History_of_Metals[13 05 2008] copy

advertisement

![History_of_Metals[13 05 2008] copy](http://s3.studylib.net/store/data/007786635_2-b3417b64b0ff0d5f7ad8659a2b09de87-768x994.png)

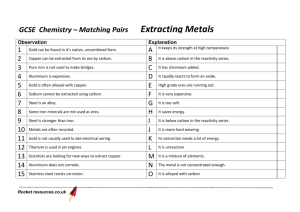

Gather process and analyse information and use the available evidence to relate the chronology of the Bronze Age, the Iron Age and the modern era and possible future developments. The desire to use and improve the technological application of metals is one of the oldest of the applied sciences. Its history can be traced back to 6000 BC. Admittedly, its form at that time was rudimentary, but Process Metallurgy has sign posted history and its documentation has provided insights into the progress of civilization. While the initial usage of metals was predominately for weaponry and jewellery, contemporary society is now inventing more practical utilizations ranging from structural engineering to electronics that define our current stage of technological advancement. Currently there are 86 known metals. Before the 19th century only 24 of these metals had been discovered and, of these 24 metals, 12 were discovered in the 18th century. Therefore, from the discovery of the first metals - gold and copper until the end of the 17th century, some 7700 years, only 12 metals were known. Four of these metals, arsenic, antimony , zinc and bismuth , were discovered in the thirteenth and fourteenth centuries, while platinum was discovered in the 16th century. The other seven metals, known as the Metals of Antiquity, were the metals upon which civilisation was based. These seven metals were: (1) Gold (ca) 6000BC (2) Copper,(ca) 4200BC (3) Silver,(ca) 4000BC (4) Lead, (ca) 3500BC (5) Tin, (ca) 1750BC (6) Iron,smelted, (ca) 1500BC (7) Mercury, (ca) 750BC There are a number of reasons that contribute to the development of the Bronze Age, the Iron Age and the modern era, and to their chronological order. These explanations include the chemical activity series of the elements, religious worship, availability, warfare and civilisation. The activity series of metals lists in order the reactivity of metals from most to least reactive as follows: Li, K, Na, Ba, Ca, Mg, Al, Zn, Cr, Fe, Co, Ni, Sn, Pb, Cu, Ag, Hg, Pt, Au. This means that Lithium (Li) is the most reactive and Gold (Au) is the least reactive. Evidence of this is that Gold is found in its elemental state in nature while Lithium is never found in its pure state being always found in compounds with other elements. Metals with high reactivity join with other elements to form extremely stable compounds, which require large amounts of energy to break their bonds, as they release a large amount of energy when they react. Therefore the more reactive an element is, the more stable a compound it forms and the harder it is to extract it from its ore. The main technological achievement that heralded the next age in metal extraction was the ability to make progressively hotter fires needed to supply the energy that would break these progressively stronger bonds. The first metal to ever be extracted from its ore was copper when the smelting of rocky ores produced a metal referred to as copper ‘globules’. This process was first discovered by Neolithic people in the near East around approximately 6000BC when they unintentionally heated this ore with carbon whilst cooking over large fires. Copper is naturally a soft metal which limited its uses to ornaments and basic utensils. The Copper Age (3500 – 2300 BC), is also referred to as the Early Bronze Age. Sumerian documents unearthed in Mesopotamia and dated to circa 3500BC reveal that the ancient Egyptians had extracted copper from what was believed to be malachite (a copper hydroxy carbonate, CuCO3.Cu (OH)2 ), an abundant mineral in Egypt. During their experimentation with the smelting of copper the Egyptians realised that temperatures exceeding 800oC were needed if the extraction process was to be effective. Nevertheless, during this time the casting of copper objects was a complicated process due to the development of gas bubbles when the metal was being poured and its susceptibility to shrinking when in the cooling stage. The desired form was shaped by hammering the copper object till it cooled down which increased the hardness of the metal. Although a comparatively soft metal, it was more durable and effectively harder than gold. This allowed Egyptians to produce convenient tools such pins, fishhooks and fancy jewellery. Uses of copper: Copper objects created during the copper age: Around 3000 BC in the Middle East, metal-smiths came to the realisation that harder metal alloys could be developed using copper in closed-furnace smelting. The first bronze alloy made was called arsenic bronze