AOAC SLV protocol_Sept 13_masterdocument 2

advertisement

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

Best Practices for Single Laboratory Validation (SLV) of Chemical Methods for Trace Elements in

Foods

Cory J. Murphy1, James D. MacNeil1

1Canadian

Food Inspection Agency, Dartmouth Laboratory, 1992 Agency Drive, Dartmouth, Nova Scotia,

B3B 1Y9, Canada

Introduction

The use of analytical methods within a regulatory analysis or accredited laboratory framework

imposes certain requirements on both the analyst and laboratory. It is expected that regulatory analyses

will be conducted according to what may generally be described as “best practices” to ensure the

reliability of findings leading to regulatory action. In some situations, such analyses and the sampling

associated with them must also be conducted in a manner that meets requirements for legal proceedings,

including presentation as evidence in court. Under the International Organization for Standardization’s

(ISO) and International Electrotechnical Commission (IEC) general requirements, accredited laboratories

are expected to demonstrate both “fitness for purpose” of the methods for which they are accredited and

competency of their assigned analysts in performance of the methods 1. There is, therefore, activity in

many areas of regulatory analysis to develop consensus on best practices associated with particular

types of analyses.

In 1997 (amended in 2006), the Codex Alimentarius Commission (CAC) issued a general

guideline for analytical laboratories involved in the import and export testing of foods which contains four

principles2:

The laboratory should have in place internal quality control procedures which meet the

requirements of the Harmonised Guidelines for Internal Quality Control in Analytical Chemistry3;

The laboratory should participate regularly in any available proficiency testing schemes,

appropriate to their area of testing, which have been designed and conducted as per the

requirements of the International Harmonized Protocol for Proficiency Testing of (Chemical)

Analytical Laboratories4;

The laboratory should become accredited according to ISO/IEC-17025:1999 General

requirements for the competence of calibration and testing laboratories (now ISO/IEC17025:20051) for tests routinely performed; and

The laboratory should use methods which have been validated according to the principles laid

down by the Codex Alimentarius Commission whenever such methods are available.

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

General requirements for validation of analytical methods according to principles laid down by the

Codex Alimentarius Commission are provided in the Codex Manual of Procedures, including provision for

“single laboratory” validation of analytical methods5. Additional guidance is provided through a number of

general guidelines issued by a consensus process in international scientific organizations and

subsequently adopted as CAC guidelines6,7,8,9,10. The CAC has also issued guidelines related to the

validation of methods used for the analysis of pesticide residues 11, mass spectrometric analysis of

pesticide residues12, the estimation of uncertainty of measurements13 and the analysis of veterinary drug

residues in foods14. A recent CAC guideline on the settlement of disputes over analytical test results also

makes reference to method validation requirements15. However, there remains considerable

misunderstanding among analysts and laboratory managers as to precisely what is meant and what is

required to demonstrate “method validation”. Furthermore, no specific guidance on the validation of

methods used for the determination of elemental composition or element speciation is provided within

Codex documents to supplement the general guidance provided in other documents or contained in

guidance from independent international scientific organizations. Additional guidance on method

validation for future inclusion in the CAC Manual of Procedures and CAC guidelines is currently under

discussion in the Codex Committee on Methods of Analysis and Sampling (CCMAS) and other Codex

Alimentarius committees, but does not relate to this specific issue 16.

A new project was established by the Analytical Chemistry Division of the International Union of

Pure and Applied Chemistry (IUPAC) in 2009 to provide guidance on experimental designs suitable for

use in method validation17, supplementing the general guidance previously provided by IUPAC on single

laboratory validation requirements18. It may reasonably be anticipated that any such guidance will also be

adopted by the CAC. While compliance with CAC standards and guidelines is voluntary for member

states, subject to World Trade Organization (WTO) agreements, they do reflect international scientific

consensus on issues related to the analysis of foods. These guidelines can therefore be informative for

the development of guidance documents to be used within AOAC International for issues such as single

laboratory validation of analytical methods for trace elements, whether in foods or in other matrices.

Validation was defined by ISO in 1994 as “confirmation by examination and provision of objective

evidence that the particular requirements for a specified intended use are fulfilled ”19. In analytical

chemistry, method validation was defined by Eurachem in 1998 as a process of “establishing the

performance characteristics and limitations of a method and the identification of the influences which may

change these characteristics and to what extent” and thereby “verifying that a method is fit for purpose,

i.e., for use for solving a particular analytical problem.”20 A recent guideline issued by CAC 21 defines a

validated method as an “accepted test method for which validation studies have been completed to

determine the accuracy and reliability of this method for a specific purpose ”22 and validation as

“verification, where the specified requirements are adequate for an intended use”23. The process includes

2

1

2

3

4

5

6

identification of the method scope and method performance characteristics. The scope defines the

7

range for the analyte, and a specified type of test material.” 18 An AOAC International guidance document

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

analytes and the matrices in which they can be determined, the concentration range and any known

effects from interferences, while the expected performance characteristics are usually stated in terms of

precision and accuracy. The IUPAC Harmonized Guidelines for Single Laboratory Validation of Methods

of Analysis state that “strictly speaking, validation should refer to an ‘analytical system’ rather than an

‘analytical method’, the analytical system comprising a defined method protocol, a defined concentration

defines validation as “the process of demonstrating or confirming the performance characteristics of a

method of analysis.”24 Similarly, the International Conference on Harmonisation of Technical

Requirements for Registration of Pharmaceuticals for Human Use (ICH) guidance states that the

“objective of validation of an analytical procedure is to demonstrate that it is suitable for its intended

purpose.”25

Method validation can therefore be practically defined as a set of experiments which confirm that

an analytical method is suitable for its intended purpose when conducted using specific instrumentation

and within a specific laboratory environment in which the set of experiments have been conducted. An

inter-laboratory collaborative study is considered to provide a more reliable indicator of statistical

performance characteristics of the method because it requires testing of the method in multiple

laboratories, by different analysts using different reagents, supplies and equipment and working in

different laboratory environments26. Validation of a method, even through collaborative study, does not,

however, provide a guarantee of method performance in any laboratory performing the method. This is

where a second term, verification, is sometimes used18. In this context, verification may be defined as a

set of experiments conducted by a different analyst or laboratory on a previously validated method to

demonstrate that in their hands, the performance standards established from the original validation are

attained. Verification has been described as part of internal quality control (QC) procedures 27. That is, the

verification experiments demonstrate that the performance achieved meets requirements for attributes

such as scope (analytes/matrices), analytical range, freedom from interferences, precision and accuracy

that have been identified for suitable application of the method to the intended use in the initial method

validation.

