APP_35485_sm_SuppInfo

Supporting Information

Polyacrylonitrile-based Electronspun Carbon Paper for Electrode Applications

Ying Yang

1,2

, Fritz Simeon

1

, T. Alan Hatton

1

* and Gregory C. Rutledge

1*

1 Department of Chemical Engineering, Massachusetts Institute of Technology, 77

Massachusetts Avenue, Cambridge, MA 02139 (USA)

2

Department of Electrical Engineering, Tsinghua University, Beijing, 100084, China.

Experimental

The electrical conductivities of the carbon papers were measured by the impedance method

(Solartron 1260 impedance analyzer) with a 40 mV amplitude signal over the frequency range from 0.1 Hz to 10 MHz at 25 °C and 25% RH. The cross-sectional area, A, of the carbon paper was calculated by multiplying the measured width by the measured thickness of the sample. The electrical conductivity σ was calculated using

σ= L/AR, (2) where R is the electrical resistance, A is the cross sectional area, and L is the distance between the electrodes.

*Corresponding author. Fax: +01 617 253 0171. E-mail address: yingyang@tsinghua.edu.cn

; rutledge@mit.edu

;

The acrylonitrile moieties in electrospun nanofibers react with oxygen and undergo chemical changes during the pre-oxidation process in air, forming a “ladder” structure due to cyclization of the nitrile groups in the acrylonitrile moieties as shown in Fig S1.

Figure S1

Chemical structural transformations during oxidative stabilization[1]

[1] M.S.A. Rahaman, A.F. Ismail, A. Mustafa. A review of heat treatment on polyacrylonitrile fiber. Polymer Degradation and Stability. 2007, 92: 1421-1432

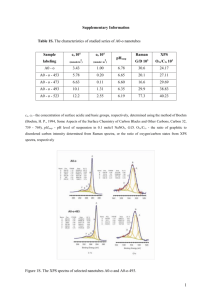

As shown in Figure S2, the effect of pre-oxidation temperature is the same as that of hot press time. The absorption bumps that appear in the ranges of 1730-1737 cm -1 and 1173 cm -1 after using a 280 ℃ pre-oxidation temperature are related to C=O or C–O bonds, which confirms that the oxidation reaction occurred. Quantitative analysis of the data in Figure 4S suggests that the trend in intensity of the FTIR spectra peaks can be related to the energy input during the pre-treatment.

(a) (b)

Figure 2S (a) after hot-press treatment for various times followed by pre-oxidation at 270°C for 90 min; (b) after hot-press treatment for 40 min followed by pre-oxidation at various temperatures.

(a) (b)

(c)

Figure 3 Example of the deconvolution of the high-resolution XPS spectra (a) C 1s; (b) N 1s; (c) O

1s.

Figure 3 shows a high-resolution XPS spectrum after 5 min hot-press time, and the peaks into which it may be deconvoluted, as an example. All the XPS spectra showed similar shapes and were similarly deconvoluted.