Study on the Optimum Hoisting Project of "Double

advertisement

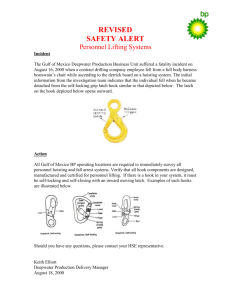

STUDY ON THE OPTIMUM HOISTING PROJECT OF “DOUBLE-CRANE AND DOUBLE-ROPE SYSTEM” FOR LARGE-SCALE SLENDER R.C. COLUMNS Fu, Bing Chen, Longzhu Chen, Xiangdu School of Structure Engineering, Zhejiang University, P.R. China School of Civil Engineering & Mechanics, Shanghai Jiaotong University, Department of Civil Engineering, North-east China Institute of Electric Power Introduction In the construction of a Large or middle-scale plant or factory, slender R.C. columns are cut into pieces beforehand to prevent them being broken in the hoisting ,but it makes the process more complicated and destroys the integrity of the structure. That problem can be resolved by applying double cranes, two rope systems and proper hoisting points. In Fig. 1, R n 1 and R n2 denote two binding forces offered by two cranes. The left rope system can be represented by “ (n 1) 1 s ”, and “ (n 2) ( s 1) n ” represents the right one. The left and right rope systems have s and n s fixed points respectively , n denotes the total number of hoisting points. m ri ( r = n+1, n+2 ; i = 1, 2, …, n ) means the multiple of distance between each fixed and movable pulley that a rope passed by. Presently, articles about this problem are few. Some authors’ opinions are only applied to brief columns[2].Some authors didn’t consider minus moments and the influence of the form of rope systems[3]. In this paper, the optimal hoisting points of rope systems are computed by optimization methods. All kinds of the rope systems drafted having one array of optimum hoisting points of their own, by comparing the inner forces a column hoisted with them receives in the process , the best rope systems can be determined to reduce the values of the inner forces further. Figure 1 Double-crane and Double-rope system Determination of Optimum Hoisting Points The column receives maximal or minimal bending moment when there is some angle between its body and ground. Because the angle is changing, the restraint reacting forces that the ropes offer generate favorable or unfavorable change to the column. So every angle in the erecting should be consider. The optimum hoisting points can be determined by optimization. In this method, the maximal bending moment in each span and minus bending moment at each hoisting point are called controlling moments. The target function is the maximal absolute value of the controlling moments from 0 0 to 90 0 . The object 49 of optimization is finding the minimum of the target function. Hoisting points’ positions are elements of vectors to be optimized. The model of optimization can be searching [ l i ]T ( i =1, 2, …, n ) max M k ( , li ) min s. t. 0 li li 1 l In the model, l i , n and l denote the position of a hoisting point, its total number, and the length of the column respectively. M denotes one controlling moment. k denotes its no.. denotes the angle. By “ Grid optimization ”, the value of the target function is searched out. That is the maximum among the maximal absolute values of the controlling moments at all angles from 0 0 to 90 0 by each array of hoisting points. The minimum of the function is found by “Simplex optimization”, and the elements of the corresponding vector are the optimum hoisting points’ positions. Analysis of Inner Forces for the Column Hoisted For a uniform column to be hoisted, let l, q, G denote its length , uniform load , and gross weight. The calculation diagram is shown in Fig. 2 . In the diagram, n+1 and n+2 denote the two movable points, their loci are like ovum. The tangents of them lie in level when the directions of the two binding forces, R n 1 , R n2 are upright. These lead to F ( xr , yr ) mrs ( xr l s cos ) 2 ( yr l s sin ) 2 Lr 0 and (1) f ( xr , y r ) mrs cos rs 0 (2) where xr ls cos yr ls sin rs c tan 1 (3) In the equations, r, s denote the no. of a movable and fixed point resp.. mrs denotes a multiple. Lr denotes a rope’s length. When r = n+1, s = 1, 2,…, s ; when r = n+2, s = s 1 , s 2 , …, n. The meanings of s and n are the same as the ones in Fig.1. .If s appears two times in a product, it implies sum of the products owning tabs that s denotes. The following equations obey those rules. Figure 2 Calculation diagram 50 The binding forces are Rr G ( xr 0.5l cos ) xr xt (4) where t = n 1, n 2 , t r . The constraint reacting forces at static points are Rs sin( rs ) R r mrs sin rs (5) Let e denotes the no. of spans, the positions where shearing force is zero in each span are i l0e R j 1 j q cos (6) where i =1, 2, …, n ; e = i+1, e n 1. Let k denotes one controlling moment’s no. , when k e , i M k ( , li ) R j (l0e l j ) 0.5q cos (l0e ) 2 j 1 when k i , i M k ( , li ) R j (li l j ) 0.5q cos (li ) 2 (7) j 1 After analysis of inner forces, the results can be programmed and applied to the optimization of hoisting points. The flow chart of calculation is shown in appendix. Study on the Optimum Hoisting Project of “ Four -Hoisting- Point ” To be convenient and save material, four hoisting points are needed. As application examples of the above mentioned method, the project of Four-hoisting point is computed. The parameters for the column are l = 32 m, q = 9 k N / m; for the rope systems, n = 4, r = 5, 6 , s =2, because the multiples’ change of the right rope has little influence to the project, m63 m64 1 , m51 m52 , but the difference between them can’t be large, L5 30m . The optimum rope systems are determined by comparison among the computation results of several rope systems drafted. They are shown in Tables 1-5. The absolute value of every controlling moment reaches its maximum at some degree, and tend to be zero when the angle approaches to 90 0 . This is shown in the tables. 51 l1 = 3. 295 l2 = 12. 315 l3 = 19. 338 l4 = 28. 789 sections in spans and at hoisting points 1 1—2 2 2—3 3 3—4 4 0 -48. 853 48. 040 -38. 274 18. 615 -35. 501 59. 598 -46. 407 10 -48. 111 39. 542 -53. 112 20. 122 -18. 659 67. 233 -45. 702 20 -45. 907 29. 932 -66. 882 20. 784 -5. 017 71. 091 -43. 608 30 -42. 308 20. 527 -77. 074 20. 436 4. 515 70. 615 -40. 190 40 -37. 424 12. 419 -81. 416 19. 020 9. 911 65. 829 -35. 550 50 -31. 403 6. 283 -78.386 16. 585 11. 746 57. 217 -29. 830 60 -24. 427 2. 321 -67. 535 13. 261 10. 870 45. 517 -23. 204 Table 1 The controlling moments by optimum hoisting points from 0 0→600 when m51= m52=1, l5 =30m l1 = 3. 980 l2 = 12. 241 l 3 = 18. 681 l 4 = 28. 132 sections in spans and at hoisting points 1 1—2 2 2—3 3 3—4 4 0 -71. 289 70. 206 38. 522 54. 633 -38. 420 48. 148 -67. 320 10 -70. 206 68. 111 36. 419 60. 519 -14. 251 60. 408 -66. 297 20 -66. 990 61. 873 30. 113 62. 509 5. 503 68. 691 -63. 260 30 -61. 738 52. 361 20. 707 60. 268 19. 019 71. 686 -50. 301 40 -54. 611 41. 071 10. 202 54. 201 25. 869 69. 004 -51. 570 50 -45. 824 29. 695 0. 971 45. 268 26. 810 61. 120 -43. 272 60 -34. 