The guidelines for conduct of an inter-laboratory collaborative study stress the importance that

the performance of the method should first be well-characterized in the developing laboratory (or

laboratory sponsoring the study) before the method is tested in multiple laboratories in the collaborative

trial28,29. Current guidance from AOAC International for conduct of a collaborative study stresses the

importance of optimizing the performance of the method (usually demonstrated through completion and

reporting of a “single laboratory validation”) before attempting the collaborative study 30. Thus, following a

recognized approach based on scientific consensus to method validation within a single laboratory is

3

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

important not only to demonstrate “fitness for purpose” as required by accrediting bodies, but also to lay

the proper base when methods are proposed to be tested in an inter-laboratory method trial.

In contrast, method development is the series of experiments conducted to develop and optimize

a specific analytical method for an analyte or group of analytes. This can involve investigations into

detection/extraction of the analyte, stability of the analyte, analytical range, selectivity, ruggedness, etc. It

is important to note that method validation experiments will always take place after method development

is complete; that is, validation studies are intended to confirm method performance parameters which

were demonstrated during method development. Validation should not begin until method development,

including ruggedness testing, has been completed. A ruggedness design should identify if small changes

at certain steps of the analytical method, which might occur when other analysts use the method, affect

method results. A common approach is to vary seven factors simultaneously and measure these

changes to determine how they may affect method performance31. Once method development and

ruggedness experiments are complete, the method should not be further modified or changed during the

validation process.

When validating a method for elements in food products, many factors should be considered

during the planning phase of the validation experimental design. For example, it should be determined if

the method is to be used in a regulatory environment, and if the analyte(s) of interest have a maximum

level (ML) which is to be assessed for compliance. In some cases, such as the analytes for which no safe

limits have been established, the purpose of the method may be to achieve the lowest possible detection

limit. The method may be intended for use in the determination of a single element in a particular matrix,

or it may require capability for multi-analyte analyses in various matrices. The availability of an authentic

blank matrix to be used as the analytical sample for method characterization should be considered. For

example, many elements are naturally present in some intended test matrices (such as arsenic or

cadmium in shellfish tissue). The inability to obtain authentic blank test sample material can therefore

cause many validation challenges when assessing parameters such as matrix effects and limits of

detection and quantification, particularly when attempting to use the signal of the “blank” as a basis for the

latter determinations.

Although food testing programs frequently include testing for a range of elements (predominantly

metals), there are actually few formally established MLs or other action limits for these analytes. The

Codex Alimentarius Commission has established limits for arsenic (total), cadmium and lead in a variety

of foods, total mercury in mineral waters and salt, methylmercury in fish and tin in canned goods 32.

Similarly, the European Union (EU) has established regulatory limits for cadmium, lead, mercury and tin in

a variety of foods33. Requirements for analytical methods to enforce EU standards for lead, cadmium and

mercury in foodstuffs are the subject of another EU regulation 34. Canada has established maximum limits

4

1

2

3

4

for arsenic, lead and tin in various foods 35 and standards for mercury in seafood have been set by both

Canada36 and the United States37.

Table 1: Regulated Toxic Elements of Codex Alimentarius Commission and Various Countries

Organization/Country

Regulated Element

Codex Alimentarius Commission32

As, Cd, Pb, Hg, methyl mercury in a variety of

foods

EU and member

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

states33

Hg, Cd, Pb Sn in some foods

Canada3536

Hg in fish, Cd, Pb, Sn in some foods

USA37

Hg in fish

Japan

Hg and methyl mercury in some fish

The aim of this paper on single laboratory validation (SLV) is to provide guidance for the scientist

when validating a method for trace elements in food as “fit-for-purpose” for an element or a group of

elements in those products. Definitions for common analytical chemistry terms used in food analysis are

taken from contemporary references and the procedures proposed for method validation are based on

available technical guidelines and recommended approaches. An example of a SLV experimental plan to

implement the proposed approach for methods used in elemental analysis in foods samples is provided.

The proposed approach is intended to address any specific requirements that are currently provided in

Codex Alimentarius guidance documents or in regulations or guidelines for the analysis of trace elements

in foods set by national or regional authorities, so is intended to be generally applicable for a variety or

potential users.

Definitions

In general, it is recommended that definitions included in the Codex Alimentarius Commission

“Guidelines on Analytical Terminology”21 should be used as a primary source for methods used in the

analysis of foods as these have been adopted after extensive international consultation and are taken

from authoritative sources, such as the Joint Committee for Guides in Metrology (JCGM), ISO, IUPAC

and AOAC International. Definitions of key terms used in method validation recommendations contained

in this document are contained in Appendix I, with a reference to the source. Adherence to these

definitions when reporting the validation of an analytical method will provide transparency to the process

and should eliminate the misunderstandings that can occur when different laboratories use different

definitions for the same analytical terminology. When definitions are available from multiple sources and

there are differences in the wording, accredited laboratories should use definitions contained in the

International Vocabulary of Metrology (VIM)23 as the primary source of definitions for analytical terms, as

5

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

national bodies performing laboratory accreditation under ISO/IEC-17025 refer to this source. The VIM is

the source of many of the definitions cited by the CAC.

For terms related to “sample” the analyst should use the nomenclature recommended by the

International Union of Pure and Applied Chemistry (IUPAC) [Reference: Horwitz, H. (1990) Nomenclature

for Sampling in Analytical Chemistry Pure & Appl. Chem. 62, 1193-1208.], for analytical chemistry, based

upon the International Organization for Standardization (ISO) recommendations. The terminology is also

supported by AOAC International [Reference: Official Methods of Analysis of AOAC INTERNATIONAL

(2005) AOAC INTERNATIONAL, Gaithersburg, MD, USA, Definition of Terms and Explanatory Notes,

Sample (23). OMA Online http://www.eoma.aoac.org/; accessed August 2, 2010. Terms most frequently

applicable to element analysis of foods are the following and will be used throughout this document:

Laboratory sample—sample or subsample sent to or received by the laboratory

Analytical (or test) sample—sample, prepared from the laboratory sample (by homogenization,

grinding, blending, etc.), from which analytical portions are removed for analysis.

Analytical (or test) portion—quantity of material removed from the analytical sample for analysis.

Analytical (or test) solution—solution prepared by dissolving (with or without reaction) of an

analytical portion in a liquid.

