Solution - Shape fac..

advertisement

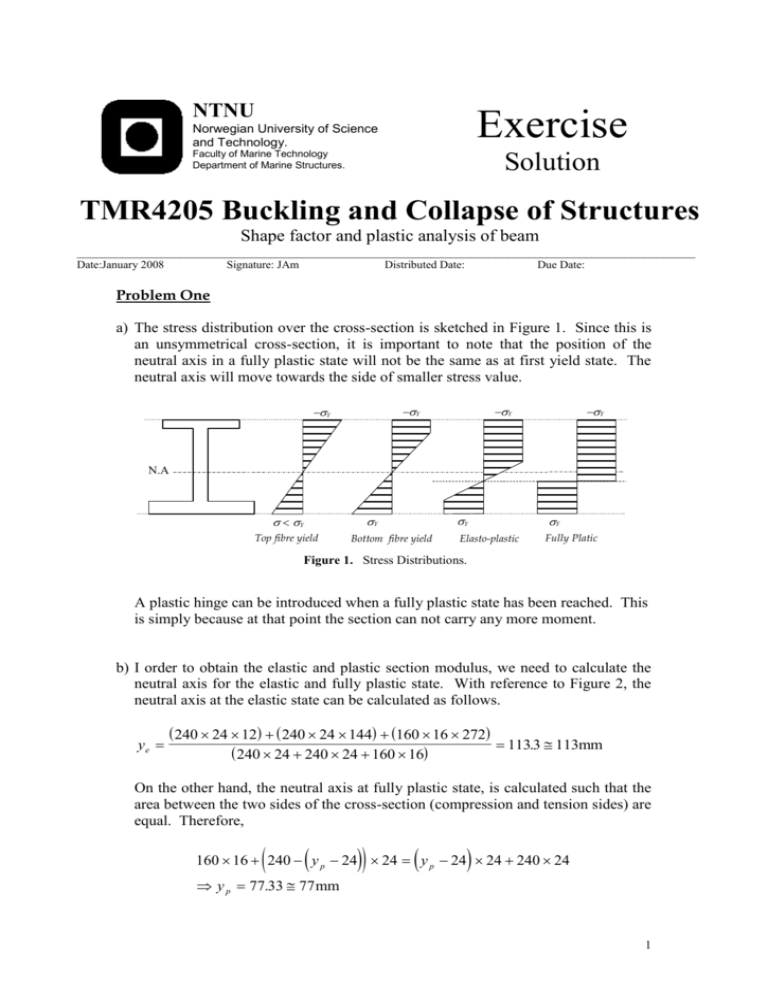

NTNU Exercise Norwegian University of Science and Technology. Faculty of Marine Technology Department of Marine Structures. Solution TMR4205 Buckling and Collapse of Structures Shape factor and plastic analysis of beam ________________________________________________________________________________________________ Date:January 2008 Signature: JAm Distributed Date: Due Date: Problem One a) The stress distribution over the cross-section is sketched in Figure 1. Since this is an unsymmetrical cross-section, it is important to note that the position of the neutral axis in a fully plastic state will not be the same as at first yield state. The neutral axis will move towards the side of smaller stress value. Y Y Y Y N.A Y Y Y Top fibre yield Bottom fibre yield Elasto-plastic Y Fully Platic Figure 1. Stress Distributions. A plastic hinge can be introduced when a fully plastic state has been reached. This is simply because at that point the section can not carry any more moment. b) I order to obtain the elastic and plastic section modulus, we need to calculate the neutral axis for the elastic and fully plastic state. With reference to Figure 2, the neutral axis at the elastic state can be calculated as follows. ye 240 24 12 240 24 144 160 16 272 113.3 113mm 240 24 240 24 160 16 On the other hand, the neutral axis at fully plastic state, is calculated such that the area between the two sides of the cross-section (compression and tension sides) are equal. Therefore, 160 16 240 y p 24 24 y p 24 24 240 24 y p 77.33 77 mm 1 160 16 24 N.A, elastic state 240 N.A, plastic state ye yp 24 240 Dimensions in mm Figure 2. The Neutral Axis at Elastic and Plastic States. The elastic section modulus is given by, W I nn y (1) where Inn is the moment of inertia about the neutral axis, and y is the longest distance perpendicular to the neutral axis which in this case is obviously to be towards the upper flange. By using Figure 2, we obtain, 1 1 I nn 240 24 3 240 24 1012 24 240 3 24 240 312 12 12 1 160 16 3 160 16 159 2 12 157 . 108 mm 4 157 . 108 W 9.4 105 mm 3 280 y e By definition, the plastic section modulus is given by, Z Mp Y (2) where Y is the yield stress and Mp is the plastic moment. From Figure 3, we can write M p P y y' (3) where, 2 24 187 935 . 160 16 195 130.4 130mm 24 187 160 16 24 53 26.5 240 24 65 y' 58.0mm 24 53 240 24 y P Y A 2 Therefore, Z Mp Y Y 2 160 16 24 240 240 24 7040 Y P y y ' Y 7040 Y 130 58 Y 13.2 105 mm 3 Y 160 16 24 P y 240 77 y' 24 P Y 240 Dimensions in mm Figure 3. Plastic Section Modulus. c) The shape factor is given by, Z 1.4 W This is a higher value as compared to those of typical I-profiles given in the Søreide’s book, (i.e 1.1 It can be inferred that the unsymmetrical I-profiles have higher shape factors compared to symmetric ones. Considering the given profile in this exercise, the factor will decrease with increasing size of the top flange until symmetry has been reached. d) The shape factor of a cross-section represents the reserve strength of that section after first yield. 3 Problem Two a) There are three possible collapse mechanisms for the given structure as shown in Figure 4. The associated collapse loads can be calculated from the principle of virtual work, Equation (4). We Wi We Wi P (4) 0.5P Loaded Structure 0.5Mp Mp 2L/3 L/3 L/2 L/2 2L w Mechanism I w Mechanism II w2 Mechanism III w1 Figure 4. Possible Collapse Mechanism. (i) Mechanism I: Pw M p 3 0.5 M p 2 P 3w 2L 6M p L (ii) Mechanism II: 0.5 Pw 0.5 M p 0.5 M p 2 P 2w L 6M p L (iii) Mechanism III: 4 Pw1 0.5 Pw2 M p 3 0.5 M p 4 P 3w1 w2 2L L 60 M p L b) From the above results, it is natural to select the true collapse load from mechanisms I and II as, Pc 6M p L Drawing the moment diagram will prove that this is the true collapse load if the moment values do not exceed the plastic moment capacity on any span. That is, M Mp for 0 x L M 0.5 M p for L x 2L Consider mechanism I and assume that the moment diagram has the shape shown in Figure 5. Then, R1 R2 Mp 2L 3 M p 3 Mp 2 L 0.5 M p L3 0.5 M p xM p L2 11 M p 2 L 2x Mp L The moment equilibrium of the left span (about point A) yields, 0.5 M p 3 Mp L R3 L 0 L 2 R3 Mp L and the moment equilibrium of span BC (about point B) yields, xM p R3 L 2 x 0.5 . Pc Static equilibrium is satisfied by R1 R2 R3 15 5 3Mp/L 6Mp/L C A R1 B R2 R3 0.5 Mp x Mp Mp Figure 5. Moment Diagram. 6