bond and shear behavior of concrete beams

advertisement

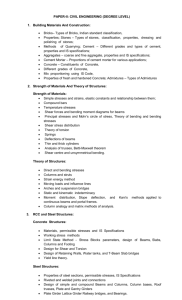

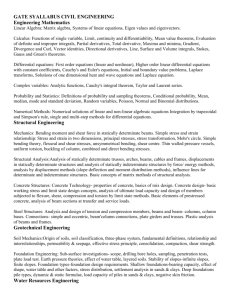

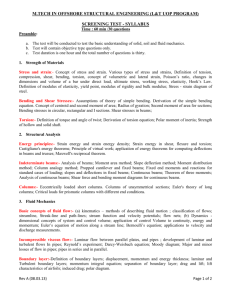

1 BOND AND SHEAR BEHAVIOR OF CONCRETE BEAMS 2 CONTAINING LIGHTWEIGHT SYNTHETIC PARTICLES 3 Matthew J. Heiser, Amr Hosny, Sami H. Rizkalla, and Paul Zia 4 5 Corresponding Author 6 7 8 9 10 11 12 13 Sami H. Rizkalla North Carolina State University Constructed Facilities Laboratory (CFL) 2414 Campus Shore Dr. Raleigh, NC 27695-7533 Email: sami_rizkalla@ncsu.edu Phone: 919-513-1733 14 Biography: 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 ACI Member Matthew J. Heiser is a graduate Research Assistant at the Civil, Construction and Environmental Engineering Department, North Carolina State University. He received his B.Sc. degree in 2008 and is expected to complete his Master of Science degree in December 2010 from North Carolina State University. ACI Member Amr Hosny is a PhD candidate in the Civil, Construction and Environmental Engineering Department, North Carolina State University. He received his M.Sc. in 2007 from NC State University and his B.Sc. from Ain Shams University, Egypt in 2004. ACI Fellow Sami H. Rizkalla is a Distinguished Professor of Civil and Construction Engineering in the Department of Civil, Construction, and Environmental Engineering, North Carolina State University, where he also serves as the Director of the Constructed Facilities Laboratory and NSF I/UCRC in Repair of Structures and Bridges with Composite (RB2C). He is also a fellow of ACI, ASCE, CSCE, EIC,IIFC and PCI. ACI honorary member Paul Zia is a Distinguished University Professor Emeritus at North Carolina State University. He served as ACI President in 1989, and is a member of several ACI committees including ACI 363, High-Strength Concrete; joint ACI ASCE 423, Prestressed Concrete; ACI 445, Shear and Torsion; the Concrete Research Council; and TAC Technology Transfer Committee, serving as chairman of its ITG-6. 36 1 1 ABSTRACT 2 This paper summarizes a comprehensive experimental program that investigated the bond 3 and shear behavior of concrete beams containing Lightweight Synthetic Particles (LSP). LSP is 4 a new concrete additive that, when used, leads to reduced unit weight of concrete, enhances 5 flowability of the fresh concrete for pumping purposes and produces durable concrete for 6 freeze/thaw and deicing exposed conditions. It also reduces the thermal conductivity (increase 7 R-value), thus reducing the energy required for heating and cooling. Use of these specially 8 formulated particles, in combination with normalweight aggregates could reduce the unit weight 9 of concrete by 10 to 20%, ranging from 120 to 130 pcf (1920 to 2080 kg/m3) depending on the 10 amount of LSP used in the concrete mixture. The experimental program included 27 large-scale 11 specimens. Research findings indicate that the bond and shear behavior of beams with LSP 12 additive is similar to the behavior of beams made by normalweight concrete. Test results confirm 13 that ACI 318-08 can be used for the design of LSP concrete members for shear and the 14 development length of steel reinforcement without the use of the reduction factor λ required for 15 lightweight concrete. 16 Keywords: 17 Particles beams, shear, additive, reduced unit weight concrete, Lightweight Synthetic 18 19 20 INTRODUCTION ACI 318-081 defines normalweight concrete as concrete containing aggregates that 21 conform to ASTM C332 with a unit weight between 135 and 160 lb/ft3 (2160 and 2560 kg/m3). 22 ACI 318-08 also defines lightweight concrete as concrete containing only lightweight aggregates 23 conforming to ASTM C3303 with a unit weight between 90 and 115 lb/ft3 (1440 and 2 1 1840 kg/m3). The Lightweight Synthetic Particles4 (LSP) are polymer spheres with a closed cell 2 inner structure containing air. They are inert and hydrophobic. They have a maximum sphere 3 diameter of 0.25 inches (6.4 mm), and a specific gravity of 0.042. They are specially formulated 4 for use with concrete with the ability to disperse uniformly in the concrete resulting in a reduced 5 concrete density. In general they are added to concrete as a partial replacement for conventional 6 fine or coarse aggregate. These specially formulated particles are considered as an additive since 7 they do not conform to either ASTM C33 or ASTM C330. Therefore, concrete made with 8 normalweight aggregates and LSP as an additive to reduce the unit weights is regarded as a 9 normalweight concrete with “reduced” density. 