CHAPTER II - Universiti Teknologi Malaysia

advertisement

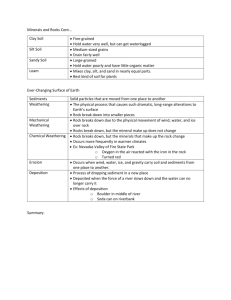

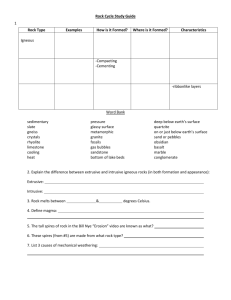

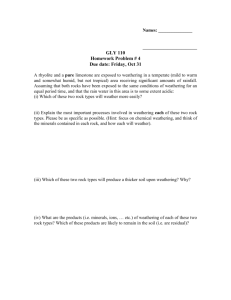

5 CHAPTER II LITERATURE STUDY 2.1 Introduction The minimum requirement for a site investigation are that of desk study and walk-over survey carried out by a competent personnel, who has been carefully briefed by the leading professionals (e.g. architect and engineer) on the forms and locations of construction proposed at the site. This approach will be satisfactory where routine construction is being carried out in well-known and relatively uniform ground conditions. The desk study and walk-over survey are intended to (Clayton C.R.I., Simons N.E. and Matthews M.C., 1995): (a) Confirm the presence of the anticipated ground conditions, as a result of the examination of geological maps and previous ground investigation records (b) Establish that the variability of the sub-soil is likely to be small (c) Identify potential construction problems such as requirements of special plants and machineries 6 (d) Establish the geotechnical limit states (e.g. slope instability and excessive foundation settlement) which must be incorporated in the design (e) Establish the likelihood of presence of hard materials in project site Items (a), (b), (c), (d) & (e) are scopes of work related to the sub-strata materials such as excavations, ground treatments and other activities to ensure the success of the construction. 2.2 Extent and depth of site investigation Most of the information collected during site investigation will relate to subsurface deposits of rocks and soils. The general objective is to build up a threedimensional picture of the site, which extends laterally and vertically to include all of the strata likely to be affected by the changes in loading brought about by the proposed structure. In order to achieve adequate coverage of the investigation, the spacing of the points of investigation needs to be based on considerations of both the type of structure (e.g. narrow or wide; low or tall; heavy or light, etc.) and the nature of the ground conditions (e.g. rock or soil; firm or soft; homogeneous or stratified, etc.). Borings should be sunk at strategic points related to the layout, near to locations where settlement is to be limited. In uniform and homogeneous conditions, boreholes may be located up to 100m apart; in conditions of lateral or vertical variability the spacing is accordingly reduced, to as close as 5m in severe cases if the presence of hard material is anticipated at shallow depth. 7 The depth of investigation is related mainly to the types of material present and their susceptibility to the structure to be built. Strata likely to be subjected to an increase in vertical effective stress of 10 percent or more should be included in the investigation. Another simple, but perhaps not so reliable, rule of thumb is to carry out borings down to at least 1.5 times the breadth of the foundation; care is required in interpreting this guideline where multiple foundations are to be installed. Where rock strata are encountered, it is a good practice to continue all borings for at least 1.5m into sound unweathered rock. In all cases, a small number of borings should be taken down significantly deeper, so that no unexpectedly weak layers are missed. This procedure is also important where presence of hard materials is anticipated in the area. Samples in the form of cores may be acquired for further assessments (field and laboratory) on the sample. Perhaps this is essential for acquiring optimum information on the sub-strata materials so that detailed and informative contract documentation could be prepared (Witlow Roy, 1995). 2.3 Methods of site investigation There are various methods of field investigation that include those discussed in the following sections depending on the number of methods by which the ground can be investigated, using geophysical techniques. Whilst these methods can be extremely valuable for ground investigation purposes, there are not in everyday use. 8 2.3.1 Trial pits In cohesive soils and soft rocks, above the water table, trial pits are often preferable to borings; they are easily dug with a mechanical excavator, or even by hand, and they have the advantage of exposing the succession of strata for easy visual examination. The main disadvantage is that they are limited to depths of 2-3 m; perhaps a little deeper by additional hand-digging. Samples may be taken by hand from the bottom and sides of the pit. Trial pits are often particularly useful in soils containing boulders or cobbles, for ground water observations and for locating buried pipes and services. For verifying the presence of mass body of hard materials, this method may not be feasible (Witlow Roy, 1995). 