A. Principles of Simple Machines

advertisement

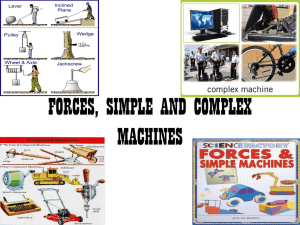

The MAPs Team Meaningful Applications Of Physical Sciences Dr. Michael H. Suckley Mr. Paul A. Klozik Materials in this manual are based upon the Operation Physics program funded in part by the National Science Foundation. All material in this book not specifically identified as being reprinted from another source is protected by copyright. Permission, in writing, must be obtained from the publisher before any part of this work may be reproduced in any form or by any means. Participants registered for this workshop have permission to copy limited portions of these materials for their own personal classroom use. Simple Machines © 2006 ScienceScene Page 1 Simple Machines A. Principles of Simple Machines 1. Naïve Ideas ................................................................................................................... 4 2. Six Simple Machines ...................................................................................................... 9 3. Why Use Simple Machines? .................................................................................10 4. Inclined Plane - Wedges At Work ......................................................................... 12 a. How Can Changing The Angle Effect Force? (Inclined Plane) ......................... 14 b. Why Take The Longer Road? (Wedge & Screw) .............................................. 17 5. Levers a. How Do You Pop The Top? ........................................................................... 18 b. Examples of the Three Types of Levers ......................................................... 19 6. Pulleys a. How Strong A Force Do You Need? .............................................................. 20 b. Gravity and the Simple Pulley........................................................................ 25 c. Which Ways Should You Pull? ...................................................................... 27 d. Student Pulley System .................................................................................... 29 e. Paperclip Pulleys ............................................................................................ 30 f. Strength of Forces ........................................................................................... 31 7. Wheel and Axle 8. Which Way Is the Force? ...................................................................................... 33 B. Investigating the Simple Machines 1. Characteristics of Simples. a. Work (W=F X D And W = F X D) b. Mechanical Advantage (Ratio of Force Exerted To Force Applied) c. Efficiency (Ratio between the Energy It Supplies and the Energy Put into It) 2. The Simple Machines Workshop ............................................................................ 38 a. Levers…………………………………………………………………..……42 b. Pulleys…………………………………………………………………….…47 c. Inclined Plane / Wedge / Screw ...................................................................... 50 d. Wheel And Axle ............................................................................................. 52 C. Work and Power 1. Car Power ................................................................................................................ 54 2. How Much Horsepower Can You Produce? ........................................................... 55 D. The Wake Me up Machine (a summary) ................................................................... 56 Simple Machines © 2006 ScienceScene Page 2 Simple Machines © 2006 ScienceScene Page 3 Simple Machines – Naïve Ideas 1. Simple machines make less work 2. Simple machines always change the direction of the applied force. 3. Work and force have the same meaning and can be used interchangeably. 4. Force X Distance (work) is a way to describe what a machine can do. 5. Simple Machines produce more work than put in. 6. In actual simple machines input work is always equal to output work. 7. Resistive forces found in simple machines can be eliminated with various lubricants. 8. Mechanical advantage is larger for big machines and smaller for smaller machines. 9. The efficiency of a machine is an indication of how fast it can do work. 10. Power of a simple machine is an indication of the amount of force that it can apply. 11. Energy changes occur are seldom found when work is done by simple machines. Simple Machines - Benchmarks 1. Identify and use simple machines and describe how they change effort. 2, Inclined planes, levers, pulleys, wedges, wheel and axle, force, distance. 3. Manipulate simple mechanical devices and explain how their parts work together. 4. Design strategies for moving objects by application of forces, including the use of simple machines. 5. Analyze pattern of force and motion in the operation of complex machines. Simple Machines © 2006 ScienceScene Page 4 Workshop Leader Topic Information Simple Machines, Work And Power This unit focuses on the topics Simple Machines, Work and Power. In the last - section of the unit are energy changes in a system discussed. The materials in the unit vary in the degree of quantification required. The materials developers felt that relative quantities would be appropriate for the lower grades, while more formal quantitative measurements should be used in the upper grades. All levels should learn that it is possible to describe observations through the use of measurements. The unit does not include extensive discussion of which measurement units should be used. Some textbooks use English units (eg. ft., lb.) while other use metric (eg. Newton, joule). The language used in many textbooks on the topics of work and simple machines is not consistent. Books may use either the terms input and output or the terms effort and resistance to distinguish forces in describing work. Books may introduce language to classify type or classes of machines. The consequence is often an extensive (and irrelevant?) introduction of new language in the science curriculum. We have tried to limit the number of terms used in these materials. Workshop leaders may need to assist teachers in linking our language to that used in the local curriculum (or, maybe the workshop leader can help to reduce and simplify the unnecessary language in the local curriculum.) The unit is organized into the subtopics of simple machines, force x distance, input/output, Rower and work/energy. The general scheme is to provide acquaintance with a wide variety of simple machines, and then to define work (Force x Distance). This unit does not include exercises regarding- the measurement of force or distance. However, these concepts should be covered by use of activities from other units if the participants are unfamiliar with the topics. The potential misconceptions likely to be encountered in this unit are of two types. One type of misconception arises when commonly used words have specific, often operationally defined, scientific meaning (eg. work). The other type of misconception occurs when there is a conflict between an intuitive notion gained through experience and the formal structure of scientific knowledge. Confusing words: work force harder/easier advantage power simple machine Confusing ideas: 1. Failing to be able to identify the direction in which a force is acting. 2. Believing that any force times any distance is work. 3. Believing that machines put out more work than we put in. 4. Not realizing that machines simply change the form of the work we do, i.e., "trade off" force for distance or distance for force. Simple Machines © 2006 ScienceScene Page 5 References And Resources The following is a list of reference materials related to this unit. Additional suggestions to this list are welcomed. Books Addison Wesley Level 6. A science text covering these topics. Darby, Gene. Finding Out About Simple Machines. Benefic Press, Chicago, Illinois. A low level student reader with chapters entitled lever, wheel and axle, pulley, incline plane, wedge and screw. Low level reading ability. Might stimulate some students to try an activity. Heath Science. Level 4. D.C. Heath and Co. A science text covering the topics of this unit. Invention Convention. Silver Burdett. A competitive program sponsored by Silver Burdett to encourage students to make "inventions." Many of these inventions relate to applications of simple machines. Contact Silver Burdett for details. Liem, Tik L. Invitations to Science Inquiry. Ginn and Co., Lexington Mass. A source book of science teaching ideas. This book stresses the use of readily available materials in demonstrations to promote student inquiry. Machines and Work. Millikea Publishing Co., St. Louis, Missouri. A book of trans pare ncieslduplicating masters on this topic. Mandell, Murell. Physics Experiments for Children. Dover Publications. New York. Marson, Ron. TOPS Learning Systems: Machines. TOPS Learning Systems, Canby, OR 97103 A series of 16 task cards and teacher manual with simple, easy to build teaching ideas. Pine, Tillie, and Lavine, Joseph. Simple Machines and How to Use Them. McGraw Hill,. pp.48. Materials List Levers Pulleys String (about 