possibilities of using olive kernel wood for pellets production in crete

advertisement

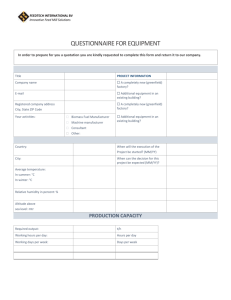

POSSIBILITIES OF USING OLIVE KERNEL WOOD FOR PELLETS PRODUCTION IN CRETE – GREECE John Vourdoubas TEI of CRETE Department of Natural resources and environment Romanou 3, Chalepa 73133, Chania – Crete – Creece Tel +30-28210-46197, Fax +30-28210-20620 e-mail: gboyrd@tee.gr ABSTRACT: Wood pellets consist a renewable energy source and are used to day in many EU countries for heating buildings. Since they find increasing use, various quality standards related with their physical and chemical characteristics have been introduced. The olive kernel wood is a byproduct of the olive oil producing industry and its production in Crete – Greece to day is approximately 110.000 tn/year. It is used without any standardization for heat production in buildings, industries and greenhouses. Currently in Crete its price in relation to its heating value is low and it can be easily used for pellets production with proper processing. It is necessary though, that its quality characteristics must comply with the existing EU specifications, particularly in relation with its high ash content. Keywords: solid biofuels, olive residues, pellets 1. INTRODUCTION Renewable energy high ash content will create probably problems a) sources including With high aerosol formation in the exit gases and b) biomass, find increasing use to day in EU countries with creation of ash slagging in the burner. Probably for heat production, power generation, and as its mixing with other wood residues, will reduce the vehicle fuels. ash content and the final pellets will have a Current EU policies for reducing the fossil permissible ash concentration. Studies of the ash fuel dependence, and mitigating CO2 emissions, content of the olive tree wood [ 13 ] , have shown significantly contribute to that. that its ash content is 5,5% wt on dry basis.However Wood pellets consist a renewable and according to the same researchers other types of environmentally friendly solid fuel, which is wood like Eucalyptus , Willow Salix and branches increasingly used for heat generation in E.U. and tops from a Scandinavean forest have lower ash Recently in Greece wood pellets are produced from content , 0,7% wt ,1,2% wt and 1,9% wt agricultural residues and the existing agricultural representively. byproducts and residues in the country could be used for the production of large quantities of pellets. 2. THE USE OF PELLETS AS FUELS Olive trees grow in many areas in Greece and give many wood byproducts and residues. Wood pellets consist a simple and Olive kernel wood is a byproduct in olive standardized solid biomass source which is mainly kernel oil producing factories, and is used for heat used for heating buildings. Since their chemical generation. It is an attractive solid fuel since its energy, is stored solar energy, wood pellets present price 0.05 €/kg, is relatively low in comparison with many advantages which are . its heating value, 3.500-4.000 kcal/kg (16 MJ/kg). a) Its transformation in the form of pellets could improve its use for heating buildings. However the As a biomass source they have a neutral impact to the greenhouse effect. b) Wood pellets are produced from wood ash content of the olive kernel wood is higher than residues which otherwise were going to be the existing specifications for wood pellets. The disposed to the environment. The wood 1 c) pellets industry was initially developed to energy countries with many forests like the north electricity, LPG) in Crete, like oil, European countries. b) Its availability, all over the year. Wood pellets are usually consumed near c) The use of simple and standardized the place of their production. Therefore burning systems. the environmental impacts from their The main disadvantages of its use are: transport are rather low. d) sources a) Wood pellets consist a clean solid fuel. makes necessary that the consumer must Their size is small and they are easily stored. Their use in simple and their The lack of its standardization which buy it directly from the plant. b) The absence of fully automated burners, energy density in high. They are burnt in makes necessary their regular systematic modern cleaning and the removal of the ash. Also systems which are highly automated. Pellets are the absence of exit gas filters in small feeded in the burners commercial mechanically and the burning system does not need frequent cleaning. They are produced in cylindrical form, systems, which creates pollution problems. c) The lack of social acceptance for its use in dense populated areas. In many cases the when wood residues are pressurized in high neighbours pressures and their size varies in length 10-30mm unaccepted odours and pollution. and width 6-10mm. During their compression their result, the olive kernel wood does not find water content is decreased. The E.U. specifications many applications to day in Crete as a fuel for the max water content of pellets, when they are for heat generation and there are not either used for heating is 10% p.w. The capacity of the applications for power generation. It plants producing pellets varies from 100 tn/year to should be noted that some quantities of 10.000 tn/year. Usually the production of pellets in raw olive kernel wood are exported to low capacity plants is not profitable. Various E.U. other countries have introduced quality specifications for analysis of olive kernel wood is presented the wood pellets and soon will be available common in table 1. E.U. are protested countries. The against As a chemical E.U. specifications. The prices of wood pellets in TABLE 1 various E.U. countries are competitive with the oil CHEMICAL ANALYSIS OF OLIVE KERNEL prices and this contributes to their success as an WOOD [ 3 ] alternative fuels. 