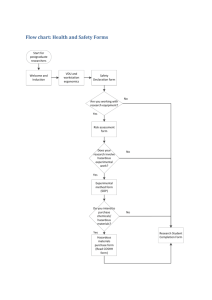

Health and Safety Check List

advertisement

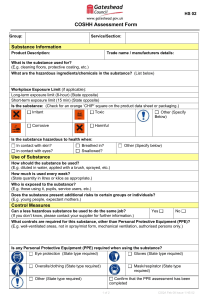

University Safety Office Laboratory Checklists Safety Office February 2012 This laboratory health and safety checklist is not exhaustive – and is provided as a general guide only for Schools / Services to follow during their own internal inspections of facilities. It is strongly recommended that inspections are carried out on a quarterly basis as a minimum and are recorded on the following form. Schools / Services should make a plan as a result of complet8ing this checklist to ensure any recommendations are implemented. If you want a specific list to be generated for any given area of activity please contact the University Safety Office with your specific requirements. Health and Safety Check List Topic Issues Risk Assessments and SOP’s Risk Assessment: Have risk assessments been carried out and implemented for your school activities? SOP’s, protocols. General Activities COSHH BIOCOSHH GM Are standard operating procedures and risk assessments identified and available where required? Do assessments identify emergency procedures? Are SOP’s available and communicated to all laboratory users? Are staff consulting and following SOP measures? General Section Display Screen Equipment. Are arrangement in place to ensure that regular DSE users receive instruction on the safe set up, use and assessment of their workstation, and that the information required by the USO website are met? Are workstations set up correctly with adjustable chair and space to carry out desk based activities? Comments Health and Safety Check List Topic Control of Substances Hazardous to Health. Issues Are arrangements in place to ensure that any hazardous substance is assessed correctly and all necessary controls are put in place, including emergency information, e.g. spillage clean up, first aid, etc. Are arrangements in place to ensure that hazardous substances are handled correctly? Are storage facilities suitable and are the controls employed adequate? Are chemicals labelled? Are chemicals being stored appropriately? Are toxins stored in a toxins cupboard separate to flammable substances? Are flammable chemicals stored in fire bins/cabinets? Manual Handling. Is equipment provided to assist Lifting, carrying and supporting people moving significant loads? of loads. Is equipment, e.g. trolleys, in good working order? Are they stored appropriately? First Aid. Are first aid contacts known to staff Not every School has to have a and available? trained first-aider, but there Is suitable first aid equipment in should be ready access to place? equipment and trained staff – Is the first aid equipment in date and see the "Emergency maintained in an accessible form? Arrangements posters. Are First aid boxes checked by first aiders? Welfare Facilities. Is drinking water available? Is soap available at hand wash sinks? Are towels available at hand wash sinks? Are restrictions in place for food and drinks within the laboratory and are these being followed by users? Are separate towels provided for cleaning and spillage? Are emergency hoses at sinks routinely inspected? Comments Health and Safety Check List Topic Issues Personal Protective Equipment Are arrangements in place to ensure (P.P.E.) that the correct type and standard of PPE is selected? Are sufficient numbers provided? Machinery and Equipment: Are arrangements in place to ensure that potentially hazardous machinery and equipment is safe? Sharps Are there arrangements in place to ensure that employees know which type of PPE to use and how to use it? Are arrangements in place to ensure that PPE is cleaned by the School and kept in good condition? Are users using the correct PPE including gloves and lab coats? Do people dress appropriately, e.g. flat and covered footwear, legs and arms covered? Is PPE being stored appropriately on hooks and not on chairs? Are they maintained? Are safety guards in place? Are fail to safety controls in place? Are demonstrations provided and operatives trained in use? Are arrangements in place to ensure students are adequately supervised while using hazardous equipment? Are manufacturer instructions available? Are written instructions available for users? Are clear warning notices in place? Are all sharps single use? Are sharps being stored in the correct location/container, e.g. tray in draw? Are tools easy to reach? Are handling devices such as forceps available for holding materials? Comments Health and Safety Check List Topic Issues Fire Safety Waste Are ALL occupiers, including visitors, aware of the actions to