Abstract

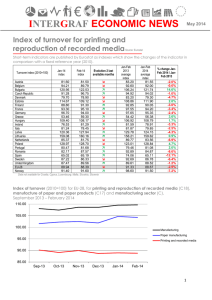

advertisement

Electrolytic gradient Al2O3-ZrO2 composite coatings on Ti-6Al-4V implant alloys S. J. Wu, S. K. Yen* Department of Materials Engineering, National Chung Hsing University 250, Kuo Kuang Road, Taichung, 40254, Taiwan Abstract The bioceramic coatings on metallic implants have the potential to improve the performance with respect to implant fixation, wear and/or corrosion resistance. In this study, a novel method of electrolytic Al2O3-ZrO2 nanostructure composite coatings were successfully conducted on F-136 Ti-6Al-4V alloy in the mixture of ZrO(NO3)2 and Al(NO3)3 aqueous solution. The uncoated and Al2O3-ZrO2 coated specimens were evaluated by cycle polarization tests in Hank’s solution, wear tests (including dry and wet) with UHMWPE (ultra-high molecular-weight polyethylene), scratch tests, and surface morphology observations. Al2O3-ZrO2 coated specimens have shown the better corrosion resistance than the uncoated specimen, such as higher corrosion potential Ecorr, lower corrosion current density icorr, and higher protection potential Epp. The nanostructure of Al2O3-ZrO2 composite films with a little gradient distribution was confirmed by AFM observations and AES components depth profiles. The wear loss of UHMWPE was dramatically reduced by the Al2O3-ZrO2 composite coating. The nature passivation film of the uncoated was destroyed during the wear corrosion test. In contrast, the Al2O3-ZrO2 coated maintained at the passive state. Al2O3-ZrO2 composite coating still remaining on the Ti-6Al-4V alloy after the scratch test indicated the excellent adhesion between the coated film and the substrate. Keywords: electrolytic coating, nanostructure Al2O3-ZrO2 composite, Ti-6Al-4V alloy, UHMWPE, gradient, wear-corrosion. Introduction The main characteristics for biomaterials are mechanical properties, biocompatibility, bioahesivity, and biodegradation. Based on the biocompatibility, biomaterials can be divided into four types: nearly inert, porous, bioactive, and resorbable. The implants of the total hip joint replacement (THR) are composed of femoral stem (alloy), ball head (alloy or ceramic), shell (alloy), and acetabular cup (polymer). Titanium alloys have been clinically used for dental and orthopaedic applications owing to their advantages, such as light, high specific strength, lower modulus of elasticity, greater corrosion resistance, and excellent biocompatibility. Ti-6Al-4V ELI is the first titanium alloy registered as an implant material in the ASTM standard (F-136-84). Ultra-high molecular weight polyethylene (UHMWPE) is an organic polymer widely used as an acetabular cup in hip joint replacement, or tibia plateau in knee joint replacement. Ti-6Al-4V/UHMWPE couple is one of the most important biomaterials systems for total joint replacement prosthesis. When the sliding surfaces of the joint components are made from titanium alloys, wear can load to dirty of surrounding tissue and failure of the joint [1-2]. Variable amounts of plastic and metal are released due to wear and wear-corrosion. Therefore, how to improve the wear resistance of UHMWPE/alloy couple and reduce the volumes of wear debris, hereby becomes a key factor for achieving the long life of orthopaedic joint prostheses. To solve the above problems, Boutin [3] in France started to develop a hip prosthesis with cup and ball made of alumina ceramic at the beginning of 1970s. Semlitsch et al. [4] have determined that the wear rate of polyethylene (PE) against alumina ceramic is about 20 times lower than that of PE against Co-Cr-Mo alloy. However, alumina ceramic exhibits to incline to the fragile and is sensitive to microstructural cracks [5]. Recently, zirconia ceramic is being recognized for its high strength and high toughness, making this material potentially suitable for the highly loaded