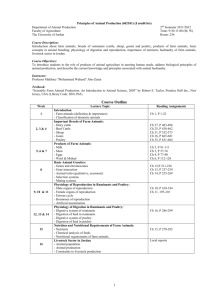

tr-animal production (ruminants) nc ii

advertisement