Infinitely Variable Transmission Utilizing Torque

advertisement

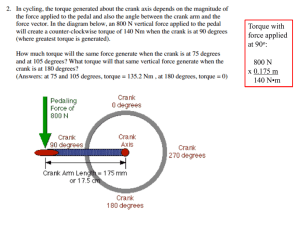

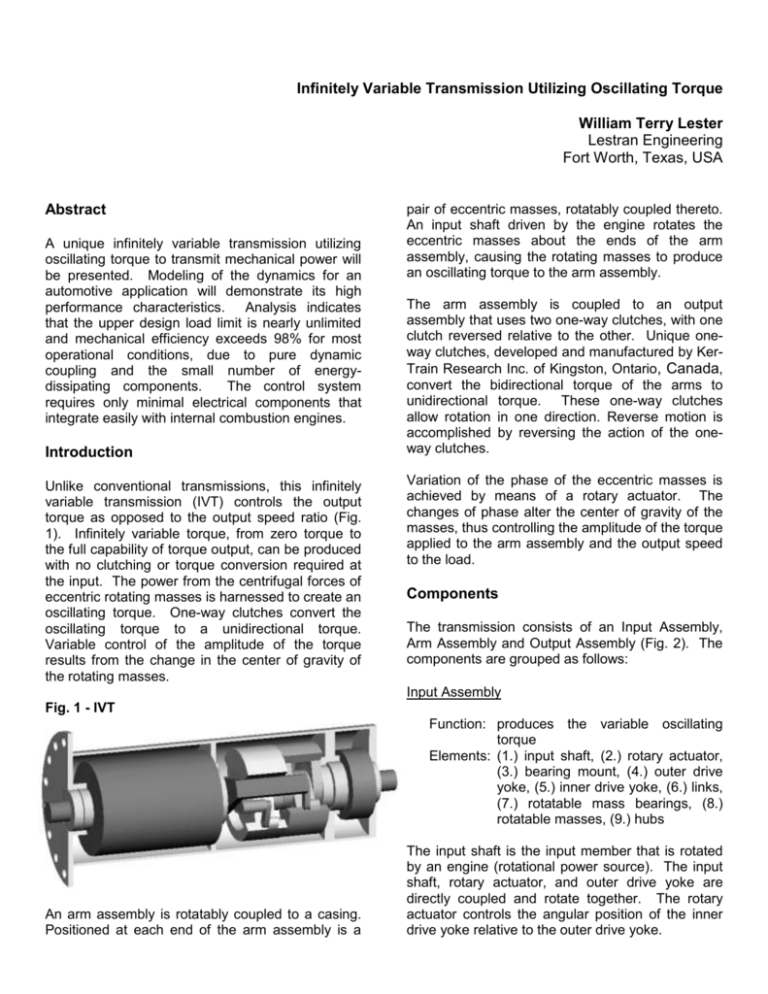

Infinitely Variable Transmission Utilizing Oscillating Torque William Terry Lester Lestran Engineering Fort Worth, Texas, USA Abstract A unique infinitely variable transmission utilizing oscillating torque to transmit mechanical power will be presented. Modeling of the dynamics for an automotive application will demonstrate its high performance characteristics. Analysis indicates that the upper design load limit is nearly unlimited and mechanical efficiency exceeds 98% for most operational conditions, due to pure dynamic coupling and the small number of energydissipating components. The control system requires only minimal electrical components that integrate easily with internal combustion engines. Introduction Unlike conventional transmissions, this infinitely variable transmission (IVT) controls the output torque as opposed to the output speed ratio (Fig. 1). Infinitely variable torque, from zero torque to the full capability of torque output, can be produced with no clutching or torque conversion required at the input. The power from the centrifugal forces of eccentric rotating masses is harnessed to create an oscillating torque. One-way clutches convert the oscillating torque to a unidirectional torque. Variable control of the amplitude of the torque results from the change in the center of gravity of the rotating masses. pair of eccentric masses, rotatably coupled thereto. An input shaft driven by the engine rotates the eccentric masses about the ends of the arm assembly, causing the rotating masses to produce an oscillating torque to the arm assembly. The arm assembly is coupled to an output assembly that uses two one-way clutches, with one clutch reversed relative to the other. Unique oneway clutches, developed and manufactured by KerTrain Research Inc. of Kingston, Ontario, Canada, convert the bidirectional torque of the arms to unidirectional torque. These one-way clutches allow rotation in one direction. Reverse motion is accomplished by reversing the action of the oneway clutches. Variation of the phase of the eccentric masses is achieved by means of a rotary actuator. The changes of phase alter the center of gravity of the masses, thus controlling the amplitude of the torque applied to the arm assembly and the output speed to the load. Components The transmission consists of an Input Assembly, Arm Assembly and Output Assembly (Fig. 2). The components are grouped as follows: Input Assembly Fig. 1 - IVT Function: produces the variable oscillating torque Elements: (1.) input shaft, (2.) rotary actuator, (3.) bearing mount, (4.) outer drive yoke, (5.) inner drive yoke, (6.) links, (7.) rotatable mass bearings, (8.) rotatable masses, (9.) hubs An arm assembly is rotatably coupled to a casing. Positioned at each end of the arm assembly is a The input shaft is the input member that is rotated by an engine (rotational power source). The input shaft, rotary actuator, and outer drive yoke are directly coupled and rotate together. The rotary actuator controls the angular position of the inner drive yoke relative to the outer drive yoke. 1 Input Shaft 2 Rotary Actuator 3 Bearing Mount 4 Outer Drive Yoke 5 Inner Drive Yoke 6 Links 7 Rotatable Mass Bearings 8 Rotatable Masses 9 Hubs 10 Alignment Bearing 11 Shafts 12 Mounting Tube 13 Casing 14 Alignment Bearings 15 Slip Ring 16 One-Way Clutches 17 Output Shaft Input Assembly 6 7 8 5 9 8 8 2 4 7 6 1 9 3 10 11 8 12 Arm Assembly Output