18_SWP_H&E Staining_JJ

advertisement

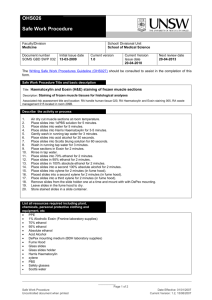

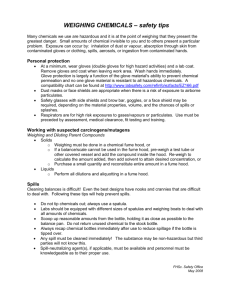

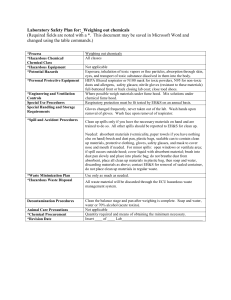

OHS026 Safe Work Procedure Faculty/Division Medicine Document number SOMS.CGM.SWP018 Initial Issue date 30/06/09 School/ Divisional Unit School of Medical Science, Neuromuscular and Regenerative Medicine Research Unit Current version Current Version Next review date 1.0 30/06/12 Issue date 30/06/09 The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form. Safe Work Procedure Title and basic description Title: Haematoxylin and Eosin (H&E) staining of frozen muscle sections Description: Staining of frozen muscle tissues for histological analyses Associated risk assessment title and location: 18_RA_H&E Staining_JJ Describe the activity or process Everyone must be inducted on the use of Neuroscience facilities (G14, G16 WW Building) before using the H&E staining apparatus. H&E Staining 1. Air dry cut muscle sections at room temperature or 10 minutes to remove moisture. 2. Fix sections in 4% PFA (diluted in 1xPBS) for 2 minutes. 3. Place slides into 1xPBS solution for 5 minutes. 4. Place slides into water for 5 minutes. All the procedures below should be perfomed using the H&E apparatus in G16 (Neuroscience laboratory, WW Building) 5. Place slides in a slide holder. 6. Place slides into Harris Haematoxylin for 3-5 minutes. 7. Gently wash in running tap water for 3 minutes. 8. Place slides into acid alcohol for 30 seconds. 9. Place slides into Scotts bluing solution for 60 seconds. 10. Wash in running tap water for 3 minutes. 11. Place sections in Eosin for 5 minutes. 12. Rinse in tap water in a coplin/staining jar 4x (Do not over wash). 13. Place slides into 70% ethanol for 2 minutes. 14. Place slides in 90% ethanol for 2 minutes. 15. Place slides in 100% absolute ethanol for 2 minutes. 16. Place slides into a second 100% absolute alcohol for 2 minutes. Succeeding procedures should be performed in a fume hood in G16 (Neuroscience laboratory, WW Building). 17. Place slides into Histolene for 2 minutes. 18. Placed slides into a second Histolene for 2 minutes. 19. Place slides into a third Histolene for 2 minutes. 20. Remove slides from the slide holder one at a time and mount with with 1 drop of DePex mounting medium for the square coverslip and 2 drops for the rectangle coverslip. 21. Leave slides in the fume hood to dry. This will take ~30min-1hr. 22. Store stained slides in a slide container. Results collagen............................................pale pink muscle...............................................deep pink nuclei.................................................blue Solutions 4% PFA in PBS (pH 7.4) o 2 g of Paraformaldehyde o 100 mL Phosphate Buffered Saline o Heat to approx. 600C, allow to cool, adjust pH to 7.4 ___________________________________________________________________________________________________________ ___________ Page 1 of 4 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 o Acid Alcohol o o o Can be stored up to two weeks at 40C or longer if stored frozen at -200C. 70 mL of Absolute Ethanol (70% final concentration) 0.5 mL of concentrated Hydrochloric Acid 29.5 mL distilled water Scotts water o 0.2 g of Potassium bicarbonate o 20 g of Magnesium sulphate o 1 L of distilled water 1 x PBS o o 10 tablets of PBS 1 L of distilled water List all resources required including plant, chemicals, personal protective clothing and equipment, etc 1% Alcoholic Eosin (Fronine laboratory supplies) 70% ethanol 95% ethanol Absolute ethanol Absolute Ethanol (Ajax Finechem) Acid Alcohol (see above) Concentrated Hydrochloric Acid (Pro Sci Tech) Coplin/staining jars Covered Shoes DePex mounting medium (BDH laboratory supplies) Face Mask Fume Hood Glass slides Glass slides holder Gloves including Nitrile gloves Harris Haematoxylin (Fronine laboratory supplies) Histolene (Fronine laboratory supplies) Lab Coat Paraformaldehyde (ProScitech) PBS (Phosphate Buffered Saline) tablets (MP biomedicals) Safety glasses Scotts water (see above) List potential hazards and risk controls including specific precautions required 1. Paraformaldehyde – Corrosive. Toxic. May cause skin or eye burns or irritation. Can cause severe burning of mouth and stomach. Harmful by inhalation, ingestion or skin absorption, ingestion may be fatal. Use gloves, laboratory coat, safety glasses and work in a fume hood when preparing the 4% PFA solution. 2. Ethanol – Highly flammable. Harmful. Cause central nervous system depression. Causes eye and respiratory tract irritation and moderate skin irritation. Ingestion can cause gastrointestinal irritation with nausea, vomiting and diarrhea. Use gloves and safety goggles when preparing solutions in a well-ventilated area. 3. Concentrated Hydrochloric Acid – Toxic. Corrosive. Dangerous for the environment. Very hazardous in case of skin contact (corrosive, irritant, permeator), of eye contact (irritant, corrosive), of ingestion. Slightly hazardous in case of inhalation (lung sensitizer). Non-corrosive for lungs. Liquid or spray mist may produce tissue damage particularly on mucous membranes of eyes, mouth and respiratory tract. Skin contact may produce burns. Inhalation of the spray mist may produce severe irritation of respiratory tract, characterized by coughing, choking, or shortness of breath. Severe over-exposure can result in death. Inflammation of the eye is characterized by redness, watering, and itching. Skin inflammation is characterized by itching, scaling, reddening, or, occasionally, blistering. Use gloves, laboratory coat, safety glasses and work in a fume hood when preparing the acid alcohol solution. 