WESTERN BLOTTING (for protein detection)

advertisement

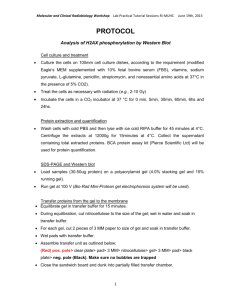

WESTERN BLOTTING (for protein detection) Date written: 18/10/06 Written by: Betty Tan A. Protein Extraction Instruments and reagents checklist: Motorized homogenizer Disposable pellet pestles 1.5 ml eppendof tubes 1.5 ml eppendof tubes rack Ice in Styrofoam container 1000ul, 200ul, 20ul, and 10ul filtered pipette tips and pipettes Complete Mini tablet (Roche Boehringer Mannheim) 10% SDS 1 x PBS Biorad DC Protein Assay Reagents 96 well microtiter plate Protocol: 1. Homogenize tissue of approx. 100 ug in 1 ml Complete Mini Lysis buffer (1 tablet of complete mini, 0.5 ml of 10% SDS, 9.5 ml of 1X PBS), on ice with motorized homogenizer. 2. Vortex vigorously for 1 min. 3. Centrifuge at full speed at 4C for 15 min to pellet insoluble material. 4. Transfer the supernatant to fresh eppendof tube. Dispose of the residual tissues in a biohazard bag. Safety Measures: Except during vortexing and centrifugation, the procedure is to be performed in a BSC-2A. Standard PPE – gloves, long sleeves lab coats, and safety goggles should be worn at all times. All contaminated materials are to be disposed into biohazard bags. After use, all equipments and work surface should be disinfected with 10% bleach (or 70% ethanol), followed by UV for 10min. Spill Procedures: In the case of spilliage, clean up with disinfectant(eg. Clorox), and inform safety officer, Shanthi Wasser at 6772 2368. MSDS Complete Mini tablet: https://www.roche-applied-science.com/MSDS/us/1836153.pdf 1 Endorsed by Name/Title/ Signature Date B. Biorad DC Protein Assay Instruments and reagents checklist: Biorad DC Protein Assay Reagents 96 well microtiter plate 200ul, 20ul, and 10ul pipette tips and pipettes Microplate reader Protocol: 1. Preparation of working reagent Add 20 ul of reagent A that will be needed for the run. (This working reagent A’ is stable for 1 week even though a precipitate will form after 1 day. If precipitate forms, warm the solution and vortex. Do not pipette the undissolved precipitate, as this will likely plug the tip of the pipette, thereby altering the volume of reagent that is added to the sample.) If sample do not contain detergent (e.g. SDS), step #i may be omitted and reagent A can be used as supplied. 2. Prepare 3 – 5 dilutions of a protein standard containing from 0.2mg/ml to about 1.5mg/ml protein. A standard curve should be prepared each time the assay is performed. For best results, the standard should be prepared in the same buffer as the sample. 3. Pipette 5 ul of standards and samples into a clean, dry microtiter plate. 4. Add 25 ul of reagent A’ or reagent A into each well. 5. Add 200 ul of reagent B into each well. If microplate reader has a mixing function available, place in reader and let the plate mix for 5 sec. If not, gently agitate the plate to mix the reagents. If bubbles form, pop them with a clean, dry pipette tip. Be careful to avoid cross- contamination of sample wells. 6. After 15 min, absorbance can be read at 750 nm. The absorbance will be stable for about 1 hr. CAUTION: DC Protein Reagent A contains sodium hydroxide, a corrosive chemical. Refer to MSDS: http://www.bio-rad.com/WWMSDS/LSGC/SGP/SGP_ENG_5000120.pdf Safety Measures: Procedure can be carried out in open work surface. However, cleaning with 70% alcohol before and after work is still necessary. All reagents spillage must be cleaned up immediately. Standard PPE – Gloves and lab coat must be worn at all times. All contaminated materials are to be disposed into biohazard bag. 2 Endorsed by Name/Title/ Signature Date C. Sample Preparation Instruments and