application of j

advertisement

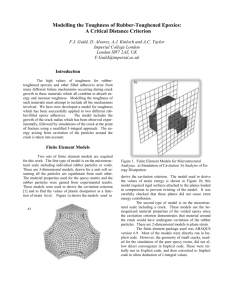

6th International Research/Expert Conference ”Trends in the Development of Machinery and Associated Technology” TMT 2002, Neum, B&H, 18-22 September, 2002 APPLICATION OF J-INTEGRAL TO STRENGTH OVERMATCH WELDED STRUCTURES Dražan Kozak Mechanical Engineering Faculty Slavonski Brod Croatia Aleksandar Sedmak Faculty of Mechanical Engineering Beograd Yugoslavia Gjorgji Adžiev Faculty of Mechanical Engineering Skopje Macedonia Nenad Gubeljak Faculty of Mechanical Engineering Maribor Slovenia ABSTRACT This paper attempts to clarify the conditions under which the J -integral is path-independent in fracture toughness specimens with heterogeneous structure. For this purpose, three point bend specimens with thickness of 36mm consisting X-welded joint were produced with surface crack (a/W=0,3) in the middle. The base material of the plate was high strength low allowed (HSLA) steel with about 700 MPa of yield strength. Welded joint has been performed as overmatch (mismatch factor M=1,2). Standard fracture mechanics testing of specimens were carried out. During experiment load (F), load line displacement (LLD), crack mouth opening displacement (CMOD), crack tip opening displacement (CTOD) as well as crack extension Δa were recorded. Plane stress and plane strain finite element (FE) models of the specimens have been performed. The validity of the numerical model has been proven comparing FE results with the same obtained experimentally. ANSYS code for the calculation of J-integral value through five paths around the crack tip has been applied. Path dependence of J-integral is more present with loading increasing, particularly after crack initiation. Calculated far field J-integral with PS assumption agrees more with experimental value. Numerical calculation of J-integral for inhomogeneous structures is possible, but one should have in mind all possible influences on results. First of all it depends on assumed state-of-stress by 2D finite element modelling and geometry of the welded structure. Keywords: welded structures, J-integral, state-of-stress, path dependency, finite element analysys 1. INTRODUCTION Last years a lot of papers has been devoted to assess the validity of J-integral as one of most used elasto-plastic fracture mechanics parameter in heterogeneous structures with cracks. J-integral application becomes questionable after crack initiation even for homogeneous structure [1]. Namely, the basis of J-integral concept is stationary crack and therefore its value is not so precise for growing crack. Related to this statement crack resistance curve J-Δa determined experimentally may be consider as material property just under some conditions [2]. Also, J-integral value is usually determined on the standard fracture specimens in the laboratory, so an additional problem may present its transferability to real structures in exploitation [3]. Size effects, especially the thickness might influence significantly on the J-integral as a crack driving force by two-dimensional numerical modelling supposing plane stress (PS) or plane strain (PE) state [4]. However, the situation with Jintegral application is more complex, when the structure is inhomogeneous (e.g. welded structures). In this paper, both the influences of weldment heterogeneity and state-of-stress assumption on the Jintegral value are discussed. There was no problem with J-integral path dependence for the “I” shaped welded joints, but problems may arise when X-welded joints were analysed. The aim of this work is to figure out a reason for variation of the J-integral with increasing of loading for different integration paths changing the state-of-stress by two-dimensional FE modelling. 