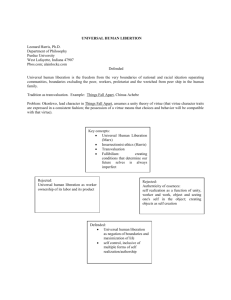

PVT Cell

advertisement

LECTURE – 8 LAB MEASUREMENT OF CRUDE OIL PROPERTIES PVT Cell Mercury reservoir PVT cell Pressure Gauge Thermal jacket Mercury pump PVT cell maintained at constant temperature Pressure controlled by positive displacement Hg-pump Plunger movement calibrated for volume of Hg injected or withdrawn PVT cell is opaque and so volume of individual fractions not known. Total fluid volume and change with pressure Bubble point established by “feel” – small change in pressure results in large change in volume Two types of experiments performed: - Flash liberation - Differential liberation Flash liberation oil v Vt=v/vb v =vb Vt=1 oil Hg P > Pb gas Vt=v/vb oil Hg P = Pb Hg P < Pb No gas removed from the PVT cell – gas remains in equilibrium with oil Overall hydrocarbon composition remains same (components are re-distributed between the gas and liquid phase) vb is known (established by “feel”) Vt expressed with respect to the volume at bubble point pressure. Hence at bp pressure Vt=1 (reservoir barrel) Experiment starts with pressure far above bp pressure and then is gradually reduced. Typical data: Pressure Relative total vol. (psia) Vt = v/vb (rb/rbb) 5000 0.9810 Initial res. 4000 0.9925 pressure 3500 0.9975 Bubble point 3330 1.0000 3000 1.0270 2400 1.1060 Differential Liberation Vto = 1 oil gas vg gas Vto=vo/vb vo oil Hg Hg P = Pb oil Hg P < Pb At each stage of depletion gas is physically removed from contact with oil by injecting Hg at constant pressure (by keeping the valve downstream of cell open) There is continual change of fluid composition in cell Remaining hydrocarbons in cell progressively become heavier (mol. wt. continually increases) Experiment starts at bubble point (since for P>Pb flash and differential liberation are the same) Vtg=vg/vb typically measured relative to the unit volume of bubble point oil (bbl/bblb). Typical data: Pressure Vtg at p and T Vtsc, at sc Vto at P and T 3330 0.0460 8.5211 1.0000 2400 0.0535 6.9457 0.9449 1500 0.0687 6.2333 0.9022 300 0.3728 6.2297 0.8459 14.7 (200oF) 0.8296 14.7 (60oF) 0.7794 Calculation using differential liberation data Gas formation volume factor Bg: Bg is the ratio of gas volume at P and T to the equivalent volume at standard conditions At 2400 psia: Bg Vt g Vt sc 0.0535 0.0077 bbl./STB or 6.9457 0.0077 cuft./SCF Gas deviation factor z: zT 0.0077 2400 Bg 0.02829 z 0.99 0.02829 660 p Oil formation volume factor Bo: Bo is the ratio of oil volume at reservoir P and T to the volume at stock tank conditions From the table, at stock tank conditions Vt o 0.7794 At 2400 psia: Bo Vto press Vto ST 0.9449 1.212 bbl/STB 0.7794 Solution gas ratio Rso: Cummulative gas liberated at the end of the experiment: Vtcum g = 8.5211 + 6.9457 + 6.2333 + 6.2297 = 27.9298 Cummulative gas produced to 2400 psia: Vt2400 g = 8.5211 + 6.9457 = 15.4668 Therefore: Rso (Vtcum g Vt 2400 g ) VtoST (27.9298 15.4668) 15.99 stb/stb 0.7794 or 89.78 SCF/STB From laboratory data to field conditions From above, computation of fluid properties hinges on oil at stock tank conditions being invariant no matter what the liberation process. For volatile oils that contain higher fraction of intermediate hydrocarbons (butane + pentane), components partition between gas and liquid differently depending on separation process. In general, the volume of oil remaining at the lowest pressure will be smaller for flash process. So which type of lab. data to use for calculating field values – a combination of both type of data required. In the reservoir, close to the well, process similar to differential liberation, since liberated gas is more mobile and quickly moves away from contact with oil At locations away from well, process similar to flash liberation In surface separator, however, there is flash expansion of oil i.e. gas stays in equilibrium with oil. If multi-stage separation, then gas is physically removed from the first stage separator, before the oil enters the second stage separator at different P and T conditions non-isothermal differential liberation Combining lab. data with separator tests Robust oil properties obtained by combining flash and differential liberation data Oil at bubble point pressure and reservoir T introduced into separators at different fixed pressure and temperature. Separator P 200 150 100 50 Formation Vol. factor, Bofb (bblb/stb) 1.253 1.251 1.261 1.276 T 80 80 80 80 Separator GOR Rsif (scf/stb) 512 510 515 526 Optimum separator pressure gives the smallest formation volume factor (since then you lose the least due to shrinkage) and correspondingly one with smallest GOR (maximizing volume of oil) Earlier Vto was the relative volume at P and T w.r.t to bubble point volume (bbl/bblb). Therefore field Bo equals: Bo voil voil ST voil v b Vto Bof b bbl/STB vb voil ST Previously we calculated cumulative gas liberated at any pressure: Vt press g (STB/bblb). Therefore: ( Rsi f Rso ) SCF/STB Vt press g Volume of gas evolved v oil ST vb voil ST 5.615 Vt press g Bofb 5.615 scf/stb Oil PVT Calculations Given the following differential data: Pressure Vtg at P and T Vtsc, at sc Vto at P and T 3330 0.0460 8.5211 1.0000 2400 0.0535 6.9457 0.9449 1500 0.0687 6.2333 0.9022 300 0.3728 6.2297 0.8459 14.7 (200oF) 0.8296 o 14.7 (60 F) 0.7794 Oil formation volume factor Bo: 0.9449 1.212 bbl/STB At 2400 psia: Bo (1) 0.7794 Designate this oil FVF as Bod – from differential test Given the following separator data: Separator Formation Vol. Separator GOR factor, Bofb Rsif P T (bblb/stb) (scf/stb) 150 80 1.251 510 We calculated: At 2400 psia: Bo Bof b Vt o = 1.251*0.9449 = 1.182 bbl/STB Vto = voil d vb d where voil is the volume at P-T and subscript d indicates differential test data voil d Therefore, Bo Bof b v ST d vb d v ST d Bof b Bod Bbd bbl/STB Oil PVT Calculations From the differential liberation data: Solution gas ratio Rso: Vt cum g = 8.5211 + 6.9457 + 6.2333 + 6.2297 = 27.9298 Vt 2400 g = 8.5211 + 6.9457 = 15.4668 Therefore: (27.9298 15.4668) 5.615 89.78 STB/STB 0.7794 vcum g Remember Vt cum g , therefore vb vcum g vb V Rso d 5.615 2400 5.615 Rsid V2400 Bbd 5.615 v ST d v ST d vb vb Rso d vcum 5.615 vr From the separator data , we calculated ( Rsi f Rso ) SCF/STB V2400 5.615 Bofb SCF/STB where Rsid Therefore Rso Rsi f V2400 5.615 Bofb Rsi f ( Rsid Rsod ) Bofb Bbd

![Decision Points []](http://s3.studylib.net/store/data/007412401_1-78f574a80702bc46413748bf49d7b1d8-300x300.png)