4. DePex – Contains Xylene. Flammable. Harmful by inhalation and in contact with skin and eyes. Causes irritation. Use gloves, laboratory coat and work in a fume hood. 5. Glass slides – May cause skin cuts if broken. Use gloves when handling unbroken slides and tweezers if broken. Always handle glass slides with care. ___________________________________________________________________________________________________________ ___________ Page 2 of 4 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 Histolene - Hazardous substance. Dangerous Goods. Flammable. Irritating to skin. May cause sensitization by skin contact. Very toxic to aquatic organisms, may cause long-term adverse effects in the aquatic environment. Use gloves, laboratory coat and work in a fume hood. List emergency shutdown instructions 6. Paraformaldehyde Small Spill: Use appropriate tools to put the spilled solid in a convenient waste disposal container. Large Spill: Flammable solid. Corrosive solid. Stop leak if without risk. Do not get water inside container. Do not touch spilled material. Use water spray curtain to divert vapor drift. Use water spray to reduce vapors. Prevent entry into sewers, basements or confined areas; dike if needed. Eliminate all ignition sources. Call for assistance on disposal. Ethanol General Information: Use proper personal protective equipment . Spills/Leaks: Absorb spill with paper towel/underpads then place in suitable container. Remove all sources of ignition. Use a spark-proof tool. Provide ventilation. A vapor suppressing foam may be used to reduce vapors if dealing with large volume. Concentrated Hydrochloric Acid Small Spill: Dilute with water and mop up, or absorb with an inert dry material and place in an appropriate waste disposal container. If necessary: Neutralize the residue with a dilute solution of sodium carbonate. Personal Protection in Case of a Large Spill: Splash goggles. Full suit. Vapor respirator. Boots. Gloves. A self contained breathing apparatus should be used to avoid inhalation of the product. Large Spill: Corrosive liquid. Poisonous liquid. Stop leak if without risk. Absorb with DRY earth, sand or other non-combustible material. Do not get water inside container. Do not touch spilled material. Use water spray curtain to divert vapor drift. Use water spray to reduce vapors. Prevent entry into sewers, basements or confined areas; dike if needed. Call for assistance on disposal. Neutralize the residue with a dilute solution of sodium carbonate. Call Renee Szokoli ext 58497 in Rm 502 or Emergency contact ext. 56666. Follow evacuation procedures. DePex Absorb on an inert absorbent, transfer to container and arrange removal by disposal company. Wash site of spillage thoroughly with water and detergent. Histolene Emergency Procedures Shut off all sources of ignition. Slippery when spilt. Avoid accidents – clean up immediately. Wear appropriate protective equipment to prevent skin and eye contamination and breathing in vapour. Contain - prevent product from entering waterways. Soak up with suitable absorbent. Collect in labelled containers for disposal. Advise local authority if contamination of waterways occurs. List clean up and waste disposal requirements Cleaning and End of Work Session. Disposal/Replacement of staining reagents to be performed by the G14/G16 Neuroscience Laboratory manager, Linda Larsen (T 02 9385 2573 E l.larsen@unsw.edu.au. ) Washing after eosin staining to be tipped into alcohol waste located under the fume hood in G16. 4% PFA disposal into allocated liquid waste container located under fume hood in G16. Unused/unwanted glass slides to be disposed into the sharps bin. List legislation, standards and codes of practice used in the development of the SWP NSW OHS Act 2000 NSW OHS Regulation 2001 Australia Dangerous Goods Code Code of Practice for the Labelling of Workplace Substances AS/NZS 2243.2:2006. Safety in laboratories. Part 2: Chemical aspects AS/NZS 2243.6-1990. Safety in laboratories. Part 6: Mechanical Aspects. AS/NZS 2243.3:2006 Safety in Laboratories Part 7 Electrical aspects AS/NZS 2161.1:2000 Occupational Protective Gloves – Selection, Use and Maintenance AS/NZS 1336:1997 Recommended Practices for Occupational Eye Protection Supervisory approval, training, and review Supervisor: Edna Hardeman Signature: Plant custodian: Signature ___________________________________________________________________________________________________________ ___________ Page 3 of 4 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 List competency required – qualifications, certificates, licencing, training - eg course or instruction: Training as per Training Needs Analysis, Induction to Lab, Training in this SWP ___________________________________________________________________________________________________________ ___________ Page 4 of 4 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007