Assembly 11 13 14 14 15 16 17 16 Fig. 2 - IVT Components The inner and outer drive yokes transmit the input torque through the links to the rotatable masses. The rotary actuator, combined with the inner and outer drive yokes, furnishes the variable control of the phase of the rotatable masses. The rotary actuator ranges from 0 to 180 degrees. The one-way clutches, functioning in directions reversed from one another, convert the oscillating torque to a unidirectional torque. The first one-way clutch connects the arm assembly to the casing; the second one-way clutch connects the arm assembly to the output shaft. Several types of rotary actuator devices are available for this transmission. The computercontrolled actuator relies on inputs from engine speed and throttle position. The internal components of the rotary actuator are not shown in the figures. The output shaft relays the resultant power to the transportation application. The rotatable masses are two pairs of side-by-side eccentric masses. Roller bearings placed inside the hubs of the rotatable masses facilitate rotation of the masses about the shafts of the arm assembly. As the masses rotate about the arm assembly, centrifugal forces generate oscillating torque. Arm Assembly Function: supplies the structural interface between the input and output assemblies Elements: (10.) alignment bearing, (11.) shafts (12.), mounting tube The arm assembly resembles a crankshaft and operates as the interface between the input and output assemblies. Rotatably coupled to the casing, the shafts support the rotatable masses. The moment arm for the output torque is the offset distance of the shafts, called the Arm Assembly Radius. The alignment bearings support the rotating components within the casings. The slip ring provides the electrical interface to the rotary actuator. Mechanics The IVT utilizes an oscillating torque to vary the mechanical power transmitted to a load. The arm assembly is rotatably coupled to the casing. Rotatably coupled to the shafts of the arm assembly are the rotatable masses, two pairs of side-by-side eccentric masses. The input shaft rotates the masses about the shafts of the arm assembly. The centrifugal forces from the rotating masses produce an oscillating torque that causes the arm assembly to oscillate. The inner and outer drive yokes and the links provide the means to transmit the input torque to the rotatable masses (Fig. 3). This mechanism resembles a four bar linkage. Rotatable Mass Link Drive Yoke The mounting tube attached to the shafts functions as the coupling component for the one-way clutches to the output assembly. Output Assembly Function: converts the oscillating torque to a unidirectional torque Elements: (13.) casing, (14.) alignment bearings, (15.) slip ring, (16.) oneway clutches, (17.) output shaft The output assembly comprises a casing that acts as a stationary support structure for the assembled transmission and incorporates two one-way clutches and an output shaft. Fig. 3 – Rotating the Rotatable Masses The arm assembly is coupled to an output assembly. The output assembly employs one-way clutches, with one clutch reversed relative to the other clutch, to convert the bidirectional torque of the arm assembly to a unidirectional rotation for the output load. In a cyclic process, the torque oscillates from a clockwise to a counter-clockwise direction as the eccentric masses rotate about the shafts of the arm assembly. The one-way clutches engage and disengage, conforming to four stages of the process (Fig. 4). The cyclic process is described