10 This paper summarizes the findings of an extensive research program conducted to 11 examine compliance to ACI 318-08 code for the bond and shear behavior of concrete members 12 containing LSP. A parallel study by the authors to evaluate the material characteristics of LSP 13 concrete indicates that, for a given mix design, as the amount of LSP is increased in the concrete 14 mix to reduce the concrete density, the compressive strength of concrete is reduced. For 15 example, when the concrete density was reduced from 145 lbs/ft3 without LSP to 130 lbs/ft3 with 16 LSP, the compressive strength of concrete was reduced by 30 percent from the original 17 compressive strength of 5740 psi (39.6 MPa). When the concrete density was further reduced to 18 120 lb/ft3, the compressive strength was reduced by 50 percent. In all cases, the tensile strength 19 and the modulus of elasticity of the LSP concrete correlated well with the predictions by the ACI 20 318-08 equations using the corresponding compressive strength and density. It should be noted 21 that by adjusting the basic mix design, one could achieve the desired structural strength after LSP 22 is added. The product is being used commercially for structural concrete ranging from 130 lb/ft3 23 to 105 lb/ft3 unit weight with 28-day compressive strengths ranging from 3000 psi to 6000 psi. 3 1 The experimental program presented in this paper consisted of 27 large-scale specimens, 2 tested under static loading up to failure. Research findings indicate that design of concrete 3 members containing LSP for bond and shear can use the provisions of ACI 318-08 for 4 normalweight concrete and the modification factor λ in the code, normally associated with 5 lightweight concrete, is not applicable in this case for concrete with LSP additive. 6 The first phase of the research program investigated the bond behavior of eighteen large- 7 scale specimens consisting of both slabs and beams. The second phase investigated the shear 8 behavior of nine large-scale beams, each end of a beam being tested to replicate the results, thus 9 providing a total of eighteen tested specimens. Test results showed that the structural behavior of 10 concrete containing LSP additive with unit weight between 120 and 130 lb/ft3 (1920 and 11 2080 kg/m3) was similar to that of normalweight concrete. 12 13 RESEARCH SIGNIFICANCE 14 Reduced unit weight concrete using Lightweight Synthetic Particles (LSP) additive has 15 several structural and economical advantages in comparison to normalweight and lightweight 16 concrete. The addition of LSP to a concrete mixture has been shown to reduce pumping 17 pressures of fresh concrete, to improve the thermal resistance and reduce the unit weight for the 18 hardened concrete. The research presented in this paper provides the data and demonstrates that 19 the ACI 318-08 code provisions can be used for the design of structural concrete members 20 containing LSP additive and normalweight aggregates without the modification factor λ 21 associated with lightweight concrete when the concrete unit weight is 120 lb/ft3 or greater. 22 23 EXPERIMENTAL INVESTIGATION 4 1 The overall experimental program consisted of twenty-seven large-scale reinforced 2 concrete specimens, tested under static loading up to failure. The first phase of the program 3 included twelve beams and six slabs tested to evaluate the bond characteristics of the LSP 4 concrete. The second phase included nine beams to evaluate the shear behavior of the concrete 5 with each beam being tested once at each end to replicate the test results. 6 reinforcement used had a specified minimum yield strength of 60 ksi (415 MPa), according to 7 ASTM A615/A615M5 specifications. 8 Phase 1: Bond Behavior of LSP Concrete Members The steel 9 Bond behavior of concrete members with LSP additive was evaluated using twelve 10 beams and six slabs. The beam specimens were divided into three main groups using two 11 targeted unit weights, 120 lb/ft3 (1920 kg/m3) for Group 1 and 130 lb/ft3 (2080 kg/m3) for 12 Group 2. The slab specimens had targeted unit weight of 130 lb/ft3 (2080 kg/m3) and were 13 classified as Group 3. The targeted concrete compressive strength for the specimens within 14 Group 1 was 2500 psi (20 MPa) and was 4000 psi (30 MPa) for specimens in Group 2 and 15 Group 3. All tested beams had cross sectional dimensions of 12 x 18 in. (305 x 457 mm) and a 16 total length of 16 ft. (4877 mm) as shown in Figure 1. All tested slabs had cross sectional 17 dimensions of 18 x 8 in. (457 x 203 mm) with a total length of 16 ft. (4877 mm). Within each 18 group the tension splice length of the reinforcement was designed according to ACI 318-08 19 based on the targeted concrete strengths of 2500 or 4000 psi (20 or 30 MPa). The specimens 20 were constructed using splice lengths equal to 0.75Ld, 1.0Ld and 1.25Ld, where Ld is the splice 21 length determined by ACI 318-08 code requirements. 22 reinforcement consisted of #3 closed stirrups designed according to ACI 318-08 requirements, For the beams, all transverse 5 1 with an extension of six times the bar diameter past the 90-degree bend. Two specimens were 2 fabricated and tested for each of the selected splice lengths for repeatability of test results. 