Concern has been expressed that the limit of detection (LOD) and the limit of quantification (LOQ)

should not always be used as mandatory fixed performance limits for validated methods, due to the

inherent variability which may be observed in the determination of these limits by different analysts using

different instruments. For example, an expert meeting on the validation of analytical methods noted in its

report that:

“LOD and LOQ are estimates of variable parameters, the values of which depend on various

factors, including the conditions of measurement and the experience of the analyst. The use of

these estimates in client reports can be misleading. In view of this, it was requested that the

FAO/IAEA expert consultation following the Workshop would consider that the lowest calibrated

level of the analysis be recommended to be used in client reports as an alternative to the LOD

and LOQ.”38

The report of the subsequent expert consultation defined two terms to reflect the performance

characteristics which may be required of analytical methods used in a regulatory setting, the accepted

limit and the lowest calibrated level (See Appendix I)27. More recently, the IUPAC Guidelines for Single

Laboratory Validation of Methods of Analysis advised that “the detection limit need not be part of

validation” when the actual concentration range measured by the method “does not include or approach”

this limit and also, regarding the limit of quantification, recommended that the measurement uncertainty

“as a function of concentration” should be assessed with regard to fitness for purpose, rather than using a

“fixed multiple” of the detection limit to establish a limit of quantification18.

6

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

It also is important to note that while many analytical chemistry texts and older papers in scientific

journals use the term “specificity” for “selectivity”, the term “selectivity” is now recommended and use of

the term specificity is discouraged21. It is considered that a method is either “specific” or it is “nonspecific”, while the term selectivity implies that there may be varying degrees of “selectivity”.

Performance Criteria

The Codex Committee on Methods of Analysis and Sampling (CCMAS) has recommended new

guidance on method performance with respect to implementation of the criteria approach for analytical

methods which has been included in the 19th Edition of the Codex Manual of Procedures5. This guidance

is based on accepted approaches to the establishment of performance criteria for analytical

methods39,40,41 and was subject to extensive consultation by representatives of major international

organizations and national regulatory authorities prior to acceptance and implementation. It therefore is

recommended that these recommendations should be followed, particularly with regard to acceptable

performance for recovery and precision expected at various concentrations of analyte(s), which may be

found in Table 1, tiltled “Guidelines for establishing numeric values for the criteria” on page 53 of the CAC

Manual5.

Performance Characteristics

In order for a method to be considered “fit-for-purpose” certain performance requirements should

be evaluated and met. Listed below are the requirements typically considered in the validation of a

quantitative method of chemical analysis18. A screening or confirmation method may require different,

usually fewer, parameters.

26

Accuracy- determined during method development, confirmed during validation

27

Analytical range- determined during method development, confirmed during validation

28

29

Intermediate precision – may be determined during method development or during method

30

Limit of Detection (LOD) – determined during method development, confirmed during validation

31

32

Limit of Quantification (LOQ) - determined during method development, confirmed during

33

validation

validation

Linearity- determined during method development, confirmed during validation

7

1

Matrix Effects - usually completed during method development phase, confirmed during validation

2

Measurement Uncertainty- determined during method development, confirmed during validation

3

Repeatability of detection system - may be completed during method development phase

4

Repeatability of method- determined during method development, confirmed during validation

5

6

Reproducibility (if appropriate) – by collaborative study, after single laboratory validation is

7

Ruggedness - completed during method development phase

8

Selectivity - usually completed during method development phase, confirmed during validation

9

Sensitivity – usually assessed during method development phase, confirmed during validation

10

Stability of analyte in standard solution - completed at start of method development

11

Stability of analyte in matrix - assessed once method is validated

12

Stability of analyte in extract/digest - assessed during method development

complete

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Technical Guidelines & Approaches

There are several additional considerations which affect the experimental design and specifically

the choice of matrices and analytes for validation of method performance. In a regulatory environment,

such as testing of foods for the presence of element contaminants or essential nutrients, there are many

sample materials which potentially require testing. Resources may not be available to fully validate each

analytical method for all analytes and matrices to which it may be applied. Therefore, the concepts of

representative commodity (matrix) and representative analytes11,27 have been proposed to facilitate

method validation and routine application. Using this approach, for example, in validating a method for

application to “fish”, representative matrices are salmon for “high fat” finfish, tilapia for “low fat”, shrimp for

“crustaceans”. Apples may be the representative matrix for apples and pears, oranges for “citrus fruit”

and strawberries for “berries”, while head lettuce may represent “leafy vegetables” and carrots may

represent “root crops”. One could also reference the food triangle when validating methods for multiple

foods as with this approach, foods can be divided into categories based on carbohydrate, fat, and protein.

Once the method has been validated for an element or elements on the “representative commodity”, it is

considered to be applicable to all commodities represented by that matrix until performance issues are

8

1

2

3

4

5

observed when the method is applied for the first time to a less commonly analyzed member of the group.

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

Calibration using the analytical function or internal standardization approach usually assumes and

23

24

25

26

27

28

29

30

31

32

33

34

35

36

When this happens, further work is required to adapt and validate the method for that application.

Representative analytes may also be used when validating methods for elements in foods. For example,

with ICP-MS, you may choose a low, medium, and high mass element to represent all elements in a

multi-analyte screen.

requires the availability of a representative blank test sample. However, situations may be encountered

when a material is unavailable for a particular commodity which is free of naturally incurred analyte.

Ideally, in such situations, a “representative commodity” which is free of the analyte can be chosen as a

surrogate material for the validation or to represent the commodity grouping of which the material is

considered a member. A surrogate material must closely relate to the matrix undergoing validation and

be blank of the analyte of interest to allow for efficient validation experiments to be completed. Use of

surrogates for the validation of methods for elements in foods has been well documented in the literatureI

Examples of use of surrogates in method validation experiments include a natural water CRM used to

assess method performance in the absence of a CRM for vinegar 42 and Brown Bread BCR CRM 191 as a

surrogate for honey (based on carbohydrate content) to assess method accuracy as a honey CRM was

unavailable43. In some situations, there is no such material available and mixing of materials may be

required to approximate the composition of the target commodity. The following sections provide some

approaches which may be used when blank test sample material is unavailable for use in method

validation or for method calibration.

Linear Range and Calibration Curve

A typical chemical measurement process at trace concentrations includes the evaluation of two

types of calibration, one involving the determination of the detector response to changing concentrations

of pure standard (instrument response), while the second assesses the response to changes in analyte

concentration in the presence of matrix components and reagents (method performance)44. In the case

of analsysis of elements in foods, standard addition techniques can also be used when a matrix effect has

been observed. The instrumental detection limit (IDL) is obtained using analyte standard solutions,. It

should be specified whether the reagents in these solutions match those of the analytical solutions. as the

detector responses may differ when the analyte standards are measured in the presence of different

reagents or because of the presence of the analytes of interest in the reagents. It should also be specified

whether calibration experiments are conducted using analyte processed through the method or analyte

added to prepared standard reagent blanks. These approaches using standards are commonly seen

when the method of “external calibration” is applied in a method, yet they will not necessarily yield the

same calibration results.