reagents: 1.5 ml Eppendof tube 200ul, 20ul, and 10ul pipette tips and pipettes Loading dye (5X) 1 M Tris-HCL, pH 6.8 Glycerol Β-mercaptoethanol SDS Bromophenol blue Water 3.1ml 5 ml 1 ml 0.46g 0.005g 0.9ml 10 ml Stored at -20C. CAUTION: Β-mercaptoethanol is a highly toxic reagent. Refer http://chemdat.merck.de/documents/sds/emd/int/en/8057/805740.pdf to MSDS: Hotplate set to 95C Protocol: 1. Calculate the concentration of the protein lysate using Prism statistical software. Work out the volume of lysate for 100 ug protein. This volume will be used to dilute a 5X loading dye at a 4:1 ratio. The total volume should not exceed 66 ul, as this is the maximum volume that the well for a 1.5mm gel can hold. 2. Mix 4 parts of protein lysate with 1 part of loading dye. Vortex and pulse down. (It is advisable to prepare 20 % more of the required loading volume as evaporation may occur during heating.) 3. Heat the sample loading dye mixture in the preset 95C hotplate for 5 min. CAUTION: Do not place combustible material near hotplate. In the event of accidental burn, apply burn cream, and report the case to safety officer (Dr. Shanti Wasser 67722368) 4. Place on ice for 5 min. Pulse down. 5. This can now be placed at room temperature till loading. Safety Measures: Standard PPE – gloves, lab coat, and safety goggles are to be worn at all times. Β-mercaptoethanol should only be opened in the fume cupboard. The rest of the procedure can be performed in open work surface. However, standard housekeeping and cleaning with 70% ethanol before and after work should still be followed. All contaminated materials are to be disposed in biohazard bag. 3 Endorsed by Name/Title/ Signature Date D. Gel Preparation and Electrophoresis Instruments and reagents: 30 % Acrylamide/Bis solution 19:1 (Biorad, cat.161-0158) MSDS: http://www.bio-rad.com/WWMSDS/LSGC/SGP/SGP_ENG_1610158.pdf 1.5 M Tris-HCL, pH 8.8 (18.17g Tris base MW=121.4 in approx. 80ml water. Adjust to pH 8.8 with HCL, and make up to 100ml with water. Store at 4C.) 0.5 M Tris-HCL, pH 6.8 (6g Tris base MW=121.4 in approx.60ml water. Adjust to pH 6.8 with HCL, and made up to 100 ml with water. Store at 4C.) 10 % SDS (Dissolve 10g SDS in water with gentle stirring. Bring to 100 ml with water. Store at room temperature.) MSDS: http://chemdat.merck.de/documents/sds/emd/int/en/1060/106022.pdf 10 % Ammonium Persulfate (APS) (0.05g of ammonium persulfate dissolved in 0.5ml water. TO BE PREPARED FRESH.) MSDS: http://www.bio-rad.com/WWMSDS/LSGC/SGP/SGP_ENG_1610700.pdf 5 x SDS/ Glycine Electrophoresis Buffer Tris Base (MW=121.4) 15.1g Glycine 72 g SDS 5g Top up to 1 L with water. Mix thoroughly with a magnetic stirrer and bar. Store at room temperature. Dilute 5X stock with water to 1X for electrophoretic run (0.025M Tris-HCL, 0.1% SDS, and 0.192M Glycine) TEMED MSDS: http://www.bio-rad.com/WWMSDS/LSGC/SGP/SGP_ENG_1610801.pdf Protein MW Marker Biorad Gel Running Apparatus 1000ul, 200ul, 20ul, and 10ul pipette tips and pipettes 1.5 ml eppendof tubes and rack Ice in Styrofoam container Disposable 2ml Pasteur pipette CAUTION: Most of these chemicals used are harmful reagents. Spills should be cleaned up immediately and the safety officer informed (Dr Shanti Wasser 67722368). Upon eyes or skin contact, flush with lots of water for 10mins. 4 Endorsed by Name/Title/ Signature Date Protocol: 1. Clean the glass plates with 70 % ethanol and leave to air-dry. 2. Set up the gel apparatus. 3. Adding in water first and TEMED last, add in all the required components for the preferred SDS separating gel with reference to the table 1. 4. After mixing with the Pasteur pipette, load the gel solution into the gel set immediately. 