Mechanical Advantage

advertisement

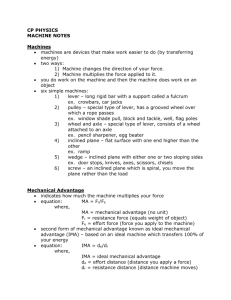

Mechanical Advantage What do simple machines do for us anyway? There are four ways that a machine helps us to do work. Transfers our effort force from one place to another. Ex: seesaw Multiply your effort force. Ex: crowbar Magnify speed and distance. Ex: baseball bat Changing the direction of the force. Ex: pulley on the flagpole There are 2 types of mechanical advantage. IMA – Ideal mechanical advantage. This is the number of times a machine is designed to multiply your effort force. It is based on measurements of the machine. Ignores friction AMA – Actual mechanical advantage This is the number of times the machine actually multiplies your effort force. AMA = resistance force/effort force. Includes the effects of friction IMA is always larger than AMA. Mechanical Advantage Definition - a quantity that measures how much a machine multiplies force or distance Two types Actual: measures the actual forces action on a machine - AMA = output force input force Ideal: measures the mechanical advantage in the absence of friction - IMA = input distance output distance Mechanical Advantage Problems Q: Alex pulls on the handle of a claw hammer with a force of 15 N. If the hammer has a actual mechanical advantage of 5.2, how much force is exerted on a nail in the claw? A: output force = (5.2)(15N) = 78 N Q: If you exert 100 N on a jack to lift a 10,000 N car, what would be the jack’s actual mechanical advantage (AMA) A: AMA= 10,000 N / 100 N = 100 Mechanical Advantage Problems Q: Calculate the ideal mechanical advantage (IMA) of a ramp that is 6.0 m long and 1.5 m high? A: IMA = 6.0m / 1.5m = 4.0 Q: The IMA of a simple machine is 2.5. If the output distance of the machine is 1.0 m, what is the input distance? A: Input distance = (2.5)(1.0m) = 2.5 m Efficiency of Machines Definition - a quantity, usually expressed as a percentage, that measures the ratio of useful work input Formula - Efficiency = useful work output work input - % of work input that becomes work output - due to friction, efficiency of any machine is always less than 100% Efficiency Problems Q: Alice and Jim calculate that they must do 1800 J of work to push a piano up a ramp. However, because they must also overcome friction, they must actually do 2400 J of work. What is the efficiency of the ramp? A: 1800 J/ 2400 J x 100 = 75% Q: If the machine has an efficiency of 40%, and you do 1000 J of work on the machine, what will be the work output of the machine? A: Work Output = (Efficiency x work input) / 100% Work Output = (40% x 1000 J) / 100% = 4.0 x 102 J Simple Machines Definition - one of the six basic types of machines 2 types or families 1. lever 2. inclined planes Levers - Definition - a rigid bar that is free to move around a fixed point ex. screwdriver all levers have a rigid arm that turns around a point called the fulcrum force is transferred from one part of the arm to another original input force can be multiplied or redirected into output force levers are divided into 3 classes, based on the locations of the input force, output force, and the fulcrum There are 3 Classes of Levers Depends on the location of 3 items: 1. Fulcrum – fixed point on a lever 2. Effort Arm – the part of the lever that exerts the effort force. 3. Resistance Arm – the part of the lever that exerts the resistance force. EA RA 1st Class Lever Changes the direction of the force Multiplies effort force Magnifies speed and distance Ex: seesaw, crowbar, scissors 2nd Class Lever Multiply effort force Mechanical advantage is always greater than 1. Ex: bottle opener, boat oars, wheel barrow 3rd Class Lever Magnifies speed and distance Mechanical Advantage always less than 1 Ex: baseball bat, golf club, broom, shovel Wheel and Axis - - Definition - simple machine that consists of two disks or cylinders, each one with a different radius ex. steering wheel, screwdriver made of a level or a pulley (wheel) connected to a shaft (axle) small input force, multiplied to become a large output force Inclined Planes - Definition - slanted surface along which a force moves an object to a different elevation ex. knife, ax, zipper, wedge, screw ramp redirects the force applied to lift object upward turns a small input force into a large output force by spreading the work out over a large distance - wedge: functions as two inclined planes back to back, turning a downward force into two forces directed out to the sides -screw: an inclined plane wrapped around a cylinder Pulleys Definition - a simple machine that consists of a rope that fits into a groove in a wheel. - very similar to a lever - point in the middle of the pulley is like a fulcrum rest of the pulley acts like the rigid arm 3 Types of Pulleys - fixed pulleys - moveable pulleys - pulley system Fixed And Movable Pulley System 1. What is the IMA of this pulley system? 2. Ignoring friction, if you want to lift the resistance 3 meters what will the effort distance be? 3. Ignoring friction how much effort force will be necessary to lift a load of 15 newtons? 4. How much work is done? Compound Machines Definition - a machine that is made of more than one simple machine ex. scissors, jacks, bicycle, washing machine, car, clock