9

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

When the calibration procedure involves determining the response of the detection system to the

analyte(s) in the presence of matrix material, it is best described by the term analytical function.

Detection and quantification limits derived from this approach to calibration are the “method” detection

and quantification limits and provide a more accurate portrayal of the actual performance capabilities of

an analytical method. Since they are intended to reflect any interferences or matrix enhancement or

suppression effects, as well as analyte recovery from the matrix during the performance of the analytical

method, the detection and quantification limits determined from these experiments are in most cases (the

exception being when there are matrix enhancement effects on the detector response to the analyte)

higher than the equivalent instrumental detection limits and quantification determined using pure analyte,

or pure analyte in the presence of method reagents. This method of calibration is used when the standard

curve is generated using analyte in the presence of matrix and is variously referred to as use of “matrix

fortified” or “matrix matched” standards, meaning that the standards may be either added to matrix

(preferably blank matrix, if available) prior to processing for analysis or added to an extract or digest of

such matrix following processing. As when pure standards are either processed through a method, or

added to a reagent blank processed through the method, the results from the two approaches are not

necessarily the same. When blank matrix is not available and the method of standard additions is used to

generate a calibration curve, the same considerations apply.

An internal standard may be used with either approach to calibration. In either case, it is assumed

that the recovery of internal standard is the same as that of the analyte(s) measured, so it is important to

characterize this relationship. Many methods in current use for trace organic chemicals incorporate

isotope-labelled versions of the target analytes and in such cases it is expected that recoveries will be

identical for the analyte and, for example, a deuterated analogue. However, when an internal standard of

this nature is used in a multi-analyte method, the assumption of equivalence of recovery may not be

warranted.

There is no clear consensus in the scientific literature on the definition of “matrix matched” and

frequently questions may be left in the mind of readers as to precisely how standards were prepared for

calibration of a method. Some authors use the term “matrix matched” when the analytical standards are

spiked into blank matrix prior to extraction, while others use the term referring to the spiking of the

standards into a matrix extract. The latter approach should be used during methods development to

examine for matrix effects by comparing the response of pure standard solutions to the response of

standards prepared at the same concentrations in an extract of digest of representative blank test

sample.. Any differences in response observed may be attributed to matrix enhancement or suppression

effects. A second experiment can then be conducted to assess if there are also differences in response

related to analytical recovery. To make this comparison, compare the response to the standards prepared

in blank matrix digest with the response when the standards are spiked into blank matrix test sample prior

10

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

to digestion. Any differences observed may be attributed to analytical recovery. Thus, preparation of

standards by addition to blank matrix extract provides a correction for matrix effects, while preparation of

standards by spiking of blank matrix prior to extraction provides a correction for both matrix effects and

method recovery45. Since there are currently no accepted definitions for these terms, which are used in

various contexts by different authors in different published papers, suggested definitions, at least to

qualify the meaning of these terms as used within this paper, are provided in Appendix I.C. Equally, when

authors refer to “external calibration”, it is not always clear whether they have used pure standards in a

solvent, pure standards prepared in a reagent blank or pure standards taken through the method. The

approach used should be clearly stated.

As noted above, the means by which the standards used in preparation of the calibration curve

are prepared may be very significant, as different methods of preparation and treatment of the standards

may influence the results. Ideally, the curve obtained when standards are prepared in the presence of

matrix should be assessed relative to the curve obtained when pure standards or standards prepared in

the presence of a reagent blank to determine if the sample treatment or the presence of matrix materials

has an influence on the detector response.

For example, various calibration strategies were evaluated in a study of the application of

ICP/MS analysis to the determination of arsenic, lead and selenium in wine 46. In this study, samples were

analyzed using calibrants prepared in surrogate solutions, with the initial calibrants prepared in a 10%

ethanol solution, then compared with results obtained when calibration was with standards prepared in

10% (w/w) alcohol and various amounts (500–2000mg/L) of potassium nitrate and nitric acid (0.1–0.5%,

w/w). Potassium typically is present in wine at concentrations in the g/L range, so this surrogate solution

used for preparation of calibration standards was intended to provide a closer approximation of the

behaviour of the elements being analyzed in undigested wine. It was found that analyte response was

about 40% higher in wine than in standards prepared in aqueous ethanol, but that addition of potassium

to the ethanol standards did not produce the same signal intensity as seen in the presence of the matrix.

The authors concluded that external calibration was not suitable for this analysis and that the method of

standard addition should be used. External calibration using aqueous standards was compared with

addition of analyte to a 0.2% (m/v) soil slurry solution for the determination of arsenic and selenium in

soils and sludges by ICP/MS47. It was observed that the slopes increased when the standard addition

technique was used, leading to more accurate results. The importance of appropriate calibration

procedures and the selection of appropriate blank materials is also discussed in a paper on the

application of ICP/MS for the determination of trace elements in environmental samples48. The authors

note that, among other issues, the slope of the calibration curve may be biased by the highest point on

the curve, which can particularly affect the accuracy of determination of low concentrations of analytes

when an extended calibration range is used. An inadequate number of procedure blank determinations

11

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

may also provide an insufficient basis for background subtraction. The discussion in this paper deals

primarily with external calibration, but the same issues are relevant to other calibration approaches.

Calibration Options

The European Commission Decision 2002/657/EC specifies microwave digestion for “elemental

confirmatory methods” and calibration by external standard or standard addition49. These two approaches

are the ones most commonly found in published methods or applications, with the external standard

method of calibration, usually in combination with the use of an internal standard to correct for instrument

drift, being the more prevalent approach for analysis of elements in

foods,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66, 67,68. External standard calibration also was the preferred

approach to calibration in a sampling of ICP/MS methods applied to non-food and environmental

matrices69,70,71,72,73,74,75,76,77 and clinical application78,79,80,81,82,83. “Matrix-matched” external standard

calibration was used in the determination of total arsenic and total selenium concentrations in fish tissues

obtained from retail sources84, while in a study to assess the applicability of ICP/MS to the determination

of metals in composite diet samples, matrix also was fortified with standards and analyzed to determine if

matrix effects were observed when compared to results for the same pure standards in solution 85. The

authors reported erratic recovery for the determination of arsenic and barium in fatty samples and

difficulty in quantification of cadmium due to the presence of high incurred concentrations of cadmium in

the material.