environments found in joint replacement [5-8]. Therefore, some authors have recently proposed ceramic balls made of a mix of zirconium and aluminum oxides [9] claiming against higher strengths and lower wear rates. Between the biocompatibility of zirconia and that of alumina ceramics, there is no apparent difference in the biological reaction in vivo [10-11]. In addition, the wear factor of UHMWPE against ZrO2 is 40%-60% less than that against Al2O3 counterfaces and 10%-20% less than that against SUS 316L metal counterfaces [12]. Also, some surface modification on alloys may be helpful. An electrolytic coating of zirconia single layer successfully conducted on pure titanium and Ti-6Al-4V substrate has shown the excellent adhesion on the metal substrate and improved corrosion resistance [13-15]. Similar results were also found on alumina and zirconia coated Co-Cr-Mo alloy [16-17]. In this study, the characterization of electrolytic gradient Al2O3-ZrO2 composite layer coating on Ti-6Al-4V alloy including the wear loss of counterpart UHMEPE, and the corrosion resistance, adhesion, and wear-corrosion resistance of the coated specimen is reported. 2. Experimental 2.1. Sample preparation An ASTM F-136 Ti-6Al-4V sheet, as received, was used as a substrate of the Al2O3-ZrO2 electrolytic gradient coating. Its nominal composition is given in Table 1. The sheet thickness is 1.0 mm with a grain size of 5 2 m. The sheet was cut into discs with a diameter of 14 mm for corrosion tests, and 28 mm for wear and scratch tests. All specimens were polished to a mirror finish with 0.3 m Al2O3 powders, then degreased by detergent and further ultrasonically cleaned in deionized water and acetone, then dried by an N2 gas gun. 2.2. Electrolytic deposition and annealing The electrolytic deposition of Al2O3-ZrO2 with gradient composition was conducted in a naturally aerated solution of ZrO(NO3)2 and Al(NO3)3 aqueous solution, at pH = 2.66 and a scanning cathodic potential from the range of -0.8 to -1.8 V (Ag/AgCl) with a scanning rate of 2 mV/sec by using an EG&G M273A Potentio-stat and M352 software. The alloy disc was the cathode, graphite the anode, and a saturated calomel the reference electrode. The above electrolytic condition was the most efficient deposition in our experiment. The post-coated specimens were naturally dried in the air and annealed at 823 K for 1h. 2.3. Scratch, wear, and wear-corrosion tests Some specimens were tested by scratch using Model ST200/F TEER COATING Limited (England) with a preload 1N, load speed 50 N/min, scratch speed 20 mm/min, and the end load 50 N. Reciprocating wear test was also conducted by the above instrument ST200/F. UHMWPE in diameter of 0.5 mm, finally polished with # 2000 SiC paper, was used as pin. The Al2O3-ZrO2 coated and uncoated specimens were used as disks respectively, with a contact surface area of 0.2 mm2 and a load of 10 N (or axial stress of 50 MPa), at the sliding distance of 1 mm per cycle with 30 cycle/min. The drive speed and room temperature (251oC) were kept constant throughout the test and the duration is 1 hr. Frictional force between the UHMWPE pin and the counterface was monitored by a strain gauge fixed on a leaf spring attached to the transverse bar holding the PE pin. The wear-corrosion experiments were performed in Hank’ solution at 37±1℃, using an Ag/AgCl reference electrode and a platinum sheet as counter electrode. A potentio-stat EG&G PAR 273A was used to measure the corrosion potential and current density. A polyvinyl chloride (PVC) cell contains the test solution and a transmission shaft with a counterface connected to the motor, as shown in Fig. 1. Wear-corrosion tests were performed in the pin-on-disk configuration, with a counter rotation speed of 458 rpm, and a weight of 21.9 MPa. The uncoated and Al2O3-ZrO2 composite coated discs(ψ22 mm) were used as the