which was an alloy of copper and arsenic. The arsenic helped to produce a more durable, stronger product which was favoured over pure copper. Copper was often found contaminated with arsenic, lead, nickel and bismuth, and through further experimentation, it became evident that tin produced the most effective alloy with copper. Tin bronzes contained about 10% tin and were more ductile than arsenic bronzes. Tin metal was extracted from tin ores such as Cassiterite (SnO2) through the process of smelting. The purified tin was then melted with copper in a furnace to produce molten bronze. Tin bronzes were more malleable than copper and were easily sharpened. Cutting tools and weaponry were then created from tin bronzes. In most cases bronze was utilised for worshipping the gods, hunting, creating huge statues and ornaments. Significantly kings and emperors included this metal in the residences and important political settings. Hence the Bronze Age led to the genesis of the Classical civilisations which unfurled in the Mesopotamia and Egypt. The availability of superior bronze weapons meant that nations which possessed bronze technology had an advantage when conquering their less well equipped neighbours thus allowing imperialist expansion to occur. Bronze objects created during the Bronze Age: The availability of tin ores increased when Egypt and the Middle East initiated trading with European countries in which tin was more abundant. An expansive trade network established between the Middle East & Europe extending from Cornwall and reaching as far as the Armenian territories. The trade networking also hastened advancement in the processes of extraction and utilisation since metal smiths of the Middle East began to cooperate with European bronze smiths. Interestingly, the Bronze Age is not attributed to a specific time frame since some areas had an earlier Bronze Age than others, while in different areas this Age lasted for a long period. Some regions did not even experience a Bronze Age. Bronze was a popular metal due to the reliability and relative ease of its manufacture once the technology matured & as such was consistently used until 1500 – 1000 BC. It was at this period in time that iron appeared, particularly in Asia Minor. Interestingly modern archaeologist have noted that stories of magical swords such as King Arthur’s “Excalibur” are generally dated to the early Iron Age for the simple reason that bronze sword manufacture was comparatively easy in comparison to steel sword manufacture. Hence any blacksmith who could consistently produce high quality steel swords was feted as a wizard eg “Merlin”. Iron was first used by Prehistoric tribes around 4000 BC who discovered the precious metal in meteorites. Tribes men utilised this native iron, also referred to as meteoric iron by literally breaking off iron from meteorites and forming tools, weapons and other convenient instruments because iron was harder than bronze weapons, even though the native iron was not in abundance or conveniently available. Further development of furnace technology for the metal purification process instigated the onset of the Iron Age by permitting metal smiths to create much higher temperatures in kilns. Because Iron is a harder metal further up the activity series from copper, it requires temperatures of approximately 1100o C to start extraction. Some of the first iron-making furnaces were quite shallow and had the schema of bowl shaped hearths in which metal smiths would heat the iron ore and charcoal. It would take several hours before the ore would release its oxygen in the hot carbon which surrounded it and then be transformed into a metal of shiny appearance. However, this metal was not actually of any use until it was reheated and continually hammered to squeeze out all the impurities from the metal. This laborious process was necessary due to the fact that the temperatures achieved were not quite high enough to truly melt the iron. Around 1400 BC large supplies of iron were produced by the Hittites in a region now known as Turkey. By 1000 BC, a large number of civilisations adapted the iron making techniques, thus prescribing this period of time as definitive of the Iron Age. Needless to say, the processes of smelting and extraction and moulding were still in the primitive stages. Hand held stones were used to hammer the iron into shape and iron tongs assisted in holding the piece in place. Iron objects created during the Iron Age: The technological breakthrough required for smelting was the invention of the blast furnace which allowed large scale casting of liquid iron. The Chinese achieved this first around 100 BC but it would be another 1000 years before the Europeans discovered this