2. J-INTEGRAL DEFINITION The J-integral, as defined by Rice [5], has been used extensively as the fracture mechanics parameter almost 35 years. Its popularity follows from the fact that the original introduction of J-integral was well established within the basic laws of continuum mechanics. Rice proved that the J-integral is path independent and it describes stress and strain fields around crack: J u v u v xy dy yx y dx W x x x x x ... (1) where is any path surrounding the crack tip, W denotes strain energy density, ij component stress and u i / x strain component. Anyhow as stated in Rice’s original paper, J-integral is valid only for two-dimensional plane (non-linear) elasticity in absence of volume and thermal forces, and for the homogeneous material, at least in crack direction. Its application beyond these limitations has been questionable, but still not unsuccessful. Thus, Sedmak introduced the modified J-integral [6] for bimaterial cracked body with the interface between two different materials. Deviations of J-integral values through different paths related to J-average value are then very small. In this paper it is assumed to calculate J-integral by finite element method over five different paths, where some paths cross bi-material interface and some not. After preliminary calculation authors concluded that J-integral becomes path dependent only if the path intersects the interface. So, we calculated the J-integral just for two paths, one is located in the homogeneous weld metal around crack tip called as J1 and the second picks up the stresses and strains through whole heterogeneous specimen (called as J2). Virtual crack extension method using by ANSYS 5.6 [7] has been applied for the J-integral determination. 3. MATERIALS AND EXPERIMENTAL PROCEDURES Test material was a HSLA steel plate of 36 mm thickness. The mechanical properties were: yield stress σY = 712 MPa, tensile strength σu = 846 MPa, work hardening exponent n = 0,095, elongation = 19 %, and the average value of Charpy tests are 85 and 54 Joules at -10˚C and -40˚C, respectively. Welded joint was made by Fluxo Cored Arc Welding (FCAW) process using tubular wires (Ø1,2 mm) named as WELTEC B 800 (COR-WEL-TEC Fügetechnik GmbH, Germany). These electrodes ensure global strength overmatching of about 20% related to base metal. The edge preparation was Xshape, as usual for welding of steel plates with the thickness of 40 mm. All the fracture toughness tests [8] were carried out on specimens of cross section W=B=36 mm, which were fatigue pre-cracked and tested in three-point bending over a span distance of 144 mm. The surface notch was in the middle of the homogeneous weld metal. In the test specimens the initial crack depth to specimen width ratio (ao/W) was in a range of 0,3. The tests were conducted on a testing machine with continuous records of applied load vs. CMOD and of applied load vs. CTOD (5) as well as of applied load vs. LLD. Crack extension Δa was measured also by using DC potential drop technique enabling us to draw crack resistance curve J- Δa. J-integral can be calculated from the experiment by: J J el J p p U p K2 E * B (W a) ... (2) where K denotes linear-elastic stress intensity factor, E*=E for PS conditions or E*=E/(1-ν2) for PE state, Up presents plastic part of the energy absorbed by the specimen (area below the F-LLD curve), B·(W - a) is cross-sectional area and ηp is dimensionless constant which depends on a/W ratio. Wang and Gordon [9] proposed expression for a wide range of a/W ratios and mismatch factors M = 0,5-1,5: a ... (3) p 3,5 1,42 W 4. NUMERICAL PROCEDURE Only one half of the specimen was modelled taking the symmetry into account (Fig. 1). Crack in twodimensional finite element model should to be parallel to x-axis according to theory for J-integral determination. Interface between base and weld metal is created as a line neglecting the heat affected zone as a third material. Law of material yielding in elasto-plastic region is defined as point-to-point curve using Ramberg-Osgood equation. The finite element mesh consists from 635 isoparametric eight-noded elements and 1998 nodes. First row of non-singular elements around the crack tip has the size of about 70 m. Due to significant plasticity appeared during testing of the specimens, radius of plastic zone defined by Schwalbe should to be added to initial crack length (a0=9,912 mm): a eff a 0 rp a 0 K2 2 y2 ... (4) where is a0 the nominally measured crack length and K is value of stress intensity factor caused by maximum fatigue load, y is yielding stress of material where the crack tip is located. Effective crack length calculated by equation (4) amounts to 10,45 mm. B=W= 36 mm S/2=72 mm base metal J2 path J1 path weld metal aeff crack tip