended to operate. Review the pertinent records (for example, air monitoring results, respiratory protection program, training records) to help you determine the status of key program elements in the checklist. After completing the checklist, determine which program elements need improvement (i.e., where there are "No" answers) and complete the Silica Control Program Audit Results found at the end of this booklet. Please Note: The audit procedures in this booklet are based on OSHA's National Emphasis Program – Crystalline Silica and NIOSH's Recommended Standard for Occupational Exposure to Crystalline Silica. Some states may impose more stringent requirements than those covered in this booklet. Be sure to refer to all applicable state and local regulations when conducting your audit. This booklet is informational only and was compiled from sources believed to be reliable. Zurich Services Corporation Risk Engineering makes no guarantee of results and assumes no liability in connection with the information, methods or safety suggestions contained herein. Moreover, it cannot be assumed that every acceptable safety or compliance procedure is contained herein or that abnormal or unusual circumstances may not warrant or require additional procedures. 1 Silica Control Program Audit Checklist A. Exposure Assessment Begin your audit with a review of the air sampling records related to employee exposure to respirable silica. Be sure to consider any new areas or processes where employee silica exposure occurs, but which have not been monitored yet Yes 1. Has air monitoring been conducted to identify employees (all job classifications) exposed to crystalline silica? 2. Are air samples representative of the breathing zone of employees, for every operation or process, and evaluated on a full-shift basis? 3. Does survey information include sampling and analytical methods; type of personal protective equipment, if any, in use at the time of sampling; environmental conditions; and the monitoring results? 4. Was all monitoring equipment calibrated before and after the survey(s) and is calibration documentation available? 5. Are reports from silica surveys available for review? 6. Are all employees found to be exposed to respirable silica above the Permissible Exposure Limit (PEL) informed of the survey results? 7. Have all employees found to be exposed above the PEL been included in your Silica Control Program? 8. If initial sampling results were between the PEL and Action Level (50% of the PEL) was additional air monitoring conducted at least every 6 months to further assess exposure? 9. Have supervisors been provided summaries of airborne silica exposure monitoring results for employees in their departments/areas? 10. Are airborne silica monitoring results used to prioritize areas and operations for control measures implementation? 11. Is breathing zone air sampling conducted within 30 days after changes in production processes, equipment, materials, or controls? 12. Are records maintained for all air sampling surveys? 13. Are records maintained for at least 30 years following termination of a worker's employment? 14. Are records maintained for at least 30 years following termination of a worker's employment? 2 No B. Evaluation of the Written Program Next, evaluate the content and implementation of your written Silica Control Program. The written program must reflect what you are doing in your workplace. For example, the written program must list the affected employees or areas at your site, indicate who is responsible for the various aspects of the program, and indicate how any written materials or exposure records will be made available to employees. Yes 1. Has a written silica control program been established and implemented for your facility or job site? 2. Does the written program include a description and instruction for the following: a. Policy statement outlining management's commitment to an effective program? b. Exposure assessments, including identification of employees/tasks where exposure to crystalline silica exists, and ongoing air monitoring procedures? c. Work practice and engineering control measures in place and planned? d. Use of personal protective equipment and work clothing, including respiratory protection procedures, if respirators are utilized? e. Labeling and warning procedures? f. Housekeeping and hygiene procedures? g. Employee Training procedures? h. Recordkeeping procedures? 3 No C. Engineering and Administrative Controls Engineering controls include substitution with less toxic materials, dust suppression methods, and ventilation control measures. Administrative controls include work practices such as appropriate housekeeping, maintenance and repair operations, hygiene procedures, and prohibited practices. 1. Are engineering controls (such as substitution, dust suppression, ventilation, and isolation) used wherever it is economically and technically feasible to lower the silica exposure of workers? 2. Are inspection and maintenance of engineering controls scheduled regularly to ensure their continued effectiveness? 3. Have preventive maintenance and prompt repair of equipment been implemented to help reduce the potential for leakage and collection of dusts containing silica? 4. Housekeeping a. Are surfaces maintained free of silica dust accumulation? b. Are spills promptly cleaned to help reduce the potential for material to become airborne? c. Is cleaning with compressed air and dry sweeping prevented? d. Have dust controlling cleaning methods such as vacuuming and washing down with water been implemented where appropriate? 