1. introduction

advertisement

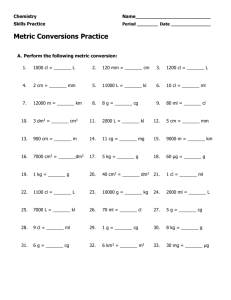

COMPARISON OF DIFFERENT HYBRID MEMBRANE SYSTEMS FOR REMOVAL OF Zn(II) AND Cu(II) Grażyna Szczepańska, Piotr Szczepański, Marek Świątkowski, and Romuald Wódzki Nicholas Copernicus University, Faculty of Chemistry 87-100 Toruń, 7 Gagarina St., Poland E-mail: wodzki@chem.uni.torun.pl 1. INTRODUCTION Purification of drinking and industrial water contaminated by toxic heavy metal ions (e.g. Zn(II) and/or Cu(II)) can be carried out by applying some membrane methods. In general, two membrane methods are nowadays considered as feasible in the recovery of metals from dilute aqueous solutions, i.e. Donnan dialysis (DD- exploiting cation-exchange membranes) [1], and pertraction with use of the selective liquid membranes (LM). However, the industrial use of LM is limited due to its instability and short lifetime [2] whereas the DD method sometimes appears to be unselective in respect to cations of similar valence. This can be overcome by constructing hybrid polymer-liquid-polymer membrane systems [3,4] MHS (or MHS[FLM] where FLM denotes the flowing liquid membrane) which combine the both techniques. Additionally, the system with a liquid membrane can be coupled to a pervaporation unit (MHS[FLM-PV]) that allows removal of water absorbed by the organic phase (LM). Furthermore, in the same way, such different process as Donnan dialysis and pertraction in the MHS can be arranged in series as a new integrated hybrid system: DDMHS[FLM-PV]. The aim of this study was to compare and develop the process of removal and separation of Zn(II) and Cu(II) as performed in the systems with D2EHPA (di-(2ethylhexyl)phosphoric acid), Cyanex 302 (di-(2,4,4-trimethylpenthyl) thiophosphinic acid), Acorga PT-5050 (5-nonylsalicyl-aldoxime) or newly synthesised macromolecular carriers. 2. EXPERIMENTAL The first membrane system (A: MHS in Tab.1) consisted of three chambers in which dense, hydrophilic, cation-exchange membranes (CEM) separated the liquid organic membrane with a dissolved mobile carrier, from the external aqueous solutions. The second one (B: MHS[FLM-PV], in Tab.1) exploited a flowing liquid membrane (FLM), i.e. an organic liquid is continuously flowing between two cation-exchange membranes and two additional pervaporation membranes (PV). The third system (C': DD-MHS[FLM-PV], in Tab.1) integrates the MHS with classic Donnan dialysis technique (DD) and consists of a DD module, pertraction module (MHS) and pervaporation unit (PV). The part of a cell corresponding with DD contained mediating solution acting simultaneously as the stripping solution for the DD process and the feed solution for the pertraction process. The external aqueous solutions were sampled in time and the concentration of metals has been determined with an atomic absorption spectrophotometer (Varian 20 ABQ). The operation conditions for each system are specified in Tab.1. The aqueous feed solution in each case was prepared by dissolving an appropriate amount of reagent grade Zn2+, Cu2+, Ca2+, Mg2+, K+ and Na+ nitrates in twice distilled water. The fluxes (stripping rates) of ionic species have been determined from the primary data in the form of the strip concentration vs. time dependence as a slope of a linear part of the Q s f ( t ) plot: J M Q s / t [eqv/cm2s] (1); (2) Q s z M M s , t Vs / 1000A s [eqv/cm2] Qs denotes the amount of metal species of valence zM transported to the receiver after the time t, through 1 cm2 of the stripping CEM area (As, cm2), Vs (cm3) is the volume