below. Centrifugal Force Rotatable Mass Arm Assembly Stage 3 the one-way clutch to the output shaft is disengaged zero torque Process from Stage 3 to Stage 4 (Process 3-4) counter-clockwise torque is applied to the arm assembly arm assembly decelerates Stage 4 the one-way clutch to the casing is engaged rotational velocity of arm assembly is zero Process from Stage 4 to Stage 1 (Process 4-1) counter-clockwise torque is applied to the casing Stage 1 Stage 2 Stage 3 Stage 4 Zero Torque Clockw ise Torque Zero Torque Counter-Clockw ise Torque Fig. 4 – Four Stages of the Cyclic Process (The arm assembly radius is exaggerated in the illustration.) Cyclic Process Stage 1 the one-way clutch to the casing is disengaged zero torque zero rotational velocity of the arm assembly Variable control is achieved by changing the amplitude of the centrifugal forces produced by the rotatable masses. The masses are paired so that their phases range from 0° in phase for maximum torque to 180 out of phase for zero torque or any intermediate setting. The output amplitude of the oscillating torque is dependent on the phase of the rotatable masses. The phase changes the center of gravity of the masses, thereby controlling the torque applied to the arm assembly (Fig. 5). The computercontrolled actuator attached to the input shaft regulates the phase. Center of Gravity Rotatable Masses Process from Stage 1 to Stage 2 (Process 1-2) clockwise torque is applied to the arm assembly arm assembly accelerates Stage 2 the one-way clutch to the output component is engaged rotational velocity of the arm assembly and the output shaft are equal Process from Stage 2 to Stage 3 (Process 2-3) clockwise torque is transmitted to the output shaft via the arm assembly In Phase Maximum Torque 90° Out of Phase Intermediate Torque 180° Out of Phase Zero Torque Fig. 5 – Phase Angle Controls Output Torque Amplitude Reverse motion is carried out by reversing the action of the one-way clutches. The capability to switch the action of the clutches is provided by the revolutionary clutch developed and manufactured by Ker-Train Research Inc., of Kingston, Ontario (U.S. Patent 6,409,001). This clutch has a load capacity five times greater than a sprag-type clutch, with an indexing rate of up to 100 Hz. This indexing rate would allow the IVT to operate at engine input speeds of up to 6000 rpm. (The indexing rate is the number of load cycles that the clutch engages and disengages per second.) Although the IVT rapidly engages and disengages the one-way clutches, the clutches do not experience impact or shock loads due to the fact Table 1 – Maximum Output Torque The product of the centrifugal force of the rotatable masses (Table 2) and the arm assembly radius is illustrated. Phase Angle Automotive Application The transmission design presented herein is sized to demonstrate the transmission’s capabilities in an automotive application. The cylindrically-shaped casing measures 75 cm in length and 25 cm in diameter. The IVT mass is estimated to be less than 70 kg. The data presented in the following sections pertain to this automotive application. Performance Performance characteristics depend on the input and output speeds (Figs. 6, 7, 8 and 9). The power and average output torque increase as input and output speeds increase, with the output speed being less than or equal to the input speed. Alterations of the phase angle of the rotatable masses maintain optimum engine speed as the vehicle accelerates. The Dynamics Characteristics (Figs. 10, 11, 12, 13, 14 and 15) result from the cyclic process