5. Hygiene Procedures a. Are smoking, eating and drinking prohibited in areas with potential silica exposure? b. Are employees' work clothing vacuumed before entering the lunch and break area and before removal at the end of the shift? c. Is cleaning of work clothing by shaking or blowing with compressed air prohibited? 4 Yes No D. Respiratory Protection Approved respiratory protection, governed by a respiratory protection program, is required for every worker exposed to silica above the OSHA PEL when exposures are not controlled by engineering means. When evaluating respiratory protection, be sure to review the most recent exposure assessments to help determine that respirators currently assigned are appropriate (i.e., have an adequate Assigned Protection Factor). A "walkthrough" should be conducted to determine, first hand, that employees are wearing and maintaining their assigned respirators, as directed Yes 1. Are respirators required wherever employee exposures can not be controlled below the exposure limit by engineering means? 2. Are respirators required as interim control measures until engineering methods have been installed and proven effective in reducing employee exposures below the Permissible Exposure Limit? 3. Is each respirator, currently assigned and in use, a NIOSH approved respirator? 4. Has each respirator been selected based on NIOSH Assigned Protection Factors and results of the most recent silica exposure assessments (See Table 1)? 5. Are NIOSH approved, Type CE abrasive blasting respirators (continuous flow air-line respirators) required during silica sand abrasive blasting operations? 6. Based on your observations during a walk-through, are employees wearing the respirators assigned to them for the job/task that requires respirator use? 7. Are supervisors adequately enforcing use of respirators where needed? 8. Is the use of respiratory protection governed by a respiratory protection program which meets the requirements of 29 CFR 1910.134, Respiratory Protection, including procedures for: a) respirator selection b) medical evaluations c) training d) fit testing e) use f) cleaning and storage 5 No E. Labeling and Warning The purpose of warning signs and labeling is to inform and alert potentially exposed workers of the presence and type of hazard associated with the area and/or product so appropriate precautions may be taken. Labeling and warnings described in your written program should be verified by a "walk-through". Yes 1. Are required warning signs printed in English and the predominant language of non-English speaking employees (unless otherwise trained and informed of the hazardous areas)? 2. Are illiterate employees otherwise trained and informed of the hazardous areas? 3. Is a warning sign restricting access posted and readily visible at entrances to work areas where exposure to crystalline silica exists? 4. Is a warning sign or other labeling with appropriate hazard warning posted or readily available in any work area where exposure to crystalline silica exists (and where respirators are required)? For manufacturers and distributors: 5. Is a warning label with appropriate hazard warning placed on all materials, mixtures, and other products containing more than 0.1% crystalline silica, or on their containers? Note: These labels must be in addition to or in combination with labels required by other statutes, regulations or ordinances? 6. Do Material Safety Data Sheets indicate the presence of silica for concentrations at or above 0.1% and indicate the IARC (International Agency for Research on Cancer) carcinogenic designation? 6 No F. Medical Surveillance An effective medical surveillance program should (1) establish a baseline with which to assess changes in an exposed worker's respiratory system, (2) provide for early detection of abnormalities, and (3) identify failures in the dust control program and potentially hazardous work areas not found by inspection and exposure monitoring. The audit should include a review of available, non confidential records to determine that the appropriate level of medical surveillance is performed for employees. An interview with the medical provider may be needed to complete the audit. Yes 1. Are medical examinations conducted on individuals who are potentially exposed to crystalline silica at one-half the permissible exposure limit (PEL) or more? 2. Do medical examinations include: a. Baseline examinations, which include a medical and occupational history to elicit data on signs and symptoms of respiratory disease, performed prior to exposure to crystalline silica? b. Baseline and follow-up chest x-ray performed prior to placement? c. Chest roentgenogram (posteroanterior 14"x17" or 14" x 14") classified according to the 1970 ILO International Classification of radiographs of Pneumoconiosis by certified class "B" reader? d. Baseline and follow-up pulmonary function tests which include FEV1 (forced expiratory volume in 1 second), FVC (forced vital capacity) and DLCO (diffusion lung capacity)? e. A baseline tuberculosis evaluation (intradermal skin test using pure protein derivative)? 3. Are follow-up medical examinations emphasizing the respiratory system, including the chest x-ray and PFT, conducted on at least the following schedule: a. Every three (3) years if the employee has less than 15 years of exposure to crystalline silica, every two (2) years if the employee has 15 to 20 years of exposure and annually if over 20 years of exposure? b. A more frequent medical examination if respiratory symptoms develop or upon the recommendation of the examining physician? 