prevention of spontaneous fires by directed nitrogen supply

advertisement

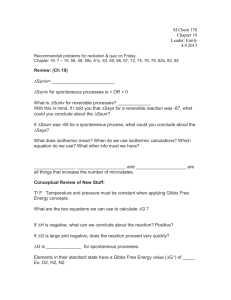

Published : PROCEEDINGS OF THE 7TH INTERNATIONAL MINE VENTILATION CONGRESS, June 17-22, Crakow, Poland PREVENTION OF SPONTANEOUS FIRES BY DIRECTED NITROGEN SUPPLY A.S. Chumak RESPIRATOR Research-andManufacturing Association on Mine Rescue Work Donetsk, Ukraine P.S. Pashkovsky, M.A. Yaremchuk RESPIRATOR Research-andManufacturing Association on Mine Rescue Work Donetsk, Ukraine ABSTRACT The most widespread means of localization and fighting the spontaneous fires are inert gases, water-air and inert foams. In spite of this tactics of their use is developed insufficiently in the mines of Ukraine. In the first place it concerns the directed inertization of the goaf. Analysis of cases shows that following mining-and-geological and mining factors influence on the endogenic fire hazard most strongly. Air losses into the goaf exert the decisive influence on development of the process of spontaneous ignition of coal. The zone of caved rocks is constantly ventilated at their expense. It creates places of spontaneous combustion of coal. The performed investigations of air losses through the goaf of the panels allowed to construct graphs of the dependence of air losses along the whole length of the zone of active ventilation of the goaf for the most typical ventilation schemes. Determination of bounds of the zone of fire-hazardous air losses, points of appearance of spontaneous heating places permits purposeful nitrogen supply only there where places of spontaneous heating are formed. The point of the matter of the method of prevention of the spontaneous fires consists in lowering the oxygen volume fraction up to 14% in the places of spontaneous heating being predicted, which excepts spontaneous ignition. KEYWORDS Prevention, spontaneous fire, fighting, endogenic fire hazard, liability of coal to spontaneous ignition, coal oxidation, air losses. The most widespread means for localization and fighting the spontaneous fires are inert gases, water-air and inert foams. Tactics of the use is developed insufficiently by their wide introduction in mines of Ukraine. In the first place it concerns the directed inertization of the goaf in the immediate proximity to a place of spontaneous coal heating. Analysis of cases of appearance of the spontaneous fires shows that following mining-and-geological and mining factors influence on the endogenic fire hazard most strongly, viz.: natural liability of coal to spontaneous ignition being determined by its chemical activity with respect to air oxygen (rate constant of oxygen sorption) and by reaction heat of coal oxidation; thickness and dip angle of a seam being mined; tectonic disturbances; strength properties of enclosing rocks, their consolidation, permeability; method of opening and preparation of the seam; mining method and its parameters (especially such as rate of face advance, seam thickness being mined, coal losses in the goaf); method and plan of ventilation, ventilating pressure drop of mine and area. Air losses into the goaf exert the decisive influence on development of the process of spontaneous ignition of coal. The zone of caved rocks being adjacent to the face is constantly ventilated at the expense of air losses. It promotes emergence of places of spontaneous combustion of coal. It was determined on the basis of results of investigations that nitrogen is the most suitable for inertization of mine atmosphere in the zone of firehazardous losses. In contrast to carbon dioxide it isn’t disposed to dividing into layers when moving in air. It is stipulated by nitrogen and air density values that are similar to each other. Over 30 years the mine rescuers use nitrogen and inert vapour-gas mixture for fighting the underground fires in mines. An attempt of realization of the technology of active fighting the fires with nitrogen and vapour-gas mixture was made in the “Your-Shor” mine of the “Vorkutaugol” coal society (Пашковский, 1984) for the first time. This mine is supercategorical in respect of methane content. Operative use of volume inertization prevented fire propagation, eliminated explosion hazard and allowed to cool burning places. straight-through ventilation directed to the pillar with sub-freshening (figure 1d). Experience of use of nitrogen for fighting the spontaneous fires in mines of the Donbas and other regions of the CIS is described in the works (Пашковский, et al., 1992; Каледин, et al., 1985). Periodic nitrogen feed into the fire-hazardous zones of the goaf allowed to mine the k8, l8' and m3 seams in Technology of inertization of atmosphere of accident areas and equipment for its realization are described in the normative documents developed by the NIIGD (Игишев, 1987; Руководство…, 1989). Analysing the cases of the use of nitrogen for fighting the spontaneous fires mentioned above one can conclude about high effectiveness of the method of inertization of fire-hazardous zones of the goaf and localization of places of spontaneous ignition of coal. But volume inertization of the fire districts was used more often. In spite of the fact that the cases of the use of nitrogen for directed feed to the burning places are adduced, the data concerning investigations of the process of directed nitrogen feed into the zones of firehazardous air losses are not cited for all this. Carryingout such investigations allows to raise effectiveness of the method of localization and fighting the spontaneous fires with nitrogen. Proceeding from above-stated the purposes of the present work are investigation of the processes of inertization of mine atmosphere and cooling the heated coal accumulations by directed feed of nitrogen into the zone of fire-hazardous air losses in the goaf. Conformably to the most widespread mining systems and development plans of panels one can pick out four ventilation schemes that are the most characteristic for mines of the Donbas: inverted ventilation directed to the goaf (figure 1a); inverted ventilation directed to the pillar (figure 1b); straight-through ventilation directed to the goaf with sub-freshening (figure 1c); Figure 1.The most widespread ventilation schemes of the panels mining flat seams. The performed investigations allowed to construct graphs of air losses along the whole length of the zone of active ventilation of the goaf for the most characteristic (typical) ventilation schemes (figures 2, 3). In this case a value of air losses by running length of 1 m of the zone of active ventilation of the haulage gate (belt road) as well of the air roadway makes up (depending on the ventilation scheme and consolidation quality of packs) from 0.1 up to 6 m3/min which is commensurable with capacity of the nitrogen gasification plants the units of the State Para-military Mine Rescue Service of Ukraine are supplied with. The constructed graphs (figures 2, 3) give a general idea of the character of air losses through the goaf (roof control with roof caving). But it is necessary to measure air volume entering the panel, longwall face and further along the whole longwall face at intervals of 10…15 m including the longwall face output in each concrete case before the feed of nitrogen for the purpose of prevention of the spontaneous fires. Air losses, m3/min Toshkovka, Bazhanow, 9th five-year plan and Chaykina mines successfully. The equipment developed by the Scientific-and-Research Institute of Mine Rescue Work (NIIGD) was used in all the cases. Analogous investigations and development of technology and equipment for inertization of mine atmosphere in workings and goafs are carried out in Russia by the Russian Scientific-and-Research Institute (RosNII), the Eastern Department of the NIIGD formerly (Судиловский, 1984; Голик, et al., 1986; Игишев, et al., 1982). Distance, m Figure 2. Air losses in the zone of active ventilation of the goaf depending on distance to the longwall face and accepted ventilation scheme: 1 – for inverted ventilation directed to the goaf; 2 – for inverted ventilation directed to the pillar. Air losses, m3/min Qi – rate of air flow passing along the longwall face at the i – measurement point, m3/sec; V1 – maximum value of the interval of fire-hazardous velocities of air losses through the goaf, m/sec (V1 = 0.0150 m/sec); V2 – minimum value of the interval of fire-hazardous velocities of air losses through the goaf, m/sec (V2 = 0.0017 m/sec); Distance, m S – cross-section area of the longwall face, m2; Figure 3. Air losses in the zone of active ventilation of the goaf depending on distance to the longwall face and