645 19. 604 -4. 983 34. 609 23. 272 49. 087 -33. 660 Table 2 The controlling moments by optimum hoisting points from 0 0→600 when m51=2, m52=1, l5 =45m 0 10 20 30 40 50 60 1 -81. 744 -80. 503 -76. 815 -70. 793 -62. 620 -52. 544 -40. 872 l1 =44. 262 l2 = 12. 063 l3 = 18. 666 l4 = 27. 589 sections in spans and at hoisting points 1—2 2 2—3 3 3—4 4 78. 175 62. 941 71. 042 -53. 483 19. 856 -87. 573 79. 485 65. 240 78. 133 -28. 120 33. 425 -86. 243 76. 136 62. 631 80. 714 -6. 225 44. 210 -82. 292 68. 366 55. 377 78. 179 9. 980 50. 578 -75. 841 57. 226 44. 716 20. 758 19. 556 51. 698 -67. 085 44. 334 32. 601 59. 432 22. 844 47. 651 -56. 291 31. 382 21. 131 45. 592 21. 106 39. 261 -43. 787 Table 3 The controlling moments by optimum hoisting points from 0 0→600 when m51=3, m52=1, l5 =60m 0 10 20 30 40 50 60 1 -65. 034 -64. 046 -61. 112 -56. 321 -49. 819 -41. 803 -32. 517 l1 = 3. 802 l2 = 12. 513 l3 = 18. 961 l4 = 28. 337 sections in spans and at hoisting points 1—2 2 2—3 3 3—4 59. 552 5. 991 34. 400 -43. 186 47. 303 53. 998 -1. 872 34. 235 -22. 978 57. 031 45. 451 -12. 179 34. 604 -6. 592 62. 959 35. 224 -22. 992 32. 536 4. 698 64. 220 24. 889 -31. 832 28. 506 10. 842 60. 742 15. 836 -36. 355 23. 225 12. 684 53. 113 8. 923 -35. 037 17. 379 11. 468 42. 280 4 -60. 389 -59. 471 -56. 747 -52. 298 -46. 260 -38. 817 -30. 194 Table 4 The controlling moments by optimum hoisting points from 0 0→600 when m51=3, m52=2, L5 =75m 52 m51 m52 L6 1 1 m63 m64 30 L5 1 1 30 2 3 3 1 1 2 45 60 75 Table 5 Figure 5 l1 l2 l3 l4 inatial positions 3. 380 12. 618 19. 380 28. 620 positions after optimization 3. 295 12. 315 19. 338 28. 789 3. 980 12. 241 18. 681 28. 132 4. 262 12. 063 18. 666 27. 589 3. 802 12. 513 18. 961 28. 337 maxim um percentage of decrease 95. 481 _____ 81. 462 15 % 71. 687 87. 573 65. 034 25 % 8% 32 % Comparison of the projects drafted shows that the parameters of the optimum project for this column are T T m51 3 , m52 2 , m63 m64 =1, L5 75m , L6 30m , [ li ] = [ 3. 802 12. 513 18. 916 28. 377 ] , i = 1~ 4. There is linear relation between inner forces and uniform load, so the optimum hoisting points’ positions are determined by the length of the column and ropes. For columns of different length, determination of hoisting points and rope systems drafted by optimization is necessary. Conclusions 1. 2. 3. Double-crane and Double-rope system are practice means for hoisting slender R.C. columns. Selection of hoisting points’ positions and rope systems drafted is important after determination of the total number of hoisting points, which can lessen inner forces and convenience hoisting. “Grid optimization” and “Simplex optimization” are effective methods for determination of hoisting points. They are easy but feasible. Reference [1] Xiangdu Chen, Mechanics of Binding Systems of Ropes and Pulleys, Huazhong University of Technology Press, 1995. [2] Xiangdu Chen, Chengjie Xu, and Yansong Zhao. ,the Mechanics Problem Existed Long of Hoisting Slender R.C. Columns, Journal of Harbin university of Architecture 29(1996) 2. [3] Binghua Zhang, Chang Hou, Design of Architectural Structure by Optimization, Tongji University Press, 1995. 53 Appendix begin read q, l, Ln+1, Ln+2, read mrs, li (i=1,...n (0) X = [l1, l2, ....ln] T (j) X = [...li-1+q, li+p, li+1+q...] T M[j]=0 compute (xr, yr) compute Mk(,li) if |Mk(,li)|>M[j] |Mk(,li)| implies M[j] proceed Simple Optimization to search new X (j) |max M - min M| < write min M, li end 54