The next most common approach used in elemental analysis of foods was the method of

standard addition46,86,87,88,89,90,91. However, some studies have investigated multiple calibration

approaches. For example, both external standard calibration and standard addition were assessed In

several studies of elements in food matrices42,92,93,94. In a study to determine concentrations of 26

potential elemental contaminants in wine using external calibration, recoveries were estimated by

fortification of sample material (standard addition)68. A recent study using laser ablation ICP/MS for the

determination of lead in blood samples included a comparison of calibration using aqueous standard

solutions with standards prepared in a matrix-matched solution prepared using a blood CRM 95.

Typically, no matter which calibration approach was used, method performance was assessed by

analysis of certified reference materials, comparison with alternate methods and/or participation in

available proficiency testing rounds. However, although external calibration, combined with internal

standards, appears to be the most widely used approach to instrument calibration, the other papers cited

above suggest additional experiments which may be conducted to assess issues such as potential matrix

effects on the analytical signal and on analyte recovery. Experiments using surrogate materials, standard

12

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

addition techniques and, when available, blank matrix, can provide a better understanding of the method

performance.

Assessment of calibration approaches

In trace organic analysis, external calibration (with use of internal standard to correct for recovery)

or preparation of “matrix fortified” calibration curves (also frequently with use of internal standard) appear

more prevalent than in trace element analysis. When methods for organic chemicals use mass

spectrometers as the detection system, the assessment of matrix effects on detector response becomes

especially important, while recovery of analyte is also usually an important issue. The International Union

of Pure & Applied Chemistry has issued guidance on recovery correction 96, but no equivalent consensus

on a standardized approach to the assessment of matrix effects on detector response has yet been

achieved. However, a systematic approach to the assessment of matrix effects and the differentiation of

matrix effects from method recovery has been proposed for bioanalytical chemical analyses 45. In either

organic or elemental analyses, instrument calibration may be achieved by use of external or internal

standard calibrations, but the calibration approach used should be clearly stated.

Based on the literature reviewed, external standard calibration, with addition of internal standards

to correct for instrument drift, is the method of choice in most circumstances involving elemental analysis.

Although analytical recovery and matrix effects are not discussed in a number of the papers reviewed, it

is recognized that both are issues for the determination of trace elements by ICP/MS or other

instrumental techniques applied to digests of sample material. In ICP/MS analysis, internal standards are

frequently used to correct for both effects, even if the effects are not specifically characterized in the

report of the work. Several authors have used either standard addition or fortification of blank matrix

(when available) for method calibration. Inherently, there is no apparent reason why the calibration

procedures used in trace element analysis should differ significantly from those used in trace organic

analysis. The availability of true matrix test sample blanks can be an issue in either case and should be

dealt with appropriately. “Best practices” should therefore include a clearly described process to

determine whether external calibration, internal calibration using fortified matrix or standard addition has

been selected for method calibration. Matrix effects should be assessed using fortified digests of blank

test sample matrix or suitable surrogates when blank matrix is not available. Recoveries should be

assessed by fortification of matrix prior to extraction or digestion. The term “matrix matched” should be

used to describe experiments in which blank matrix test sample extracts or digests are fortified with

standards prior to instrumental analysis, while “matrix fortified” should refer to experiments in which the

matrix is fortified with standards prior to extraction or digestion. Certified reference materials should be

used, when available, to assess method accuracy and the effectiveness of the calibration procedures

used in compensating for recovery issues or matrix effects.

13

1

2

3

4

5

6

7

8

Analytical range of method and linearity

Linear range is determined by the injection of standard solutions in order to determine at what

level the instrument response no longer conforms to a linear equation (y = mx + b). This is determined in

the following manner:

Injections of standard solutions (minimum six) made up in similar reagents as the analytical test

solutions.

9

10

11

12

13

14

The concentrations of the solutions must be evenly spaced to determine the precise level at

which the calibration curve is no longer linear.

The range of concentration should encompass the expected concentration range from routine

samples if known.

The amount or concentration of the element injected is plotted against the instrument response to

determine the linear portion of the curve.

15

16

17

18

19

20

The instrument linear range is used to determine the analyte concentration range for which the method

21

Matrix effect

22

23

24

25

26

27

28

29

30

31

will be fit for purpose. The calibration curve should be properly evaluated as the highest standard

solution may have a large impact on the line of best fit for the curve. Other points to consider are whether

to force the calibration curve through the origin, through the standard blank, or no forcing whatsoever.

The approach used by the analyst in the laboratory can have drastic effects on reported results 48.

Linearity can be presented with R2 to determine if curve is linear over the concentration range chosen.

The lab sample matrix may alter the results or create an enhanced or suppressed response from

the detector. Prior to experiments to determine if matrix effects are evident, several possibilities can be

explored to compare the results obtained for pure standard solutions in comparison to pure standard

solutions taken through the method, matrix matched and matrix fortified standards, The following

comparisons can then be made:

Pure standard solutions taken through the method compared to pure standard solutions made

prior to instrumental determinations is indicative of any losses of analyte which are related to the

method, while enhanced results may indicate reagent contamination.

Matrix fortified standards (standards added to “blank” test sample matrix prior to digestion)

compared with pure standards made prior to instrumental determinations provides an indication

14

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

of the combined effect of matrix enhancement/suppression effects and losses/gains related to the

method.

Matrix matched standards (standards added to “blank” test solutions after digestion) compared to

pure standard solutions made prior to instrumental determinations, provides an indication of

matrix enhancement/suppression effects only.

Blank Matrix

In order to determine matrix effect, calibration curves of pure standard solutions and matrix

matched standard solutions must be prepared and compared. The matrix matched calibration curves are

prepared by using extracted/digested blank matrix test portion solution as diluent. Prior to instrumental

determination, fortify the test solutions with aliquots of standards to provide the required concentration in

the final test solution to be equivalent to that of pure standard solutions. The standards are analysed by

duplicate or triplicate injections. When the results (as indicated by the slopes of the curves) obtained for

matrix-matched standard solutions are different than the results obtained for pure standard solutions, than

matrix suppression or enhancement effects are evident. Calibration curves for the pure standard solutions

and matrix fortified standard solutions are prepared by plotting the average response of the standard

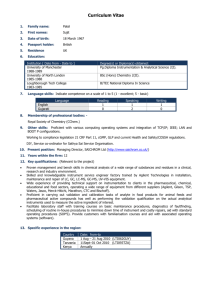

solution against the standard concentration (Figure 1). As shown in Figure 1, matrix effects are not

evident, therefore, the use of pure standard solutions for the quantification of Hg in tuna is warranted.