30 lb. fishing line - braided - works) Weights Scales Hammers Nails Screw drivers Screws Wood & Styrofoam blocks Paint can and lid 10-20 Meter rope, and 2 short ropes (approximately 2 meters) Rubber bands Tacks Rulers (meter sticks) 5 kg mass 1 kg mass Single pulleys Paper cups Paper clips Stop watch Straws (flexible) Boards 2 Pairs of work gloves 2 Large pulleys (one with a strap so that a rope can be attached to either end) Bicycle Simple Machines © 2006 ScienceScene Page 6 Workshop Leader's Planning Guide Some simple machines are introduced to provide an overview of mechanical devices, with the stress on the ability of machines to change the amount, distance and direction of a force needed to do work. The introductory section simple machines is not meant to include details of work done, mechanical advantage or-discussions of energy. This section provides lots of examples of the use of different types of simple machines. While the activities focus on the uses of machines, participants may need a definition of what is a simple machine and names and examples of different types of simple machines. The order of activities in this section is not critical. Confusing words: force and simple machine Confusing Idea: Failing to be able to identify the direction in which a force is acting. A. The Incline Plane, Lever, Pulley And The Wheel And Axle Are Examples Of Simple Machines. 1. Activity: "Why Use Simple Machines?" A short lab which uses simple tools to insert/remove nails and screws from soft wood or Styrofoam boards. 2. Overhead/Discussion: "Wedges at Work" An overhead which illustrates the use of several different kinds of wedges (e.g. door stop, knife) used in everyday activities. 3. Demonstration: "How Do You Pop the Top?" An introductory demonstration activity which contrasts the futility of attempting to pull the top off of a paint can, and the use of a tool (screwdriver - lever) to do the same task. B. MACHINES CAN CHANGE THE AMOUNT OF FORCE NEEDED TO DO WORK . (All of the activities in Section B address the confusing word "force"). 1. Activity: "How Strong A Force Do You Need?" This is an activity in which students analyze various pulley systems by using them in "tugs-ofwar." This activity explores how machines can change the direction of a force, the amount of force, and the distance moved. 2. Overhead/Discussion: "Strength Of Forces." This overhead shows several simple machines used to change the amount of force used to do a task. 3. Activity: "How Can Changing The Angle Affect Force?" A lab exploring the use of an incline plane. Books are used to give the board a height and rubber bands are used to measure force. Simple Machines © 2006 ScienceScene Page 7 C. MACHINES CAN CHANGE THE DIRECTION OF A FORCE NEEDED TO DO WORK. 1. Demonstration/Discussion: "Gravity and the Simple Pulley." A demonstration using the Atwood machine single pulley with two weights in balance. This demonstration encourages prediction and discussion because many teachers believe the system will change position. 2. Overhead/Discussion: "Which Way?" This is an overhead which illustrates several ways simple machines can be used to change the direction of a force. 3. Activity: "Which Way Should You Pull?" A short lab in which teachers predict and measure the amount of force required to pull a rope wrapped over a single pulley. The direction of the pulling force is varied. D. MACHINES CAN CHANGE THE DISTANCE THROUGH WHICH A FORCE ACTS TO DO WORK. 1. Overhead/Discussion: "Why Take the Longer Road?" This is an overhead showing a truck driving straight up a mountain and a truck driving an incline road up a mountain. E. SIMPLE MACHINES CAN BE COMBINED TO DO WORK. 1. Overhead: "Wake-Me-Up Machine." This is a drawing of several machines connected in an unnecessary complex manner to wake up someone. The drawing can serve as a worksheet. or overhead for discussion. Simple Machines © 2006 ScienceScene Page 8 The Six Simple Machines Simple Machines © 2006 ScienceScene Page 9 Why Use Simple Machines? Materials: hammer 2 nails, #8 or #10 screwdriver 2 sheet metal #12 x 2" screws scrap lumber (at least 5 cm thick, soft wood) 1. Pound 2 large nails into scrap lumber. Be sure at least 3 cm of the top-of the nail sticks up above the board. Which moves farther the head of the hammer or your hand? 2. Try to remove the first nail with your fingers. Were you able to remove the nail? 3. Use the claw of the hammer to remove the second nail. Was it easier to remove the nail with the hammer? Why? 4. Turn two wood screws in the piece of scrap lumber. 5. Try to turn out the first screw with your fingers. Try to remove the second one with the screwdriver. Why do we use a screwdriver to turn the screw? Simple Machines © 2006 ScienceScene Page 10 Why Use Simple Machines? IDEA: Machines change the amount of force, the distance PROCESS SKILLS: Observe direction .of the force and/or the Explain through which the force acts. LEVEL: Teacher Notes DURATION: 20 Min. STUDENT BACKGROUND: None. ADVANCE PREPARATION: Gather materials. Use lumber that is soft wood. Styrofoam may be used instead, especially with younger children. MANAGEMENT TIPS: For students who are too "overactive" to use the tools as described, the lab may be done by the class as a whole. RESPONSES TO SOME QUESTIONS: 1. The head of the hammer. 3. The hammer acts as a simple machine to increase the force. Note that the handle of the hammer is pushed down a greater distance than the nail moves. Force is traded for distance. 5. A screwdriver is a wheel and axle. The handle has a larger circumference than the blade, making the hand turn a larger distance. The force on the handle, however, is less than the force transmitted to the screw. POINTS TO EMPHASIZE IN THE SUMMARY DISCUSSION: We use machines because they help us to do work. Machines can change force, change direction in which the force acts, or change the distance through which the force acts. The way in which they help us is different in each situation. People design machines to do a specific job -the machine fits the job. POSSIBLE EXTENSIONS: None. Simple Machines © 2006 ScienceScene Page 11 WEDGES AT WORK (Discussion) Wedges are a form of incline plane. The picture illustrates several different kinds of wedges (a door stop, needle, wood plane, chisel, awl, axe, pick, knife and boat).This picture should be used as a key to discussion. First students could name the objects and you could check if they know what each object does and describe why each item is a wedge. Encourage them to phrase their responses in operational terms of what is forced where. Ask them to describe other "wedges" that are useful in doing work. Simple Machines © 2006 ScienceScene Page 12 Focus On Physics What Every Teacher Should Know About Measuring (Discussion) Some basic rules of measuring are: 1. Do not use ends of a measuring device when measuring length because they may be damaged. . 2. Position head carefully so that eye is directly in front -of the measuring device to avoid parallax. 3. If possible, place the object on measuring device or the measuring device on the object. 4. Be consistent when measuring - always use the same side or center of the line for every measurement. 5. Estimate one more digit than is shown on the measuring device. 6. When measuring mass make sure balance is clean and adjusted before measurements are taken. 7. When measuring a liquid volume, use the bottom part of the curved line (meniscus). These rules should be introduced in a discussion after students have obtained different measurements of the same objects. Students should not be given a "list of rules" to know but rather these "rules" or techniques should be stressed in every measuring activity. These skills or techniques are a major part of every measurement activity. A good way to see how accurate and reliable students are measuring is* to repeat an activity several days after it was first done allowing each student to compare individual results with the first results and those of other students. Remember to keep the results so that they can repeat it and compare their results later. Simple Machines © 2006 ScienceScene Page 13 How Can Changing The Angle Affect Force? Materials: inclined plane, slinky and weight found in 35mm film container 1. Place the weight/resistance at the end of the slinky. 2. OBSERVE the distance the slinky is stretched while the slinky and weight/resistance lay on the inclined plane placed flat on the table. Record the observations in data chart. (a) 3. PREDICT, while holding the slinky and weight placed on an inclined plane, what will happen as the inclined plane is tilted. Do you think the slinky will stretch more or less as the inclined plane is tilted toward the perpendicular? 4. CONDUCT the experiment, lifting the inclined plane approximately 1/3, 2/3, 3/3 of the distance, from flat to perpendicular, and record the results, in the table, (b, c, and d). Record results. Description of Data Amount of Slinky Stretch (cm) (a) Flat on the table top (b) Tilted inclined plane (1/3) (c) Greater tilt of inclined plane (2/3) (d) Perpendicular to the floor (3/3) Questions: 1. How did the stretch length of the slinky change when you used the inclined plane? 