2.3.2 Hand auger The hand auger (also called a post-hole or Iwan auger) is a very simple handtool used for drilling into soft soils down to a maximum of 5-6 m. The usual form consists of a 100mm diameter half-cylinder clay auger, which is attached, through a series of 1 m extension rods, to a cross-piece, that may be turned manually at the surface (Fig. 1.1(a)).To obtain samples, the clay auger is replaced with a 38mm sample tube attached to a sliding percussion link (Fig. 1.1(b)). By raising the extension rod/percussion link assembly and forcing it downwards, the sample tube is driven into the ground at the bottom of the hole. The cross-piece is then rotated to shear off the bottom end of the sample and the sample tube driven upwards using the percussion link. This method may also be employed to detect the presence of hard materials (e.g. stiff clay, dense sand and rock body) or changes in the compactness of sub-strata materials. 9 It is not suitable for penetration through harder materials thus, it is not appropriate for the determination of depth or thickness of such materials. Fig. 1.1 Hand auger and sampler: (a) Iwan auger (b) 38mm sample tube (after Witlow Roy, 1995) 2.3.3 Probing A wide range of dynamic and static penetrometers are available, with different types being used in different conditions of sub-strata materials. However, the objective of all probing is the same, namely to provide a profile of penetration resistance with depth, in order to give an assessment of the variability of in-situ materials on site. Probing is carried out rapidly, with simple equipment. It produces simple results, in 10 terms of blows per unit depth of penetration, which are generally plotted as blowcount/depth graphs. One of the most common types of probing is Mackintosh Probe. The Mackintosh prospecting tool consists of rods which can be threaded together with barrel connectors and which are normally fitted with a driving point at their base, and a light hand-operated driving hammer at their top (Fig. 1.2). The tool provides a very economical method of determining the thickness of soft deposits such as peat. The driving point is streamlined in longitudinal section with a maximum diameter of 27mm. The drive hammer has a total weight of about 4kg. The rods are 1.2m long and 12mm dia. The device is often used to provide a depth profile by driving the point and rods into the ground with equal blows of the full drop height available from the hammer: the number of blows for each 150mm of penetration is recorded. When small pockets of stiff clay are to be penetrated, an auger or a core tube can be substituted for the driving point. The rods can be rotated clockwise at ground level by using a box spanner and tommy bar. Tools can be pushed into or pulled out of the soil using a lifting/driving tool. Because of the light hammer weight the Mackintosh probe is limited in the depths and materials it can penetrate (Clayton C.R.I., Matthews M.C. and Simons N.E., 1995). 11 Fig. 1.2 Mackintosh probe (after Clayton C.R.I., Matthews M.C. and Simons N.E., 1995) 2.3.4 Percussion Rig Boring The equipment for Percussion Rig Boring (Wash Boring) consists of a derrick, power-winch (Fig. 1.3(a)) and a set of drilling tools. A percussion method is used, whereby the tool assembly is raised by the winch to about 1 m above the bottom of the hole and then allowed to fall under its own weight, thus driving the cutting tool into the soil. When the tool becomes full of soil, it is raised to the surface, where disturbed samples may be taken from its contents. The most usual borehole diameter is 150mm, but others up to 300mm can be drilled; the maximum depth of exploration, although dependent on soil type to some extent, is around 50-60 m. 12 In compact cohesion-less soils, or where boulders or cobbles are encountered, the chisel (Fig. 1.3(d)) is used to break up hard materials; fragments and slurry are then removed using the bailer. In wet conditions and in loose soils, and for very deep holes, a casing must be installed near the surface. This usually consists of steel tubes, screwed together in as many lengths as appropriate, and jacked or knocked into the drilled hole as drilling proceeds. They can be hauled out after completion of drilling or left in place if further observations are required (Witlow Roy, 1995). Fig. 1.3 Percussion drilling equipment: (a) Derrick and winch; (b) Bailer; (c) Clay cutter; (d) Chisel (after Witlow Roy, 1995 ) 13 2.3.5 Core-drilling In stiff soils and rocks power-operated core-drills are used, consisting of smalldiameter hollow tube, fitted at the lower end with a coring bit (Fig. 1.4). The core barrel is rotated at speeds ranging between 600 and 1200 rpm, a controlled pressure applied and water circulated through the bit. The fragments removed in the annular cut are brought to the surface with the circulating water as the core fills the barrel. A drilling run of 1-3 m is usually made before raising the barrel and removing the core. The more usual standard sizes of core barrel used in site investigation range between 30 and 100 mm (hole diameter), although larger-diameter equipment is available for special uses (Witlow Roy, 1995). Fig. 1.4 Rotary coring equipment: (a) Double-tube core barrel; (b) Coring bits (after Witlow Roy, 1995) 14 2.3.5.1 State of Recovery of Core The state of rock cores recovered is largely a