Reaction and Process Design Vision Document

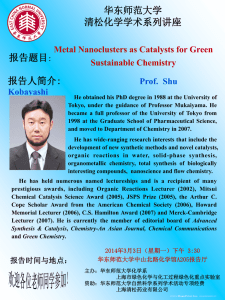

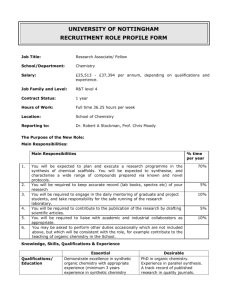

advertisement