2. What other changes did you see? Simple Machines © 2006 ScienceScene Page 14 3. How did the steepness of the inclined plane affect the force needed to pull the mass? Simple Machines © 2006 ScienceScene Page 15 How Can Changing The Angle Affect The Force? IDEA: To demonstrate that the angle of an inclined plane affects the force required to move an object. PROCESS SKILLS: Predict Observe Compare Measure Control Variables Interpret LEVEL: Teacher Notes DURATION: 20 Min. STUDENT BACKGROUND: None. ADVANCE PREPARATION: Set up the equipment. MANAGEMENT TIPS: Participants may need help constructing their slinky force measurers RESPONSES TO SOME QUESTIONS: POINTS TO EMPHASIZE IN THE SUMMARY DISCUSSION: The greater the angle of the incline, the greater the force that is required. POSSIBLE EXTENSIONS: How did making the angle greater affect the amount of work done? (More work w as done because the mass ended up higher above the floor). Simple Machines © 2006 ScienceScene Page 16 Why Take The Longer Road? (Discussion) The engine in the truck doesn't have enough force to get the truck straight up the steep mountain. The winding road, really an inclined plane turning in a circle, makes the mountain less steep to climb. On the winding road, the truck can get to the top because less force is needed. However, the truck must travel a much longer distance. Simple Machines © 2006 ScienceScene Page 17 How Do You "Pop The Top?" (Discussion) 1. Would it be difficult to remove the lid on a paint can using your fingers? (Use a paint can with a good lip for the fulcrum.) 2. What can you use to open the can? (Key, coin, screwdriver, etc. - Discuss hazards to fingernails, keys, etc.) 3. What do all these tools have in common? (All of these tools are rigid -- that is they do not bend easily. All of these tools rest on the edge of the can. You need both the rigid tool and the resting place for the tool to work. This, tool is called a lever -- a rigid bar and a pivot point. Using this tool, it is much easier to remove the lid. This tool is a simple machine, a lever, that increases the output force.) 4. Which way do you push to open the lid? (You push down. The tool pushes up on the lid. The simple machine changes the direction of the force.) 5. What can you observe about the distance traveled by the tip,of the tool and the handle? (The handle travels farther. A simple machine changes the distance through which the force moves an object.) Extension: Extension Activity: Compare removing the lid with a coin, a short handled screwdriver and a long handled screwdriver. Consider how a soda can and soda bottle are opened. Simple Machines © 2006 ScienceScene Page 18 Examples Of The Three Types Of Levers Simple Machines © 2006 ScienceScene Page 19 How Strong A Force Do You Need? (Pulley System "Tug-of-War") M a t e r i a l s : 2 Large pulleys ( one with a strap so that a rope can be attached at either end ). 1 Long rope, approximately 10-20 meters 2 Short ropes, approximately 2 meters 2 Pairs of gloves Introduction: In this activity, a participant will use a pulley system to move one or more other participants. This activity can take place in the classroom or out in the school yard. Procedure: 1. Two participants that have about the same strength (this can be determined by a simple tug-of-war), should set up the pulley system as shown in figure 1. Wearing gloves, they should begin to pull at the same time. DESCRIBE the force on each participant. Describe the distance each student moves. Simple Machines © 2006 ScienceScene Page 20 How does this COMPARE to a simple tug-of-war? What is the pulley doing? Student #2 Student #1 Figure 1 2. Set up the pulley system as shown in figure 2. Describe the distance each student moves. Simple Machines © 2006 ScienceScene Page 21 COMPARE this to the first procedure. What is the pulley doing? Student #2 Student #1 3. Setup the pulley system as shown in figure 3. DESCRIBE the force on each student. Describe the distance each student moves. Compare this to the other two systems. What are the pulleys of this system doing? Student #2 Student #1 Simple Machines © 2006 ScienceScene Page 22 How Strong A Force Do You Need? (Pulley System "Tug-of-War") IDEA: To demonstrate that simple machines can change the direction of a force, the amount of force or the distance moved. (This is a good introduction to 111131). PROCESS SKILLS: Observe Describe Compare Measure Design Experiments LEVEL: Teacher Notes DURATION: 30 Min. STUDENT BACKGROUND: None. ADVANCE PREPARATION: Gather the equipment. If this is done as a participant participation demonstration, only one set is needed. If the extension is done, double pulleys will be needed. MANAGEMENT TIPS: 1. Stress safety in this activity. Do not allow participants to wrap the rope around their hands, and require that they wear gloves. Be sure the anchor point is solid (tree, large swing set, strong pipe). 2. Have the participants hold the rope in one place, and not move their hands along the rope: This will allow them to tell which one moved the most. 3. It is a good idea to have the participants trade places (particularly if one is stronger) to determine if the pulley system is really doing something. 4. The purpose of this activity is to give participants a "feel" for what machines can do. . Simple Machines © 2006 ScienceScene Page 23 RESPONSES TO SOME QUESTIONS: 1. The forces should be about the same, and the distance each person moves will be equal. This is the same as a simple tug-of-war. What the pulley does is change the direction of pull. 2. The machine multiplies the force of participant 1, but participant 1 had to move farther than participant 2. This machine changes both the amount of force and the distance, but not the direction. 3. The machine multiplies the force of participant 1, but participant 1 had to move farther than participant 2. This system also changes the direction of the force of participant 1. This machine is a combination of the first two. It changes the amount of force, the distance, and the direction. POINTS TO EMPHASIZE IN THE SUMMARY DISCUSSION: POSSIBLE EXTENSIONS: Machines can change the amount of both force and distance, as well as the direction of a force. It might be pointed out that as the force is increased, the trade-off is that the distance is decreased. 1. For systems 2 and 3, it is interesting to see how many participants it would take to hold off participant 1. (It should be two because this machine has a mechanical advantage of two). 2. If double pulleys are available, participants can design their own systems. Care should be used as more participants are pulling on the rope. Simple Machines © 2006 ScienceScene Page 24 Gravity And Simple Pulley (Demonstration/Discussion) Many people believe that gravity will exert very different forces at slightly different elevations. This demonstration helps to dispel this notion, and serves as a good preliminary to working with simple machines. Set up the demonstration apparatus as diagrammed. Teachers should hold both A & B or have each of two students hold one of the weights while teacher introduces the question/problem to the class. Be sure string is very light in comparison to the masses A & B. Otherwise, the additional weight of the string on side B could make that side go down. A B Prediction Q: "When I let go of these two identical masses what will happen? Write or draw your prediction on paper, but don't say your answer yet. (Have students write or draw their predicted result to get them to commit their thinking.) Simple Machines © 2006 ScienceScene Page 25 Justification Q: "Without talking about it yet, think how you decided that's what will happen." Discussion 1: Now let's talk about our predictions and our_ reasons for those predi ctions." (Discussion, then do the demo.) Observation Q: "What did happen?" (Help students classify their observations, if necessary.) Interpretation Q "What does the result tell us?" Discussion 2 Allow students to express themselves fully during Discussion 1. Then during Discussion 2, call on students who had reasonably clear justifications for correct predictions to report and elaborate on their ideas. Allow other students who would like to elaborate on the explanations or who have alternative expl anations to speak fully. Allow students who have rational objections to speak. Summarize the most defensible interpretation from the class. Perhaps something like, "The weights pull equally hard on the string, whether they are high or low." "Gravity seems to pull about equally hard on the two masses, regardless of how high they are above the floor" (in the room at least). Listen to the kids for possible extensions. e.g. "Would the result be different outside?" or "What if mass B was here and A was up as high as a mountain?" (This would need to be a thought experiment and it turns out that weight -- the gravitational pull exerted by the earth in this case -would change gradually as the object is moved farther and farther away from the surface of the earth. To be half as heavy, for example, the object would need to be more than 