function of the drilling method, and the amount of care employed by the driller during a core run and extraction of core from the core-barrel, and hence these factors must be considered when assessing core recovery and fracture state. The nature and amount of core recovered from good careful drilling can provide a valuable indication of the in-situ condition and probable engineering behavior of the rock mass. In any core recovered there will be fractures of natural and artificial origin. It is important that natural fracturing is distinguished from artificial fracturing on the log. Artificially induced fractures should not be ignored since they may assist in the assessment of rock excavation (Clayton C.R.I., Simons N.E. & Matthews M.C., 1995). The core recovered can be divided into five categories: (i) solid core greater than 0.1m in length (ii) solid core less than 0.1m in length (iii) fragmental material not recovered as core (iv) additional material which may have been lost from the previous core (v) reduced length and/or diameter of core due to erosion of soft or friable material 15 Table 2.1: Methods of classifying the quality of rock cores (after Clayton, Simons & Matthews, 1995) _____________________________________________________________________________ Category of Classification Definition core considered Remarks _____________________________________________________________________________ totalcore percentage of the (i) (ii) (iii) (v) gives indication of recovery rock recovered i.e. all the core material that has been during a single placed in the washed into coring ‘run’ core box suspension or the presence of natural voids solid core recovery percentage of full (i) and (ii) diameter core recovered during a single coring ‘run’ rock quality percentage of designation constant diameter (R.Q.D) (Deere) solid core 1964) greater than 0.1m in length recovered during a single coring ‘run’ Stability index (Ege, 1968) (i) gives indication of fracture state can give indication of fracture state but does not take changes in core diameter into account. The diameter of the core should preferably not be less than 55mm (NWX or NWM size) index no.= 0.1 x (i)(ii)(iii)(v) can give indication core loss (length of fracture state drilled – total but does not take recovery x 10ֿ² changes in core + diameter into account no. of fractures per 0.3m (1ft) + 0.1 x broken core (core < 7.5cm in length) + weathering (graded 1-4 from fresh to completely weathered) + hardness (graded 1-4 from very hard to incompetent) ____________________________________________________________________________ 16 The quality of rock recovered may be classified in terms of total or solid core recovery or in terms of a quality index such as Rock Quality Designation (RQD) or stability index, provided only natural fractures are considered. The definitions of these terms are given in Table 2.1 above. Solid core recovery, RQD and stability index may be used as criteria for a quantitative description of the fracture state of the cores. The simplest of these is solid core recovery, particularly when contrasted with total core recovery. The stability index is the most complicated method of assessing rock quality and hence in most cases RQD is used in preference. Deere et al introduced the concept of RQD as a means of classifying rock masses. The RQD is a more general measure than fracture frequency and is based indirectly on both the degree of fracturing and the amount of weathering in the rock mass. One of the most recent classifications has been advanced by Beniawaski. This initially incorporated the RQD: the unconfined compressive strength; the degree of weathering; the spacing, orientation, separation and continuity of the discontinuities; as well as the ground water flow. The grades of rock quality related to RQD are given in Table 2.2. Unfortunately, however, the RQD takes no account of the spacing, orientation, tightness, roughness of the surface or continuity of discontinuities, or the presence and character of infilling material. 17 Table 2.2: Description of the weathering zones of the in-situ rock (after Attewell, 1993) Weathering Zone (material grade) Zone 6 (Grade VI) Descriptive terms Material description and likely engineering characteristics Residual soil. Zone 5 (Grade V) Completely weathered Zone 4 (Grade IV) Highly weathered Zone 3 (Grade III) Moderately weathered Zone 2 (Grade II) Slightly weathered Zone 1 (Grade I) Fresh Completely degraded to a soil; original rock fabric is completely absent; exhibit large volume change; the soil has not been significantly transported. Stability on slopes relies upon vegetation rooting and substantial erosion & local failures if preventive measures are not taken. Rock is substantially discolored and has broken down to a soil but with original fabric (mineral arrangement & relict joints) still intact; the soil properties depend on the composition of the parent rock. Can be excavated by hand or ripped relatively easily. Not suitable as foundation for large structures. May be unstable in steep cuttings and exposes surfaces will require