5. Level the separating gel with absolute ethanol, and leave for 10 min for the gel to set. 6. Pour away the absolute ethanol, and allow to air dry briefly. 7. Prepare the stacking gel as on Table 1. 8. After the addition of TEMED, mix with the Pasteur pipette, and load the gel immediately. 9. Place in the comb, and leave to set for 10 min. 10. Remove the comb, and flush wells with water and then with 1 X electrophoresis buffer. Place the gel into the gel tank and fill with the 1 X electrophoresis buffer. 11. Load desired sample volume and approx. 8 ul of protein MW marker (previously staw to room temperature, and vortex). 12. Resolve at 100V for approx. 1.5 hr with 1 X electrophoresis buffer. CAUTION: Do not turn on the power pack during loading. Do not handle any electrical appliances with wet hands. Make sure that all electrical appliances are grounded, and that electrical cord are neatly coiled and arranged. 13. At the end of the run, turn off the power pack and then the power supply before disconnecting the leads. 14. Allow the tank to cool down for 5 min before opening. 15. Pour the electrophoresis buffer into a 1 L duran bottle. The electrophoresis buffer can be recycled for approx 3X. 16. Remove the gel assembly. Safety Measure: Standard PPE – gloves and lab coat are to be worn at all times. Care should be taken when handling all the chemicals. The procedure can be performed in open work surface. However, standard housekeeping and cleaning with 70% ethanol before and after work should still be followed. All contaminated materials are to be disposed in biohazard bag. 5 Endorsed by Name/Title/ Signature Date Table 1. Recipe for SDS-PAGE SEPARATING GEL 6% Water 30 % Acrylamide mix 1.5 M Tris, pH 8.8 10 % SDS 10 % Ammonium Persulfate TEMED 8% Water 30 % Acrylamide mix 1.5 M Tris, pH 8.8 10 % SDS 10 % Ammonium Persulfate TEMED 10 % Water 30 % Acrylamide mix 1.5 M Tris, pH 8.8 10 % SDS 10 % Ammonium Persulfate TEMED 12 % Water 30 % Acrylamide mix 1.5 M Tris, pH 8.8 10 % SDS 10 % Ammonium Persulfate TEMED 15 % Water 30 % Acrylamide mix 1.5 M Tris, pH 8.8 10 % SDS 10 % Ammonium Persulfate TEMED 10 ml (1 Gel) 5.3 2.0 2.5 0.1 0.1 0.032 10 ml (1 Gel) 4.6 2.7 2.5 0.1 0.1 0.024 10 ml (1 Gel) 4.0 3.3 2.5 0.1 0.1 0.016 10 ml (1 Gel) 3.3 4.0 2.5 0.1 0.1 0.016 10 ml (1 Gel) 2.3 5.0 2.5 0.1 0.1 0.016 15 ml (2 Gels) 8.0 3.0 3.8 0.15 0.15 0.048 15 ml (2 Gels) 7.0 4.0 3.8 0.15 0.15 0.036 15 ml (2 Gels) 5.9 5.0 3.8 0.15 0.15 0.024 15 ml (2 Gels) 5.0 6.0 3.8 0.15 0.15 0.024 15 ml (2 Gels) 3.5 7.5 3.8 0.15 0.15 0.024 STACKING GEL Water 30 % Acrylamide mix 0.5 M Tris, pH 6.8 10 % SDS 10 % Ammonium Persulfate TEMED 2 ml (1 Gel) 1.4 0.33 0.25 0.02 0.02 0.008 4 ml (2 Gels) 2.7 0.67 0.5 0.04 0.04 0.016 6 Endorsed by Name/Title/ Signature Date E. Electro-Transfer of Protein Instruments and reagents: Transfer Buffer (with 20 % methanol) 1 L 5X SDS/ Glycine Electrophoresis Buffer Methanol Water 200ml 200ml 600ml Stored at 4C MSDS of methanol: http://chemdat.merck.de/documents/sds/emd/int/en/1060/106009.pdf Biorad protein electro-transfer apparatus. 2 Fibrous pads Transfer cassettes Transfer tank Cooling unit (Prefreezed to -20C with water) Stacking gel cutter Containers for laying out transfer “sandwich”. Disposable 2 ml Pasteur pipette. Empty 12 ml tube for evening out blot. 4 pieces of 9 x 8 cm Whatman chromatography paper (3mm Chr,cat.3030917)/ transfer cassette. 1 PVDF transfer membrane 8.5 x 6 cm/ transfer cassette. Magnetic stirring bar Magnetic stirring plate Forceps 7 Endorsed by Name/Title/ Signature Date Protocol: 1. Mark top right corner of the PVDF membranes with pencil. Using a forceps, place the PVDF membranes in methanol for a few sec to soak. After soaking, pour the methanol into a 100 ml duran bottle to be recycled. 