1500 miles above the earth.) Simple Machines © 2006 ScienceScene Page 26 Which Way Should You Pull? Materials: pulley and clamp hardware spring scale, a weight string 1. Record the force readings for each position shown below: 2. What does using a pulley to change string direction do the force? Simple Machines © 2006 ScienceScene Page 27 Which Way Should You Pull? IDEA: PROCESS SKILLS: Machines can change the direction. of a force needed to do work. LEVEL: Teacher Notes DURATION: 20 Min. STUDENT BACKGROUND: ADVANCE PREPARATION: Measuring Inferring a rule Facility with use of force scale. - MANAGEMENT TIPS: Set out (or set up) equipment for each group -- see Student Activity Sheet. Perhaps hand out the Student Activity Sheet. The force scale readings should come out approximately the same. They may differ slightly due to the weight of the spring scale itself helping to pull down on the string. This probably can be minimized by using a light weight force scale and a large mass ≥ 1 kg. RESPONSES TO SOME QUESTIONS: POINTS TO EMPHASIZE IN THE SUMMARY DISCUSSION: POSSIBLE EXTENSIONS: A pulley can be used to change the direction without changing the size of a force exerted to do work. None. Simple Machines © 2006 ScienceScene Page 28 Student Pulley System Simple Machines © 2006 ScienceScene Page 29 Simple Machines © 2006 ScienceScene Page 30 Strength Of Forces (Discussion) This overhead contains several examples of simple machines changing the amount of force required to do a task. Because the overhead uses "real world" situations, students may discuss forces (and work) related to several objects. The emphasis of the discussion should be on the items in the questions below. The "answers" following each question address key points which may be part of the student discussions. 1. The girl on the sailboat can "pull in" the sail with the use of pulleys. How would her job be different if the rope went only from the sail to her hand? Why are there two pulleys used on this rope? (It would take much more force to "pull in" the sail if the rope was tied directly to it. In this case it is possible to think of one pulley reducing the force required, and the other pulley changing the direction (location) of the force). 2. Could the piano be lifted by the man if only one pulley was used? How high can the piano be lifted using this arrangement? (The man probably would not be strong enough to lift the piano with the aid of just one pulley. This combination of two pulleys helps the man to lift the piano; The height that the piano is lifted is restricted by the location of the pulleys). 3. Can you crack a nut in your fingers? Why does a nut cracker work? (The nut cracker works for two reasons, it acts to increase the force from the hand and it is designed to hold the nut in a manner that it cannot "slip away"). 4. Why does the man roll the barrel up into the truck instead of lifting it? (Probably because of its weight. The ramp allows the man to exert a smaller force over a larger distance to lift the barrel). 5. What are the pliers being used for in the picture? (it appears that the pliers are being used to "grip" something. The pliers could be used to exert a strong squeeze on an object). 6. What is shown in the lower right drawing? How is this drawing similar (different) to the other pictures shown? (The picture shows a screw jack holding up a very large force, e.g., a comer of a building. The picture is like others in that it shows work being done or work that has been done. The screw of the jack is a special form of an incline plane (ramp). Simple Machines © 2006 ScienceScene Page 31 Strength Of Forces (Overhead) Fulcrum Simple Machines © 2006 ScienceScene Page 32 Which Way Is The Force? (Discussion) The following overhead illustrates several ways simple machines change the direction of a force. The overhead is designed for general discussion of this concept. The discussion should be qualitative, no analysis needs to be made of how much the force direction is changed or of how much work will be done. 1. The girl pulls down on the flag rope to raise the flag. Although it cannot be seen, there is probably a pulley at the top ot the flag pole to change the direction of the force. 2. The farmer is using the tractor to pull on the rope attached to the bale of hay. The tractor will drive away from the barn while the bale will be lifted to the hay loft. If someone notes the tractor wheel is a simple machine which changes the direction of a force so that the tractor may go forward, okay. However, that is not the primary focus of this picture. 3. In which direction is the man pushing? (down). In which direction is a force being exerted on the rock? (up). 4. In the picture of "pulling the nail" which direction is the man pulling? (toward him, horizontally). In which direction is the nail being pulled? (up). 5. The skier is being pulled down the slope (an incline plane) due to gravity. If the skier makes a smooth turn, what machine is used in the turn (the edge of the ski can act like a wedge). 6. The wedge is being used to drive the post upward, the wedge is being driven away from the man (horizontally). Simple Machines © 2006 ScienceScene Page 33 Which Way Is The Force? (Overhead) Simple Machines © 2006 ScienceScene Page 34 Focus On Physics Simple Machines (Discussion) Simple machines are devices that help us do work. Many books list six basic simple machines: the inclined plane, wedge, screw, lever, wheel and axle, and pulley. Notice that these simple machines do not have energy sources of their own, such as batteries or fuel tanks. Simple machines do not do any work by themselves; they merely transfer work done by a human to something else. What is the advantage of using a simple machine if it doesn't really do any work? Simple machines can change the amount of force required to do work. ' They can also change the distance through which the force acts or the direction in which it acts. By changing these characteristics, simple machines allow humans to do things that they otherwise might not be able to do. For example, could you pull a nail out of a board with your bare hands? Probably not. You could, however, use a hammer as a lever to do the job. Your hand would move farther than the nail, but-the force on the nail would be increased. Using a hammer also changes the direction of the pull. Your hand would move in a sideways arc, and the nail would move up. The lever changed the amount of force, the distance of the force, and the direction of the force to get the job done. The activities in this section are designed to show you many examples of how machines can help people do work. Several of the six simple machines are related. The wedge is a moving inclined plane, and a screw is an inclined plane wrapped around a shaft. The wheel and axle is an often misunderstood machine. It is essentially a lever that can move in a circle. The steering wheel in a car and the shaft it is attached to is an example of a wheel and axle. The larger the wheel is as compared to the shaft, the more "leverage" it has. The wheel must be attached to the shaft (axle) to transfer force to it. All simple machines transfer work and, therefore, they must also transfer force. The wheel of a child's wagon that is free to rotate around the axle is not an example of a simple machine becaus e it does not transfer force. The "Focus on Physics" notes that accompany the other sections of this book will specifically address the ideas of work, input and output of machines, power, and the way work is related to energy. POINTS TO EMPHASIZE IN THE SUMMARY DISCUSSION: POSSIBLE EXTENSIONS: Simple machines can be combined. List the simple machines. List in order, the events that will occur. Events can cause other things to happen. 1. Discuss compound words to extend the idea of simple things combining to form more complex things. Compound words can be broken down in the same way a compound machine can be broken down. 2. Have the students create their own machine as a home project. Simple Machines © 2006 ScienceScene Page 35 Making 1 and 2 Newton Forces Materi als: Jumbo Paper Cli ps # 6 lead Shot Tri pple beam ballance Fi lm Cani sters Step 1 Step 4 Step 3 Step 2 2 Newtons Step 5 • add 102g of shot for 1 newton force. • add 204g of shot for 2 newton force. • drill 1/16 in hole through cap and container Step 6 • Insert wire through the hole. Step 7 Step 8 • Bend wire and bend a loop at the end. • bend hook into position. • Add label Simple Machines © 2006 ScienceScene Page 36 Simple Machine Terms 1. The Mechanical Advantage (M.A.) of a machine is the ratio of the resisting weight (R) to the acting force (E), or the ratio of the distance through which the resistance is moved divided by the distance the weight is raised. M.A. = R / E 2. The Ideal Mechanical Advantage (I.M.A.) depends upon the kind of machine and is defined separately for each machine. 3. Ideal Effort (I.E.) is the force needed to move a resistance that is equal to the resistance divided by the I.M.A. I. E. = R / I.M.A. 4. Actual Effort (A. E.) is the force needed to move the resistance. 