Managing risks to health and safety at the

advertisement

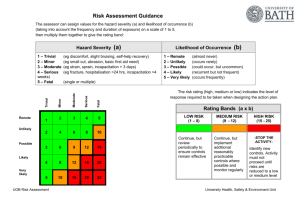

FACT SHEET—MANAGING RISKS TO HEALTH AND SAFETY AT THE WORKPLACE This fact sheet provides general guidance for persons conducting a business or undertaking (PCBUs) and workers on managing health and safety risks at the workplace. It is based on and should be read together with the Work Health and Safety (WHS) Act and Regulations, the Code of Practice: How to Manage Work Health and Safety Risks and any other applicable codes of practice or guidance material. Managing risks to health and safety at the workplace Managing work health and safety risks involves four steps (see figure below): 1. identifying hazards—finding out what could cause harm 2. assessing risks (if necessary)—understanding the nature of the harm that could be caused by the hazard, how serious the harm could be and the likelihood of it happening 3. controlling risks—implementing the most effective control measure that is reasonably practicable in the circumstances 4. reviewing control measures—ensuring control measures are working as planned. Control measures must be selected to eliminate the risk, so far as is reasonably practicable. If elimination is not reasonably practicable, the risks must be minimised so far as is reasonably practicable. PCBUs’ responsibility for managing risk PCBUs are responsible for managing work health and safety risks. Sometimes several PCBUs may share responsibility with other business operators who are involved in the same activities or who share the same workplace. These PCBUs must consult, cooperate and coordinate activities with all other persons who have a work health or safety duty in relation to the same matter, so far as is reasonably practicable. Tasks to manage risks may be delegated, but ultimately each relevant PCBU holds this responsibility under the law. Each PCBU must ensure that relevant workers and their health and safety representatives are involved in the risk management process. PCBUs should also ensure that whoever carries out any step in the risk management process has the necessary skills and experience to do so and understands when specialist help might be needed. More information and guidance on consultation is available in the Code of Practice: Work Health and Safety Consultation, Cooperation and Coordination. Consultation and managing risks Consultation with workers and their health and safety representatives is required at each step in managing risks to health and safety at the workplace. By drawing on the experience, knowledge and ideas of workers, PCBUs are more likely to identify all hazards and choose effective control measures. Workers should be encouraged to report any hazards and health and safety problems immediately so that risks can be managed before an incident occurs. If there is a health and safety committee for the workplace, it should also be engaged in managing health and safety risks at the workplace. Using a consultant In most cases the relevant PCBU can carry out the risk management steps with the help of workers. External help or advice may be necessary if there is insufficient in-house experience or knowledge, or if risks are complex. Managing risks–who should be covered Risks must be managed to ensure the health and safety of workers and other people affected by the conduct of the business or undertaking including visitors and customers at a workplace. Special consideration must be given to vulnerable workers including: contractors and shift workers who may not be familiar with the workplace, including the systems of work implemented at the workplace new and young workers who may be inexperienced or lack the maturity to recognise risks workers with poor literacy skills—if staff can’t sufficiently read, write or add, this can affect their ability to understand and follow guidance and instructions and expose them to greater risk new or expectant mothers who may be more prone to health-related risks such as physical, biological or chemical risks persons with a disability—reasonable modifications to the workplace and work tasks may be required to enable them to work safely. PCBUs should also think about other people such as members of the public and groups of people who share the workplace (for example childcare centres, nursing homes and sporting venues) when considering how to control risks. Four steps to managing risks to health and safety 1. Identify hazards—finding hazards and potential hazards A hazard is anything that could be harmful to any person. Some hazards will be obvious because they may be common to a particular industry, but others can by more difficult to identify. Working closely with workers and looking at every task at the workplace will assist in finding potential hazards. Information and advice about hazards and risks relevant to particular industries and types of work is available from regulators, industry associations, unions, technical specialists and safety consultants. Manufacturers and suppliers can also provide information about hazards and safety precautions for specific substances (safety data sheets), plant or processes (instruction manuals). Analyse records of health monitoring, workplace incidents, near misses, worker complaints, sick leave and the results of any inspections and investigations to identify hazards. If someone has been hurt doing a particular task, then a hazard exists that could hurt someone else. These incidents need to be investigated to find the hazard that caused the injury or illness. Once identified, hazards should be recorded in writing. 2. Assessing the risks A risk assessment involves considering what could happen if someone is exposed to a hazard and the likelihood of it happening. A risk assessment can help determine: 1. how severe a risk is 2. whether any existing control measures are effective 3. the action that should be taken to control the risk 4. how urgently the action needs to be taken. A risk assessment does not have to be complex—this will depend on the type of hazards and the information, data and resources that are available. It can be as simple as a discussion with workers or may involve specific risk analysis tools and techniques recommended by safety professionals. 