Quickstart

The Columbia University/Lamont Doherty Earth Observatory

Underway pCO2 System Startup Procedure

Adjust the equilibrator seawater flow to about 10 liters per minute. Measure the flow rate with a beaker at the outflow (about 1 liter per 6 seconds).

1.

Turn the instrument power strip switch on.

2.

Turn the Li-Cor CO2 analyzer on, (Toggle the small switch to Down then back Up .)

Note: The small green light on the IR box will come on in a few minutes.

3.

Open the valves on the nitrogen and standard gas cylinders. (Open all the way then back off about 1/4 turn).

4.

Set the flows of the standard gases. a) Step the standard selector valve to Position 2, (the stepping switch is on the red LED display box and the LED indicates the position number). b) Activate the standard solenoid by pushing the small button labeled “standard” and adjust the flow to approximately 60 cc/min at the nitrogen cylinder regulator if necessary. c) Step the standard selector valve to each next even position, activate the standard solenoid and adjust the flows to approximately 60 cc/min for each corresponding standard gas. (50-60 ml/min is OK) d) When done Step the standard selector valve to Home.

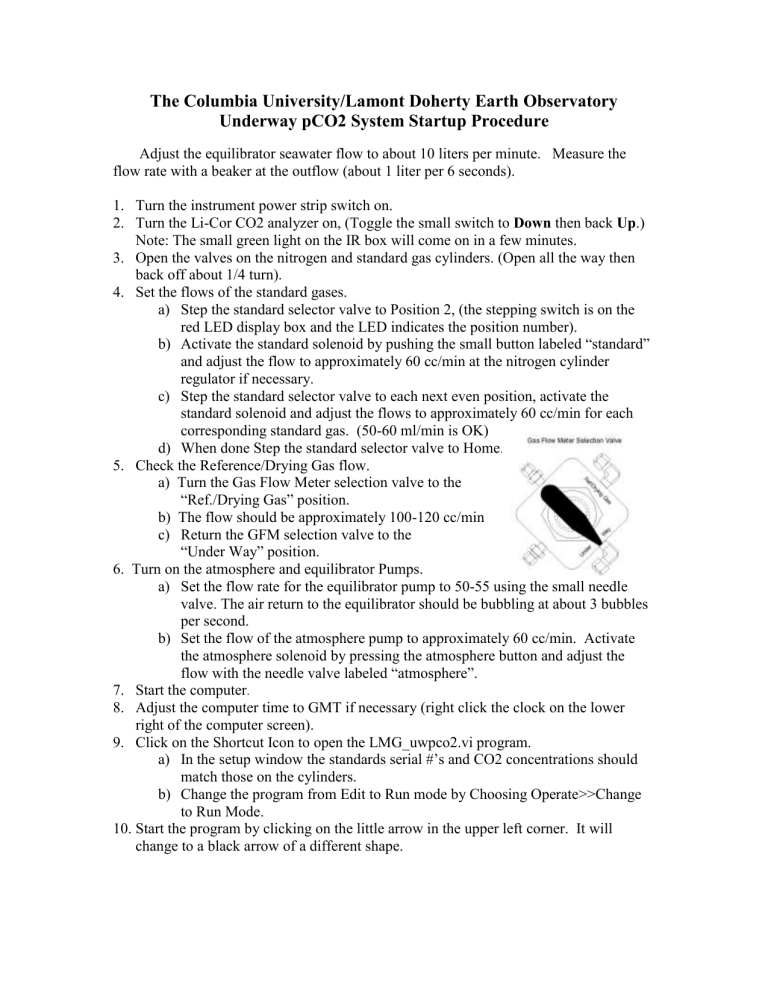

5.

Check the Reference/Drying Gas flow. a) Turn the Gas Flow Meter selection valve to the

“Ref./Drying Gas” position. b) The flow should be approximately 100-120 cc/min c) Return the GFM selection valve to the

“Under Way” position.

6. Turn on the atmosphere and equilibrator Pumps. a) Set the flow rate for the equilibrator pump to 50-55 using the small needle valve. The air return to the equilibrator should be bubbling at about 3 bubbles per second. b) Set the flow of the atmosphere pump to approximately 60 cc/min. Activate the atmosphere solenoid by pressing the atmosphere button and adjust the flow with the needle valve labeled “atmosphere”.

7. Start the computer .

8.

Adjust the computer time to GMT if necessary (right click the clock on the lower right of the computer screen).

9.

Click on the Shortcut Icon to open the LMG_uwpco2.vi program. a)

In the setup window the standards serial #’s and CO2 concentrations should match those on the cylinders. b) Change the program from Edit to Run mode by Choosing Operate>>Change to Run Mode.

10.

Start the program by clicking on the little arrow in the upper left corner. It will change to a black arrow of a different shape.

11.

Click on the “Run Time Display” tab to bring up the graphic data display window.

Check the flow rates and make additional adjustments if necessary as the program steps through each standard.

12.

Log any info such as startup time, shut down time, cylinder pressures and any other activities) in the logbook with the GMT date and time.

Shut Down Procedure

1)

Click on the dark green “Stop Sampling, Run Standards” button in the upper right side of the run time display window. This will initiate a final run of standards. When complete, the program will stop as indicated by the reappearance of the small white arrow. a) exit the program. b) shut down the computer.

2) Turn off the power to the instrument.

3) Turn off the atmosphere and equilibrator pumps.

4) CLOSE THE VALVES ON THE NITROGEN AND STANDARD GAS

CYLINDERS .

5) Turn off the seawater flow to the equilibrator.

6) Drain the equilibrator by opening the drain valve underneath.

7) Rinse the equilibrator with fresh water and let drain. Connect the larger diameter end of the siphon breaker purge hose (a Tygon tubing assembly) to the fresh water at the sink. Thread the small diameter end up through the siphon breaker tube on the equilibrator and slowly turn on the fresh water to wash salts from the siphon breaker.

Additional Notes

1) Record the cylinder pressures at least once per cruise. The standard gases (excluding nitrogen) should last many years so a large pressure drop in a short time indicates a leak. Email pressures at the end of each cruise to tnewberg@ldeo.columbia.edu.

2) When the data is logging on the RVDAS the pco2 indicator on the display monitor will be green. Notify the ET if the indicator remains red.

3) Write notes and comments concerning the pCO2 system in the notebook, include date and GMT time with your notes.

4) Maintain the water level in the manometer to the black line using fresh water only.

5) Maintain flow rates of standards and sample gases.

6) Wash salts from the siphon breaker and manometer tube as needed.

7) Change Vacu-shield on Equilibrator air outlet as needed. Wash salts out of “wet side” only with DI water after each cruise.

Contact Information

pCO2 List Server, gould@ldeo.columbia.edu

Tim Newberger, tnewberg@ldeo.columbia.edu

Colm Sweeney, csweeney@ldeo.columbia.edu