5. Actual Mechanical Advantage (A.M.A.) is the ratio of the resistance to the actual effort. A.M.A. = R / A.E. 6. Percentage of Efficiency (A.M.A. / I.M.A.) x 100 Simple Machines © 2006 ScienceScene Page 37 Simple Machines Workshop Objectives 1. Given the following list of terms, identify each term's correct definition. Conversely, given the definition, identify the correct term. Actual Effort, Actual Mechanical Advantage, effort, fulcrum, Ideal Effort, Ideal Mechanical Advantage, inclined plane, lever, Percent efficiency, pulley, resistance, screw, wedge, wheel and axle 2. Identify and give examples of the six types of simple machines. 3. Identify and give examples of the three types of levers. 4. Given appropriate data determine Ideal Mechanical Advantage (IMA) of a simple machine. IMA = Distance effort moved (DE) / Distance resistance moved (DR ) 5. Given appropriate data determine Ideal Effort (IE) of a simple machine. IE = Resistance (R) / IMA 6. Given appropriate data or equipment determine Actual Effort (E) of a simple machine. 7. Given appropriate data or equipment determine Work Output (W O) of a simple machine. WO = Resistance (R) x Distance the resistance moved (DR ) 8. Given appropriate data or equipment determine Work Input (W I) of a simple machine. WI = Effort (E) x Distance the effort moved (DE) 9. Given appropriate data determine Actual Mechanical Advantage (AMA) of a simple machine. AMA = Resistance (R) / Effort (E) 10. Given appropriate data determine its percent of efficiency (%E) of a simple machine. %E = (Work output / Work input) x 100 INTRODUCTION Trucks, railroads, and ships are machines used to haul goods to and from markets. Without machines, the residents of our cities would find it more difficult to live, and farmers could not raise enough food to feed us. According to many experts without machines we would still be an agrarian society. Almost every activity of our daily life depends in some way on machines. We have constructed a wide variety of machines to satisfy our needs. Early people made stone axes that served as weapons and tools. The machines that we gradually developed gave us great control over our environment (physical surroundings). To operate our improved machines, we harnessed the energy of falling water and of such fuels as coal, oil, and the atom. Today, since we use so many machines the age we live in is often called the machine age. Principles of Machines A machine produces force and controls the direction and the motion of force. But it cannot create energy. A machine can never do more work than the energy put into it. In other words a machine can change the relationship between force and distance (work = F x d) but the total amount of work done is constant. It only transforms one form of energy such as electrical energy, to another form of energy, such as mechanical energy. The ability of a machine to do work is measured by two factors. These factors are known as efficiency and mechanical advantage. Simple Machines © 2006 ScienceScene Page 38 The efficiency of a machine is the ratio between the energy (work) it supplies and the energy (work) put into it. Machines that transmit only mechanical energy may have an efficiency of nearly 100 percent. But some machines have an efficiency as low as 5 percent. No machine can operate with 100 percent efficiency, because the friction of its parts always uses up some of the energy that is supplied to the machine. All machines produce some friction. For this reason, a perpetual-motion machine is impossible. %E = (Work output / work input) x 100 Ideal Mechanical Advantage (IMA) can be demonstrated with a crowbar, which is a type of lever. When one end of the crowbar is directly under the resistance a part of the crowbar must rest on a fulcrum (support). The closer the fulcrum is to the resistance, the less effort there is required to raise the resistance by pushing down on the handle of the crowbar; and the greater the mechanical advantage of the crowbar. For example, if the resistance is 200 kilograms, and the distance from the resistance to the fulcrum is one fourth of the distance from the handle to the fulcrum, the mechanical advantage will be four to one. Therefore, it will take 200/4 or it will take 50 kilograms of effort to raise the resistance. But the distance the resistance will be moved will be only one-fourth of the distance through which the effort is applied. IMA = Distance effort moved (DE) / Distance resistance moved (DR ) This sounds very good but we understand that machines are not one hundred percent efficient. This affects the mechanical advantage of our machine. This means that IMA may not be the best way to describe our machine. In fact the Actual Mechanical Advantage (AMA) that is the ratio of the force exerted by the machine (resistance) to the force applied to the machine (effort), may be the best way to describe our machine. AMA = Resistance (R) / Effort (E) Six Simple Machines Most machines consist of a number of elements, such as gears and ball bearings that work together in a complex way. But no matter how complex they are, all machines are based in some way on six types of simple machines: the pulley, the lever, the wheel and axle, the inclined plane, the wedge, and the screw. ef f ort resistance A pulley is a wheel over which a rope or belt is passed. It is a form of the wheel and axle. The mechanical advantage of a single pulley is one, because the downward effort exerted on the rope equals the resistance at the other end of the rope that passes over the pulley. The advantage of the single pulley is that it changes the direction of the force. For example, to lift a resistance, a person can more conveniently pull down on a rope thus using the entire ef f ort resistance weight of their body. When one pulley is attached to a support and second pulley is attached to the resistance a definite mechanical advantage is obtained. A lever consists of a rigid body, typically a metal bar, pivoted on a fixed fulcrum. There are three basic types of levers. Which type of lever we have depends upon the position of the Fulcrum (F), Resistance (R), and Effort (E). The three types of levers may seem a bit confusing at first but the word FRE (F-Fulcrum, R-Resistance, and E-Effort) can help us remember the types of levers. The order of the letters (FRE) refers to the class (1st, 2nd, and 3rd) of the levers. In a first class lever (represented by the F in FRE) the Fulcrum (F) is between the Resistance (R) and the Effort (E). A crowbar is an example of a first class lever. In a second class lever (represented by R in FRE) the Resistance (R) is between the Fulcrum (F) and the Effort (E). A wheel barrow is an example of a second class lever. In a third class lever (represented by the E in FRE) the Effort is between the Fulcrum (F) and the Resistance (R). An example of a third class lever occurs when a person lifts a ball in the palm of the hand. The Resistance (R) is at the hand, the Fulcrum (F) is at the elbow, and the forearm supplies the Effort (E) to lift the ball. Simple Machines © 2006 ScienceScene Page 39 First Class effort Second Class resi stance fulcrum F resi stance Third Class effort resi stance effort fulcrum fulcrum R E The wheel and axle is essentially a modified lever, but it can move a resistance further than a lever can. In a windlass, or winch, used to raise water from a well, the rope that carries the resistance is wrapped around the axle of the resistance wheel. The effort is applied to a crank handle on the side of ef f ort the wheel. The center of the axle serves as a fulcrum. The mechanical advantage depends upon the ratio between the radius of the axle and the distance traveled by the crank handle. The wheel and axle machine has important applications when it is used to transport heavy goods by rolling rather than by sliding. The wheel itself is regarded as one of the most important inventions of all time. It is widely used in all types of machinery and motor vehicles. The inclined plane allows the average person to raise a 200-pound box up 2 feet into the rear of a truck. By placing a 10-foot plank from the truck to the ground, a person ef f ort could raise the resistance easily. If there were no friction, the force required to move the box would be exactly 40 pounds. resistance The mechanical advantage of an inclined plane is the length of the incline divided by the vertical rise. The mechanical advantage increases as the slope of the incline decreases. But the resistance will then have to be moved a greater distance. The wedge is an adaptation of the inclined plane. It can be used to raise a heavy resistance over a short distance or to split a log. The wedge is driven by blows from a mallet or sledge hammer. The effectiveness of the wedge depends on the angle of the thin end. The smaller the angle, the less the force required to raise a given resistance. Simple Machines © 2006 ScienceScene ef f ort resistance Page 40 resistance The screw is actually an inclined plane cut in a spiral around a shaft. The mechanical advantage of a screw is approximately the ratio of the circumference of the screw to the distance the screw advances during each revolution. Wood