process. Old Blast Furnace There were also other problems with the purification process, primarily that iron in its pure form was not much harder than the earlier bronze counterpart. For this reason, carburizing was introduced to turn iron into steel. Carburizing was the inclusion of a small quantity of carbon, from ½% to 2% followed by “quenching” it via sudden immersion in cold water to turn the iron into a metal which was more suitable for making weaponry and manufacturing tools. The technology of iron manufacture drastically evolved societies and their industries. Obviously countries with superior iron weapons now wielded a significant advantage on the battlefield as demonstrated by the first western Iron Age Empire belonging to the Romans whose 1st century AD soldiers were clad in steel “lorica segmentata” armour. By 700 AD the Europeans had a new process of blowing air into the furnace through tuyeres which aided in making the fire hotter and which actually improved the quality of the metal. This was further enhanced when a device called a billows was added to the process, thus the quality of iron continued to improve. In Catalonia, now referred to as north-eastern Spain, a more effective hearth furnace was introduced, which forced air to the bottom by using water power. The Catalan forge could extract roughly about 150 kilograms of wrought iron in approximately five hours. With the advent of the blast furnace in Europe around 1300 AD temperatures began exceeding 1530 0 C which allowed molten iron to be produced. By the 1500’s, Europe began to flourish economically in part due to the increasing familiarity with methods of shaping iron in liquid form and utilisation for commercial products. The industrial revolution of the 18th century resulted in dramatic improvements in the extracting processes and manufacturing methods of iron and steel. In the mid 1800’s the genesis of modern steelmaking occurred with the invention of the Bessemer process which was the first inexpensive industrial process for the massproduction of steel from molten pig iron. The process is named after its inventor, Henry Bessemer, who took out a patent on the process in 1855. The Process happened inside the Bessemer Converter, the container in which the steel was made. The process was independently discovered in 1851 by William Kelly. The process had also been used outside of Europe for hundreds of years, but not on an industrial scale. The key principle is removal of impurities from the iron by oxidation through air being blown through the molten iron. The oxidation also raises the temperature of the iron mass and keeps it molten. This process was still in use up to the late 1960’s when further advances finally rendered it obsolete. The modern era with regard to metal usage has witnessed the application of many different metals for structural engineering and in the later part of the 20th century, electronics. However it is most obviously defined by the almost ubiquitous use of Aluminium on an industrial scale. In fact some commentators have even labeled the modern era the “Aluminium Age”. Although aluminium is the most abundant metallic element in the Earth's crust (believed to be 7.5 to 8.1 percent), it is rare in its free form, occurring in oxygendeficient environments such as volcanic mud, and it was once considered a precious metal more valuable than gold. Napoleon III, emperor of France, is reputed to have given a banquet where the most honoured guests were given aluminium utensils, while the other guests had to make do with gold. At that time, aluminium was more expensive than silver, gold, or platinum. Aluminium has been produced in commercial quantities for just over 100 years. Aluminium is a strongly reactive metal that forms a high-energy chemical bond with oxygen. Compared to most other metals, it is difficult to extract from ore, such as bauxite, due to the energy required to reduce aluminium oxide (Al2O3). For example, direct reduction with carbon, as is used to produce iron, is not chemically possible, since aluminium is a stronger reducing agent than carbon. Aluminium oxide has a melting point of about 2,000 °C. Therefore, it must be extracted by electrolysis. In this process, the aluminium oxide is dissolved in molten cryolite and then reduced to the pure metal. The operational temperature of the reduction cells is around 950 to 980 °C. Cryolite is found as a mineral in Greenland, but in industrial use it has been replaced by a synthetic substance. Cryolite is a chemical compound of aluminium, sodium, and calcium fluorides: (Na3AlF6). The aluminium oxide (a white powder) is obtained by refining the ore bauxite. Bauxite occurs as a weathering product of low iron and silica bedrock in tropical