3. OLIVE KERNEL WOOD Olive kernel wood is a byproduct of the Water content 6.30% Ash 8.80% Organic matter 65.50% Sulphur 0.11% Chlorine 0.69% olive processing industry and it is produced in the Total Carbon 45.30% olive kernel oil producing plants. Its production in Hydrogen 5.17% Crete to day varies to 110.000 tn/year. The main Nitrogen 1.33% Oxygen 34.30% Heating value 4051 Kcal/kg uses of olive kernel wood are for heat generation in the factories, in buildings and in greenhouses. The main advantages of its use are: a) The low price in comparison with the heating value (compared with other 16.96 MJ/Kg Residual Oil 2.44% Residual hexane <10 mg/kg 2 4. POSSIBILITIES PELLETS OF FROM PRODUCING OLIVE KERNEL WOOD Comparing tables 1,2 and 3 it is concluded that the concentration of olive kernel wood in various elements, exceeds the E.U. proposals for maximum permissible concentrations. The production of wood pellets from olive kernel Therefore wood is easily feasible and the product can be used a) The ash content is significantly higher for heating buildings. Pellets can be produced than the maximum accepted. This could without the use of additives. For its utilization as a lead to ash slagging during combustion fuel, it should comply with the existing and probably the final product is not specifications for wood pellets, which apply in suitable for burning in existing residential varions E.U. countries (table 2). Proposals also exist pellets burners [ 9 ]. Also its high ash for future quality specifications of wood pellets in content could lead to formation of high all E.U. countries (table 3). temperature aerosols [ 12]. TABLE 2 b) The sulphur concentration is slightly higher than the max accepted WOOD PELLETS SPECIFICATIONS IN VARIOUS c) E.U. COUNTRIES [ 4 ] the max accepted for good quality pellets AUSTRIA SWEDEN GERMANY <12 <10 <12 Water The Nitrogen concentration is higher than d) The Clorine concentration is also higher than the max accepted. content e) (%) Some times the produced olive kernel ash (%) <0.5* <1.5 <1.5 wood has water content higher than 10%, heating ≤18* ≥16.9 17.5-19.5 but this can be reduced with proper drying. value (MJ/kg) Therefore for the production of wood Sulphur ≤0.04* ≤0.08 ≤0.08 ≤0.3* - ≤0.3 ≤0.02* ≤0.03 ≤0.03 (%) Nitrogen (%) Chlorine pellets form olive kernel wood, it should be mixed with other agricultural of forest by products or residues, having very low ash content, resulting in a final product complying with the E.U. specifications. The most important parameter of (%) olive kernel wood which must be reduced *in dry basis significantly is its ash content. CONCLUSIONS TABLE 3 1. Wood pellets are a rather new solid biomass fuel which is used increasingly in PROPOSED WOOD PELLETS SPECIFICATIONS E.U., for heating buildings. FOR E.U. COUNTRIES [ 4 ] 2. Various E.U. countries which use broadly Water content (%) ≤10 Ash (%) ≤0.7 wood heating value (MJ/kg) ≥16.9 specifications for it, and soon new quality Sulphur (%) ≤0.05 Nitrogen (%) 0.3-3 Chlorine (%) 0.03-1 Additives (%) <2 in dry basis pellets as fuel, have quality specifications for EU countries are expected. 3. For wood pellets productions, agricultural and forest residues are used to day. 4. Olive kernel wood is a byproduct of olives processing plants, and it is used to day as 3 a solid fuel without any standardization. 5. The chemical concentration of olive , “ Using biomass for climate change Kernel wood does not allow its use for mitigation and oil use reduction” , Energy wood policy , 35 , (2007) ,p. 5671-5691. the pellets production, since its existing quality specifications. D. Bostrom , ” Slagging combustion in residential pellet burners.” , concentration of various substances and to Biomass and Bioenergy , 27 ,(2004), p. produce good quality pellets. The high ash 585-596. 10. P. Lehtikangas , “ Quality properties of pellets production. pelletised sawdust logging residues and The high ash content of olive kernel wood bark” Biomass and Bioenergy , 20 ,( could probably lead to ash slagging for 2001) ,p. 351-360. burning temperatures 900-1000 oC . 11. Yadong.li. , Henry Liu , “ High pressure Further experiments are needed to find the densification of wood residues to form an degree of sintering of the ash deposits. upgraded fuel”, Biomass and Bioenergy , Also the formation of high temperature 19,( 2000) , p. 177-186. 12. H. Wiinikka , R. Gebart , C. Boman , D. Bostrom , M. Ohman. „Influence of fuel ash composition on high REFERENCES M. Griffiths “Pellets appeal”, Renewable temperature aerosol formation in fixed bed energy world, March – April 2005, vol. 8, combustion of woody biomass pellets.“, Fuel , number 2, p. 52-59. 86 ,(2007) , p. 181-193. B. Hahn Umbera “Establishing a wood 13. B.J. Skrifvars , R. Backman , M. Hupa ” pellet market – Incorporating total quality Chartacterization of the sintering tendency of management”, Competence center wood ten biomass ashes in FBC conditions by a technologie – Holzforschung, Austria. laboratory test and by phase equilibrium ABEA, Chemical calculations” , Fuel processing technology , 56, Analysis of olive Kernel wood, Chania, Crete, Greece. 4. Nordin, other solid biomass sources, to reduce the concentration. 3. M.Ohman, C. Boman, H. Hedman , A. tendencies of wood pellet ash during aerosols are expected due to high ash 2. 9. Therefore it is necessary to mix it with content makes possible its use for bark 1. L.Gustavsson,J.holmberg,V.Dornburg,R.S thre,T.Eggers, K. Mahapatra , G. Marland concentration in various elements exceeds 6. 8. Its price is attractive . ( 1998) , p. 55-67. Quality standards for pellets in E.U. countries, www.pelletcentre.info 5. Heating buildings with wood – An investors guide (in Greek), Greek centre of Renewable energy sources. www.cres.gr 6. Energy plantations for the production of solid biofuels in Greece (in Greek), Greek centre of Renewable energy sources. www.cres.gr 7. Heating buildings with biomass, technical guide (in Greek), Greek centre of RES, www.bioheat.info 4