3. Control the risks—fixing the problems Once the hazards have been identified (and where necessary, any relevant risks assessed) start on the most important step of all—fixing the problems. The various ways of controlling risks can be ranked from the highest level of protection and reliability to the lowest. This is referred to as the hierarchy of controls. The most efficient way of controlling risks is to eliminate a hazard, so far as is reasonably practicable. If not reasonably practicable the next step is to minimise the risks so far as is reasonably practicable, by doing one or more of the following: 1. substituting (wholly or partly) the hazard creating the risk with something that creates a lesser risk 2. isolating the hazard from any person exposed to it, and/or 3. implementing engineering controls. If a risk then remains, the remaining risk must be minimised, so far as is reasonably practicable, by implementing administrative controls. An administrative control means a method of work, a process or a procedure designed to minimise risk, but does not include an engineering control or the use of personal protective equipment (PPE). Following the implementation of administrative control, if a risk still remains, then the remaining risk must be minimised, so far as is reasonably practicable, by ensuring the provision and use of suitable PPE. A combination of controls should be used if a single control is not sufficient for the purpose. 4. Reviewing risk controls Controlling health and safety risks in the workplace is an ongoing process that needs to take into account changes in the workplace. This is why procedures and risk controls must be reviewed regularly to ensure they are still effective. Risk control measures implemented to meet work health and safety requirements must be reviewed and as necessary revised to maintain, so far as is reasonably practicable, a work environment that is without risks to health or safety. This includes when: the control measure does not control the risk it was implemented to control, so far as is reasonably practicable before a change at the workplace that is likely to give rise to a new or different risk to health or safety that the measure may not effectively control a new relevant hazard or risk is identified the results of consultation required under the laws indicate that a review is necessary a health and safety representative requests a review and they reasonably believe that: a circumstance referred to above affects or may affect the health and safety of a member of the work group they represent, and the control measure has not be adequately reviewed. When to assess risk A risk assessment is mandatory for certain high risk activities such as entry into confined spaces, diving work and live electrical work. Although a risk assessment may not be mandatory under the WHS Regulations, it should be conducted when: there is uncertainty about how a hazard may result in injury or illness the work activity involves a number of different hazards and there is a lack of understanding about how the hazards may interact with each other to produce new or greater risks changes at the workplace occur that may impact on the effectiveness of control measures. A risk assessment is not necessary if: laws already require the relevant hazards or risks to be controlled in a specific way—these requirements must be complied with a code of practice or other guidance sets out a relevant way of controlling a hazard or risk that is applicable to your situation—this guidance can be followed well-known and effective controls that are used in the particular industry, are suited to the relevant circumstances in a particular workplace—these controls may be implemented. New or different risks associated with a change in work systems or work location should be covered by a specific assessment. Deciding what is ‘reasonably practicable’ Deciding what is ‘reasonably practicable’ to protect people from harm requires taking into account and weighing up all relevant matters including: 1. the likelihood of the hazard or the risk occurring 2. the degree of harm that might result from the hazard or the risk 3. knowledge about the hazard or risk 4. ways of eliminating or minimising the risk, and 5. the availability and suitability of ways to eliminate or minimise the risk. It is only after assessing the extent of the risk and the available ways of eliminating or minimising the risk, that consideration may be given to the cost associated with available ways of eliminating or minimising the risk. A relevant factor at this point is whether the cost is grossly disproportionate to the risk. Keeping records It is good practice to keep records of risk management activities while they remain relevant. Keeping records of the risk management process demonstrates compliance and may help when undertaking subsequent risk assessments. For most workplace risks there is no set amount of time that records must be kept. However records for certain high risk activities such as entry into confined spaces, diving work and live electrical work must be kept for a prescribed period of time. More information More information about the risk management steps is included in the Code of Practice: How to Manage Work Health and Safety Risks. This code includes a risk management template at Appendix B. Disclaimer Note: this fact sheet provides general information only and should not be used as a substitute for seeking professional legal advice for your specific circumstances. The contents of this fact sheet are correct and based on available information at the time of writing. However, there may be subsequent decisions of courts or tribunals on the matter covered by this fact sheet which mean that the contents are no longer accurate.