3 The bond specimens given in Table 1 are identified using three parameters: the first 4 letter “B” stands for bond specimens, the second identifies the targeted unit weight of concrete in 5 pounds per cubic feet “120 or 130”. The third number identifies the specimen within each group 6 and ranges from 1 to 3. A letter “R” indicates the replicate specimens. The letter “S” was used 7 to designate the slab specimens. 8 The test setup and cross sectional dimensions for beams and slabs are shown in Figure 1. 9 All beams and slabs were tested using a four point bending setup to develop a constant moment 10 region at the location of the spliced bars. The length of the beams and the slabs was kept 11 constant at 16 ft. (4877 mm). 12 (1829 mm) with two outer shear spans of 4.5 ft. (1372 mm) each. The beams were supported at 13 both ends using composite steel sections restrained to the floor. A 150 kip (670 kN) load cell 14 was placed at one end of the beams to measure the reaction at the support, while the loads were 15 applied using four hydraulic jacks, two at each location, with a capacity of 120 kip (535 kN) 16 each. Vertical deflections were measured using string potentiometers located at the mid-span of 17 the test specimen. The test setup allowed a constant moment region of 6 ft. 18 The ready mix concrete supplied by a local concrete producer consisted of Lehigh Type I 19 cement, Class F fly ash, ASTM C33 natural sand, #78 granite, the LSP concrete additive 20 commercially known as Elemix® XE concrete additive4, and standard HRWR. Compressive 21 strength of the concrete was determined using 4 x 8 in. (102 x 204 mm) cylinders cured in the 22 same environment as the test specimens. Table 2 provides the mix design of the two concrete 23 mixtures. 6 1 Test Results 2 Material Properties — Table 3 summarizes the measured compressive strength of the 3 concrete at 28 days and on the day of testing for both the bond and the shear study. It should be 4 noted that the concrete produced for the first cast according to the given mix design resulted in 5 both higher unit weight and higher compressive strength than the targeted values. It is believed 6 that the moisture content of the sand measured at the ready mixed concrete plant was higher than 7 the actual moisture content, making the total water less than designed, which led to a lower water 8 to cement ratio and consequently higher concrete compressive strength. 9 Tension coupons from the Grade 60 steel reinforcement were tested according to ASTM 10 A370-096 to determine the material characteristics. The typical coupon length was 2 ft. (610 mm) 11 taken from the same batches of the longitudinal reinforcement used in the beams. The #9 12 (No. 29) bars used as the longitudinal reinforcement and the #3 (No. 16) bars used as the 13 transverse reinforcement of the bond specimens had yield strengths of 74 ksi (510 MPa) and 69 14 ksi (476 MPa), respectively. The yield strength of the #5 bars used as the longitudinal 15 reinforcement in the slabs for bond tests was 61 ksi (421 MPa). 16 Load-Deflection Behavior — The load-deflection relationship of the tested beams in the 17 second group is shown in Figure 2. Test results indicate that the beams with splice length shorter 18 than the required splice length failed before achieving their full design capacity. When the full 19 splice length was provided, the beams were able to achieve their design capacity but failed due to 20 splitting without providing much ductility. 21 required splice length up to 1.24Ld, the beams achieved the flexural strength and a sufficient 22 level of ductility. Similar behavior was observed for the beams tested in the first group and the 23 slabs in the third group. When the provided splice length exceeded the 7 1 Crack Width — Crack width was measured by using PI gages located at the ends of the 2 splice and at mid-span of the specimens. A crack comparator was also used to measure the crack 3 width at different load levels. It was observed that in all cases the first flexural cracks developed 4 at the two ends of the splice zone, at the maximum moment and shear locations. As the load was 5 increased, the flexural cracks propagated towards the compression zone and increased in number 6 and width. Further increase in the applied load led to the formation of splitting cracks parallel to 7 the longitudinal bars, initially on the tension surface of the beam, followed by splitting cracks on 8 the side of the beam. Measurement using the crack comparator was discontinued after yielding 9 of the longitudinal reinforcement, however, PI gage measurements showed that with adequate 10 development length according to the ACI 318-08 code, the yield strength of the longitudinal bar 11 was fully developed and the beam achieved considerable ductility. Figure 3 shows the width of 12 the splitting crack and the applied loads for first group of beams reinforced with No.9 (No. 29) 13 bars. The test results indicate that the splitting cracks occurred at the same range of load level for 14 all tested beams of the same group. The initiation of the splitting cracks occurs when the stresses 15 in the spliced bars induce forces in the concrete cover equal to the tensile strength of the 16 concrete. The figure shows also that as the load was increased, widths of the splitting cracks 17 were larger for the shorter splice lengths. This was due to the higher stresses induced in the 18 longitudinal bars with shorter splices in comparison to the bars with longer splice length at the 19 same load levels and consequently higher induced strains in the steel and the surrounding 20 concrete causing wider cracks. 