2. Transfer the PVDF membranes to a container with the chilled transfer buffer. 3. Soak the chromatography papers and fibrous pads in another container with the chilled transfer buffer. 4. Placing the stacking gel cutter between the gaps the 2 gel plates, gently force the plates open. 5. Cut away the staking gel, and immerse the remaining separating gel on the gel plate into to a container with the chilled transfer buffer. Gently shake to dislodge the gel from the plate. 6. Open the transfer cassette, and place 1 fibrous pad on top of the black colored side, followed by 2 pieces of chromatography paper. 7. Gently remove the gel from the transfer buffer, and place it on the stacked chromatography paper. Pipette some transfer buffer with the Pasteur pipette onto the gel, and gently even it out. 8. Noting the on the PVDF membrane, place the membrane on top of the gel. Pipette some transfer buffer with the Pasteur pipette onto the gel, and roll the empty 12 ml tube over the membrane to remove bubbles formed between the gap of the membrane and gel. 9. Place 2 pieces of chromatography papers followed by another fibrous pad, and close the transfer cassette. 10. Place the cassette into the transfer tank, with the black side of the cassette to the black side of the tank. The tank should contain some amount of transfer buffer so as to prevent drying up of the PVDF membrane. 11. Do the same to the other cassette. 12. When both cassettes have been set into the transfer tank, fill the tank with more transfer buffer. Put the magnetic stirring bar into the tank, and place the cover on making sure that the electrode is properly connected (i.e. black to black, red to red). 13. Slot in the cooling unit, and place the assembled transfer tank on the magnetic stirring plate. 14. Turn the power pack on, and electro-transfer at 100V, 400mA for 1 hr. Observe bubbles formation to ascertain that the power in on. Turn on the magnetic stirring plate to enable stirring. CAUTION: Do not turn on the power pack during loading. Do not handle any electrical appliances with wet hands. Make sure that all electrical appliances are grounded, and that electrical cord are neatly coiled and arranged. 15. At the end of the run, turn off the power pack and then the power supply before disconnecting the leads. 16. Allow the tank to cool down for 5 min before opening. 17. Pour the transfer buffer into a 1 L duran bottle. The transfer buffer can be recycled for approx 3X. 18. Remove and open the cassettes. The PVDF membrane is now ready for immuno-detection. Safety Measure: Standard PPE – gloves and lab coat are to be worn at all times. Care should be taken when handling all the chemicals. The procedure can be performed in open work surface. However, standard housekeeping and cleaning with 70% ethanol before and after work should still be followed. All contaminated materials are to be disposed in biohazard bag. 8 Endorsed by Name/Title/ Signature Date F. Immunoblotting Instruments and reagents: 10 X Wash buffer 1 L (10mM Tris-HCL, pH 7.4, 100mM NaCl, 0.1% Tween 20) 1M Tris, pH 7.4 100ml 5M NaCl 200ml Tween 20 10ml Water 690ml 1 X Wash buffer (Diluted from 10 X wash buffer with water at a 1:9 ratio) Blotting buffer (5% non-fat milk in wash buffer) Non-fat milk powder 5g Wash buffer top to 100ml Containers for blotting or hybridization bags (and bag sealer) Primary and secondary antibodies Shaking platform Protocol: 1. Place the PVDF membranes that have been removed from the transfer cassettes into the wash buffer, and rinse for 5 min with shaking. 