or machine screws are common examples of the screw. ef f ort In the following laboratory we will investigate the pulley, lever, inclined plane, and the wheel and axle. We will not investigate the wedge and the screw because they are considered extensions of the inclined plane. Thus, through the study of the inclined plane, we will gain an understanding of the screw and wedge. In the laboratory we will collect the same type of data for each machine and use it to evaluate the machine. For each machine we will measure the: • resistance • effort needed to move the resistance • distance effort moved R E DE • distance the resistance moved DR From this data you will calculate: • Actual Mechanical Advantage • Ideal Mechanical Advantage AMA = = R/E DE / D R • Ideal Effort • Work Output IE WO = = R / IMA R x DR • Work Input WI = E x DE • Percent efficiency %E = (WO / WI) x 100 IMA Did you notice that you will measure only four variables; resistance, effort, effort distance and resistance distance for each of the simple machines? The resistance is the force exerted by the object being moved. The effort is the force that is exerted to move the object. The effort distance is the distance the force (effort) moved. The resistance distance is the distance that the object (resistance) actually moves. As you work on simple machines try to identify these four variables. These four variables represent the relationship between work input, to the machine, and work output. Work input = Work output (Feffort x Deffort) input = (Fresistance x Dresistance) output This relationship between input force and distance can vary as long as the equality is maintained by varying the output force and distance. (F D) x input = (F D ) x output or (F D) x Simple Machines © 2006 ScienceScene input = (F D ) x output Page 41 WORKSHOP Materials: Simple Machine Device, Mass For Resistance(0.320-N), Pulleys, Newton Scale, String, Lever, Wheel And Axle Device, 1 Meter Stick, Inclined Plane LEVERS Part A - Problem: How does a Lever act as a simple machine? Section 1: First Class Lever Notes on levers: • The lever is attached to the side of the simple machine device. • The single pulley/paper clip only changes direction and provides no mechanical advantage. • Connect the string as indicated in the drawing. • Add masses until the lever is level. 1. Set up the simple machine device as indicated in A1. 2. To investigate the effort or work done (work input) and the resistance or work done (work output) we will need to obtain distance and force data. a. Distance Data 1) Attach the effort at the distances listed in the data tablet as measured from the fulcrum. 2) Place the “refrigerator” at the distance listed in the data table as measured from the fulcrum. This is the resistance placement. 3) Lift the effort/lever the distance indicated in the data table. This is the effort distance (DE). Resistance Distance Effort 4) Carefully measure the distance that the “refrigerator” moves. This is the resistance distance (DR). b. Force Data 1) Hook the “refrigerator” directly on the Newton scale and measure its force. This force (weight) is referred to as the resistance (R). Record the resistance on the data sheet. 2) Measure the force (E) exerted by the mass by adding masses until the lever is level. This would indicate the effort needed to lift the resistance. Each mass represents a force of .08-n. Simple Machines © 2006 ScienceScene Effort Distance Resistance Distance Figure A-1 Page 42 3. Calculate the work input (WI = E x DE) and the work output (WO = R x DR ). 4. Calculate the: Ideal Effort Ideal Mechanical Advantage Actual Mechanical Advantage Percent efficiency Average percent efficiency for first class levers. IE IMA AMA %E = = = = R / IMA DE / D R R/E (WO/WI) x 100 Av. %E Note: Remember the IE should be approximately equal to the E. Effort Section 2: Second Class Lever Add mass until Resistance begins to move. Each mass is .08-n Effort Distance 1. Set up the simple machine device as indicated in figure A2. 2. Using the procedures indicated in section 1 obtain D E, DR, R, and E. 3. Calculate the work input (WI = E x DE) and the work output (WO = R x DR ). 4. Calculate IMA, IE, AMA, %E and the Average percent efficiency for second-class levers. Resistance Distance Figure A2 Section 3: Third Class Lever 1. Set up the simple machine device as indicated in figure A3. 2. Using the procedures indicated in section 1 obtain DE, DR, R, and E. 3. Calculate the work input (W I= E x DE) and the work output (WO= R x DR ). Effort 4. Calculate IMA, IE, AMA, %E and the Average percent efficiency for third-class levers. 5. Determine the average percent efficiency for all levers (Av. %E) 6. Describe the relationship of force and distance for work input and work output. E x DE = R x DR Add mass until Resistance begins to move. Each mass is .08-n Effort Distance 7. Explain why WO and WI are not the same for levers. 8. How one could obtain an efficiency of greater than 100%. 9. How does the mechanical advantage compare to the change in effort? 10. Could the placement distances of the effort and the resistance be used to estimate the work input and work output? Resistance Distance Figure A3 Simple Machines © 2006 ScienceScene Page 43 Part A - Lever Section 1: 1st Class Levers 1. Distance (meters) a. Resistance Placement b. Resistance Distance Trial 2 Trial 3 Trial 4 0.090 0.060 0.03 0.090 0.090 0.12 0.12 0.120 0.090 0.12 0.12 0.120 0.32-n 0.32-n 0.32-n 0.32-n DR c. Effort Placement d. Effort Distance DE 2. Force (Newton’s) a. Resistance R b. Effort E 3. Work Input (joules) WI = E x D E 4. Work Output (joules) 5. % EFFICIENCY Trial 1 W O = R x DR %E = (WO/ WI ) x 100 6. Ideal Mechanical Advantage IMA = DE / DR 7. Ideal Effort (Newton) IE = R / IMA 8. Actual Mechanical Advantage AMA = R /E Average % Efficiency of First Class Levers = Simple Machines © 2006 ScienceScene Page 44 Section 2: 2nd Class Levers 1. Distance (meters) a. Resistance Placement b. Resistance Distance Trial 2 Trial 3 Trial 4 0.0300 0.0400 0.0600 0.0700 0.1200 0.0800 0.0800 0.1400 0.1200 0.0800 0.0800 0.1400 0.32-n 0.32-n 0.32-n 0.32-n DR c. Effort Placement d. Effort Distance DE 2. Force (Newton’s) a. Resistance R b. Effort E 3. Work Input (joules) WI = E x DE 4. Work Output (joules) 5. % EFFICIENCY Trial 1 W O = R x DR %E = (WO/ WI ) x 100 6. Ideal Mechanical Advantage IMA = DE / DR 7. Ideal Effort (Newton) IE = R / IMA 8. Actual Mechanical Advantage AMA = R /E Average % Efficiency of Second Class Levers = Simple Machines © 2006 ScienceScene Page 45 Section 3: 3rd Class Levers 1. Distance (meters) a. Resistance Placement b. Resistance Distance 2. Force (Newton’s) a. Resistance b. Effort 3. Work Input (joules) 4. Work Output (joules) 5. % EFFICIENCY Trial 2 Trial 3 Trial 4 0.1000 0.1200 0.0600 0.0900 0.0500 0.0600 0.0300 0.0600 0.0500 0.0600 0.0300 0.0600 0.32-n 0.32-n 0.32-n 0.32-n DR c. Effort Placement d. Effort Distance Trial 1 DE R E W I = E x DE W O = R x DR %E = (WO/ WI ) x 100 6. Ideal Mechanical Advantage IMA = DE / DR 7. Ideal Effort (Newton) IE = R / IMA 8. Actual Mechanical Advantage AMA = R /E Average % Efficiency of Third Class Levers = Average % Efficiency for All Levers = 1. (6) Describe the relationship of force and distance for work input and work output. E x DE = R x DR 2. (7) Why are WO and WI are not the same for levers. 3. (8) How one could obtain an efficiency of greater than 100%. 4. (9) How does the mechanical advantage compare to the change in effort? 5. (10) Could the placement distances of the effort and the resistance be used to estimate the work input and work output? Simple Machines © 2006 ScienceScene Page 46 PULLEYS Part B - Problem: How does a Pulley act as a simple machine? Section 1 - One Pulley plus a directional pulley Notes on pulleys: • The Simple Machine Device has a linear measuring scale one side. Turn that side, of the Simple Machine Device, toward you and set-up the resistance to be close to that scale so you can measure the resistance distance. • You may have to shorten the string by placing a small loop in the string and attaching the loop to the effort. • Refrigerator = 0.32-n or 4- w (washers) Washer = 0.080-n or 1-w Small washer = 0.016-n or 0.2-w Add mass until Resistance begins to move. Each mass is .08-n Effort Effort Distance 1. To investigate the effort or work done (work input) and Resistance Distance the resistance or work done (work output) we will need to obtain distance and force data. a. Force Data Resistance 1) Setup Pulley system. (without resistance) 2) Add enough force (washers) to balance pulleys (zero the system) 3) Hook the resistance (refrigerator) directly on the Newton scale and measure its force. This force (weight) is referred to as the resistance (R). The Figure B1 resistance is on the data sheet. (0.32-n) 4) Hook the resistance (refrigerator) on the pulley system. 5) Add enough force (washers) to balance the pulley system. Then add enough small washers to cause the effort to drop (move). Then remove one small washer. The system should be stable. This added force, step 5, is the actual force needed to move the resistance. Record this force as the effort (E). b. Distance Data 1) Resistance Distance (set up) By placing the resistance near the support side of the Simple Machine Device, which has a metric measuring scale, any movement of the resistance can be measured. 