in which power is transmitted: Stage 3 Stage 4 degree cm 0.0 64.4 92.3 114.8 134.8 153.3 6.5 5.5 4.5 3.5 2.5 1.5 Maximum Output Torque N-m Input Speed 1000 rpm 97 82 67 52 37 22 Input Speed 2000 rpm 388 328 268 209 149 89 Input Speed 3000 rpm 872 738 604 470 336 201 Input Speed 4000 rpm 1551 1312 1074 835 597 358 Table 2 – Rotatable Mass Centrifugal Force One of this IVT’s strengths is its ability to produce high output torque, as exhibited in Tables 1, 2 and 3. Stage 1 Stage 2 Radius to C.G. of Rotatable Masses The process begins. The arm assembly speed matches the output speed. The arm assembly begins to decelerate. The arm assembly reaches zero velocity. The output torque resembles the performance characteristics of a two-piston internal combustion engine. The arm assembly transmits torque to the one-way clutches, which then distribute the torque to the output shaft and to the casing. The maximum magnitude of the reaction torque to the casing and the output shaft are equal. The product of the rotatable masses and their centrifugal acceleration (Table 3) is illustrated. Phase Angle Radius to C.G. of Rotatable Masses degree cm 0.0 64.4 92.3 114.8 134.8 153.3 6.5 5.5 4.5 3.5 2.5 1.5 Rotatable Mass Centrifugal Force N Input Speed 1000 rpm 9700 8200 6700 5200 3700 2200 Input Speed 2000 rpm 38800 32800 26900 20900 14900 8900 Input Speed 3000 rpm 87200 73800 60400 47000 33600 20100 Input Speed 4000 rpm 155100 131200 107400 83500 59700 35800 Table 3 – Rotatable Mass Centrifugal Acceleration The magnitude of the centrifugal acceleration is a function of the input speed and the radius to the center of gravity of the rotatable masses from the center of the arm assembly shafts. The radius varies from 6.5 cm for 0° phase angle to 0.0 cm for 180° phase angle. The arm assembly radius and the total mass of the rotatable components amount to 1.0 cm and 13.6 kg, respectively. Phase Angle Radius to C.G. of Rotatable Masses degree cm 0.0 64.4 92.3 114.8 134.8 153.3 6.5 5.5 4.5 3.5 2.5 1.5 Rotatable Mass Centrifugal Acceleration m/sec2 Input Speed 1000 rpm 713 603 493 384 274 164 Input Speed 2000 rpm 2851 2413 1974 1535 1097 658 Input Speed 3000 rpm 6415 5428 4441 3454 2467 1480 Input Speed 4000 rpm 11405 9650 7896 6141 4386 2632 0.0° 114.8° 6 64.4° 134.8° Average Output Torque (N-m) Power (kw) 8 92.3° 153.3° 4 2 0 0 200 400 600 800 Output Speed (rpm) (a) 80 0.0° 114.8° 60 64.4° 134.8° 92.3° 153.3° 40 20 0 1000 0 200 400 600 800 Output Speed (rpm) (b) 1000 60 50 40 30 20 10 0 0.0° 114.8° 0 64.4° 134.8° Average Output Torque (N-m) Power (kw) Fig. 6 – Performance Characteristics for 1000 rpm Input Speed (Legend: Phase Angle of Rotatable Masses) 92.3° 153.3° 500 1000 1500 Output Speed (rpm) (a) 300 250 200 150 100 50 0 0.0° 114.8° 2000 0 64.4° 134.8° 92.3° 153.3° 500 1000 1500 Output Speed (rpm) (b) 2000 Power (kw) 200 0.0° 114.8° 150 64.4° 134.8° Average Output Torque (N-m) Fig. 7 – Performance Characteristics for 2000 rpm Input Speed (Legend: Phase Angle of Rotatable Masses) 92.3° 153.3° 100 50 0 0 1000 2000 Output Speed (rpm) (a) 3000 750 0.0° 114.8° 600 64.4° 134.8° 92.3° 153.3° 450 300 150 0 0 1000 2000 Output Speed (rpm) (b) 3000 Power (kw) 500 0.0° 114.8° 400 64.4° 134.8° Average Output Torque (N-m) Fig. 8 – Performance Characteristics for 3000 rpm Input Speed (Legend: Phase Angle of Rotatable Masses) 92.3° 153.3° 300 200 100 0 0 1000 2000 3000 Output Speed (rpm) (a) 4000 1250 0.0° 114.8° 1000 64.4° 134.8° 92.3° 153.3° 750 500 250 0 0 1000 2000 3000 Output Speed (rpm) (b) 4000 Fig. 9 – Performance Characteristics for 4000 rpm Input Speed (Legend: Phase Angle of Rotatable Masses) Arm Speed (rpm) Arm Position (degree) 75 50 25 0 0.00 0.05 0.10 Time (sec) (a) 0.15 0.20 75 50 25 0.00 150 100 50 0.05 0.10 Time (sec) (c) 0.05 0.10 0.15 0.20 0.15 0.20 Time (sec) (b) Output Torque (N-m) Input Torque (N-m) 100 0 200 0 0.00 125 0.15 400 350 300 250 200 150 100 50 0 0.00 0.20 0.05 0.10 Time (sec) (d) 300 Arm Speed (rpm) Arm Position (degree) Fig. 10 – Dynamics Characteristics, 2000 rpm Input Speed, 100 rpm Output Speed, 0.0° Phase Angle 250 200 150 100 50 0 0.00 0.10 Time (sec) (a) 0.15 0.20 300 200 100 0.00 250 200 150 100 50 0.05 0.10 Time (sec) (c) 0.05 0.10 0.15 0.20 0.15 0.20 Time (sec) (b) Output Torque (N-m) Input Torque (N-m) 400 0 0.05 300 0 0.00 500 0.15 0.20 400 350 300 250 200 150 100 50 0 0.00 0.05 0.10 Time (sec) (d) Fig. 11 – Dynamics Characteristics, 2000 rpm Input Speed, 400 rpm Output Speed, 0.0° Phase Angle Arm Speed (rpm) Arm Position (degree) 600 500 400 300 200 100 0 0.00 1000 800 600 400 200 0 0.05 0.10 0.15 0.20 0.00 0.05 Time (sec) (a) Output Torque (N-m) Input Torque (N-m) 400 300 200 100 0 0.00 0.05 0.10 Time (sec) (c) 0.10 0.15 0.20 0.15 0.20 Time (sec) (b) 0.15 400 350 300 250 200 150 100 50 0 0.00 0.20 0.05 0.10 Time (sec) (d) 1200 Arm Speed (rpm) Arm Position (degree) Fig. 12 – Dynamics Characteristics, 2000 rpm Input Speed, 800 rpm Output Speed, 0.0° Phase Angle 800 400 0 0.00 0.05 0.10 0.15 1400 1200 1000 800 600 400 200 0 0.20 0.00 0.05 Time (sec) (a) Output Torque (N-m) Input Torque (N-m) 500 400 300 200 100 0 0.00 0.05 0.10 Time (sec) (c) 0.10 0.15 0.20 0.15 0.20 Time (sec) (b) 0.15 0.20 400 350 300 250 200 150 100 50 0 0.00 0.05 0.10 Time (sec) (d) Fig. 13 – Dynamics Characteristics, 2000 rpm Input Speed, 1200 rpm Output Speed, 0.0° Phase Angle Arm Speed (rpm) Arm Position (degree) 1600 1200 800 400 0 0.00 2000 1500 1000 500 0 0.05 0.10 0.15 0.20 0.00 0.05 Time (sec) (a) Output Torque (N-m) Input Torque (N-m) 600 500 400 300 200 100 0 0.00 0.05 0.10 0.15 Time (sec) (c) 0.10 0.15 0.20 0.15 0.20 Time (sec) (b) 400 350 300 250 200 150 100 50 0 0.00 0.20 0.05 0.10 Time (sec) (d) 4000 Arm Speed (rpm) Arm Position (degree) Fig. 14 – Dynamics Characteristics, 2000 rpm Input Speed, 1600 rpm Output Speed, 0.0° Phase Angle 3000 2000 1000 0 0.00 2000 1500 1000 500 0 0.10 0.20 0.30 0.00 Time (sec) (a) Output Torque (N-m) Input Torque (N-m) 500 400 300 200 100 0.10 Time (sec) (c) 0.20 0.20 0.30 Time (sec) (b) 600 0 0.00 0.10 0.30 400 350 300 250 200 150 100 50 0 0.00 0.10 0.20 Time (sec) (d) 0.30 Fig. 15 – Dynamics Characteristics, 2000 rpm Input Speed, 1900 rpm Output Speed, 0.0° Phase Angle that there is no instantaneous change in velocity. The driver (arm assembly) and driven members (casing and output shaft) rotate at the same velocity when the one-way clutches are engaged (Stages 2 and 4). Mechanical Efficiency In addition to the transmission’s ability to match continuously the optimum engine speed to any vehicle speed, the small number of energydissipating components yields a high mechanical efficiency that exceeds 98% for most operational conditions. The energy losses are attributable to the rotatable mass bearings, the rotary actuator and the one-way clutches. The primary power loss emanates from the bearings for the rotatable masses. Power losses from the rotary actuator and one-way clutches are negligible. Endurance The compact design and small number of components enable the IVT to be manufactured for long service life, primarily by selecting rugged and efficient one-way clutches and the rotatable mass bearings. Ker-Train Research Inc. of