erosion protection. Rock is substantially discolored and more than 50% of the material is in degraded soil condition; the original fabric near to the discontinuity surfaces have been altered to a greater depth; a deeply weathered, originally strong rock, may show evidence of fresh rock as a discontinuous framework or as core stone; an originally weak rock will have been substantially altered, with perhaps small relict blocks but little evidence of the original structure. Likely engineering characteristics are as in Zone 5. Rock is significantly discolored; discontinuities will tend to be opened by weathering process and discoloration have penetrated inwards from the discontinuity surfaces; less than 50% of the rock material is decomposed or disintegrated to a soil; rock samples containing discoloration are noticeably weaker than the fresh un-discolored rock; an originally weak rock will comprise relict blocks of substantially weathered material. Occasionally may be excavated without blasting or cutting (i.e. by block leverage at the discontinuities); will be relatively easily crushed by construction plant moving over it in situ, may be suitable as rock foundation (with some reinforcements); joints may exhibit lower strength characteristics, so rendering side slopes unstable. Some discoloration on and adjacent to discontinuity surfaces; discolored rock is not significantly weaker than un-discolored fresh rock; weak (soft) parent rock may show penetration of discoloration. Normally requires blasting or cutting for excavation; suitable as a foundation rock but with open jointing will tend to be very permeable. No visible sign of rock material weathering; any internal discoloration or disintegration. Normally requires blasting or cutting for excavation; may require minimal reinforcement in cut slope unless rock mass is closely jointed. 18 2.3.6 Weathering Weathering of rocks is brought about by physical disintegration, chemical decomposition and biological activity. The type of weathering which predominates in a region is largely dependent upon climate, which also affects the rate at which weathering proceeds. The latter is also influenced by the stability of the rock mass concerned, which in turn depends upon its mineral composition, texture and porosity, and the incidence of discontinuities within it. Many rocks were originally formed at high temperatures and pressures and a large part of the weathering process consists of an attempt to reach a new stability under atmospheric conditions. High temperature minerals occur in the ultra basic and basic igneous rocks. Hence such rocks tend to offer less resistance to weathering than the acid igneous rocks which are largely composed of soda and potash feldspar, quartz and, to a lesser extent, mica. The latter two minerals are particularly stable. Generally coarse grained rocks weather more rapidly than do fine grained types of similar mineral composition (Bell F.G., 1983). 2.3.7 Geophysical Methods Certain geophysical properties, such as electrical resistance, elasticity, magnetic susceptibility, etc., vary from stratum; a stratum boundary is therefore indicated by an anomaly in the measurements of the particular property (Witlow Roy, 1995). Geophysical methods do not actually measure engineering properties, hence they provide indirect methods of soil exploration; they can be used economically to 19 determine soil stratum boundaries, to locate bedrock and water table levels, to detect organic soil areas and the presence of sub-surface cavities. In all cases, geophysical data needs to be correlated with information gathered from borings or trial pits. The geophysical method is one of the most common supplementary methods used for detecting the presence of hard materials on site. 2.3.7.1 Seismic refraction method Seismic refraction is possibly the most important and commonly used supplementary methods in site investigation. This is because if used in the correct manner under favorable conditions, it can provide reliable quantitative data relating to the geological section across a site. The seismic refraction method can also provide the necessary data for assessing the quality of rock and soil masses in engineering terms. Seismic waves travel at different velocities through different types of material; several factors affect the velocity of shock-wave propagation, such as density, moisture content, and texture, presence of voids or discontinuities and elasticity. The method of seismic refraction involves generating a sound wave in the rock or soil, using a sledgehammer, a falling weight or a small explosive charge, and then recording its reception at a series of geophones located at various distances from the shot-point (Fig. 1.5(a)). The time of the first sound arrival at each geophone is noted from the pen-trace of a continuous recorder. For geophones close to the shotpoint, the direct wave, traveling with velocity VA in the upper layer A, arrives first. If the velocity in the lower layer is greater, then at some distance away from the shotpoint, the refractive wave, traveling with velocity