22433 Plan apparel or textile machinery maintenance

advertisement

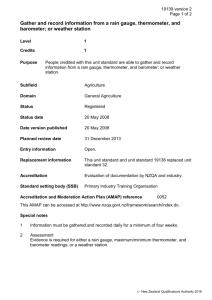

22433 version 2 Page 1 of 3 Plan apparel or textile machinery maintenance activities using project management techniques Level 5 Credits 25 Purpose People credited with this unit standard are able to: determine work required for an apparel or textile machinery maintenance activity; produce a plan for an apparel or textile machinery maintenance activity and consult with parties affected by the planned activity; and produce work instructions for a planned apparel or textile machinery maintenance activity. Subfield Textiles Manufacture Domain Core Yarn Processing Status Registered Status date 19 May 2006 Date version published 16 April 2010 Planned review date 31 December 2013 Entry information Open. Accreditation Evaluation of documentation and visit by NZQA and industry. Standard setting body (SSB) Competenz Accreditation and Moderation Action Plan (AMAP) reference 0030 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes 1 Performance of the elements of this unit standard must comply with the Health and Safety in Employment Act 1992. 2 Company procedures refer to the documented methods for performing work activities and include health and safety, operational, environmental, and quality management requirements. They may be manuals, manufacturer’s specifications, or policy statements. New Zealand Qualifications Authority 2016 22433 version 2 Page 2 of 3 3 This unit standard is intended to cover either the planned annual maintenance of processing machinery or the major overhaul of the machine/s in a department. It is not intended to cover minor preventative maintenance activities or minor repairs. Elements and performance criteria Element 1 Determine work required for an apparel or textile machinery maintenance activity. Performance criteria 1.1 Planned work meets machinery and company maintenance requirements. 1.2 Special requirements applicable to the machine, process, and/or company are identified and added to the work requirements in accordance with company procedures. Range requirements may include but are not limited to – specific machine or component inspection, timed replacement or rebuild. Element 2 Produce a plan for an apparel or textile machinery maintenance activity and consult with parties affected by the planned activity. Performance criteria 2.1 Maintenance task requirements are determined in terms of resources, task sequence, and time to complete. 2.2 Resource constraints are established in terms of quantity and availability. 2.3 Parties affected by the planned maintenance activity are identified and consulted. Range must include – production personnel, engineering and support workshops, part suppliers; may include – technical services personnel, quality control personnel, customers and/or others depending on nature of the maintenance. 2.4 Consultation with affected parties obtains the information needed to develop the maintenance plan. 2.5 Tasks are sequenced, using project management techniques, to achieve required completion time. Range 2.6 techniques – one or more of network diagram, gantt chart, critical path, resource levelling. Maintenance activity completion time meets requirements of the company. New Zealand Qualifications Authority 2016 22433 version 2 Page 3 of 3 2.7 Final approval and/or agreement for the maintenance plan are obtained from affected parties in accordance with company procedures. 2.8 Maintenance plan is produced and published in accordance with company procedures. Range manually or by computer. Element 3 Produce work instructions for a planned apparel or textile machinery maintenance activity. Range planned activities may include – routine work, non-routine work, machinery modifications, inspections, component replacements. Performance criteria 3.1 Maintenance work instructions are produced and distributed in accordance with company procedures. Please note Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact Competenz info@competenz.org.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016