21 Splice Strength —Two different modes of failure were observed for the bond specimens. 22 The first mode was splitting failure, characterized by the formation and propagation of splitting 23 cracks parallel to the longitudinal bars along the splice length as shown in Figure 4. Such failure 8 1 is generally sudden and brittle. The second mode of failure was typical flexural failure initiated 2 by the yielding of reinforcement, followed by final crushing of the concrete in the compression 3 zone. A summary of the test results for Phase I of the experimental program is presented in 4 Table 1. 5 The test results presented in Table 1 indicate that when the provided development length 6 was equal to or more than the required by the ACI 318-08 code using the measured material 7 properties, the specimens were able to achieve their respective nominal flexural capacity after 8 yielding of the longitudinal reinforcement as indicated by the strain measurements. When the 9 provided development length was less than the required value, the specimens showed bond 10 failures with slightly less capacity in comparison to the predicted nominal flexural strengths. 11 The test results clearly confirm compliance of the LSP concrete to the ACI 318-08 provisions for 12 development length of the flexural reinforcement. It should be noted that an increase in the 13 splice length does not necessarily increase the load carrying capacity of the beam due to the 14 nonlinear stress distribution along the splice length7 and increase only the ductility as shown in 15 Figure 2. For example, in Table 3, although the development length increased from 33 in. (838 16 mm) in Beam B-120-2-R to 41 in. (1041 mm) in Beam B-120-3-R, the load carrying capacity 17 increased by only 4 percent. 18 Phase II: Shear Behavior of LSP Concrete Members 19 Shear behavior of reinforced concrete beams containing LSP was evaluated using nine 20 beams, each tested twice, for a total of eighteen tests. The specimens were divided into three 21 main groups with two targeted unit weights, 120 and 130 lb/ft3 (1920 and 2080 kg/m3). Similar 22 to the bond investigation, target compressive strengths of 2500 and 4000 psi (20 and 30 MPa) 23 were selected for the 120 and 130 lb/ft3 (1920 and 2080 kg/m3) groups, respectively. Two 9 1 additional parameters considered in the experimental program were the shear span-to-depth ratio, 2 a/d, and the transverse reinforcement ratio, ρt. The beams were designed according to ACI 318- 3 08 provisions for shear and flexure and the design ensured a shear-controlled failure mode. 4 Some of the beams were designed without transverse reinforcement to evaluate the concrete 5 contribution to shear strength, Vc, while others were designed with minimum and maximum 6 allowable transverse reinforcement ratios as specified by ACI 318-08 to cover the two levels of 7 shear capacities. Table 4 provides details of the beams tested in shear. Each beam specimen was 8 identified by four parameters: 9 identifies the targeted unit weight in pounds per cubic feet “120 or 130”, the third parameter 10 defines the transverse reinforcement ratio “0%, 0.25% and 0.5%” for the beams without 11 transverse reinforcement, with minimum and maximum stirrups, respectively. A number “1.5” 12 following the transverse reinforcement ratio refers to the shear span-to-depth ratio of 1.5 which 13 is different from the beams tested with shear-span-to-depth ratio of 3.0 in the first two groups. the first letter “S” stands for shear specimens, the second 14 The test setup and cross sectional dimensions for all shear tests are shown in Figure 5. 15 Two test setups were used, one for each of the selected shear-span-to-depth ratios, a/d. The test 16 setup was designed to allow each end of a beam to be tested so that the test can be replicated. 17 The first setup was used to test the first and second groups of beams with a/d of 3.0 by locating 18 the applied point load at a distance “a” of 43 in. (1092 mm) from the left support as shown in 19 Figure 5. The second setup was used to test the third group of beams with a/d of 1.5 and the 20 single applied load at a distance “a” of 22 in. (559 mm) from the left support as show in Figure 5. 