plane composite

advertisement

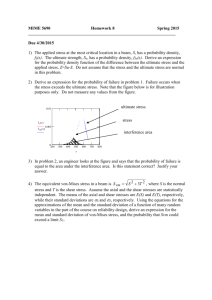

7. Anisotropy – direction-dependence of elastic properties We have seen in Chapter 6 that the elastic properties of a fibrereinforced composite may depend on the loading direction. Anisotropy is a general term which simply means ‘not isotropic’. Most of the composites of commercial interest are actually orthotropic – they have three mutually perpendicular planes of symmetry, with different properties in each of the three directions. In the unidirectional composite in Fig. 6.1, these so-called principal directions were assigned the labels ‘1’, ‘2’, and ‘3’, and appropriate subscripts were added to the elastic properties to identify them. Other forms of reinforcement will use the same nomenclature, with ‘1’ and ‘2’ being always ‘in-plane, and ‘3’ through the thickness of the layer. The UD composite is referred to as ‘transversely isotropic’ because it is assumed that E2 = E3. A random reinforcement such as chopped strand mat will result in the in-plane properties being isotropic (E1 = E2), although due to the way in which composites are laminated, it may not be appropriate to assume E1 = E2 = E3. Anisotropy should not be confused with homogeneity. A homogeneous material has uniform properties throughout, but this description clearly depends on the scale we are considering. The micromechanical equations presented in Chapter 6 describe an inhomogeneous or heterogeneous solid, as the individual properties of fibre and matrix are taken into account. On a larger scale (say greater than a few mm), we are interested in the properties of composites in engineering applications, so we assume the composite to be macroscopically homogeneous, even though we know it is heterogeneous on the fibre scale. The purpose of this chapter is to establish how the orthotropic composite responds to applied loads which may not be aligned with the principal directions of the material. The concepts serve as a basis for calculating the effective engineering properties of composite laminates, which comprise many individual layers, each with different orientations. The mathematics in Chapters 7 and 8 has deliberately been kept to a minimum. The detailed derivations of laminate theory are to be found in all the existing text books, and only the essential results are included here. What is important, however, is that the engineer understands the assumptions and approximations which lie behind the mathematical theory, so that the results can be interpreted appropriately. For a detailed discussion of laminate analysis, the reader is recommended to consult Powell (1994). 7-1 7.1 Hooke’s law in an orthotropic material The situation considered here is one of plane stress, so we only consider stresses and strains in the ‘1-2’ plane. This is appropriate as long as the thickness of our composite is negligible compared to its lateral dimensions. For an isotropic material, Hooke’s law is 1 1 E 2 E 12 0 E 1 E 0 1 0 2 1 12 G 0 (7.1) where the applied stresses 1, 2 and 12 result in strains 1, 2 and 12. Generalising Equation (7.1) to an orthotropic material, we can write: 1 1 E1 12 2 E1 12 0 12 E1 1 E2 0 0 1 0 2 1 12 G12 (7.2) Using [S] to denote the 3 x 3 compliance matrix in Equation (7.2) gives: S (7.3) We can invert any of the above equations to express the stresses in terms of the strains. In our abbreviated notation: Q (7.4) where [Q] is the stiffness matrix. For an orthotropic material: 7-2 Q S1 with E1 J E 12 2 J 0 2 J 1 12 21 1 12 12 E 2 J E2 J 0 0 0 G12 (7.5) E2 E1 The form of the compliance and stiffness matrices in Equations 7.2 and 7.5 confirms that the application of direct stresses alone (i.e. 12 = 0) gives rise only to direct strains - there are no shear strains, and the deformation is independent of G12. Also, an applied shear stress produces only shear strain. We say that there is no coupling between tensile and shear stress/strain. This is always true for an isotropic material, and also applies to an orthotropic materials providing that the loading is aligned with the material axes (‘1-2’). 7.2 Off-axis loading In general, loads may be applied at any angle to the principal axes of the composites. We have already seen that E1 E2 in the UD lamina. But how does the effective tensile modulus vary with the direction of the applied load? In order to progress, we need to be able to transform stresses and strains from one coordinate system to another. We identify ‘x-y’ as the loading axes, and ‘1-2’ as the principal material axes, as in Fig. 7.1. y 2 1 Fig. 7.1: Definition of loading axes (‘x-y’) and material axes (‘1-2’) x The transformation laws for stress and strain are completely standard, and their derivation may be found in any solid mechanics text book. For two-dimensional stress we have 7-3 x 1 2 T y 12 xy (7.6) and for strain: x 1 2 T y 1 1 2 12 2 xy (7.7) The transformation matrix is given by c2 s2 2sc 2 2 T s c 2sc sc sc c 2 s 2 (7.8) where c = cos and s = sin . Thus, the application of a uniaxial stress x results in stresses in the material axes given by: 1 x cos 2 2 x sin 2 (7.9) 12 x sin cos The final stage is to apply Hooke’s law (in its generalised form), combined with stress and strain transformation. Formally, what we are doing is, starting with applied strains in ‘x-y’: (i) Calculate the strains in the material axes (Equation 7.7) (ii) Apply Hooke’s law to obtain stresses in the material axes (Equation 7.4) (iii) Transform the stresses back to the loading axes. The 3rd stage involves the use of Equation 7.6, but with replaced by –. These operations can be combined mathematically to give: x x (7.10) y Q y xy xy where the reduced stiffness matrix is given by 7-4 Q T 1 QT Similarly, we can start with applied stresses in the loading axes, and derive Hooke’s law in the form: x x y S y xy xy (7.11) where we now have a reduced compliance matrix given by S T 1 ST Comparing Equation 7.11 with the isotropic version (Equation 7.1) enables us to associate the terms in the reduced compliance matrix with the effective elastic properties of the off-axis composite. Matrix multiplication results in: S11 2 1 cos 4 sin 4 1 12 sin 2 cos 2 Ex E1 E2 E1 G 12 S 22 2 1 sin 4 cos 4 1 12 sin 2 cos 2 Ey E1 E2 E1 G 12 S 66 1 2 12 1 1 2 1 sin cos 2 4 cos 2 sin 2 G xy E1 E2 G 12 E1 2 1 1 1 2 sin cos 2 E x S12 xy E x 12 sin 4 cos 4 E 1 E 2 G 12 E1 (7.12) The above equations may appear daunting, but they are easily displayed with the aid of a spreadsheet. Off-axis elastic properties are plotted in Fig. 7.2 and 7.3 for UD carbon/epoxy, using the principal properties given in Table 6.2 for a fibre volume fraction of 0.6. 7-5 normalised tensile modulus 1 Fig. 7.2: Normalised elastic moduli for off-axis UD carbon/epoxy composite. 0.9 Ex/E1 0.8 Ey/E1 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 0 20 40 60 80 angle (degrees) 2.5 Gxy / G12 2 1.5 1 xy / 12 0.5 Fig. 7.3: Normalised inpane shear modulus and Poisson’s ratio for UD carbon/epoxy composite. 0 0 20 40 60 80 angle (degrees) 7.3 Interpretation of off-axis properties Fig. 7.2 shows that the elastic modulus of a unidirectional composite falls sharply as the angle between the fibres and the loading direction increases – at only 10o off axis, over 40% of the longitudinal modulus has been lost. It is this sensitivity to orientation that makes unidirectionally-reinforced composites rather rare in practical applications. The effective in-plane shear modulus is a maximum when the fibres are at 45o to the loading axis. This is reasonable if we consider an applied 7-6 shear stress to be equivalent to tension and compression at 45o. What is less intuitive is the increase in Poisson’s ratio. It is common for the off-axis Poisson’s ratio in a UD reinforced composite to be greater than 0.5, which is, of course, not permitted in an isotropic material. We an see that the result of uniaxial loading of an off-axis composite may be a combination of direct, transverse and shear strains. The possibilities are shown in Fig. 7.4 and 7.5. Fig. 7.4: Stretching, lateral contraction and shear in an off-axis ply. Fibres are at 30o to the applied load. Fig. 7.5: Stretching, lateral contraction and shear in an off-axis ply. Fibres are at 30o to the applied load. We say that direct stress and shear strain are coupled in the off-axis composite. This arises not because the material is orthotropic, but because the principal axes (‘1-2’) are not aligned with the loading axes (‘x-y’). We also note that in an isotropic material, the direction of the shear stress is not important. In our off-axis composite, however, the direction does matter, as shown in Fig. 7.6. Positive shear is equivalent 7-7 to a tensile stress in the fibre direction and a compressive stress in the transverse direction; negative shear stress gives the opposite state of stress in the material axes. fibre direction positive shear stress Fig. 7.6: Positive and negative shear stresses expressed as equivalent direct stresses in the material directions. negative shear stress 7.4 Principal Stresses in Isotropic Materials The concept of principal stresses is used widely in the failure analysis of isotropic materials, particularly ductile metals. The procedure of two-dimensional stress transformation already outlined gives the direct stress () and shear stress () on any chosen plane inclined at angle to the reference (loading) axes, as a result of applied stresses. The equations are: x cos 2 y sin 2 xy sin 2 ( x y ) sin cos xy cos 2 (7.13) We define principal stresses with respect to the plane on which the shear stress is zero. The angle of this plane is obtained by putting = 0 in Equation 7.13. The mutually perpendicular principal stresses are then obtained at this angle: 7-8 1 1 2 2 1 2 x y 12 x y 1 2 x y 4 2xy x y 4 2 2 (7.14) 2 xy and the maximum shear stress, given by = ½(1-2), is then on the plane at 45o to that of the principal stresses (Fig. 7.7). 