of the stripping solution, [M]s,t (mol/dm3) is the concentration of metal species at the time t. The separation of cations was evaluated by standard separation coefficients α MΣM and fractional fluxes N: k z M k [ M ] k ,s MMk z M k [ M ] k ,f z z j k j k M i [ M ] j,f (3); N M i [ M ] j,s J Mk J 100 , [%] (4) M Tab.1. Membrane systems and their operation conditions System Conditions A MHS V Composition 500 cm3 110-2 mol/dm3 V Composition - V Solvent 30 cm3 0,011 mol/dm3 D2EHPA, CYANEX 302, ACORGA PT-5050 technical kerosene distilled kerosene V Composition 30 cm3 1 mol/dm3 H2SO4 400 cm3 1 mol/dm3 H2SO4 Area Type 13 cm2 FKS Area Type - Carrier B MHS[FLM-PV] Feed solution 2,5 dm3 210-3 mol/dm3 Mediating soln. - C MHS[FLM-PV] C DD-MHS[FLM-PV] 50000 cm3 110-3 mol/dm3 50000 cm3 110-3 mol/dm3 - 400 cm3 Liquid membrane 90 cm3 500 cm3 3 12 g/dm 0,010,1 mol/dm3 macromolecular D2EHPA carriers 1,2 dichloroethane distilled kerosene Stripping solution 50 cm3 400 cm3 0.5 mol/dm3 H2SO4 1 mol/dm3 H2SO4 Cation exchange membrane 28,3 cm2 200 cm2 NAFION 117 FKS Pervaporation membrane 72,6 cm2 23 cm2 PERVAP 2201 PERVAP 2201 0,010,3 mol/dm3 H2SO4 500 cm3 0,1 mol/dm3 D2EHPA 200 cm2 FKS 23 cm2 PERVAP 2201 3. RESULTS AND DISCUSSION System A In order to check the MHS effectiveness, the dependence of system performance on the carrier concentration in the liquid membrane was studied. Some representative results are presented in Fig.1. High separation coefficients were found for Zn2+ in the MHS with Cyanex 302 and for Cu2+ with Acorga PT-5050. The use of Cyanex 302 instead of D2EHPA considerably lowers the flux of calcium and leads to the effective separation of Zn 2+ over Ca2+. In view of the results, the MHS can be considered as a basic unit for the removal of Zn(II) and Cu(II) from liquid solution such as domestic water. The system can be applied in order to diminish the concentration of Zn2+ and Cu2+ or other harmful heavy metals according to pro-ecological requirements. 1.0e-9 1.0e-10 2 Flux [eqv./cm s] 2 Flux [eqv./cm s] 1.0e-10 1.0e-11 1.0e-12 a) b) 1.0e-11 1.0e-12 1.0e-13 1.0e-13 1.0e-14 0.0 1.0e-14 0.0 0.2 0.4 0.6 0.8 1.0 3 D2EHPA concentration [mol/dm ] 0.1 0.2 0.3 0.4 0.6 0.5 3 Acorga PT-5050 concentration [mol/dm ] Fig.1. Fluxes vs carrier concentration in MHS-BLM (system A) with D2EHPA (a) and Acorga PT-5050 (b) as a carrier: Cu(II), Zn(II), Ca(II), Mg(II), Na(I), K(I), System B The experiments in the system B, were carried out using macroionophore of the composition presented in Fig.2. The polymer [star shaped polymer: I arm(POE Mn=3370)[DGEEG]-II arm (POE, Mn=5440) with CH3O-(I) and –OP(O)(OH)2 (II) end-groups] has been synthesized in Polish Academy of Science in Łódź [5]. The pertraction properties of this carrier were compared with the properties of poly(ethylene glycol) (PEG6000, Mn=6000 g/mol)and poly(oxyethylene) bisphosphates (BFPEG6000, Mn= 6200 g/mol) R a: P P R P R R P R -CH3O end groups P -OP(O)(OH)2 end groups PEG chain: b: (HO)2P(O)O-(CH2CH2O)n-P(O)(OH)2 c: HO-(CH2CH2O)n-H Fig.2. Scheme of composition of STAR-SHAPED macroionophore (a), BFPEG6000 (b) and PEG6000 (c). Data in Tab.2 show that the use of ionizable carriers results in overall fluxes higher than PEG600. This indicates the counter-transport mechanism to be dominant in the case of star shaped and BFPEG macroionophores. Tab. 2. Stationary fluxes J of cations in the MHS[FLM-PV] system with various macroionophores Carrier Star shaped BFPEG PEG Zn(II) 8,110-12 35,410-12 0,1610-12 Cu(II) 1,1610-12 16,1 10-12 0,04 10-12 Flux, Js 1012 (eqv./cm2s) Ca(II) Mg(II) 0,410-12 0,2210-12 0,9410-12 0,9710-12 -12 Nd. 0,0810 K(I) 3,410-12 3,1510-12 0,9910-12 Na(I) 0,4210-12 0,2110-12 0,0610-12 The separation characteristics for studied macroionophores indicate high separation ability of the star-polymer towards Zn(II) and K(I) cations. Selectivity for Zn(II) is caused by phosphate groups, as observed also for the simpler macroionophore (BFPEG6000). On the other hand, both side arms: with –OCH3 and –OP(O)(OH)2 end groups of the star shaped macroionophore can facilitate the pertraction of K+ similarly to PEG6000 when applied as a selective carrier for K+ cation. System C The results (Tab.3.) indicate the preferential transport of Zn2+ cations, according to the properties of D2EHPA used as the carrier in a liquid membrane. The fluxes decrease in the following order: Zn2+ >> Ca2+ > Cu2+> Mg2+ > K+ > Na+, in all cases. Thus, the final effect of the MHS[FLM-PV] system operation is the separation of Zn2+ from a multication mixture. Tab.3. The effect of carrier concentration in system C: pH f=2,5; 1M H2SO4 in the strip solution Concentration of D2EHPA [mol/dm3] 0,01 0,05 0,1 Striping rates, J (eqv./cm2s) Fractional fluxes N (%) Ca2+ Mg2+ Zn2+ Cu2+ 5,3910-12 3,2010-14 6,7610-14 96.96 2,4010-10 67.74 1,6310-10 51.59 0.58 1,5810-11 4.46 3,5710-11 11.30 1.21 9,7110-11 27.40 1,1410-10 36.08 Na+ K+ 3,1610-14 1,0010-14 2,8010-14 0,57 7,2710-13 0.21 3,0310-12 0.96 0.18 3,3710-14 0.01 1,0110-13 0.03 0.50 6,5610-13 0.18 1,1310-13 0.04 System C’ In order to check the influence of sulphuric acid concentration in the mediating acid solution, its initial concentration was varied in the range from 0,01 to 0,3 mol/dm3. The values of resulting fluxes are collected in Tab.4. It was found that separation ability of the system towards Zn2+ depends highly on the concentration of mediating solution - the optimal results are achieved at 0,05M H2SO4. Tab.4. The effect of mediating solution concentration in system C’: pH f=2,5; 0,1M D2EHPA; 1M H2SO4 in the strip solution Concentration of H2SO4 in mediating sol. 0,3 0,1 0,05 0,03 0,01 Striping rates, J (eqv./cm2s) Zn(II) Cu(II) -11 1,6410 9,2910-11 2,0310-10 1,7710-10 7,6710-11 -13 1,3110 1,6210-12 1,5110-11 2,9910-11 7,3510-12 Ca(II) Mg(II) -12 1,3510 1,4710-11 9,8610-11 1,4410-10 6,1310-11 -13 1,1810 1,8110-13 1,3710-12 2,2510-12 1,1910-12 Na(I) K(I) -13 1,2210 3,6210-14 4,3910-14 6,6710-14 4,0110-14 3,6310-13 5,2310-14 1,6110-13 1,6910-13 1,4110-13 4. CONCLUSION The experiments proved that the cation exchange membranes applied in the MHS, and in more advanced hybrid systems, prevent a loss of a carrier and contamination of external aqueous solutions by an organic solvent of LM. The MHS system is easy to reconstruct, resize and regenerate, without the loss of stability and ability to work over a long time period. The MHS system enables the removal of Zn(II) and/or Cu(II) from dilute aqueous solutions using the standard carriers (D2EHPA, Acorga PT-5050, Cyanex 302) or a new star-shaped macroionophore. A moderate scale application, especially for the removal of Zn(II) and Cu(II) from solutions in food industry and pharmacy can be recommended. 5. REFERENCES [1] Wódzki R., Szczepański P., Sep. Purif. Technol., 22-23, 697, (2001). [2] Wijers M. C., Wessling M., Strathmann H., J. Memb. Sci., 147, 117, (1998). [3] Wódzki R., Sionkowski G., Sep. Sci. Technol., 30, 2763, (1995). [4] Wódzki R., Sionkowski G., Poźniak G., Sep. Sci. Technol., 34, 627, (1999). [5] Wódzki R., Świątkowski M., Łapienis G., React.Funct.Polym., 52, 149, (2002).