21 The untested portion of each beam was cantilevered over the right support. Load was applied by 22 using a 440 kip (1960 kN) capacity hydraulic actuator supported by a steel frame that was 23 securely anchored to the laboratory strong floor. The load provided by the actuator was 10 1 transferred by a single steel loading plate that measured 1 in. (25 mm) thick by 8 in. (203 mm) 2 wide. The beams were simply supported by a steel pin and 1 in. (25 mm) thick bearing plate at 3 the left end support and a steel roller and 1 in. (25 mm) thick bearing plate at the right support. 4 For each test setup, two 200 kip (890 kN) capacity load cells were placed under the left support 5 to measure the reaction, which represented the maximum shear forces within the short shear span 6 under consideration. One linear variable differential transducer (LVDT) was used at the top 7 surface of the beam at both supports to measure any possible deflection at the support. Vertical 8 beam deflections were measured by two string potentiometers placed directly under the beam at 9 the location of the actuator, and 1.5 in. (38 mm) from the edge. Crack widths and the strains in 10 selected stirrups were measured by using PI gages and weldable strain gages, respectively. PI 11 gages were arranged in a rosette configuration to capture most of the cracks within the shear span 12 region. For test specimens in Group 1 and Group 2, three PI gage rosettes were arranged 13 diagonally between the applied load and the left support reaction as shown in Figure 6(a) while 14 only 2 PI rosettes were used for the shorter beams of Group 3. On the opposite face of the test 15 specimen, PI gages were arranged vertically, at the location of selected stirrup located within the 16 shear span region as shown in Figure 6(b). Stirrup strains were measured using weldable strain 17 gages placed on some selected stirrups within each beam. 18 The same concrete mix designs given in Table 2 were used for the shear specimens. 19 Table 3 also summarizes the measured concrete compressive strength at 28 days and at the day 20 of testing for the shear specimens. Tension coupons for the Grade 60 reinforcing steel were 21 tested according to ASTM A370-09 using 2 ft. (610 mm) coupons that were taken from the same 22 batches of the transverse reinforcement used in the beams and had yield strength of 69 ksi (476 23 MPa). 11 1 Test Results 2 Load-Deflection Behavior — The load-deflection behavior of beams with LSP concrete 3 was similar to that of beams of normal concrete reported in the literature8. The beams without 4 transverse reinforcement failed shortly after initiation of the first diagonal cracks. Test beams 5 with transverse reinforcement were able to sustain higher load levels as shown in Figure 7 for the 6 beams of Group 2. The load at the formation of the first critical diagonal crack for members 7 without shear reinforcement was taken as the concrete contribution to shear resistance Vc for all 8 beams within the same group. It can be observed from Figure 7 that by increasing the transverse 9 reinforcement ratio from 0.25% to 0.5% the shear resistance of the beams was increased. The 10 shear at failure for the specimens with shear reinforcement was taken as the nominal shear 11 strength, Vn. The steel contribution to the shear strength, Vs, was simply determined as the 12 difference of (Vn – Vc). The load-deflection behavior of the beams in Group 3 is shown in 13 Figure 8. From this curve it can be observed that the behavior of the specimens within Group 3 14 is quite different from those within Group 1 and Group 2 shown in Figure 7. This is due 15 primarily to the small shear span-to-depth ratio of this category of beams and the formation of a 16 compression strut mechanism in resisting the applied shear. This arching action mechanism is the 17 cause of the significant increase in the shear capacity of the beams within Group 3, especially for 18 those without transverse reinforcement. 19 Cracking Behavior — Cracking on the side of the beam was measured using PI gage 20 rosettes within the shear span, “a”, while cracking on the opposite side of the beam was 21 measured using the vertical PI gages as shown in Figure 6. Crack width comparators were also 22 used to measure the crack width at different load levels. It was observed that initiation of the 23 first flexural cracks occurred at the location of maximum bending moment directly under the 12 1 applied load. Flexural cracks propagated upwards and increased in number and width as the load 2 was increased. 