4. Are chest x-rays obtained upon employment termination? Medical Management Procedures 5. Is a worker with a positive chest x-ray (1/0 or greater) placed in mandatory respiratory protection, or if already wearing a respirator, is the program re-evaluated to assure proper fit and that the elements of 29 CFR 1910.134 are being met? 7 No Yes 6. Is the worker referred to a physician specializing in lung diseases for a medical evaluation and medical monitoring as warranted by the examining physician? 7. Is a written opinion from the examining physician as to whether the employee has any detected condition that would place the worker at an increased risk provided to the employer and employee, while specific medical findings remain confidential? 8. Are employees, with or without roentgenographic evidence of silicosis who have respiratory distress and/or pulmonary functional impairment, fully evaluated by a physician qualified to advise the employee whether he/she should continue in a dusty trade? 9. Are all medical test results discussed with the worker by the physician and is each employee able to obtain information on his/her medical exam? 10. Are medical records maintained for at least 30 years following the employee's termination of employment, unless the employee is employed for less than one year and the records are provided to the employee upon termination? 8 No G. Training Program Employee training is an integral part of any effective safety and health program. A training program and material safety data sheets are required to inform employees about the hazards of crystalline silica, the controls implemented to prevent overexposure, and precautions to take in areas of potential exposure. For the audit, review the written program and training records. Yes 1. Has a training program for the prevention of silicosis been developed and implemented? 2. Are all employees exposed to respirable silica included in the training program? 3. Do new employees receive the training as part of their orientation? 4. Is the training repeated annually? 5. From the training program materials, determine if they include at least the following information: a. The effects of silica exposure on the lungs and symptoms of exposure. b. The increased risk of impaired health due to the combination of smoking and respirable silica dust exposure. c. The specific nature of work place operations that could result in exposure to silica above the OSHA PEL and the type and function of engineering controls. d. Instruction about obeying signs that mark the boundaries of regulated areas containing crystalline silica. e. Proper conditions and precautions for safe use or exposure. f. Appropriate emergency procedures. g. The purpose of respiratory protection, with instruction on fitting, use and care. h. Description and purpose of the medical surveillance program. i. 6. Availability and location of written procedures and health information, such as the material safety data sheet, and the company's Silica Control Program. Are records of employee training maintained? 9 No Table 1: Recommended Respiratory Protection based on NIOSH Assigned Protection Factors Exposure Condition Up to 5 x PEL Respiratory Protection Single-use or quarter mask respirator Up to 10 x PEL Up to 25 x PEL Up to 50 x PEL Air-purifying half-mask respirator.1 Air-purifying full-facepiece respirator equipped with any type of particulate filter. Supplied-air half-mask respirator operated in a demand mode. Powered, air-purifying respirator with a hood or helmet and any particulate filter. Supplied-air respirator equipped with a loose fitting facepiece and operated in a continuous-flow mode. Air-purifying full-facepiece respirator equipped with a high efficiency particulate (HEPA)3 filter. Powered, air-purifying respirator with a tight-fitting facepiece and a high-efficiency particulate (HEPA)3 filter. Supplied-air or self-contained2 respirator equipped with a full facepiece and operated in a demand (negative pressure) mode. Supplied-air respirator equipped with a tight-fitting facepiece and operated in a continuous-flow mode. Up to 1,000 x PEL Supplied-air respirator equipped with a half-mask and operated in a pressure-demand or other positive pressure mode Up to 2,000 x PEL Supplied-air respirator equipped with a full facepiece and operated in a pressure-demand or other positive pressure mo Up to 10,000 x PEL Self-contained breathing apparatus equipped with a full facepiece and operated in a pressure-demand or other positive-pressure mode. Supplied-air respirator equipped with a full facepiece and operated in a pressure-demand or other positive pressure mode in combination with an auxiliary selfcontained breathing apparatus operated in a pressuredemand mode. PEL = Permissible Exposure Limit 1Includes disposable half-mask and elastomeric facepieces 2Self-contained breathing apparatus 3Also known as N100, P100, or R100. 10 Silica Control Program Audit Results 1. List below the item numbers that were answered "No" in the audit checklist. 2. Identify the Corrective Action that will be taken to address each item. 3. When the Corrective Action has been completed, fill in the Completion Date. Example: Item # A14 Item # Corrective Action Make results of Silica Survey available for review Corrective Action Date of Audit: Audited By: 11 Completion Date 5/30/08 Completion Date