HIBBING COMMUNITY COLLEGE

advertisement

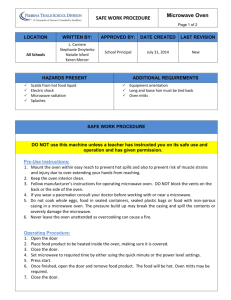

HIBBING COMMUNITY COLLEGE COURSE OUTLINE COURSE TITLE & NUMBER: RHAA1500: Cooking Systems Technology CREDITS: 4 (Lecture Hours 17 / Lab Hours 102 per Semester) PREREQUISITES: RHAA1400: Introduction to Electricity CATALOG DESCRIPTION: Cooking Systems Technology covers electric and gas ranges, cook tops, wall ovens, microwaves, and convection ovens. The theory and operating principles are studied. Advanced troubleshooting techniques of the electrical systems are studied and practiced. OUTLINE OF MAJOR CONTENT AREAS: I. Electric ranges A. Parts identification B. Parts location C. Parts function II. Troubleshooting electric ranges: wiring diagram interpretation III. Gas range 1. Parts identification 2. Parts location 3. Parts function IV. Troubleshooting electric ranges 1. Wiring diagram interpretation V. Microwave oven 1. Safety system 2. Low voltage system 3. High voltage system 4. Parts identification 5. Parts function 6. Parts location VI. Troubleshooting M/W: Wiring diagram Hibbing Community College, a technical & community college an equal opportunity educator & employer COURSE GOALS/OBJECTIVES/OUTCOMES: The student will 1. describe the causes of electrical problems associate with oven element failure. 2. list the three operating systems in a microwave. 3. identify the typical components in the operating system of a microwave. 4. identify the typical components in the protective system of a microwave. 5. identify the typical components in the high voltage system of a microwave. 6. describe the function of each component in the high voltage system of a microwave. 7. select the proper equipment for diagnostic work . 8. explain the operating principle associated with automatic re-ignition. 9. explain the difference between convection & conventional cooking. 10. describe the door locking safety mechanism for self cleaning ranges. 11. determine when to call a electrician. 12. discuss the operating characteristics of Halogen surface elements. 13. discuss the operating characteristics of Induction type surface elements. 14. identify safety hazards. 15. list causes of surface element failure. 16. discuss the operating conditions of the electronic clock. 17. explain the theory of microwave cooking. 18. construct a sequence of operation for the self clean cycle. 19. construct a sequence of operation for the preheat cycle. 20. construct a sequence of operation for the timed bake cycle. 21. associate the need for proper cookware as it relates to type of surface elements. 22. compare the differences between manual, continuous and self clean ovens. 23. discuss venting options for over the range type microwaves. 24. define and explain the use and function of hot wire relays. 25. define and explain the use and function of thermostats. 26. determine correct sequence of operation from ladder diagram. 27. draw electrical circuits that conform to industry logic and symbols using loads and controls. 28. describe the function and application of regulators. 29. describe how the glow coil and gas valve work together for proper operation. 30. explain the function of a triac. 31. construct a sequence of operation for the bake cycle. 32. demonstrate the proper use of computer for parts research. 33. perform proper test out procedure on high voltage transformer. 34. demonstrate shop safety continuously while in the lab. 35. perform power output test on microwave oven. 36. calibrate oven temperature that incorporates electronic oven control. 37. calibrate oven temperature. 38. perform oven temperature check. 39. generate a estimate of repair statement. 40. demonstrate the proper use of microfiche and reference material for parts research. Hibbing Community College, a technical & community college an equal opportunity educator & employer 41. 42. 43. 44. 45. 46. 47. 48. 49. 50. 51. 52. 53. 54. 55. 56. 57. 58. 59. 60. 61. 62. 63. 64. 65. 66. 67. 68. 69. 70. 71. perform proper test out procedure on high voltage capacitor. use computer to generate and complete all paperwork. perform simulated service calls. troubleshoot ignition modules. determine what would be required to convert from L.P. gas to natural gas. perform conversion from natural gas to L.P. gas. adjust outlet gas pressure. wire actual electrical circuits using wiring diagrams. measure gas pressure with a pressure gauge. measure gas pressure with a u-tube type manometer. use correct terminology when discussing function or part identification. perform installation of a over-the-range microwave. demonstrate the cycling characteristics of a burner switch using a voltmeter. using ladder diagram troubleshoot system failure. convert pictorial wiring diagram to a ladder type diagram. perform troubleshooting techniques on glow coil ignition system using a voltmeter. perform troubleshooting techniques on glow coil ignition system using a ampmeter. perform test out procedure of electronic oven sensor. perform proper test out procedure on magnetron tube. properly install a gas range. perform proper test out procedure on the high voltage diode. define the purpose of the monitor switch in the microwave. identify the primary, secondary and monitor interlock switches. analyze microwave leakage results knowing excepted guidelines. record microwave leakage results determined by using correct instrument. explain the purpose of the hot surface indicator light. identify the components that operate a standard electric surface element. perform proper test out procedure on standard coil type surface element. perform the proper test out procedure on ceran type surface burner. perform proper test out procedure on the triac. properly install a electric range. HCC COMPETENCIES MET: Working Productively & Cooperatively, Communicating Clearly & Effectively, Thinking Creatively & Critically, Social Responsibility, Valuing Self. STUDENT CONTRIBUTIONS: The student is expected to 1. demonstrate and exercise safety skills. 2. attend all lectures. 3. participate in class activities. Hibbing Community College, a technical & community college an equal opportunity educator & employer 4. participate and implement input into class discussions. To request disability accommodations, please contact Bonnie Olson, Central Campus, 218-262-7246 Students are encouraged to discuss their individual needs with the instructor. METHODS FOR EVALUATING STUDENT LEARNING: Exams, quizzes, outside assignments, class attendance/participation, group discussions, behavioral observations, simulations and other learning experiences will be translated to points earned. Letter grades A-F will be earned based on points earned. SPECIAL INFORMATION: (SPECIAL FEES, DIRECTIVES ON HAZARDOUS MATERIALS, TEXTBOOK USED, ETC.) Whirlpool workbooks Instructor hand-outs ___________________________ Date Approved RHAA1500.con 11/97 Hibbing Community College, a technical & community college an equal opportunity educator & employer