3 Formation of shear cracks was dependent on the presence of shear reinforcement and the 4 a/d ratio. For beams with shear reinforcement and a/d ratio of 3.0, the first shear cracks appeared 5 as an extension of the flexural shear cracks in the diagonal direction. When the applied load was 6 increased, new diagonal shear cracks formed and were observed on both sides of the tested 7 beam. In this study, failure of the beams was determined when the beam was no longer able to 8 sustain any increase in the applied load. For the beams without transverse reinforcement, once 9 the first shear crack appeared, it propagated diagonally through the shear span and suddenly 10 increased in width by a slight increase in applied load before failure. For beams with shear 11 reinforcement, once the first diagonal tension crack occurred, measurements of the strain in the 12 stirrups, using the weldable strain gages, clearly indicated participation of the stirrups in resisting 13 the applied load. The presence of the stirrups controlled the increase in width of the diagonal 14 tension crack, which led to the formation of multiple diagonal cracks within the shear span. 15 Cracking behavior for specimens with no stirrups, minimum stirrups and maximum stirrups are 16 shown in Figure 9. The figure clearly indicates a single diagonal crack, spanning from the 17 location of the applied load to the support for the beams without stirrups and multiple diagonal 18 cracks for the beams with stirrups. Figure 10 shows the measured width of the diagonal shear 19 crack using the crack comparators for the second group of beams with a/d ratio of 3.0. It should 20 be noted that the graph does not include the beams without transverse reinforcement as these 21 beams failed suddenly after the initiation of the diagonal crack. The graph also shows the effect 22 of the transverse reinforcement ratio in controlling the crack width. It can be seen that for the 23 same load level, the beams with the minimum transverse reinforcement ratio had a wider crack 13 1 width compared to the beams with the maximum transverse reinforcement ratio. Increase of the 2 crack width is expected due to the high stresses induced in the stirrups of the beams with the 3 minimum transverse reinforcement ratio in comparison to the beams with the higher transverse 4 reinforcement ratio at any given load. The higher stress levels correspond to higher strains in the 5 stirrups and thus wider cracks in the concrete. 6 Failure Mode — The failure mode of each group of test beams was highly dependent on 7 the a/d ratio. For Group 1 and Group 2, specimens with a/d ratios of 3.0, the failure mode was 8 also affected by the amount of transverse reinforcement used. For beams without transverse 9 reinforcement the failure mechanism occurred as a single shear crack that extended from the 10 support to the location of applied load. The typical failure observed for beams with shear 11 reinforcement was due to crushing of the concrete at the nodal region of the diagonal 12 compression strut well after the formation of many diagonal cracks within the shear span. 13 The behavior of Group 3 specimens with a/d ratio of 1.5 was controlled, as expected, by 14 stirrup spacing within the member. For the beams without transverse reinforcement, failure 15 occurred at much higher than anticipated loads due to arching action within the short span. For 16 the beams with the minimum amount of transverse reinforcement, although arching action 17 controlled the short shear span, flexural shear failure was observed in the longer shear span in the 18 uninstrumented side of the beam when the load carrying capacity of that side was reached. When 19 the transverse reinforcement ratio was increased, the load carrying capacity of the longer shear 20 span was increased and failure was due to arching action within the short shear span of the beam. 21 The measured ultimate loads are significantly higher than the predicted values according to the 22 ACI 318-08 design equations. However, when the strut and tie method is used as recommended 23 by ACI 318 code for low shear-span-to-depth ratios, the behavior is accurately predicted. 14 1 The results from the 18 shear tests are summarized in Table 4, which shows the 2 maximum measured shear force in comparison to the ACI 318-08 predicted values. Since the 3 beams were designed to have a shear failure, the longitudinal reinforcement was increased to 4 avoid premature flexural failure. To account for the increase of the flexural reinforcement, the 5 concrete contribution to the shear strength, Vc, was predicted by using the following ACI 318-08 6 equation 11-5, which accounts for the effect of the longitudinal reinforcement ratio, ρw. Vd Vc 1.9 fc' 2500 w u bw d Mu 7 where; is a reduction factor used with the lightweight concrete, and was assumed unity for the 8 the LSP concrete, Vu and M u are the ultimate shear force and moment, respectively, at the 9 section considered, bw is the width of the member and d is the depth from the centroid of the 10 longitudinal reinforcement to the extreme compression fiber. For the beams with a/d ratio of 3.0, 11 the table shows a very close correlation between the measured and predicted shear force for the 12 case without transverse reinforcement. With transverse reinforcement, the average measured / 13 predicted ratio becomes 1.20 with a coefficient of variation of 0.14, which shows that the ACI 14 318-08 provisions for shear can be safely used for the design of structural members with LSP 15 additive. For the beams with a/d ratio of 1.5, the measured to the predicted shear strength 16 according to ACI 318-08 was significantly higher due to the arching action mechanism 17 developed for this category of beams. 