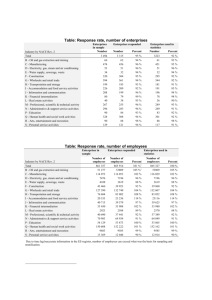

Manufacturing Sector Study 2004

advertisement