2) Effort Distance (set up) a) Place measuring device behind pulleys (or use scale on the side of the Simple Machine Device). b) Adjust resistance to lineup with a “zero” point on the scale. (lift up or down on resistance) c ) Hold the effort string, with your fingers, at a point that is lined up with a number on the scale. d) Move that point (your fingers) the indicated effort distance provided on the data table. e) Observe and record the movement of the resistance (refrigerator). 3) Measure the distance (DR) the resistance moves and record this distance as the resistance distance. 2. Calculate the work input (WI = E x DE) and the work output (WO = R x DR ). 3. Calculate the: Ideal Effort Ideal Mechanical Advantage Actual Mechanical Advantage Percent efficiency Average percent efficiency for one pulley systems. IE IMA AMA %E = = = = R / IMA DE / D R R/E (WO/WI) x 100 Av. %E Note: Remember the IE should be approximately equal to the E. If they are not you should review your measurements. Simple Machines © 2006 ScienceScene Page 47 Section 2 - Two Pulleys plus a directional pulley 1. Set up the simple machine device as indicated in figure B2. 2. Using the procedures indicated in section 1 step 1 obtain DE, DR, R, and E. .Remember to “zero the system’ as indicated B1-a ,(1), (2) 3. Calculate the work input (W I = E x DE) and the work output (WO = R x DR ). Add mass until Resistance begins to move. Each mass is .08-n 4. Calculate IMA, IE, AMA, %E and the Average percent efficiency for two pulley systems. Effort Effort Distance Resistance Distance Resistance Effort Effort Distance Figure B2 Resistance Distance Resistance Add mass until Resistance begins to move. Each mass is .08-n Section 3 - Three Pulleys plus a directional pulley 1. Set up the simple machine device as indicated in figure B3. 2. Using the procedures indicated in section 1 step 1 obtain DE, DR, R, and E. .Remember to “zero the system’ as indicated B1-a ,(1), (2) 3. Calculate the work input (WI = E x DE) and the work output (WO = R x DR ). 4. Calculate IMA, IE, AMA, %E and the Average percent efficiency for three pulley systems. Figure B3 Section 4 - Four Pulleys plus a directional pulley 1. Set up the simple machine device as indicated in figure B4. 2. Using the procedures indicated in section 1 step 1 obtain DE, DR, R, and E. .Remember to “zero the system’ as indicated B1-a ,(1), (2) 3. Calculate the work input (W I = E x DE) and the work output (WO = R x DR ). 4. Calculate IMA, IE, AMA, %E and the Average percent efficiency for four pulley systems. 5. Determine the average percent efficiency for all pulleys. (Av. %E) 6. Calculate and describe the relationship of force and distance for work input and work output. E x DE = R x DR Effort Effort Distance Resistance Distance Resistance Add mass until Resistance begins to move. Each mass is .08-n 7. Explain why WO and WI are not the same for levers. 8. How one could obtain an efficiency of greater than 100%. 9. How does the mechanical advantage compare to the change in effort? Simple Machines © 2006 ScienceScene Figure B4 Page 48 Part B - Pulley Section 1 One Pulley Section 2 Two Pulleys Section 3 Three Pulleys Section 4 Four Pulleys DE 0.2000 0.2000 0.1500 0.2000 2. Force (Newton’s) a. Resistance R 0.320-n 4.0-w 0.320-n 4.0-w 0.320-n 4.0-w 0.320-n 4.0-w b. Effort E 1. Distance (meters) a. Resistance Distance b. Effort Distance 3. Work Input (joules) 4. Work Output (joules) 5. % EFFICIENCY DR W I = E x DE W O = R x DR %E = (WO/ WI ) x 100 6. Ideal Mechanical Advantage IMA = DE / DR 7. Ideal Effort (Newton) IE = R / IMA 8. Actual Mechanical Advantage AMA = R /E Average % Efficiency for All Pulleys = 1. (6) Describe the relationship of force and distance for work input and work output. E x DE = R x DR 2. (7) Explain why WO and WI are not the same for levers. 3. (8) How one could obtain an efficiency of greater than 100%. 4. (9) How does the mechanical advantage compare to the change in effort? Simple Machines © 2006 ScienceScene Page 49 INCLINED PLANE Part C - Problem: How does an Inclined Plane act as a simple machine? Notes on inclined planes: • To change the length (DE) of the inclined plane, stops are placed on the back of the inclined plane. The length of the inclined plane is measured from the end of the inclined plane to the stop, which is resting on the support rod. Add mass until Resistance • A support rod must be inserted in the position begins to move. Each mass indicated so that the inclined plane can rest on is .08-n the rod. • To properly read the force (effort) on the Newton scale, make sure you pull the mass up the inclined plane at a constant speed. 1. Obtain the simple machine device and set it up as indicated in the figure. 2. To investigate the effort or work done (work input) and the resistance or work done (work output) we will need to obtain distance and force data. a. Distance Data Effort 1) Select the support rod position from the Resistance Distance Distance table in your data sheet. This will determine the resistance distance (DR). The resistance distance (DR) is measured from the tabletop to the top of Resistance the inclined plane at the point it crosses the support rod. Note: the resistance Figure C distance is the actual distance that you wish to move an object (the resistance). 2) The inclined plane has notches on the back to hook over the rod. Select the notch indicated in the data table labeled as effort placement. With the inclined plane in position carefully measure the effort distance. The effort distance (DE) is measured from the end of the inclined plane to the support rod position on the inclined plane. b. Force Data 1) Hook the “refrigerator” directly on the Newton scale and measure its force. This force (weight) is referred to as the resistance (R). Record the resistance on the data sheet. 2) For each trial listed in the data table place the “refrigerator”(mass) at the bottom of the inclined plane and attach the masses until the resistance begins to move. This would be the force, effort, needed to move the resistance up the incline. Record the effort (E). 3. Calculate the work input (W I = E x DE) and the work output (WO = R x DR ). 4. Calculate IMA, IE, AMA, %E and the Average percent efficiency for inclined planes. 5. Determine the average percent efficiency for all levers (Av. %E) 6. Describe the relationship of force and distance for work input and work output. E x DE = R x DR 7. Explain why WO and WI are not the same for inclined planes. 8. How one could obtain an efficiency of greater than 100%. 9. How does the mechanical advantage compare to the change in effort? Simple Machines © 2006 ScienceScene Page 50 Part C - Inclined Plane Support Rod Placement 1. Distance (meters) a. Resistance Distance b. Effort Distance 2. Force (Newton’s) a. Resistance b. Effort DR DE R Trial 1 Trial 2 Trial 3 3 3 3 0.195 0.195 0.195 0.240 0.340 0.440 0.32-n 0.32-n 0.32-n E 3. Work Input (joules) 4. Work Output (joules) 5. % EFFICIENCY W I = E x DE W O = R x DR %E = (WO/ WI ) x 100 6. Ideal Mechanical Advantage IMA = DE / DR 7. Ideal Effort (Newton) IE = R / IMA 8. Actual Mechanical Advantage AMA = R /E Average % Efficiency for Inclined Planes = 1. (6) Describe the relationship of force and distance for work input and work output. E x DE = R x DR 2. (7) Explain why WO and WI are not the same for inclined planes. 3. (8) How one could obtain an efficiency of greater than 100%. 4. (9) How does the mechanical advantage compare to the change in effort? Simple Machines © 2006 ScienceScene Page 51 WHEEL AND AXLE Part D - Problem: How does a Wheel and Axle act as a simple machine? Notes on wheels and axles: • Insert the wheel and axle device into the marked leg of the Simple Add mass until Resistance Machine Device. begins to move. Each mass is .08-n • Make sure that the handle is pointing toward you so that it can be used as a handle. • Adjust the effort distance by sliding the wheel handle the specified distance. Effort Resistance Distance • Make sure that the scale is adjusted Distance so that it is positioned above the wheel. • When reading your scale "bounce" Effort or carefully lift and release the Resistance mass (resistance) approximately 2 or 3 cm. to make sure that you get the most accurate readings. 1. Set up the simple machine device as indicated. 2. To investigate the effort or work done (work input) and the resistance or work done (work output) we will need to obtain distance and force data. a. Distance Data 1) Adjust the wheel to the distance listed in the data tablet and attach the Newton scale. This is the effort placement. 2) Place the “refrigerator” on the axle at the distance listed in the data table as measured from the center of the axle to outside. This is the resistance placement. 3) Lift the Newton scale/wheel the distance indicated in the data table. This is the effort distance (D E). 