HeatXchng_corr

advertisement

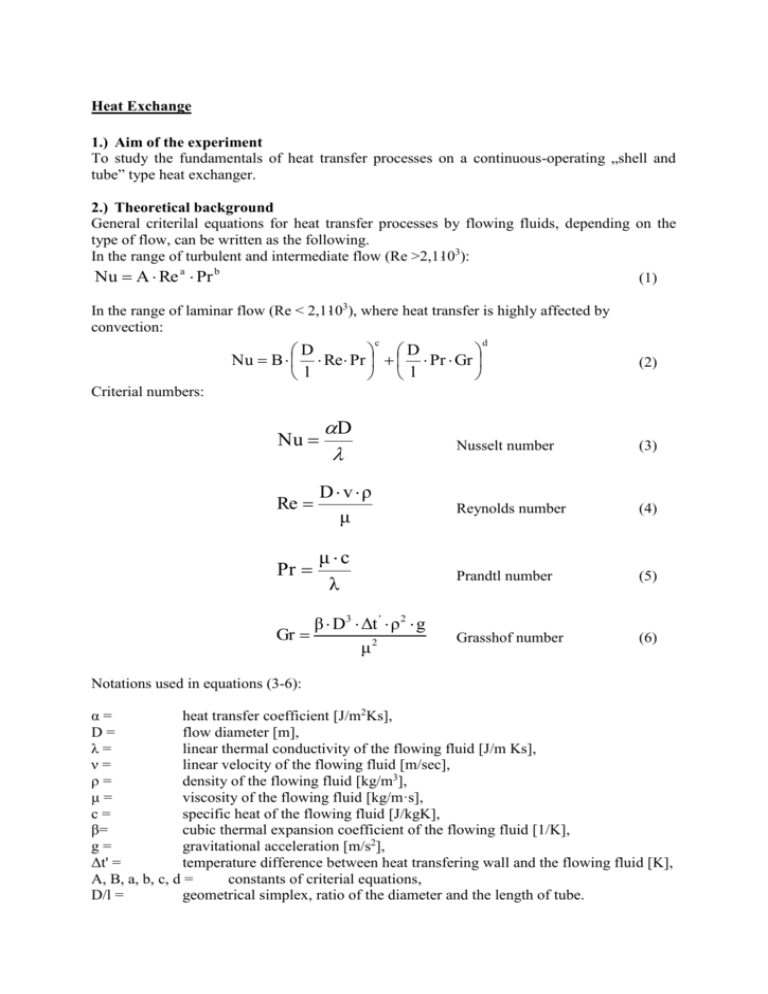

Heat Exchange 1.) Aim of the experiment To study the fundamentals of heat transfer processes on a continuous-operating „shell and tube” type heat exchanger. 2.) Theoretical background General criterilal equations for heat transfer processes by flowing fluids, depending on the type of flow, can be written as the following. In the range of turbulent and intermediate flow (Re >2,1ּ103): Nu A Re a Pr b (1) In the range of laminar flow (Re < 2,1ּ103), where heat transfer is highly affected by convection: c D D Nu B Re Pr Pr Gr l l d (2) Criterial numbers: Nu D Re D vρ μ Pr μ c λ β D3 Δt ' ρ 2 g Gr μ2 Nusselt number (3) Reynolds number (4) Prandtl number (5) Grasshof number (6) Notations used in equations (3-6): α= heat transfer coefficient [J/m2Ks], D= flow diameter [m], λ= linear thermal conductivity of the flowing fluid [J/m Ks], ν= linear velocity of the flowing fluid [m/sec], ρ= density of the flowing fluid [kg/m3], μ= viscosity of the flowing fluid [kg/m·s], c= specific heat of the flowing fluid [J/kgK], β= cubic thermal expansion coefficient of the flowing fluid [1/K], g= gravitational acceleration [m/s2], Δt' = temperature difference between heat transfering wall and the flowing fluid [K], A, B, a, b, c, d = constants of criterial equations, D/l = geometrical simplex, ratio of the diameter and the length of tube. Thermal conductivity can be derived based on equations (1-6) as the following: 1 k calc 1 δw 1 α1 λ w α 2 (7) where: kcalc = calculated thermal conductivity [J/m2 Ks], α1 = heat transfer coefficient of medium 1 [J/m2 Ks], α2 = heat transfer coefficient of medium 2 [J/m2 Ks], δw = thickness of heat transfering wall [m], λ w = linear thermal conductivity of the heat transfering wall [J/m Ks], Heat transfer rate can be calculated based on transfer rates and temperatures: J s Q w c t (8) where Q = derived heat transfer rate [J/ s], W = volumetric flow rate of the medium [m3 /s], ρ = density of the medium [kg/m3], c = specific heat of the medium [J/kg K], Δt = temperature change of the medium [K]. Based on the derived heat transfer rate and the instrument parameters, measured thermal conductivity can be also calculated: Q k m A Δt a J s (9) where km = measured thermal conductivity [J/m2 Ks], Δta = average temperature difference between the media [K] A = Heat transfering surface area [m2]. Average temperature difference between the two ends of the heat exchanger: Δt Δt i Δt a o Δt ln o Δt i where t 0 = temperature difference between the media at either end of the heat exhanger ti = temperature difference between the media at the other end of the heat exhanger (10) Equation (10) can be used in the case of concurrent as well as counter-current flow. Δt o 2 – in most cases – mathematical average can be used instead for Δt i logarithmic average of temperatures: In the case of Δt a Δt o Δt i 2 (11) kcalc calculated by equations (1-7) and km calculated by equations (8-11) should be equal (within experimental error), so their comparison can be used to check the accuracy of the measurement. In the experiment both media are water, hot water is indexed with 1, cold water with 2. Let’s look through the equations above applied to our system. Δt = temperature change of the media In the case of hot water: Δtl= tlk-tlv, In the case of cold water: Δt2= t2v-t2k, so Q1 = wl·ρ·c·Δtl, and Q2 = w2 ρ·c·Δt2 In the case of concurrent: Δt0 = tlv – t2v and Δti = tlk– t2k; In the case of counter-current: Δt0 = tlv – t2k and Δti = tlk– t2v; (k index is for initial, v is for final temperatures) t1k t1k w1 ti t2v ti w1 w2 t1v t0 t2v t1v w2 t0 t2k t2k w2 t2v w2 t2v w1 w1 t1v t1k w1 t1k w2 t2k w1 t1v w2 t2k Counter-current heat exchanger Concurrent heat exchanger Diagrams upward indicate temperature changes. 3.) Measurement experiment Using the current (concurrent or counter-current), flow rate and temperature settings given by the supervisor, determine the temperatures at steady state. Calculate heat trasfer rate, thermal conductivities (measured and calculated) and heat transfer coefficients for each setting. 3.1. Handling of the instrument K1 V1 T V3 R1 220 V C V4 R2 V5 V6 V7 V9 220 V T4 V8 V10 T1 T2 T3 Legends Jelmagyarázat Cold water Hideg ág Hot water Meleg ág Cooling water Hűtővíz Regulation Szabályozás T C Valve V Szelep, csap R Rotaméter K Kontakthőmérő T Hőmérő Flow meter Contact thermometer Thermometer Concurrent V5 V6 V7 V8 V9 V10 Open/Closed C O O O O C Counter-current V5 V6 V7 V8 V9 V10 Open/Closed O O C C O O Figure 1. Scheme of the heat exchanger T C K2 V2 Study the construction of the instrument, material and energy flows, handling of the thermostate. Set the current with the valves, the temperature of the hot water on the thermostate and the flow rates given by the supervisor. Record the 4 temperatures (T1 – T4) in every 2 minutes until steady state (no change to the temperatures measured before). Calculate the following parameters. 4. Calculation Determine the calculated thermal conductivity (kcalc) and the measured one (km) at steady state. During the calculation use index 1 for hot and 2 for cold water. Recommended order of the calculation is Re, Pr, (Gr), Nu, α, kcalc. Balance of the absorbed and the retained heat indicates the accuracy of the measurement. At steady state absorbed, transferred and retained heat are equal, and km can