Kingston, Ontario, Canada offers a one-way clutch for low Hertz stresses which measures 3.8 cm in length and 12.8 cm in outer diameter and has a maximum torque rating of 10000 N-m. The IVT’s maximum output torque of 1551 N-m (Table 3) would merely consume 1/8 of the torque rating for this one-way clutch, translating into a transmission service life that will exceed the vehicle’s life. (Fig. 16) Bearing power losses are the product of the input speed in radians per second and the bearing friction torque. Equation 1 governs the bearing friction torque (Mfriction). The input speed, as shown in Table 4, affects the magnitude of these losses. The centrifugal force from the rotatable masses produces the load on the bearing (F). The percentage of the power loss from the bearings results from the power transmitted by the IVT, and is small for any significant power transmission. Mfriction = f F dm Equation 1 coefficient of friction (f) = 0.0003 bearing pitch diameter (dm) = 7.9 cm Incremental usage of the rotary actuator combined with its maximum power rating of 0.20 kw produces a minimal power loss projection of less than 0.02 kw. Maximum power is not required for most of the changes in the phase angle of the rotatable masses. The resulting incremental usage of the actuator is estimated to be less than 10%. Tests conducted by Ker-Train Research Inc. conclude that the power losses for the one-way clutches should amount to less than a fraction of one percent. Table 4 – Bearings Power Losses Input Applied Bearing Bearing Speed Load Friction Torque Power Loss rpm N N-m kw 1000 9700 0.229 0.023 2000 38800 0.916 0.192 3000 87300 2.062 0.648 4000 155200 3.666 1.536 Fig. 16 – One-Way Clutch The service life for the rotatable mass bearings is determined by the input speed and the applied load, presented in percentage of bearing life and time in Table 5. For this design eight Torrington spherical roller bearings (22211CJ) are used, with a dynamic loading of 120000 N per bearing and dimensions of 5.5 cm bore diameter, 10.0 cm outer diameter and 2.5 cm width. Table 5 – Rotatable Mass Bearing Life Input Applied Service Service Speed Load Life Life rpm N Percentage Hours 1000 9700 0.3 200000 2000 38800 8.6 30000 3000 87300 63.0 10000 4000 155200 28.2 500 Development History and Status While in graduate school, I read an article about the importance and advantages of CVTs. My interest in CVTs was piqued by a statement in the article that it is physically impossible to engineer a CVT that is practical for high power applications. I took on this issue as a personal challenge and began a twenty-three year quest to develop a high torque CVT. In the mid-nineties, I recognized that the centrifugal force from a rotating mass generates high torque, spurring me to pursue the development of a new class of IVT. During the development process extensive kinematic analyses were performed, several working models were constructed, and patents were issued (U.S. Patents 6,044,718 and 6,062,096). A model (Fig. 17 and 18) was installed in a go-kart to demonstrate my concept. The transmission supplied smooth acceleration and high torque. Two large men attempted to hold back the go-kart from 1 2 3 4 5 6 7 an idling position as the driver depressed the accelerator, but were unable to do so. This model had only one pair of rotatable masses; therefore, the center of gravity of the rotatable masses did not change in this model. It performed like a mechanical torque converter. Also, gears were used to transfer torque to the rotatable masses. Subsequently, a second go-kart model (Fig. 