counterpart and connected to the working electrode. The test duration was 3 h for a total wear path length of 1250 m. 2.4. Corrosion test All annealed specimens were potentiodynamically polarized with EG&G Model 273A M352 in aerated Hank’s solution with pH value of 7.1 which compositions are given as: NaCl 8.00 g/L, CaCl 0.14 g/L, KCl 0.40 g/L, NaHCO3 0.35 g/L, Glucose 1.00 g/L, MgCl26H2O 0.10 g/L, KH2PO4 0.06 g/L, Mg2SO47H2O 0.06 g/L, and Na2HPO4 0.06 g/L. The cyclic polarization test was from -0.80 to +0.80 V (Ag/AgCl), then back to -0.80 V at a scanning rate of 0.166 mV/sec. The first oxidation-reduction equilibrium potential E01 was derived when current density equals zero during the applied voltage increased (forward cycle). At E01, the reduction current density is equal to the oxidation current density. This exchange current density is defined as the equilibrium current density i0. They are also called corrosion potential Ecorr and corrosion density icorr respectively, when the oxidation is attributed to metal corrosion. 2.5. SEM, AFM, and AES The surface morphology of coated specimen after scratch, or wear test was observed by scanning electron microscopy/energy depressive spectroscopy (SEM/EDS, JEOL JSM-5400 Japan). The nanostructure of Al2O3-ZrO2 composite film was clarified by the observation using atomic force microscopy (AFM, Digital instrument NS3a controller with D3100 stage), with an attempt to evaluate the surface morphology of thin films in terms of the three-dimensional roughness, obtained by the image analysis. The component depth profiles were plotted using an Auger electron spectroscopy (AES Fison VG Microlab 310D). Specimens were sputtered by 5 KeV Ar+ with a beam current of 0.05 A, and a sputtering rate about 1 nm s-1. 3. Results and Discussion 3.1. Corrosion resistance From polarization curves as shown in Fig. 2, the first redox potential E1 (or corrosion potential Ecorr), the second redox potential E2 (or protective potential), equilibrium current i0 (or corrosion current), cathodic polarization slope c, anodic polarization slope a are analyzed, as given in Table 2. Obviously, the Al2O3-ZrO2 coated specimen have shown the better corrosion resistance than the uncoated specimen, such as higher corrosion potential Ecorr, lower corrosion current density icorr, and higher protection potential Epp. In other words, the Al2O3-ZrO2 composite coated film is more inert than the nature passive film of a Ti-6Al-4V alloy. 3.2. Adhesion The friction versus load curve of scratch test on the Al2O3-ZrO2 coated specimen reveals a smooth line with a lower slope about 0.14 of the first stage, and the higher slope about 0.79 of the second, as shown in Fig. 3. The surface morphology and EDS mapping of the Al2O3-ZrO2 coated specimen after scratch tests are shown in Fig. 4. EDS mappings of elements Al and Zr indicate that a complete Al2O3-ZrO2 composite film is still found at the end of scratch stage with a load of 50 N. The first stage (0 N 25 N) is a smooth region without cracking the coated film and the second stage (25 N - 50 N) is more striated since the coated film was broken to let pin plow the substrate. The plastic deformation of the substrate resulted in increasing wear slope (friction coefficient). However, the most of Al2O3-ZrO2 composite film was still found on the scratch end of the coated specimen by EDS mapping. The excellent adhesion between the coated and the substrate was concluded. 3.3. Wear and wear-corrosion tests The wear loss of UHMWPE after the pin-on-disk wear test is given in Table 3. The wear loss of UHMWPE countered by the Al2O3-ZrO2 specimen is obviously less than that by the uncoated specimen. 