accepted ventilation scheme: 1 – for straight-through ventilation directed to the pillar with sub-freshening (air roadway); 2 – for straight-through ventilation directed to the pillar with sub-freshening (haulage gate); 3 – for straightthrough ventilation directed to the goaf with subfreshening (air roadway); 4 – for straight-through ventilation directed to the goaf with sub-freshening (haulage gate). Boundaries of the zone of active spontaneous heating for the inverted ventilation scheme of the panel with directing an air stream returning from the longwall face to the rock mass which is widely practised in mines of the Donbas are determined from the mathematical dependences: Q n Qут V1 S A1 kl Q n Qут ; Q n Qут V 2 S , A2 kl Q n Qут (1) where A1 and A2 – distances from the face up to the neighbouring and distant boundaries of the zone of active spontaneous heating accordingly, m; k – index characterizing roof stability (k=0.5 for the unstable roof; k=0.7 for the average stable roof; k=1.0 for highly stable roof); l – distance from the face up to the caving zone of the rock mass where the process of caving the roof rock and its placing in the goaf brings to a stop (for conditions of the Donbas l=100…150 m); Qn – rate of air flow arriving into the longwall face, m3/sec; Qут max Qn Qi )i 1,2... - air loss into the goaf, m3/sec; d kmlQ n Q ут ( S hlk ) - dimensionless parameter Q ут S charakterizing intensity of reduction of air losses through the goaf depending on distance from the longwall face; А - width of the zone of active spontaneous heating, m А А2 А1 . Fire-hazardous zones and places of origin of the fires in the goaf of panels in mines of the Donbas (flat and inclined seams) are shown in figures 4, 5, 6 for four ventilation schemes named before and being the most characteristic. Determination of boundaries of the zone of firehazardous air losses, points of appearance of spontaneous heating places permits purposeful nitrogen feed only into that part of the goaf where places of spontaneous heating are formed. Figure 4. Fire-hazardous zones of the panel by inverted ventilation directed to the pillar (flat and inclined seams). Figure 5. Places of origin of the fires by straightthrough ventilation of the panel (flat and inclined seams): 1 – return air borders upon the goaf; 2 – return air borders upon the unworked coal. Figure 6. Places of origin of the spontaneous fires in the panel by inverted ventilation directed to the goaf (flat and inclined seams). As migration of nitrogen takes place in direction of air losses the point of the matter of the method of prevention of the spontaneous fires by its directed feed consists in lowering the volume fraction of oxygen up to 14% in the places of spontaneous heating being predicted. In this case the oxidation processes slow down so that heat accumulation and spontaneous combustion, therefore, are impossible. Intensity of nitrogen feed can be 40…50% from the value of air losses in the zone of the spontaneous heating place being forecasted in this case. REFERENCES Голик, А.С., Палеев, Д.Ю., Кунавина, Н.А., 1986, Математическое моделирование газодинамики выработанного пространства при запуске азота в метаноопасные зоны. Прокопьевск. Игишев, В.Г., Лагутин, В.И., Мальцев, Д.И. и др., 1982, "Борьба с эндогенными пожарами при отработке мощных крутых пластов," Безопасность труда в промышленности, № 3, с.10-12. Игишев, В.Г., 1987, Борьба с самовозгоранием угля в шахтах. Недра, Москва. Каледин, Н.В., Яремчук, М.А., Пашковский, П.С. и др., 1985, "Применение азота для локализации очага самонагревания угля," Деп. в ЦНИЭИуголь 26.06.85, № 3422. Пашковский, П.С., 1984, "Исследование процессов локализации эндогенных пожаров с применением азота," 1930309000, № Гр 01829010609, инв. № 02850012550, 1984, ВНИИГД, Донецк. Пашковский, П.С., Шецер, Г.М., Яремчук, М.А., Попов, Э.А., 1992, "Новые средства профилактики и тушения подземных пожаров с применением азота," Научно-технические достижения и передовой опыт в угольной промышленности: Информационный сборник, ЦНИЭИуголь, № 1-2, с.25-27, Москва. Руководство по применению жидкого и газообразного азота, 1989. Утв. Минуглепромом СССР 17.09.89. ВНИИГД, Донецк. Судиловский, М.Н., 1984, "Использование азота для борьбы с эндогенными пожарами," Безопасность труда в промышленности, № 9, с.52-55.