Differences (>10%) of the slope of the matrix matched calibration curve in relation to that of the pure

standard curve, or significant changes in the instrument responses for corresponding standards indicates

that the matrix does indeed affect the instrument response. If this is the case, routine analysis will have

to be performed using matrix matched standards or possibly standard additions.

15

Hg in Tuna - Neat vs Matrix Fortified Standards

0.25

Instrument Response

y = 0.0138x + 0.0023

R2 = 0.9996

0.2

y = 0.0136x + 0.0035

R2 = 0.9998

0.15

0.1

Pure Standards

Matrix Fortified Standards

0.05

0

0

5

10

15

20

Concentration (µg/L)

1

2

Figure 1: Matrix Effects Experiments for Total Hg in Tuna

3

4

5

6

7

8

9

10

11

12

13

14

15

No Blank Matrix

If blank lab sample matrix cannot be found, such as the case in many elemental analysis

techniques, a different approach is needed. First, test material must be characterized to determine the

analyte concentration in tissue by conducting a total of 20 determinations over 4 days. Then, prepare a

solution with similar analyte concentration to the matrix under investigation. Run matrix and prepared

solution with varying fortification levels (ie. 3 levels) in the same analytical run and repeat on a second

day. Plot theoretical analyte concentration versus instrument response for both matrix and solution on

the same graph (Figure 2). As shown in Figure 2, matrix effects are evident, therefore, the use of matrix

matched standards or standard additions is needed for the quantification. If the slopes of the curves

diverge by >10% or final fortification level concentrations show a >10% difference, then a matrix effect is

evident. If curves do not diverge (<10% difference in slopes), or final fortification level concentrations

show a <10% difference then no matrix effects are evident.

16

17

16

As+3 in Pears - Neat vs Matrix Fortified Standards

1

50000

3

4

5

Instrument Response

2

y = 2721.1x - 34.931

R2 = 1

Neat

Standards

25000

y = 2238.4x + 33.419

R2 = 1

Matrix

Fortified

Standards

6

0

7

0.0000

2.0000

4.0000

6.0000

8.0000

10.0000

12.0000

14.0000

16.0000

Theoretical Standard Concentration (ng/mL)

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

Figure 2: Matrix Effects Experiments for Speciated Arsenic (As +3) in Pears

Analyte Stability

While the stability of the analyte and the recovery of analyte from matrix may both be issues of

considerable concern in dealing with the analysis of organic chemicals, particularly residues and

contaminants in biological matrices, it is generally considered that stability of the analyte and recovery

from the original sample matrix, typically after a chemical digestion process, are of less concern in

elemental analysis. However, there can be exceptions, particularly when it is necessary to differentiate

between different chemical forms or species of an element. For example, conversion between oxidation

states of chromium has been observed97,98. Thus, part of the validation strategy for elemental analysis,

particularly when the analysis involves the speciation of different oxidation states of an element, should

include a demonstration that the species targeted is stable and recovered without loss or conversion

during the processing prior to instrumental analysis. Peer reviewed literature can also be a valuable

resource with respect to determining the stability of the analyte in solution.

Limit of Detection and Limit of Quantification

There are several approaches and multiple procedures typically used to determine LOD and LOQ

which have been presented in recent publications5,99. It is recommended to use an approach that is

common to the field of analytical chemistry you are practicing and would be accepted by other scientific

colleagues. Whatever the technique used must be defended scientifically for the circumstances of the

method and provided that the basis for the estimates is clearly stated. Typically, LOD determinations can

be grouped into three common approaches; (1) an evaluation of the noise/background of matrix and/or

method blanks; (2) the use of the calibration curve and y-intercept, (3) and matrix spiking experiments. In

17

1

2

3

4

5

6

7

8

9

10

11

the more familiar approach, the LOD and LOQ are calculated as multiples of the standard deviation of the

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

There are three approaches, involving analysis of different types of materials, which have been reported

mean response for a blank (typically, 3x for LOD and either 6x or 10x for LOQ). The alternative approach

estimates the LOD and LOQ based on method precision, so that LOD is based on “the rounded value of

the reproducibility relative standard deviation when it goes out of control (where 3 σR = 100%; σR = 33%,

rounded to 50% because of the high variability)”, while the LOQ is set at the concentration where σ R =

25%. This latter approach may give a more practical and realistic estimate, as it is based on performance

where known concentrations of analyte are present and the method goes “out of control” for quantitative

purposes. The more commonly used alternative attempts to make an estimate based on “typical” blank

signals processed through a data system and is based on an approach that was used when data from

instruments typically were recorded on a strip-chart recorder with little or no intermediate modification of

the detector output.

in papers on ICP/MS analysis of foodstuffs and environmental samples for the determination of limits of

detection and quantification (LOD, LOQ), The developers of an ICP/MS method for the determination of

arsenic, cadmium, lead and mercury in animal-derived foodstuffs (meat, fish, milk and milk products)

reported that they were able to identify suitable representative “blanks” which contained very low

concentrations of the target analytes and based the method LOD and LOQ on fortification of these

materials (test sample fortification as opposed to fortification of matrix test solutions)100. These authors

noted the importance of the availability of homogeneous blank material for assessment of method

performance limits. Method performance was validated by procedures which included the analysis of

certified reference materials, comparison with results of other validated methods and participation in

proficiency tests (FAPAS). Instrumental detection and quantitation limits were based on method reagent

blanks, while diluted milk was used for assessment of method LODs and LOQs in a recent study of trace

elements in milkError! Bookmark not defined.. Similarly, the authors of a recent method for the analysis of

cadmium and lead in animal offal using ICP/MS calculated method performance characteristics (LOD,

LOQ) using fortified offals which were “blank”101. Instrumental LODs were estimated using digestion

blanks (ng/mL), while method LOD’s and LOQ’s were estimated using digested milk (ng/g) in another

recent study90. LOQs have also been estimated by dilution of CRMs58.

An alternative approach, calculation of LOD from digestion blanks, was used by Chan et al Error!

Bookmark not defined.

. This approach was also used by Cubadda et al, who determined limits of detection and

quantification by analysis of digests of matrix blanks, with the result then adjusted for dilution factors

applied to matrix digests to estimate these factors for the elements in matrix 52. Similar approaches to the

calculation have been described in numerous other papers Error! Bookmark not defined., 60, Error! Bookmark not defined.,

Error! Bookmark not defined.

. In a recent study of selenium species and concentrations in surface waters on the

Canadian prairies, method detection limits for the ICP/MS analysis were calculated from the standard

deviation of the lowest calibrated concentration102.