be determined after the calculation of w then Q. Calculations must be done in SI units! Figure 2 shows the most important parameters of the heat exchanger: f d D l Figure 2. Parameters of the heat exchanger d = inner tube inner diameter = 8 mm δ = wall thickness of inner tube = 1 mm D = shell inner diameter = 30 mm l = length of heat exhanger tubes = 2 m Based the data above heat transfering surface area and the linear velocities of the flowing fluids can be calculated. The D geometrical size - used in equations (1-6) – is the diameter of the tube in the case of the inner tube, and the so-called equivalent diameter generally describing the flow diameter in the case of the outer flow, as the following: De 4 Where q k q = real flow cross-section [m2], k = circumference touched by the flowing fluid in the cross-section of the flow [m]. Values of the material-based coefficients for calculations: λwater = 0,62802 J/mKs, λcopper = 3,94•102 J/mKs, 3 3 ρwater = 10 kg/m , λiron = 7,12•10l J/mKs, 3 cwater = 10 •4,19 J/kgK, βwater = 2,07•10-4 K-1. ηwater = use the nomogramme below!, Values of criterial constants for equations (1) and (2): A = 0,023 B = 1,86 a = 0,8 c = 0,33 b = 0,4 d = 0,28 When calculate Gr number, accept that values of Δt' and Δta are equal, because the wall temperature cannot be measured. When calculate heat transfer rate (Q), calculation must be done for both direction of water flow (equation 8), and transferred heat should be accepted as the average heat transfer rate (Qa), which is the average of absorbed (Q1) and retained (Q2) heat (equation 9) (these values should not be differ too much). Record the calculated values according to the following table (with units!): w1v1Re1Pr1α1Nu1w2v2Re2Pr2Gr2α2Nu2kszt1kt1vt2kt2vΔt0ΔtiΔtaΔt1Q1Δt2Q2Qatlkm Viscosity of water as a function of the temperature Temperature Viscosity Temperature (°C) (10-3 Ns/m2) (°C) 0 1,792 40 1 1,731 41 2 1,673 42 3 1,619 43 4 1,567 44 5 1,519 45 6 1,473 46 7 1,428 47 8 1,380 48 9 1,346 49 10 1,308 50 11 1,271 51 12 1,236 52 13 1,203 53 14 1,171 54 15 1,140 55 16 1,111 56 17 1,083 57 18 1,056 58 19 1,030 59 20 1,005 60 20,2 1,000 61 21 0,9810 62 22 0,9579 63 23 0,9358 64 24 0,9142 65 25 0,8937 66 26 0,8737 67 27 0,8545 68 28 0,8300 69 29 0,8180 70 30 0,8007 71 31 0,7840 72 32 0,7679 73 33 0,7523 74 34 0,7371 75 35 0,7225 76 36 0,7085 77 37 0,6947 78 38 0,6814 79 39 0,6685 80 Viscosity (10-3 Ns/m2) 0,6560 0,6439 0,6321 0,6207 0,6097 0,5988 0,5883 0,5782 0,5683 0,5588 0,5494 0,5404 0,5315 0,5229 0,5146 0,5084 0,4985 0,4907 0,4832 0,4759 0,4688 0,4618 0,4559 0,4483 0,4418 0,4355 0,4293 0,4233 0,4174 0,4117 0,4061 0,4006 0,3952 0,3900 0,3849 0,3799 0,3759 0,3702 0,3655 0,3610 0,3605