79.23% reduction of the wear loss, which is found on the coated specimen compared with the uncoated one, may be resulted from the improved mechanical properties of coated film such as hardness from 323 to 483 (Hv). Also, the roughness of the uncoated specimen reduced by the coating, as listed in Table 3, was the other factors on reducing wear loss of UHMWPE. Similar to Fig. 4, a complete Al2O3-ZrO2 composite film, which was still found after the wear test, reconfirmed the excellent adhesion of coated film on Ti alloy. The corrosion potential of the Al2O3-ZrO2 coated and uncoated were varied with wear-corrosion testing time, as shown in Fig. 5. When a load of 21.9 MPa is applied (using a PE pin counterface), the corrosion potential dropped from -120 to - 610 mV (Ag/AgCl), and became unstable. After the wear load was removed, the original potential was regained little by little. On the contrary, the corrosion potential of Al2O3-ZrO2 coated was kept at 100 mV and with little striation. These results indicate that passivation film of the uncoated was destroyed but that of the Al2O3-ZrO2 coated remained stable during the wear corrosion test. The effect of wear-corrosion on anodic dissolution current of the uncoated and the Al2O3-ZrO2 coated at an imposed potential of + 0.5 V (SCE) is shown in Fig. 6. Before abrasion, the anodic dissolution currents of the uncoated and the Al2O3/ZrO2 coated were 7.1 and 0.9 μA/cm2, respectively. When the wear was on, the current density of the uncoated was increased to 63 μA/cm2, and back down to 8 μA/cm2 when the wear off. In contrast, the current density of the Al2O3-ZrO2 coated remained constant during the test. A lower and more stable anodic dissolution current density was found for the Al2O3-ZrO2 coated than the uncoated. It is conclusive that the Al2O3-ZrO2 coated specimen is much more wear-corrosion resistance than the uncoated. 3.4. AFM image and Component Profiles AFM measurement revealed this tendency of the surface structure more clearly than SEM. Fig. 7 shows the AFM image for Al2O3-ZrO2 composite film. The detailed profiles of surface, within a 1x1 μm2 image window, are observed in this figure. The mean roughness of the surface roughness is the range of 0.952 nm. This value is small compared with the peak size parallel to the plane, which may be considered as the particle size about 30 nm. In other word, the coated film was composed of Al2O3-ZrO2 composite particles with size about 30 nm and finally revealed the surface roughness of 0.952 nm. AES component depth profiles are plotted in Fig. 8. It is confirmed that the deposited film is composed of zirconium and aluminum oxides composite layer. AES components depth profiles of Al2O3-ZrO2 composite films revealed a little gradient distribution, which was attributed to the scanning applied voltage. 4. Summary and conclusions A novel electrolytic coating method of Al2O3-ZrO2 composite coating has successfully been conducted on an ASTM F-136 Ti-6Al-4V alloy to investigate its characteristics. Through the annealing, polarization tests, surface observations, wear, wear-corrosion, and scratch tests, several conclusions are drawn: 1. The Al2O3-ZrO2 composite film revealed a nanostructure with a little gradient component distribution and the excellent adhesion between the Al2O3-ZrO2 composite coating and Ti-6Al-4V alloy was found. 2. The Al2O3-ZrO2 coated specimen showed the more corrosion resistance than the uncoated specimen, such as the higher corrosion potential Ecorr, higher protection potential Epp and lower corrosion current density icorr in Hank’s solution. 3. The roughness of the uncoated was further reduced by the Al2O3-ZrO2 coating and so was the wear loss of UHMWPE. 4. The natural passivation film of the uncoated was destroyed during the wear corrosion test but that of the Al2O3-ZrO2 coated was not. Also, a higher (more noble) corrosion potential, and a lower and more stable anodic dissolution current density was found for the coated than the uncoated. Acknowledgements The authors are grateful for the support of this research by National Science Council, Republic of China under contract No. NSC 91-2213-E-005-014. References 1. Nasser S, Campbell PA, Kilgus DJ, Kossovsky N and Amstutz HC, Clin. Orthop 1990; Vol.261, p.171-185. 