19) was constructed with the improved simpler design to transmit the input torque to the rotatable masses by means of the drive yoke and links, yielding a smoother performance. The IVT presented herein is being developed for a full-sized automotive application. In the development process a desktop model is being designed to demonstrate the computer control system in a controlled environment. After verification of the control system is completed, the IVT will be constructed and tested in a full-sized vehicle. Input Shaft Timing Gears Rotatable Masses Arm Assembly Frame Output Shaft One-Way Clutches 3 7 1 2 3 4 6 5 Fig. 17 – Test Model Components but would result in a 70% reduction in overall performance. Fig. 18 – Test Model Installed in Go-Kart Fig. 20 – Constantinesco CVT The process of power transmission presents another difference between the Lester IVT and previous designs. The inertia reaction loads applied to the differential lever provides the variable transmission of power in the Constantinesco CVT. The differential lever functions as a gear that supplies the interface for the input from the crank shaft, the reaction loads from the inertia wheel, and the output to the drive shaft. Conversely, the centrifugal force from the rotatable masses directly transmits power in the Lester IVT. Fig. 19 – Improved Go-Kart Model Conclusion Prior Art This unique IVT design harnesses the power from the centrifugal force of a rotating mass. High torque is smoothly generated from the centrifugal force of a small mass. This design satisfies the torque, size, mass and endurance requirements for all transportation applications. Additionally, the small number of energy-dissipating components provides a high mechanical efficiency under all driving conditions and keeps manufacturing costs low. In addition, exotic materials are not required. Previous CVTs, including the Belt, toroidal, and Constantinesco, control the speed ratio. Their output torque is the product of the input torque and the speed ratio. In contrast, the Lester IVT operates as an infinitely variable mechanical torque converter. It controls the magnitude of the output torque instead of the speed ratio. Similarly, the Constantinesco CVT (Fig. 20) and the Lester IVT apply a ratcheting or one-way clutching device to convert an oscillating torque into a unidirectional torque. Also, they both utilize an inertial reaction force to achieve variable control. However, both of the one-way clutches transmit power for the Constantinesco CVT, while the one-way clutch that is constrained to the casing does not transmit power in the Lester IVT. Incorporating the Constantinesco CVT’s ratcheting methodology in the Lester IVT would be possible, This rugged and economical IVT can easily be engineered for even a semi-truck application (Table 6). Table 6 – Semi-Truck IVT Specifications Length 125 cm Diameter 50 cm Maximum Output Torque 10000 N-m Mass 150 kg Input Speed 2000 rpm Endurance Life for continuous 50000 hours operation at maximum torque. References 1. Tedric A. Harris, “Rolling Bearing Analysis, Third Edition,” Wiley-Interscience Publication, dated 1991, pages 149 and 504-511. 2. “The Torrington Company Service Catalog,” dated 1991, pages 244 and E54-E57. 3. George Constantinesco: Inertial Transmission, http://www.rexresearch.com/constran/1constran.htm Contacts 1. William Terry Lester 4008 Shannon Dr. Fort Worth, Texas 76116 Phone: 817.735.1824 E-mail: wmterrylester@aol.com 2. Mitch Kerr Ker-Train Research Inc. Kingston, Ontario, Canada Phone: 613.531.3155 Ex 100 E-mail: mitch@kertrain.com