Before J-integral determination finite element model should be proven comparing obtained FE results for displacements (LLD, CTOD, CMOD) with measured displacements at a certain loading level. This is important because we can not expect J-integral calculation with high accuracy using finite element method if the model gives us unreal stresses or strains distribution. Here above mentioned characteristic displacements of fracture toughness specimen recorded during testing are greater than the same displacements calculated by finite element analysis for about 30%, even for pure plane stress. It is difficult to understand the main reason of such FE model behaviour. Supposing that X-welded joint geometry is modelled properly, although welded joint after welding has no straight edges as we take in the FE model, we think that material model has more influence, especially in the region immediately after yielding in - diagram (up to 5% of strain). Two paths, one near to the crack tip all located in the homogeneous weld metal and the second which is crossing the metals interface remote from the crack are used to calculate J-integral. Four values of J-integral are determined for corresponding load level, J1 and J2, but each for F/2 plane stress and plane strain conditions, respectively. The aim was to analyse the influence of the state-of-stress on the numerical value of the J-integral and its path dependency in the case of inhomogeneous structure. Figure 1. FE model of one half of the specimen 5. RESULTS WITH DISCUSSION Because numerically obtained displacements are smaller than measured it seems from the Fig. 2 that J-integral solution with PS condition and remote path J2 is closest to determined J from the test. Path dependence of J-integral is more present with increasing of loading (after crack initiation). Generally, if the path integration crosses over the homogeneous weld metal, but with higher strength, J-solution is more conservative. Most conservative approach presents plane strain assumption (J1-PE state curve). Effects of the state-of-stress assumption and chosen path on the J-integral value are cancelling mutually for the maximum load. As a consequence we have the same result for J (see the figure). One can conclude that J-integral is less path dependent under PE conditions. However, this conclusion may lead to underestimation of J-integral value. Average 3-D numerical solution of J-integral should to be much closer to experimental value, because takes the thickness effects into account. J-int, N/mm 160 * 120 J1 (PS state) J1 (PE state) J2 (PS state) J2 (PE state) 80 * * * 40 * * experiment 0 0 40 80 120 160 F, kN Figure 2. J-integral values for J1 and J2 paths with presumption of PS or PE state 6. REFERENCES [1] Yuan, H., Brocks, W.: On the J-integral concept for elastic-plastic crack extension, Nuclear Engineering and Design 131, 1991, pp 157-173, [2] Schwalbe, K.H.: Ductile crack growth under plane stress conditions: size effects and structural assessment – I. Size and geometry effects on crack growth resistance, Engineering Fracture Mechanics, Vol. 42, No. 2, 1992, pp 211-219, [3] Shan, G.X., Kolednik, O., Fischer, D.: On constraint effects in fracture – A numerical study, Acta Mechanica Solida Sinica, Vol. 8, S. Issue, 1995., [4] Alfirević, I., Matejiček, F., Kozak, D.: State-of-stress modelling in an inhomogeneous SENB fracture toughness specimens, 18th Danubia-Adria Symposium, Steyr, 2001., [5] Rice, J.R.: A path independent integral and the approximate analysis of strain concentrations by notches and cracks, Journal of applied mechanics, Transactions of ASME E35, 1968, pp. 379-386. [6] Sedmak, A.: The role of weldment interfaces in fracture mechanics parameters evaluaton, International Conference on Fracture 9, Sydney, 1997., [7] ANSYS, User’s Manual Rev. 5.6, Swanson Analysis System Inc., 1999., [8] Gubeljak, N.: The effect of strength mis-match on welded joint fracture behaviour, Dissertation (in English), University of Maribor, 1998., [9] Wang, Y.-Y., Gordon, J.R.: The limits of applicability of J and CTOD estimation procedure for shallow cracked SENB specimens, in Shallow Crack Fracture Mechanics, Toughness Tests and Applications, M.G.Dawes Ed’s,. Cambridge, UK, September 23-24, 1992.