18 19 SUMMARY AND CONCLUSIONS 15 1 Based on the test results of the experimental program and the comparisons to the ACI 2 318-08 provisions for shear and development of reinforcement, the following conclusions may 3 be drawn. 4 1. The concrete containing the LSP additive used in this investigation, with unit weights 5 ranging between 120 and 130 lb/ft3 (1920 and 2080 kg/m3), achieved comparable 6 compressive strength to what is commonly used for structural applications. 7 2. Concrete containing LSP additive was flowable and had good workability. 8 3. The load-deflection characteristics and the crack pattern of the beams and slabs tested in 9 this experimental program were similar to the expected behavior of beams and slabs 10 11 12 13 14 using normalweight concrete. 4. Cracked section analysis used to predict the behavior of regular concrete could be used to predict the behavior of concrete members produced with LSP additive. 5. ACI 318-08 equations could be applied for the design of the tension splice required to develop the design strength of the reinforcement at a critical section. 15 6. Analysis of the bond specimens accurately predicted the behavior of all tested beams. 16 With sufficient splice length, the beams were capable of achieving their load carrying 17 capacity. 18 concrete additive met the bond requirements specified by ACI 318-08. 19 20 The results confirmed that the bond strength of beams containing LSP 7. The beams with the LSP concrete additive satisfy the shear design requirements of the ACI 318-08 building code. 21 8. The test results also confirmed that, for structural design of LSP concrete containing 22 normalweight aggregates, the reduction factor λ normally used for the lightweight 16 1 concrete, need not be applied for LSP concrete with unit weight equal to or higher than 2 120 lb/ft3 (1920 kg/m3). 3 Further research is still required to provide confidence in the use of LSP as an additive to 4 reduce the concrete density. Due to the limited number of bond and shear specimens used in this 5 study, additional tests to include a wider range of concrete densities would be desirable. Whether 6 the use of LSP in a concrete mixture will affect the long-term bond and shear behavior of 7 concrete members is a question that remains to be investigated. 8 9 ACKNOWLEDGEMENTS 10 The authors would like to thank NOVA Chemicals Inc. for their financial assistance and for 11 providing the Elemix® XE concrete additive for construction of the test specimens. The 12 authors would also like to thank Argos USA for supplying the ready mix concrete of the 13 research program. Special thanks go to the staff at the Constructed Facilities Laboratory, 14 including J. Atkinson, J. McEntire, G. Lucier, and M. Dawood for their invaluable help. 15 16 17 18 19 20 21 22 REFERENCES 1. ACI Committee 318, 2008, “Building Code Requirements for Structural Concrete (ACI 318-08) and Commentary,” American Concrete Institute, Farmington Hills, MI, 465 pp. 2. ASTM C33/C33M, 2008, “Standard Specifications for Concrete Aggregates,” ASTM International, West Conshohocken, PA, 11 pp. 3. ASTM C330/C330M, 2005, “Standard Specification for Lightweight Aggregates for Structural Concrete”, ASTM International, West Conshohocken, PA, 4 pp. 17 1 2 4. NOVA Chemicals Inc., 2008, “Elemix Concrete Additive”. Retrieved February 19, 2010, from http://www.elemix.com/. 3 5. ASTM A615/A615M, 2009, “Standard Specification for Deformed and Plain Carbon- 4 Steel Bars for Concrete Reinforcement,” ASTM International, West Conshohocken, PA, 5 6 pp. 6 7 8 9 10 11 6. ASTM A370, 2009, “Standard Test Methods and Definitions for Mechanical Testing of Steel Products (REV A),” ASTM International, West Conshohocken, PA, 47 pp. 7. Canbay, Erdem and Frosch, Robert J., 2005, “Bond Strength of Lap-Spliced Bars”, ACI Structural Journal, V. 102, No. 4, July-August, pp. 605-614. 8. Wight, James K. and MacGregor, James G., 2009, Reinforced Concrete Mechanics & Design (5th Ed.), Prentice Hall, New Jersey. 12 18 1 2 TABLES AND FIGURES 3 List of Tables: 4 Table 1 – Test results of the bond experimental program 5 Table 2 – Typical concrete mix design 6 Table 3 – Concrete strength for test specimens 7 Table 4 – Test results of the shear experimental program 8 9 List of Figures: 10 Figure 1 - Test setup used for bond beams and slabs 11 Figure 2 - Load deflection relationship for Group 2 bond beams 12 Figure 3 - Splitting crack width for beams of Group 1 13 Figure 4 - Splitting failure of beam B-130-2-R 14 Figure 5 - Typical shear beam cross section and test setup 15 Figure 6 - Location of PI gage rosettes and PI gages on the back of the shear beams 16 Figure 7 - Shear load deflection behavior for Group 2 shear beams 17 Figure 8 - Shear load deflection behavior for Group 3 shear beams 18 Figure 9 - Typical shear cracking