climatic conditions. Aluminium is the most widely used non-ferrous metal. Global production of aluminium in 2005 was 31.9 million tonnes. It exceeded that of any other metal except iron (837.5 million tonnes). Relatively pure aluminium is encountered only when corrosion resistance and/or workability is more important than strength or hardness. A thin layer of aluminium can be deposited onto a flat surface to form optical coatings and mirrors. When so deposited, a fresh, pure aluminium film serves as a good reflector (approximately 92%) of visible light and an excellent reflector (as much as 98%) of medium and far infrared. Pure aluminium has a low tensile strength, but when combined with thermomechanical processing, aluminium alloys display a marked improvement in mechanical properties, especially when tempered. Aluminium alloys form vital components of aircraft and rockets as a result of their high strength-to-weight ratio. Aluminium readily forms alloys with many elements such as copper, zinc, magnesium, manganese and silicon (e.g., duralumin). Today, almost all bulk metal materials that are referred to loosely as "aluminium," are actually alloys. For example, the common aluminium foils are alloys of 92% to 99% aluminium. New light alloys are being developed and employed but with the periodic table being effectively complete science is now turning increasingly to modern composite materials such as carbon fibre which are supplanting metals in many areas of engineering. Hence the future may indeed be labeled the “plastic age”. This progression in material usage is best illustrated by the example of bicycle technology. The first practical bicycles became available with the development of tubular steel at the end of the 19th century. For the next 100 years the main advancements were in the method of joining the frame together by either lugs or welding. New and stronger alloys of steel were developed to increase strength. In the 1980’s Aluminium frames became available due to new manufacturing techniques. With the collapse of the USSR in the early 1990’s frame builders found the market flooded with ex soviet stocks of Titanium & Scandium originally intended for the aerospace industry. Today Carbon fibre frames are supplanting metals in lightweight frames for racing and steel is making a resurgence for commuting and touring frames where strength is the main concern before weight. From this short review of metallurgical developments it can be seen that as the early metallurgists became more sophisticated their ability to discover and separate all the metals grew. However in all of their work it was necessary for these basic steps to be carried out: 1. 2. 3. 4. the ore had to be identified (usually an oxide of the metal) separated from gangue concentrated Reduced Reduction of the ore to reveal the pure metal was the major technological hurdle at the beginning of each new stage. Invention and ingenuity had to be employed to find a way of supplying the energy required to break the increasing strength of the bonds formed as mankind worked its way up the reactivity series. TIMELINE- HISTORY OF METALS 6000BCE- First time copper was extracted from its ore in Egypt 5000BCE- First Egyptian Artefacts 4000BCE- Egyptians wore beads of meteoric iron. - Soldering in Mesopotamia 3000BCE- Stone Age Ends - Lead used to join copper in Mesopotamia 3600 BCE- Hard Soldering in Egypt 3200BCE- Copper Age Begins 2600BCE- Hard soldering with silver began - Hard soldering in Greece 2500BCE- Oldest Bronze artefacts 2300- Beginning of Bronze Age 1500BCE- Silver and copper first used as a means of exchange 1300 BC- Oldest article of Iron found to be from this era 1000 BCE- Physical properties of Gold first refined – Beginning of Iron Age 200- Tin extracted in Egypt 10BCE- Ionians Begin to use Iron 1CE – “Modern” Age begins 1880- Alloy Steels such and Manganese Steel and Tungsten Steel used 1886- Aluminium first extracted from its ore 1890- High Speed steel created - Nickel-alloy steels made 1990- Stainless Steels came into use 1904- Vanadium steel used in automobiles and tool manufactory 1935- Magnesium primarily used during WW2 1940- Titanium came into use 1970- Tungsten in pure form used 2000- Silicon used as a semi-conductor in computers BIBLIOGRAPHY The World Book Encyclopedia Volume 2; World Book Inc: 1984. Zronik, J. “Metals (Rocks, Minerals, and Resources)”, Hallmark: 1995 http://www.world-aluminium.org/production/mining/index.html http://nefertiti.iwebland.com/index.html http://www.ancientroute.com/#Route http://www.brass.org/index.htm http://www.neo-tech.com/index.php http://www.geology.ucdavis.edu/~cowen/~GEL115/index.html http://www.mse.uiuc.edu/info/mse182/t41.html www.encarta.msn.com By Jackie Galatis