Yeast and Fermentation: the influence of ethanol

advertisement

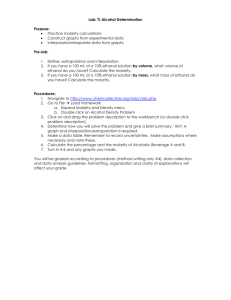

Influence of the D-glucose concentration on the fermentation process . Influence of the D-glucose concentration on the fermentation process Bulthuis, L.C.M., Eggenkamp, M.W., Verdam, M.C. . Team GGH26 Gemeentelijk Gymnasium Hilversum, The Netherlands March 2010 Abstract One of mankind’s most used fuel and oil will be exhausted in the future. Because of this, interest has grown in an old chemical process: the production of bio-ethanol out of sugars by fermentation. Yeasts are eukaryotic micro-organisms, with about 1500 species known and described. They can ferment glucose into ethanol and carbon dioxide. This will happen when there is no oxygen in the environment. This raises the question of what the optimal concentration D-glucose will be in the conversion of glucose to ethanol by yeast cells. The fermentation progress was followed at different solutions, following amounts of D-glucose were dissolved: 1 g, 2 g, 3 g, 4 g, and 5 g. This results in a process that will be more efficient with a higher amount of Dglucose in the solution. Introduction Several laboratories and industries use synthetic ethanol. They use ethene to produce ethanol. The main source of ethene is crude oil. This production of synthetic ethanol may become a problem when crude oil will run short. Synthetic ethanol is now chiefly produced by the reaction between ethene (g) and water (g): CH2=CH2 (g) + H2O (g) CH3CH2OH (g) There must be another way to produce ethanol without the use of crude oil. One of the oldest chemical processes to produce synthetic ethanol is the production of ethanol from sugars by fermentation. The main source of sugars for fermentation is starch. Starch is made with the influence of sun. The energy of the sun is used to synthesize sugars. In this process, atmospheric carbon dioxide and water are used to produce glucose: sunlight 6CO2 (g) + 6H2O (g) ------ C6H12O6 (s) + 6O2 (g) Saccharomyces cerevisiae can invert the C6H12O6. Yeast cells of Saccharomyces cerevisiae are used in research to increase the yield of the production of bio-ethanol from sugars. Yeast does not require sunlight to grow, but they use the sugars as source of energy. This yeast uses two major pathways for growth on glucose: (1) The fermentation of glucose: C6H12O6 (s) 2CH3CH2OH (l) + 2CO2 (g) (2) The oxidation of glucose: C6H12O6 (s) + 6O2 (g) 6CO2 (g) + 6H2O (l) These pathways show us that S. cerevisiae cells can grow in an oxygen free environment and an oxygen rich setting. The first pathway is the most interesting one, because we were looking for a way to replace the crude oil as a source of ethene. But which is the cheapest way to produce ethene using S. cerevisiae? This raises the following question: In which condition, considering the concentration of glucose, will yeast cells produce the most ethanol? There can be another way. The enzyme invertase is found in yeast, which is used to convert disaccharides and polysaccharides to glucose and other stereoisomers of C6H12O6. Yeast cells of Beside ethanol carbon dioxide is produced. The more ethanol is produced, the more carbon dioxide is released. We expect the amount of released carbon dioxide will be the highest in the third tube. Page 1 Influence of the D-glucose concentration on the fermentation process This is the tube with an average concentration of glucose. The activity of enzymes is determined by several factors, including the amount of ethanol. Ethanol is one of the substrates of the fermentation of glucose. The more glucose will be inverted, the more ethanol will be produced. In the end there is so much ethanol that it will have a negative feedback on the enzymes. This means, the yeast cells activity will be reduced or stop. With a little amount of ethanol as substrate, there will not be any negative feedback, which we expect to happen in the first 3 tubes. But we expect the amount of ethanol to have influence on the enzyme activity in the fourth and fifth tube. Experimental procedure and approach Within a day we measured the flasks again. Table 1 presents, in duplicate, the mass (in grams) of the released CO2 gas at 1, 2, 3, 4, and 5 g D-glucose solution. Moreover, it presents the averaged masses of the released CO2 (in grams) and its deviations at the various % of D-glucose. D-glucose (g) Mass CO2 (g) 1 0.15 0.13 0.28 0.27 0.00* 0.41 0.60 0.51 0.60 0.61 2 3 4 5 Averaged Mass CO2 (g) 0.14 ± 0.01 0.275 ± 0.005 0.41 0.555 ± 0.045 0.605 ± 0.005 Table.1. Release of CO2 (in grams) and averaged release of CO2 at 1, 2, 3, 4, 5 g D-glucose. * The mass CO2 is 0.00. This result