VB 20 in the lower layer B and with velocity VA in the upper layer, will arrive first. The first arrival times are plotted against distance from the shotpoint (Fig. 1.5(b)), to give two time/distance straight-line curves of slopes 1/VA and 1/VB respectively. If the intersection of the two slopes occurs at ‘distance’ X, it can be shown that the depth of layer A is given by: hA = 1/2 X[(VB – VA)/(VB + VA )]½ The seismic refraction method can be used for explorations down to about 300m, but it is a prerequisite that the wave velocity in the upper layer must be less than that in the lower layer(s), i.e. VB > VA. This condition arises from the fact that for the waves to be refracted along the boundary they have to arrive along a path which lies at the critical angle ic to the boundary normal, such that sin ic = VA/ VB. In a multiplayer series of stratum a ‘blind’ layer will occur when its wave velocity is less than that in the overlaying layer: the direct wave will pass through a blind layer perpendicular to the boundary and is then not refracted. Other errors may be caused due to the fact that lithological boundaries do not always correspond with boundaries between strata of different wave velocity; also in isotropic strata there may be a difference between the vertical and horizontal velocities (Witlow Roy, 1995). The accuracy of velocity and depth determinations together with the chances of actually detecting different strata (or other geological bodies) is very much dependent on velocity contrast between different media. Providing the velocities of the layers increase with depth, in general the greater the velocity contrast the greater the confidence in identifying different strata and the greater the accuracy of depth determinations (Clayton C.R.I., Simons N.E. & Matthews M.C., 1995). 21 Seismic refraction method is suitable for detecting rock bodies at depth due to its effectiveness, relatively cheap and wider coverage area compared to borehole. This method is always used in complementary with boreholes. In some cases once a limitation is recognized, it may be overcome, either by modification of the refraction method by special field techniques or by integrating the seismic data with other geophysical data or borehole data. It is important that as the direct investigation progresses the borehole data are made available to the geophysicist so that the geophysical interpretation may be continually updated and limitations causing ambiguities and erroneous interpretations overcome where possible. Direct investigations should be flexible enough to be modified by any updated geophysical interpretations where necessary. Seismic refraction methods are used mainly for quantitative depth determinations and profiling velocity interfaces to obtain a more complete geological section than can be achieved using direct methods of investigation. The refraction method may also be used to asses the quality of rock and soil masses in engineering terms (Clayton C.R.I., Simons N.E. & Matthews M.C., 1995). Fig. 1.5 Seismic refraction method (after Witlow Roy, 1995) 22 2.4 In-situ Tests and data collected Type of data collected includes essential information on the degree of hardness and strength of the materials and parameters that affect their excavatability on site. Relevant field and laboratory strength tests provide numerical values for assessment and comparison purposes. The tests conducted include uniaxial compression, rebound hammer, point-load, Brazilian, and slake durability and ultrasonic velocity test. Relevant properties of the tested materials are then analyzed and plotted on appropriate charts in order to evaluate their degree of excavatability variations (Mohd For Mohd Amin & Edy Tonnizam Mohamad, Universiti Teknologi Malaysia, 2003). 2.4.1 In-situ Tests Several field index tests can be conducted on the exposed rocks in order to assess their in-situ strengths and surface hardness. These tests include Point Load and Rebound Hammer. The rebound number is a measure (index value) of surface hardness of a material. If test is conducted on weak materials (e.g. clays and highly weathered rock) rebound number will be negligible as soft surface will not induce any rebound variations (Mohd For Mohd Amin & Edy Tonnizam Mohamad, Universiti Teknologi Malaysia, 2003). 23 2.5 Laboratory Tests Block samples from the study can be collected for laboratory tests. Laboratory tests give a more detailed and specific data for the purpose of assessments. Moreover, equipments used enable direct strengths, rather than index properties, of sample to be obtained. Tests on specific shape and size of sample helps to minimise random error resulting from sample variations (Mohd For Mohd Amin & Edy Tonnizam Mohamad, Universiti Teknologi Malaysia, 2003). Types of laboratory tests usually conducted for the assessments on the degree of excavatability of rock material on site are: Dry Density test. Rebound hammer (L-type) test. Slake Durability Index test. PUNDIT or Ultrasonic Velocity test. Brazilian (indirect tensile) test. Uniaxial Compression test (UCT). Point Load Index Test.