18

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

Blank Matrix

The limit of detection (LOD) must be determined for each analyte for which the method is

validated. This is done preferably by evaluating the noise level of 5 blank test samples per run on 4

separate instrument runs (n=20). One approach that could be used to determine the LOD for the analyte

in the matrix is by calculating the average noise of the 20 observations + 3SD. A procedure for estimation

of the LOD and the LOQ from the y-intercept of the calibration curve is used in many laboratories 103, as it

is considered to provide a more realistic estimate of these parameters than a direct calculation from the

observed noise level. The third approach is to determine the concentration at which the relative standard

deviation exceeds the requirements for quantitative analysis 5. With some techniques, a method reagent

blank taken through the method may be the only means of evaluating background noise. In this case 5

reagent blank samples per run on 4 separate instrument runs (n=20) would be completed and 3 standard

deviations of the background analyte level may be used as a good indicator of LOD, while 10 standard

deviations may be used to estimate the LOQ. Using this approach, the LOQ is approximately 3 times the

LOD.

No Authentic Blank Matrix

With some techniques, a reagent blank taken through the method may be the only means of

evaluating background noise. In this case 5 method reagent blank samples per run on 4 separate

instrument runs (n=20) would be completed and 3 standard deviations of the background analyte level

may be used as a good indicator of LOD, while 10 standard deviations may be used to estimate the LOQ.

Using this approach, the LOQ is approximately 3 times the LOD.

Since all approaches may give varied results for LOQ, an experiment could be conducted where

solutions of the analyte of interest are prepared at increasing intervals between the lowest and highest

calculated LOQ. If multiple injections of a particular solution has acceptable precision then this

concentration would be indicative of the LOQ.

Method Recovery

The recovery of the analyte(s) by the method for each validated matrix is to be determined by the

analysis of that matrix fortified with a specified amount of the analyte(s) 20. Certified reference materials

(CRM) representing a closely related matrix to the material undergoing validation should be used when

available to assess method recovery in combination with spiking experiments. Several studies in the

31

literature have supported the use of CRMs to access method recovery. In a recent report on monitoring

32

of the arsenic, lead and mercury content of traditional herbal preparations method performance was

19

1

2

3

4

5

6

7

8

9

10

11

12

verified by analysis of a certified reference material.104. Method accuracy and precision were assessed

13

Blank Matrix with ML/Target Level

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

against guidelines issued by AOAC International for single laboratory validation of methods used in the

analysis of botanicals and dietary supplements105. In a recent investigation of the effects of cooking on

concentrations of arsenic, cadmium, lead and mercury in foods, the authors reported use of a certified

reference material to assess method performance106. In another study, the analysis of CRMs were used

to assess method performance107 and recoveries, based on the mean values for the elements in the

certified reference materials, ranged from 84-114%, demonstrating that, as in trace organic analysis, it

cannot be assumed that recovery is always 100%. Recovery studies are to be carried out on a minimum

of three fortification levels. These levels should be chosen depending on the intended use for the

method, and whether authentic blank matrix can be found. Five replicated analyses at each fortification

level shall be carried out on 3 separate days. Calculate the mean, standard deviation and % relative

standard deviation for each of the three levels.

If authentic blank material is available, and there is a published concentration of importance (ie.

Canadian ML for mercury in fresh tuna is 0.5 μg/g) then spike levels should be a factor of this ML. Spike

at ½ML, 1ML, and 2ML with each level replicated 5 times over three days. A CRM can also be used here

for additional information (if it contains appropriate concentration of the element of interest).

Blank Matrix with no ML/Target Level

If authentic blank material is available, and there is not a published concentration of importance

then spike levels should be a factor of the LOD. Spike at 3LOD, 10LOD, and the tissue equivalent

concentration of the upper limit of the calibration curve. Each level will be replicated 5 times over three

days. A CRM can also be used here for additional information (if it contains appropriate concentration of

analyte of interest).

No Blank Matrix with ML/Target Level

If authentic blank material cannot be found, a surrogate matrix (one in which low or nondetectable levels of the analyte(s) of interest are present) may be used to fulfill validation requirements. If

an appropriate surrogate matrix cannot be found, spike solution is added to previously characterized

tissue so that target concentration(s) (background level + spike added) of tissue are equal to ½ ML, 1ML

and 2ML with each level replicated 5 times over three days. A CRM can also be used here for additional

information (if it contains appropriate concentration of analyte of interest).

No Blank Matrix with no ML/Target Level

20

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

If authentic blank matrix cannot be found and there is no published ML or concentration of

interest a surrogate matrix (one in which low or non-detectable levels of the analyte(s) of interest are

present) may be used to fulfill validation requirements. If an appropriate surrogate matrix cannot be

found, spike levels will be determined based on the previously characterized analyte concentration(s). A

low, medium, and high spike level will be used for this study, ie. spike equivalent to ½X, 1X, and 2X (or

upper limit of the calibration curve) of the analytical range of the characterized tissue concentration. A

CRM can also be used here for additional information (if it contains appropriate concentration of element

of interest).

In all scenarios, spiking at the LOQ may be required for verification purposes (if possible). Other

spiking levels may be used in place of those prescribed above. The objective is to have at least three

fortification levels (low, medium, and high) so confidence can be gained in the method’s and analysts’s

ability to recover the element of interest in the analytical test portion over a specific concentration range.

Calculate average spike recovery for each level, standard deviation and percent relative standard

deviation (%RSD) and compare to “Guidelines for establishing numeric values for analytical method

performance criteria, as recommended by the Codex Alimentarius Commission5.”

Repeatability

There are two types of repeatability that are to be determined. The first type is a function of the

instrument. Instrument repeatability is determined by repeat injections of the standard solutions as well

as a fortified sample, naturally incurred material, or a CRM at least one level. The second type is the

method repeatability. It is determined by replicate digestion and analysis of a fortified, incurred material

at or near each of the fortification levels. Certified reference materials (CRM) representing a closely

related matrix to the material undergoing validation should be used when available to assess method

repeatability in combination with experiments with fortified matrix.

Instrument Repeatability

Inject each of the standard solutions that are used to prepare the working calibration curve as

well as an incurred or fortified test sample at one of the spike levels 5 times. These injections should be

done in random order to reduce any bias. Calculate average, standard deviation and percent relative

standard deviation (%RSD). In most cases, precision should not exceed 10%RSD for replicate injections.

If this is the case, the analyst must investigate why the instrument is not repeatable.