shows that the process did not occur. Release CO2 Averaged Mass CO2 (g) 5 D-glucose solutions were prepared in duplo. In 30mL demi-water the following amounts of Dglucose were dissolved: 1 g, 2 g, 3 g, 4 g, and 5 g. For the yeast solution a tablet of S. cerevisiae was dissolved in demi-water. After that all test tubes were filled with the D-glucose solutions and 1 mL S. cerevisiae dissolved in demi-water. All the test tubes were closed with a hydrogen stop (figure 1). Now the mass of the test tubes was measured. The labeled test tubes were placed in a water bath of 37 °C. After one day the test tubes were measured again. Before the tubes were measured it was made sure that the reaction in the tube was completed. Reaction is completed when all the yeast cells are at the bottom of the tube and no bubbles are seen. Results 0,7 0,6 0,5 0,4 0,3 0,2 0,1 0 0 2 4 6 D-glucose (g) Fig.2. The averaged measured release of CO2 (g) at the D-glucose solutions of 1, 2, 3, 4, and 5 g. Fig. 1. hydrogen stop Page 2 Influence of the D-glucose concentration on the fermentation process Data analysis As shown in table 1, the average maximum amount of released CO2 (g) in the fermentation process is 0.605 g. This is equal to 0.605g/44.01u = 0.014 mol CO2. The first equation shows that in theory 2.00 moles of CO2 gas can be produced. The percentages of the produced moles CO2 in our experiments are: 1. 29% 2. 28% 3. 28% 4. 28% 5. 25% Hereby the calculation of the percentages of the produced moles CO2 in our experiment. First, we divided the Molair Mass of CO2 by the grams of CO2: 1. 0,14/44,0 = 0,0032 mol 2. 0,275/44,0= 0,00625 mol 3. 0,41/44,0= 0,0093 mol 4. 0,555/44,0=0,0126 mol 5. 0,605/44,0= 0,01375 mol After this calculation, we divided the grams of Dglucose by the Molair Mass of Glucose and we multiplied the result by 2, because the proportion between D-glucose and CO2 is 1:2. 1. 1/180,2 x 2 = 0,01109 mol 2. 2/180,2 x 2 = 0,02219 mol 3. 3/180,2 x 2 = 0,03329 mol 4. 4/180,2 x 2 = 0,04439 mol 5. 5/180,2 x 2 = 0,05549 mol After this, we divided the moles CO2 by the moles D-glucose and multiplied the result by 100%: 1. 0,0032/0,01109 x 100%= 29% 2. 0,00625/0,02219 x 100%=28% 3. 0,0093/0,003329 x 100%=28% 4. 0,0126/0,04439 x 100%=28% 5. 0,01375/0,5549 x 100%=25% As shown in figure 2, the averaged maximum amount of released CO2 (g) in the fermentation process is 0.605 g. The form of the figure shows that the process will be more successful if the concentration of D-glucose is more than 1 or 2 g D-glucose. The line is less straight when the concentration of D-glucose becomes too high. Conclusion, discussion and evaluation As shown in table 1, the CO2 gas production was highest at a 5g D-glucose solution. The 0.605 g CO2 or 0.014 mol of CO2 gas produced less than the 0.56 moles that can be produced. The proportion between D-glucose and CO2 is 1:2. 5g D-glucose or 0.028 mol can produce 0.056 mol of CO2. Looking critically at our results will show that one of our results is not in line with the others. The weight did not increase, so the process has not occurred. Therefore we have decided to exclude this value in our data. Something must have been present in this sample that prevented the reaction to occur. When we took a look at the test tubes, it seems that all the reactions were completed. There were no more bubbles in the test tubes and the yeast descended to the bottom of the test tubes. Apparently something happened with the first test tube which had 3 g D-glucose in our experiment. We think this is strange, because both test tubes were prepared the same way. We have the opinion nothing went wrong during the preparation of the test tubes. As we have said in our hypothesis, the forming of CO2 will increase when the concentration Dglucose in the solution is higher. We also predicted a decrease in the graphic (figure 2) caused by an excessive concentration of ethanol. However, this is not shown in our graphic. This will not say we are wrong. When there is a bigger difference between the Dglucose concentrations, there is a possibility that the decrease is shown in our graphic, because there is more ethanol produced. However, you can see that the line in the graphic inclined less when the concentration of D-glucose became higher. As mentioned, we have said in our hypothesis that we would see a parabola. If we would repeat the experiment, we will increase the amount of D-glucose in the beginning. There would be more ethanol produced, which would have a negative feedback on the enzyme activity. Bibliography - www.bioplek.org The influence of ethanol on the activity of enzymes. http://en.wikipedia.org/wiki/Ethanol_fermen tation Page 3