1 max x Fig. 7.7: Principal stresses and maximum shear stress in an isotropic material. 2 xy y In assessing failure, it is sometimes convenient to calculate the socalled ‘von Mises’ stress. This combines the principal stresses to give: VM 12 1 2 22 (7.15) which is then compared with the uniaxial yield stress of the material. Thus the orientation of the principal stresses in an isotropic material, as well as their magnitude, depend only on the applied stresses (x, y and xy). In fact, as far as failure is concerned, the orientation is not of particular interest. This is quite different from the situation in orthotropic materials. Here we are interested in stresses on planes which correspond to the axes in which the material is aligned. So where we refer to ‘principal stresses’ we really mean the material principal stresses. Unfortunately, we use the same nomenclature (1, 2, etc.), but these stresses must not be confused with the isotropic principal stresses defined in Equation 7.14. Note that, unlike in isotropic materials, the shear stress is not generally zero on the 1-2 plane. The concept of von Mises stress also has no relevance in orthotropic materials, although we shall manipulate 7-9 material principal stresses in a similar way when considering failure criteria in Chapter 9. 7.5 Stresses, strains and curvatures in bending It is convenient to start by considering an isotropic plate in bending, then generalise the equations for an orthotropic material. Here we simply state the standard results from bending theory, which are based on the assumptions of small deflections and a linear variation of strain through the thickness of the plate. The stresses due to bending are: Ez x y 1 2 Ez y x y 1 2 x (7.16) where z is the distance from the mid-plane and x and y are the curvatures in the x and y directions. Curvature has the dimensions of length-1, since it is equal to the reciprocal of radius of curvature ( = 1/R). Consideration of equilibrium in a plate of thickness h results in relationships between the external applied moments per unit length (M) and the curvatures: M x D x y M y D y x (7.17) Eh 3 where D is the flexural rigidity of the plate. 12 1 2 Rearranging Equation 7.17, we obtain expressions for the plate curvatures in terms of the applied bending moments: x y M x M y D 1 M y M x 2 D 1 2 12 M x M y Eh 3 12 M y M x Eh 3 (7.19) The plate may also experience twisting if an appropriate moment (labelled Mxy) is applied. Twisting is a little more difficult to visualise than ordinary bending. Formally, it is defined in terms of the rate of change of the slope of the plate. This is illustrated in Fig. 7.8. 7-10 Mxy Fig. 7.8: Twisting curvature resulting from applied twisting moment Mxy (after Powell, 1994). Mxy The centre of the plate is at (0, 0). At any point (x, y), the vertical displacement is given by w d2w xy xy xy dxdy (7.20) The shear strain in the plate at a distance z from the neutral plane is related to the curvature by xy z xy (7.21) and the application of equilibrium gives M xy Gh 3 D xy 1 xy 12 2 (7.22) which follows from G = E / [2(1+)] for an isotropic material. We can now write the relationship between moments and curvatures for isotropic thin plates in matrix form: M x D D M y D D M 0 xy 0 7-11 x x 0 y [D] y D 1 xy xy 2 0 (7.23) The matrix [D] is called the bending stiffness matrix of the plate. Equation 7.23 would appear to be an unnecessarily complicated way of describing the plate’s response, but the form of this equation will be useful when mode complex laminated composites are considered later. For our orthotropic composite ply, which may, in general, be loaded off axis, Equation 7.23 becomes more complex. As before, we only state the result here, which is Mx x x h3 M y [D] y Q y 12 M xy xy xy (7.24) This now includes the reduced stiffness matrix, as already used in Equation 7.10. This term allows for the elastic properties of the composite and the necessary transformations between loading and material axes. By inversion, we can write curvatures in terms of applied moments: x Mx Mx 1 y [D] M y [d] M y M M xy xy xy (7.25) Both [D] and its inverse [d] are fully populated (i.e. there are no zero terms) – this means that the application of, for example a uniaxial bending moment may result in both bending and twisting. This is another form of coupling which does not occur in homogeneous, isotropic materials, and is illustrated schematically in Fig. 7.9. Fig. 7.9: Coupling between bending and twisting in a single UD ply with fibres oriented at 30o to the x-axis. y x 7-12