2. Pour away the wash buffer and blot the membranes with the blotting buffer with gentle shaking for 1 hr. 3. While the membranes are being blot. Dilute out the antibodies with the blotting buffer. The dilution factor should be determined empirically for each antibody. Place antibodies on ice at all times. Sufficient volume of diluted antibodies should be used to 4. After 1 hr, pour away the blotting solution and add in the diluted primary antibody. Incubate 1 hr – overnight with shaking at room temperature or at 4C respectively. 5. Collect the primary antibody in a 15 – 50 ml falcon tube, and store it at -20C. The antibodies can be reused. 6. Rinse the membranes with 4ml/ cm2 of 1 X wash buffer with shaking for 10 min. Repeat 2X. 7. Add in the diluted secondary antibody, and incubate for 1 hr with shaking at room temperature. 8. Collect the primary antibody in a 15 – 50 ml falcon tube, and store it at -20C. The antibodies can be reused for approx. 3X. 9. Rinse the membranes with 1 X wash buffer with shaking for 10 min. Repeat 2X. 10. Transport the membranes in a closed container with 1 x wash buffer to the darkroom. Safety Measure: Standard PPE – gloves and lab coat are to be worn at all times. The procedure can be performed in open work surface. However, standard housekeeping and cleaning with 70% ethanol before and after work should still be followed 9 Endorsed by Name/Title/ Signature Date G. ECL Detection Instruments and reagents: ECL reagents MSDS for reagent A: http://www6.amershambiosciences.com/applic/upp00609.nsf/(viewXDomainSearch)/408516C94D278B8 0C12571E3003957BB/$File/Lumigen_PS_3_detection_reagent__Solution_A__part_of__ECL_Plus_Wes tern_Blotting_Detection_Reagent__for_3000_cm2_.pdf MSDS for reagent B: http://www6.amershambiosciences.com/applic/upp00609.nsf/(viewXDomainSearch)/7500F11C52624FA 5C12571E300399055/$File/Lumigen_PS_3_detection_reagent__Solution_B__part_of__ECL_Plus_West ern_Blotting_Detection_Reagent__for_3000_cm2_.pdf X-ray film Developing cassette Darkroom with photo developer Protocol: 1. Remove the detection reagents from storage at 2-8C and allow to equilibrate to room temperature before opening. 2. Mix detection solutions A and B in a ratio of 40:1 (e.g. 2ml of solution A + 50ul of solution B). The final volume of the detection reagent required is 0.1ml/cm2. If the mixed reagent is not to be used immediately, protect it from exposure to light either by wrapping in a foil of storing in a dark place. 3. Drain the excess wash buffer from the washed membranes and place protein side up on a sheet of SaranWrap or other suitable clean surface. Pipette the mixed detection reagent onto the membrane. The reagent should cover the entire surface of the membrane, held by surface tension onto the surface of the membrane. 4. Incubate for 5 min at room temperature. 5. Drain off excess detection reagent solution by holding the membrane gently in forceps and touching the edge against a tissue. Place the protein side down onto the fresh piece of Saran Wrap, wrap up the blots and gently smooth out any air bubbles. 6. Place the wrapped blots, protein side up, in an x-ray film cassette. Ensure there is no free detection reagent in the cassette; the film must not get wet. 7. In the darkroom with red safe lights, open the autoradiography film and place a sheet on top of the membrane. Close the cassette and expose for 15 sec. 8. Remove the film and place it into the photo developer for developing. On the basis of its appearance estimate how long to continue the exposure of the next film. Second exposure can vary from 1 min to 1 hour. 10 Endorsed by Name/Title/ Signature Date