behavior 19 Figure 10 - Shear crack width for the beams of Group 2 20 21 19 1 Table 1: Test results of the bond experimental program fc fy ld,required ld,provided Beam ID psi ksi in [MPa] [MPa] [mm] B-120-1 B-120-1-R B-120-2 6000 74 B-120-2-R [41.4] [510] 32.3 [818] B-120-3 B-120-3-R B-130-1 B-130-1-R B-130-2 5500 74 B-130-2-R [37.9] [510] 33.8 [859] B-130-3 B-130-3-R B-130-1-S B-130-1-R-S B-130-2-S 6000 61 [41.4] [421] B-130-2-R-S B-130-3-S B-130-3-R-S 11.8 [300] in [mm] Ratio of ld,provided to ld,required 31.0 [787] 0.96 41.0 [1041] 1.27 51.0 [1295] 1.58 26.0 [660] 0.77 33.0 [838] 0.98 41.0 [1041] 1.21 11.0 [279] 0.93 15.0 [381] 1.27 18.0 [457] 1.52 Predicted failure load kip [kN] 40.1 [178] 39.9 [177] 6.1 [27] Maximum Measured measured / load Predicted load kip [kN] Mode of failure Yield Strain Maximum measured strain in/in in/in 37.8 [168] 0.94 Splitting 0.0030 31.5 [140] 0.79 Splitting 0.0024 40.3 [179] 1.00 Flexural 0.0060 0.0026 40.6 [181] 1.01 Flexural 0.0060 39.2 [174] 0.98 Flexural 0.0060 39.5 [176] 0.99 Flexural 0.0060 31.8 [141] 0.80 Splitting 0.0022 34.8 [155] 0.87 Splitting 0.0023 38.2 [170] 0.96 Splitting 0.0027 0.0026 38.4 [171] 0.96 Splitting 0.0026 39.8 [177] 1.00 Flexural 0.0060 40.2 [179] 1.01 Flexural 0.0060 5.8 [26] 0.95 Splitting 0.0021 6.4 [28] 1.05 Splitting 0.0060 7.1 [32] 1.16 Splitting 0.0026 0.0021 6.7 [30] 1.10 Splitting 0.0060 7.3 [32] 1.20 Flexural N/A 7.8 [35] 1.28 Flexural 0.0060 2 3 4 20 1 Table 2: Typical concrete mix design Target Unit Weight Class F Natural Fly Ash Sand #78 Granite lb/cy (kg/m3) lb/cy (kg/m3) lb/cy (kg/m3) lb/cy (kg/m3) lb/cy (kg/m3) W/CM lb/ft3 (kg/m3) Elemix Concrete AdditiveType XE Cement Water Reducer HRWR oz/cwt oz/cwt (ml/100kg) (ml/100kg) By Weight 120 (1922) 0.4 752 (446) 188 (112) 1380 (819) 722 (428) 9 (5.34) 4 (261) 3 (196) By Weight 130 (2082) 0.4 677 (402) 200 (119) 1675 (994) 914 (542) 4 (2.37) 4 (261) 5 (326) 2 3 4 Table 3: Concrete strength for test specimens Specimens Cast Bond Beams Target U.W. = 120 pcf Bond Beams Target U.W. = 130 pcf Bond Slabs Target U.W. = 130 pcf Shear Beams Target U.W. = 120 pcf Shear Beams Target U.W. = 130 pcf Compressive Strength psi (MPa) Measured Unit Weight lb/ft3 (kg/m3) Target f 'c fc Day of Testing 126.6 (2030) 2500 (20.0) 5660 (39.0) 6000 (41.4) 132.6 (2125) 4000 (30.0) 5000 (34.5) 5500 (37.9) 131.2 (2105) 4000 (30.0) 5470 (37.7) 6000 (41.4) 120.2 (1925) 2500 (20.0) 3620 (25.0) 4120 (28.4) 131.1 (2100) 4000 (30.0) 5930 (40.9) 6890 (47.5) 5 6 21 1 Table 4: Test results of the shear experimental program VC Beam Max Measured Shear kip [kN] S-120-0% VS fc Measured Predicted Measured Measured Predicted Measured Predicted Measured vs vs vs Predicted Predicted Predicted psi kip kip kip kip kip [MPa] [kN] [kN] [kN] [kN] [kN] 35 [156] a/d =3.0 Group 1 S-120-0%-R 43 [191] S-120-0.25% 93 [414] 4150 [28.6] 39 [173] 36 [160] 54 [240] 1.08 S-120-0.25%-R 83 [369] S-120-5% 126 [560] 87 [387] S-120-0.5%-R 124 [552] 85 [378] S-130-0% 41 [182] 44 [196] Group 2 S-130-0%-R 38 [169] S-130-0.25% 97 [431] 6750 [46.5] 40 [178] 42 [187] 57 [254] 0.95 S-130-0.25%-R 104 [463] S-130-0.5% 130 [578] 90 [400] S-130-0.5%-R 132 [587] 92 [409] S-130-0%-1.5 153 [681] 64 [285] a/d=1.5 Group 3 S-130-0%-1.5-R 206 [916] S-130-0.25%-1.5 194 [863] S-130-0.25%-1.5-R 159 [707] S-130-0.5%-1.5 Vn 6970 [48.1] 56 [249] 42 [187] 138 [614] 1.32 103 [458] 214 [952] 158 [703] S-130-0.5%-1.5-R 215 [956] 159 [707] - 31 [138] 62 [276] - 31 [138] 62 [276] - 31 [138] 62 [276] 1.73 1.42 1.39 1.36 1.82 2.05 1.43 1.47 4.40 3.29 2.53 2.54 36 [160] 67 [298] 99 [440] 42 [187] 73 [325] 104 [463] 42 [187] 74 [329] 105 [467] 0.97 1.18 1.38 1.24 1.28 1.26 0.97 0.92 1.32 1.42 1.24 1.26 3.61 4.87 2.63 2.16 2.04 2.05 2 3 4 22 192" (4877mm) 12" (305mm) 54" (1372mm) 72" (1829mm) 54" (1372mm) Splice Length 1.5" (38mm) A 1.5" (38mm) 4 #9 (No. 29) 18" (457mm) 2 #6 (No. 19) A #3 @ 6.0" (No. 10 @ 152mm) P 1.5" (38mm) P Section A-A Bond Beam 192" (4877mm) 72" (1829mm) 54" (1372mm) 54" (1372mm) 18" (457mm) 1.5" (38mm) Splice Length B 6 #5 (No. 16) 1.5" (38mm) 8" (203mm) B P 1 2 P Section B-B Bond Slab Figure 1: Test setup used for bond beams and slabs 3 4 Figure 2: Load deflection relationship for Group 2 bond beams 23 1 2 Figure 3: Splitting crack width for beams of Group 1 3 4 5 Figure 4: Splitting failure of beam B-130-2-R 24 L 10" a y x a/d P L a x 12" (305mm) y Setup 1 3.0 192" (4877mm) 43" (1092mm) 86" (2184mm) 53" (1346mm) Setup 2 1.5 108" (2743mm) 22" (559mm) 44" (1118mm) 32" (813mm) A 4 #10 (No. 32) 6 #9 (No. 29) #3 (No.10) A 1.5" (38mm) 18" (457mm) 1.5" (38mm) Section A-A 1 2 Figure 5: Typical shear beam cross section and test setup 3 (a) 4 (b) Figure 6: Location of PI gage rosettes and PI gages on the back of the shear beams 5 25 1 2 Figure 7: Shear load deflection behavior for Group 2 shear beams 3 4 Figure 8: Shear load deflection behavior for Group 3 shear beams 26 1 2 Figure 9: Typical shear cracking behavior 3 4 5 Figure 10: Shear crack width for the beams of Group 2 27