2. Agins HJ, Alcock NW, Bansal M, Salvati EA, Wilson PD J. Pellicci PM and 4. Bullough PG, J. Bone Joint Surg 1998; Vol. 70-A, p. 1337-1342. Pizzoferrato A, Savarino L, Stea S, Tarabusi C, Biomaterials 1988; Vol. 9: 314-318. Betts F, Wright T, Salvati EA, Boskey A, Bansal M, Clinical Orthopaedics and 5. Related Research 1992; Vol. 276: 75-82. Henning FF, Raithel HJ, Schaller KH, Döhler JR. Nickel-, J Trace Elem 3. 6. 7. 8. 9. Electrolytes Heath Dis 1992; Vol. 6: 239-243. Boutin P. L’alumina et son utilisation en chirugie de la hanche, Press Med 1971; Vol. 79: 639. Semlitsch M, Lehmann M, Weber H, J Biomed Mater Res 1977; 11: 537-552. Torre JP. Proc Materials Eng Conf, 5-7th November 1985, London, UK, Mechanical Engineering Publication Ltd., Bury St., Edmund, Suffolk, 1986. Mandrino A, Moyen B, Ben Abdallah A, Treheux D, Orange D. Biomaterials 1990; Vol. 11:88-91. 10. Shimizu K, Kumar P, Oka M, Kotoura Y, Nakayama Y, Yamamuro T, Yanagida T, Makinouchi K, Transaction of the 3rd. World Biomaterial Congress, 21-25th. April 1988, Kyoto, Japan, 1988; Vol. 11: 406. 11. Makinouchi K, Yanagida T, Shimizu K, Kumar P, Kotoura Y, Oka. In: Oonishi H, Ooi Y, eds, Proc Jap Soc Orthop Ceramic Implants, 1984: 4. 12. Christel P, Meunier A, Heller M, Torre JP, Peille CN, J Biomed Mater Res 1989; 13. 14. 15. 16. 17. Vol. 23: 45-61. Yen SK, Materials Chemistry and Physics 2000; Vol.41, p.256-262. Yen SK, Huang TY, Material Chemistry and Physics 1998; Vol. 56, p.214-221. Zhitomirsky I, Advances in Colloid and Interface Science 2002; Vol. 97, p279-317. Yen SK, Hsu SW, J. Biomed. Mater. Res 2001; Vol.54, p.412-418. Yen SK, Guo MJ, Zhan HZ, Biomaterials 2001; Vol.56, p.998-1004. Element Al V Fe O N C Y H Wt ﹪ 3.86 0.12 0.12 0.019 0.022 0.001 0.0032 Bal. 6.04 Ti Table 1. The nominal composition of Ti-6Al-4V alloy. Uncoated Al2O3-ZrO2 coated E1 (Ecorr) i0 (icorr) [mV] [nA/cm2] -301.1 1000 14.06 6 E2 (Epp) [mV] 177.7 c [V] 0.2521 a [V] 0.2078 438.9 0.3227 0.6792 Table 2. List of the first redox potential E1 (or Ecorr), equilibrium current density i0 (or icorr), the second redox potential E2 (or Epp), cathodic polarization slope c, and anodic polarization slope a, derived from the polarization test in Hank’s solution. Counterpart Uncoated Ti-6Al-4V Al2O3- ZrO2 coated Hardness (Hv) 323 483 Surface roughness (nm) 42 0.95 S1 S2 S3 S1 S2 Weight before test (mg) 1232.25 1245.39 1239.50 1235.06 1245.09 Weight after test (mg) Weight loss (mg) Average (mg) 1232.14 1245.26 1239.35 1235.02 1245.06 0.11 0.13 0.15 0.13 ± 0.02 0.03 S3 1219.05 1219.03 0.03 0.02 0.027 ± 0.003 Table 3. Weight loss of UHMWPE after the reciprocating wear test, using the uncoated and Al2O3-ZrO2 coated as the counterparts. Fig.1. Illustration of wear-corrosion test. (R: reference electrode (Ag/AgCl), C: counter electrode (Pt), W: working electrode, H: Hank’s solution, P: UHMWPE pin, S: specimen) Fig. 2. Polarization curves of uncoated specimen and the Al2O3-ZrO2 composite coated annealed at 873 K tested in Hank's solution (pH=7.1). Fig. 3. Friction force versus load diagram of the scratch test on the Al2O3-ZrO2 coated specimen. Fig. 4. SEM observations and EDS mappings of the Al2O3-ZrO2 coated specimens, at a scratch load of 50 N. Fig.5. Ecorr of the Al2O3-ZrO2 composite coated and uncoated specimens during wear-corrosion tests. Fig. 6. Effects of wear-corrosion on anodic dissolution current density of the uncoated and Al2O3-ZrO2 composite coated specimens at an imposed potential of +0.5 V (SCE). Fig.7. AFM image of the Al2O3-ZrO2 composite film (Z range: 14.475 nm, Ra: 0.952 nm, Rms: 1.203 nm). Fig.8. AES component depth profiles of the Al2O3-ZrO2 composite film.