4) Carefully measure the distance that the “refrigerator” moves. This is the resistance distance (D R). b. Force Data 1) Hook the “refrigerator” directly on the Newton scale and measure its force. This force (weight) is referred to as the resistance (R). Record the resistance on the data sheet. 2) Measure the force (E) exerted by the mass. With the resistance attached level it and attach the masses until the wheel remains level. The total mass is the force (E) needed to support the resistance. Record the effort E. 3. Calculate the work input (W I = E x DE) and the work output (WO = R x DR ). 4. Calculate the: Ideal Effort Ideal Mechanical Advantage Percent efficiency IE IMA AMA %E Average percent efficiency for Wheel and Axles. Av. %E Actual Mechanical Advantage = = = = R / IMA DE / D R R/E (WO/WI) x 100 Note: Remember the IE should be approximately equal to the E. If they are not you should review your measurements. 5. Determine the average percent efficiency for all levers (Av. %E) 6. Describe the relationship of force and distance for work input and work output. E x DE = R x DR 7. Explain why WO and WI are not the same for inclined wheel and axles. 8. How one could obtain an efficiency of greater than 100%. 9. How does the mechanical advantage compare to the change in effort? 10 Compare the efficiencies of all the machines studied. Which one would you use to move your refrigerator? Simple Machines © 2006 ScienceScene Page 52 Part D - Wheel and Axle Trial 1 Trial 2 Trial 3 Trial 4 0.015 0.015 0.015 0.015 c. Effort Placement (Wheel) 0.015 0.033 0.045 0.065 d. Effort Distance 0.015 0.033 0.045 0.065 0.32-n 0.32-n 0.32-n 0.32-n 1. Distance (meters) a. Resistance Placement (Axle) b. Resistance Distance 2. Force (Newton’s) a. Resistance b. Effort 3. Work Input (joules) 4. Work Output (joules) 5. % EFFICIENCY DR DE R E W I = E x DE W O = R x DR %E = (WO/ WI ) x 100 6. Ideal Mechanical Advantage IMA = DE / DR 7. Ideal Effort (Newton) IE = R / IMA 8. Actual Mechanical Advantage AMA = R /E Average % Efficiency for Wheel and Axle = 1. (6) Describe the relationship of force and distance for work input and work output. E x DE = R x DR 2. (7) Explain why WO and WI are not the same for inclined wheel and axles. 3. (8) How one could obtain an efficiency of greater than 100%.? 4. (9) How does the mechanical advantage compare to the change in effort? 5. (10) Compare the efficiencies of all the machines studied. 6. Which simple machine would you use to move your refrigerator? Simple Machines © 2006 ScienceScene Page 53 Car Power Power is the rate of doing work. Power is commonly measured in watts and horsepower. Power = work / time or p=w/t Where: p = the rate of doing work. Power is measured in watts or horsepower. A watt is 1 joule / sec. and 746 watts are approximately equal to 1 horsepower. a unit of power equal to w = the work done and is equal to force (in Newtons) multiplied by distance moved. The result is a unit of measurement labeled meters-meters. 1 meter-meter is a unit called a joule. t = time taken to do the work done to occur (measured in seconds). 1. Determine the horsepower of a small battery powered car as it lifts a load (force) through a timed distance. Set-up the equipment on the table top as indicated in the above figure. If the wheels spin you will need to wash them with soapy water and possibly even the tabletop to get the best traction. To calculate Horsepower you will need to determine force, work, and power. power(watts) horsepower = 746 watts power (watts) = work (joules) / time (seconds) work (joules) = f (Newtons) x d (meters) 2. To determine force, obtain the mass (in Kilograms) of the object to be lifted by the battery-powered car. Convert the mass to nektons by multiplying by 9.8 m/sec2. (You may wish to try other masses, but you will need a mass that the car can pull.) Force (Newtons) = mass in Kg x 9.8 m/sec2 3. To determine work identify and measure, on the track, the distance, in meters (approximately 0.50-m), that your car pulls the load and multiply it times the force of the load being lifted. work (in joules) w=fxd 4. To determine power obtain the work and then divide it by the average time needed to lift the load. power (watts) p=w/t 5. To determine the horsepower divide the power, in watts, by the number of watts in a horsepower (746). 1 Hp horsepower = power( watts) x 746 watts Force F=mxg Trial m. (Kg.) g (m/s2) 1 9.8 2 9.8 3 9.8 Average 9.8 Work W=fxd F Newtons d (meters) W (joules) Power Power - work / time t (seconds) Simple Machines © 2006 ScienceScene P (watts) Horsepower Hp= watts/746 Hp Page 54 How can you determine your horsepower? 1. Determine your horsepower by timing yourself walking up a flight of stairs. horsepower = power (watts) = power(watts) 746 watts work (joules) / time (seconds) work (joules) = f (Newtons) x d (meters) 2. Distance is determined by measuring the height of one stair (in meters) as shown in the illustration and counting the number of stairs, you climbed, then multiply the height of one stair by the number of stairs. distance = stair height x number of stairs 3. To determine the force that moved up the stairs take your weight, in pounds, which reflects the pull of gravity, and convert this pull (force) to Newtons. Since one pound is approximately 4.5 Newtons, multiply your weight by 4.5 Newtons/pound to calculate the force in Newtons. force = your weight x 4.5 Newtons/pound 5. The energy used in climbing the stairs can be determined by measuring the amount of work done. (Work = Force X Distance). Note: the force is in Newtons and the distance in meters producing an answer with a label of Newtonmeters. Another name for a Newton-meter is called a joule. Express your work done in joules. Work = Force x Distance 6. Determine the power that was exerted as you walked up the flight of stairs. Power = work / time Note: the answer will have a label of joules / second. This is the definition of a unit of power called the watt. Express your power in watts. 7. Finally, let's see how we compare to our friend the horse by determining our horsepower. 1 Hp Horsepower = power( watts) x 746 watts Force Trial F (Newton) Work W=fxd d (meters) w (joules) Power Power - work / time t (seconds) p (watts) Horsepower Hp = watts / 746 Hp 1 2 3 Average Simple Machines © 2006 ScienceScene Page 55 Wake-Me-Up Machine 1. Study the drawing of the Wake-me-up machine. 2. IDENTIFY the simple machines in the picture. 3. DETERMINE how the simple machines work together. Simple Machines © 2006 ScienceScene Page 56 Wake-Me-Up Machine IDEA: Simple machines can be combined to do work PROCESS SKILLS: Identify Determine LEVEL: Teacher Notes DURATION: 10 Min. STUDENT BACKGROUND: Students should be familiar with the types of simple machines. ADVANCE PREPARATION: None. MANAGEMENT TIPS: Class discussion will play a major role in this activity. RESPONSES TO SOME QUESTIONS: 2. Three pulleys, an inclined plane and a wedge. 3. When the alarm goes off, you hit the off* switch. The motion pulls a rope that is part of the three pulleys. The rope pulls on a board and tilts it.. The board is now an inclined plane. A ball rolls off the inclined plane and falls on a dog. The dog becomes frightened and runs. It's leash pulls on a peg that is holding back the string of a bow and arrow. The wedge-shaped arrow shoots and burst a balloon full of water. The water falls over your bed. Simple Machines © 2006 ScienceScene Page 57 Physical Science Materials Vendor List Oriental Trading Company, Inc. P.O. Box 3407 Omaha, NE 68103 1-800-228-2269 Laser glasses Operation Physics Supplier Arbor Scientific P.O. Box 2750 Ann Arbor, Michigan 48106-2750 1-800-367-6695 Astronomy Learning Technologies, Inc. Project STAR 59 Walden Street Cambridge, MA 02140 1-800-537-8703 The best diffraction grating I've found Chemistry Flinn Scientific Inc. P.O. Box 219 Batavia, IL 60510 1-708-879-6900 Discount Science Supply (Compass) 28475 Greenfield Road Southfield, Michigan 48076 Phone: 1-800-938-4459 Fax: 1-888-258-0220 Educational Toys Electronic Kits Chaney Electronics, Inc. P.O. Box 4116 Scottsdale, AZ 85261 1-800-227-7312 Electronic Kits Mouser Electronics 958 N. Main Mansfield, TX 76063-487 1-800-346-6873 All Electronics Corp. 905 S. Vermont Av. Los Angeles, CA 90006 1-800-826-5432 Radio Shack See Local Stores Lasers Metrologic Coles Road at Route 42 Blackwood, NJ 08012 1-609-228-6673 laser pointers KIPP Brothers, Inc. 240-242 So. Meridian St. P.O. Box 157 Indianapolis, Indiana 46206 1-800-832-5477 Rainbow Symphony, Inc. 6860 Canby Ave. #120 Reseda, California 91335 1-818-708-8400 Holographic stuff Rhode Island Novelty 19 Industrial Lane Johnston, RI 02919 1-800-528-5599 U.S. Toy Company, Inc. 1227 East 119th Grandview, MO 64030 1-800-255-6124 Magnets The Magnet Source, Inc. 607 South Gilbert Castle Rock, CO. 80104 1-888-293-9190 Dowling Magnets P.O. Box 1829/21600 Eighth Street Sonoma CA 95476 1-800-624-6381 Science Stuff - General Edmund Scientific 101 E. Gloucester Pike Barrington, NJ 08007-1380 1-609-573-6270 Materials for making telescopes Marlin P. Jones & Associates, Inc P.O. Box 12685 Lake Park, Fl 33403-0685 1-800-652-6733 Natural Wonders Nature Store Flea Markets Garage Sales Simple Machines © 2006 ScienceScene Page 58