take in the event of fire? Are staff aware of the assembly point and is a fire evacuation notice available? Are the evacuation routes clear? Are ALL doors on escape routes unlocked and unobstructed? Are fire doors closing properly? Are fire doors being wedged open? Are fire blankets available where required? Are appropriate fire extinguishers available? Have extinguishers been maintained and inspected? Are sharps containers in close proximity to activities undertaken? Are sufficient containers available? Are sharps containers over filled? Are lids locked in place? Statutory Inspections Are the necessary specific statutory inspections / test arrangements to be carried out by specialist contractors in place for the following equipment where installed / used in the premises? Fixed and mobile lifting equipment, e.g. passenger lifts, mechanical hoists? Pressure Systems, e.g. steam heating systems, autoclaves, compressed air systems / air receivers? Has all Local Exhaust Ventilation (specialist ventilation systems to remove hazardous substances such as gases or dusts) been tested? Premises Notices and Signs. Are they clear and unambiguous? Are suitable fire action signs located adjacent to red-break glass alarm point explaining contacts, exits and assembly points? Comments Health and Safety Check List Topic Lighting. Heating. Ventilation. Housekeeping. Means of Access: Ladders and stepladders. Issues Has the laboratory got appropriate signage on the entrance, e.g. chemicals, biohazards, radiation and PPE? Are emergency laboratory contacts available on the access door? Is the containment level of the laboratory displayed on the door? Is it subjectively acceptable? Note DSE assessments also include notes on the quality as well as quantity of lighting. Is it a subjectively acceptable and a "reasonable" temperature? Is it subjectively acceptable? In some areas there is a need for quantitative testing of ventilation as a risk management precaution. Is the area suitably clean, free of obstructions, damaged carpets and other tripping hazards? Are the flooring surfaces suitably non-slip for the activities (bearing in mind the foresee-ability of spills and wet surfaces etc)? Is storage an issue leading to safety problems? (Overhead, obstructing routes, causing clutter under desks, etc.) Are the means of access in a suitable condition for the workplace concerned? Are stepladders / ladders of industrial /commercial specification and not for domestic use? Are the means of access subject to an inspection programme which is documented and available? Is use limited to authorised staff having received appropriate instruction and / or training? Are hop up stools in good condition? Comments Health and Safety Check List Topic Issues Gas and Gas Cylinders. Are hoses to Bunsen burners free from defect such as splits and perishing? Are hose lengths appropriate, e.g. <2ft? Are connections tight and secure at the tap and burner? Are gas isolations easily available? Are manufacturers instructions used for the day to day use of gas appliances and cylinders? Are cylinders secured in storage? Are cylinder valves and regulators in good condition? Are regulators: Damaged; The correct specification; Less than 10 years old; Have maximum pressure markings shown? Are gas detection monitors in place where required? Hoses checked, in good condition and secured? Flashback arrestors checked and working? Pressure Systems. Are pressure systems current condition satisfactory? Are manufacturer instructions available and used? Electricity. Are all portable equipment PAT tested? Are cables in good condition? Are extensions in use and are they daisy chained? Emergency Procedures. Have the worst reasonably Do you need additional foreseeable contingencies been Emergency Procedures beyond identified for worst case scenario? those operating at the Are plans in existence for such University level? contingencies? (e.g. Specific Chemical or Has a drill of emergency procedures Biological Hazards, specific been carried out? Comments Health and Safety Check List Topic Issues fire / explosion risks.)? Are emergency procedures available and known amongst staff and students? Training and Competency Are staff and students trained Have they completed the training and competent to carry out their required by the Faculty Training activities Policy and Matrix Have they been provided with additional training specific to their work environment and activity Have they been provided with supervision where required Other Health and Safety Risks Are arrangements in place to manage other significant health and safety risks not covered in this checklist? Comments