Method Repeatability

Prepare pools of test sample material with levels of the analyte(s) at or near the same

concentrations that were used for the method recovery studies. This may be completed by using incurred

material or by fortifying test sample material (blank or incurred) with the required amount of the analyte(s).

21

1

2

3

4

5

Prepare five replicate test portions of each of these test samples and analyse on the same day. This

process is to be repeated on two more days. A CRM can also be used here for additional information (if it

contains appropriate concentration of analyte of interest). Calculate average, standard deviation and

percent relative standard deviation (%RSD and compare to “Guidelines for establishing numeric values

for analytical method performance criteria, as recommended by the Codex Alimentarius Commission 5.”

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Intermediate Precision

This parameter is used to determine if there are biases in the method. The bias can come from

the analyst, instrumentation, or other sources. To study this parameter prepare pools of test sample

material with, either incurred or fortified, levels of the analyte(s) at or near the same concentrations that

were used for the recovery and repeatability studies. The same material should be used as was prepared

for the repeatability studies if sufficient is remaining. Certified reference materials (CRM) can also be

used for the evaluation of intermediate precision. The CRM used should be a closely related matrix as

the material undergoing validation.

At a minimum the study must be carried out by an additional analyst over three separate days. The

second analyst is to prepare all fresh reagents and the test samples are to be analysed in 5 replicates

over three separate days by the second analyst. If multiple instruments are available then the study by

the second analyst must be carried out on the second instrument, to take into account any instrument

bias.

20

21

22

23

24

25

26

27

28

29

30

31

Measurement Uncertainty

The uncertainty of a result from a chemical analysis can be caused by many steps in the process.

In practice the uncertainty on the result may arise from many possible sources, including examples such

as incomplete definition, sampling, matrix effects and interferences, environmental conditions,

uncertainties of masses and volumetric equipment, reference values, approximations and assumptions

incorporated in the measurement method and procedure, and random variation.20, 108

A document which provides extensive guidance on the estimation of measurement uncertainty in

analytical methods is available from Eurachem109. Rather than attempting to calculate the uncertainty

from each factor independently and combining the results, an approach is to the look at the methodology

as a whole and group the uncertainty into two categories: Accuracy and Precision.

22

1

2

3

4

5

Data sets that are to be considered for Accuracy are; recovery, CRM data, PT samples etc. Data

to be included with precision are; intermediate precision, in-house check samples, CRM data, etc. The

relative uncertainty (MU) for the method is calculated by determining square root of the sum of the

squares of the respective relative uncertainties for accuracy and precision.

2

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

2

MU (RU (accuracy) RU ( precision)

6

Ruggedness

The ruggedness of an analytical method is the resistance to change in the results produced by an

analytical method when minor deviations are made from the experimental conditions described in the

procedure. The ruggedness of a method is tested by deliberately introducing small changes to the

procedure and examining the effect on the results. Methods should be ruggedness tested as the last

stage of method development, prior to method validation. Ruggedness testing should not be used to

determine critical control points (these should be determined earlier during method development) and

critical control points should not be included in ruggedness testing, as they are known to have a

significant impact on the analysis. Ruggedness testing does not need to be performed for each matrix

tested as this examination of matrix effects should be performed in method development. The matrix

used for ruggedness testing should be as representative as possible of the proposed workload, i.e. the

most common matrix, or material representative of the matrix components (non-fat, low-fat, high-fat).

Examples of variables to be tested for elemental analysis include:

pH

temperature (digestion)

acid concentrations

reagents (age, source, concentrations)

delays in continuing the method at different stages

analytical portion mass

extraction/digestion (time, technique, solvents/acids)

different instruments

different instrument parameters

The easiest approach is to use Youden’s factorial approach31, where seven variables can be

combined in a specific manner to determine the effects of all seven variables using eight combinations in

a single experiment. If the method has fewer variables to be tested, then blanks can be included, or

23

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

variables can be examined individually. The experiment should also be repeated on two separate days in

order to eliminate the possibility of a single sample affecting the outcome. Values for each sample should

be spike recoveries or concentrations if incurred/fortified tissue is being used.

Sample

Factor Combinations

Measurement

1

ABCDEFG

s

2

ABcDefg

t

3

AbCdEfg

u

4

AbcdeFG

v

5

aBCdeFg

w

6

aBcdEfG

x

7

abCDefG

y

8

abcDEFg

z

To determine effect of individual factor,

Effect of A and a:

[(s + t + u + v)/4] – [(w + x + y + z)/4] = J

This simplifies to:

(4A/4) – (4a/4) = J

Effect of B and b:

[(s + t + w + x)/4] – [(u + v + y + z)/4] = K

Effect of C and c:

[(s + u + w + y)/4] – [(t + v + x + z)/4] = L

Effect of D and d:

[(s + t + y + z)/4] – [(u + v + w + x)/4] = M

Effect of E and e:

[(s + u + x + z)/4] – [(t + v + w + y)/4] = N

Effect of F and f:

[(s + v + w + z)/4] – [(t + u + x + y)/4] = O

Effect of G and g:

[(s + v + x + y)/4] – [(t + u + w + z)/4] = P

After calculating the differences between factors (J-P) examine those values. Small changes in

factors with larger differences can lead to significant changes in results. Determine which factors create

statistically significant changes by performing a two-sample t-test assuming equal variance for each

factor. If the p-value is <0.05 the factor is significant, if the p-value is >0.15 the factor is not significant,

and if 0.05<p<0.15 the factor may be significant.

If factors are determined to be significant the procedural instructions dealing with those factors

should be made more specific and the ruggedness testing repeated, including those factors with

intermediate p-values (0.05<p<0.15). These factors may be determined to be critical control points, and if

this is the case the procedural instructions should be changed to reflect an acceptable variance.

24

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

If intermediate precision data are available then an additional comparison may be made.

Comparing the standard deviation of the method as determined in intermediate precision testing to the

standard deviation of the differences of factors examined during ruggedness testing may reveal that a

combination of factors has a significant effect on the method even though no individual factors have a

significant effect on the method. In this case the procedural instructions should be made more specific

and the ruggedness testing should be repeated using the more specific instructions.

25

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

Appendix 1: Example of an Experimental Method Validation Plan for Tin in Canned Foods

Method Title: Validation of a Method for the Determination of Tin (Sn) in Canned Pears

Project Participants: Analyst 1, Analyst 2

Start Date: January 1, 2009

Projected Completion Date: March 31, 2009

Instrument(s): ICP-OES

ML/Target Level: 250 μg/g

NOTE: For this validation plan, tin levels were negligible in the pear matrix

Linearity Survey: