Introductory Soldering Techniques for Electronics

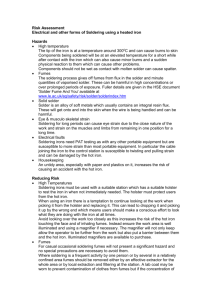

advertisement

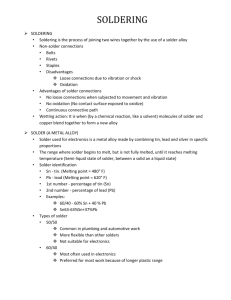

Introductory Soldering Techniques for Electronics Prepared by Mike Crompton (Rev. 19 Jan 2005) Soldering Techniques for Electronics. Soldering is a method for making reliable electrical connections. Good soldering is better than most other mechanical connections (screws, push on connectors, crimp connectors, nuts, bolts etc ) because: a) Vibration or mechanical shock does not loosen it. b) It prevents oxidation and corrosion of the soldered surfaces. c) It produces a good electrical connection between the soldered objects. Solder is an alloy of tin (Si) and lead (Pb). Tin melts at 232 C, lead melts at 327 C, and surprisingly solder melts at around 189 C, a lower temperature than lead or tin. When solder melts - it goes through 3 stages: 1. Solid, below melting temperature. 2. Plastic, where it begins to melt but is not completely liquid or solid. 3. Liquid, above melting temperature. As the solder cools it moves through the three stages again in reverse order: liquid plastic - solid. Solder that is 60% tin and 40% lead (60/40 solder) is solid below 183 C, plastic from 183 C to 191 C and liquid above 191 C. This makes it ideal for hand soldering, particularly if any components have to be removed or reworked. A special case solder is ‘Eutectic’ or Sn-63 solder. Made from 63% tin and 37% lead, it has no plastic range and goes almost instantly from solid to liquid and vice-versa. This solder is ideal for ‘flow’ or ‘wave’ soldering machines as it goes to a solid as soon as the printed circuit board (PCB) leaves the ‘wave’ of solder. This eliminates fractured joints caused by components moving during the cooling or plastic period. Eutectic solder makes reworking by hand difficult. It solidifies too quickly allowing no time for component removal. This leads to overheating damage due to multiple attempts at removal. SOLDER 1S NOT A GLUE! When hot liquid solder contacts copper it penetrates the copper surface creating a new alloy of solder and copper. This action (forming the new alloy) is called the ‘wetting action’. It is this wetting action that creates the bond that forms the good connection between the solder and the copper. 2 THE WETTING ACTION Molten solder can only penetrate the copper if the surface is clean. Surface dirt, oil, finger prints, water etc must be removed before soldering. Solvents such as isopropyl alcohol, trichloroethane, freon and acetone are often used as cleaning agents. Most solvents are volatile, toxic and flammable making them a hazard. Always take precautions when using them. 1) 2) 3) 4) DO NOT breathe the fumes. DO NOT smoke when using the chemicals. KEEP them away from your skin. DO NOT use near open flame. Even when cleaned with solvents a thin film of oxide remains or will reform very rapidly. This film is removed, usually during the soldering operation, by ‘Flux’ that is contained in the solder. In automated soldering (wave or flow soldering) the flux is applied just before the wave. Flux is a liquid, paste or powder containing ‘Resin’ Flux cored solder (made from the sap of evergreen trees). When it is heated it becomes slightly acid and removes any oxide or corrosion film from the copper. Once it cools the acidity disappears preventing the objects from being ‘eaten away’ with time. Most electronic solder has flux in the centre or core and is known as flux cored solder. flux cores Normal and low deposit fluxes are available and this refers to the amount of flux residue left after the soldering operation is complete. Removing flux residue is sometimes difficult but essential for high quality Printed Circuit Boards (PCBs). To this end special water soluble fluxes have been developed, and completed PCBs are put through a wash and rinse cycle in a dishwasher to ensure complete removal of residues. WORK CONSIDERATIONS Several conditions effect good solder connections. The most obvious are: a) Relative size (mass) of the components being soldered. Obviously this mass varies with the size of the terminal, pad, component or the size and number of wires. The larger the mass the larger the soldering iron tip required. b) Surface Condition. The soldering surfaces MUST be clean. Remove heavy dirt with a small wire brush, cloth or mild abrasive (e.g. abrasive stick, ink eraser). Remove oils with solvents. c) Thermal Linkage created by the contact area between the work and the soldering iron tip. This linkage can be improved by adding a small amount of solder between the work and the iron tip. Apply a small amount of solder to increase thermal linkage from iron to component 3 d) Applying the iron to the point of maximum mass and allowing the heat to penetrate all the parts to be soldered. USING THE IRON Match the tip to the work, tip too small = too slow heating, tip too large = too fast heating i.e. no time to work properly without damaging (overheating) components and PCB. Use a tip that allows a 2 - 4 second work time. The heat moves from the tip to the work. A small contact area = small heat flow, large contact area = large heat flow. We can increase the contact area and the heat flow by putting a little solder between the tip and the part as shown above (Thermal Linkage). If ready to use the iron, quickly clean the tip on a damp (not wet) sponge and then ensure the tip is “tinned” by applying a small amount of solder. When soldering melt the solder on the wires or component leads, not on the iron. Follow the steps below to create a good soldered connection: 1. Place the tip on the largest mass. 2. Add a small amount of solder (a bridge) to the part/tip contact area and heat the connection. Allow sufficient time for the heat to penetrate all parts, but not long enough to overheat any component. 3. Touch the solder to the connection at a point farthest from the tip. NOT to the iron. 4. Remove the solder and the iron together. 1. 2. 3. 4. 5. Allow the joint to cool without disturbing (moving) any part. 6. Replace the iron in its holder. The whole operation should take approximately 3 to 4 seconds. Use a light touch and do NOT press hard with the iron. WIRE CONNECTIONS Before wire is soldered, it is prepared by stripping off some insulation and tinning the exposed wire. This prepares it for a good solder connection. Strip the required amount of insulation off the wire with a good quality wire stripping tool. The tool should be 4 adjusted so that the strands of wire are not damaged or cut. Gently re-twist the strands if they have splayed out during the stripping. Do not over twist them. Tinning Procedure a) Heat the iron and put it on a holder or on the work surface with the tip up. b) Hold the wire in position against the tip. c) Allow the wire to heat for a short period taking care NOT to melt the insulation. d) Touch the solder to the wire and move it across the tip, add more solder if required. To make a loop after tinning, - use the round nose pliers and cut off the excess wire. The three typical loops are 180°, 270° and 360°. Place the loop on the terminal and squeeze it closed for a good mechanical contact, then solder. Apply the iron to point of maximum mass. Make a solder bridge to increase thermal linkage, and apply solder to the side opposite the iron. Remove the iron tip with a wiping motion. Characteristics of a Good Connection Inspect the finished connection. A good connection should: a) Be a bright silver (like a mirror) b) Have minimum solder - the strands are still visible c) Have feathered edges d) Have a smooth concave fillet e) Have no holes, pockets or peaks f) Have no flux between the work and the solder g) Have no extra wire extending from the connection h) Have a minimum of 1 wire diameter and a maximum of 2 wire diameters space between the insulation and the connection. TERMINAL CONNECTIONS There are 5 basic terminals. They are - turret, bifurcated, perforated (or eye), hook and cup terminals. Turret Terminals Turret terminals look like a post with two locations for soldering connections. Usually wire connections are made at the base and component connections are made at the top. Connections to turret terminals always come in from the side. Turret terminals are soldered from the base up. The first connection is at the bottom, the next is above that and so on. The insulation of the wires should touch when there is more than l wire on 5 the same section. The space between the connection and the insulation should be approximately 1 to 2 diameters of the wire. All connections should come in from the same direction. Bifurcated Terminals Bifurcated terminals can have 3 types of entry : from the top, from the bottom and from the side. The top entry is not very typical. Side entry - the wire comes in from the side and is wrapped around 1 fork or tang of the terminal for 90 or 180 (2 - 90 bends). The wire must touch the terminal completely no space between the terminal and the wire. When two wires come in from the side the hooks must go to the opposite sides. The wire insulation should touch. The ends should not protrude beyond the edge of the terminal. Typical side entry bifurcated terminal wire positions Top entry - the wire comes in from the top. The wire end is folded and inserted between the forks. The connection is soldered the full length of the fork. The wire should contact the fork for the full length. (This entry is not very common). Bottom entry - the wire passes through the terminal from the bottom. The wire is wrapped round one fork of the terminal and it contacts two sides of the fork. When two wires are connected they should connect on opposite forks. Perforated Terminals The perforated terminal is usually connected from the top, but side entry is permitted. Use a 90 or 180 hook and do NOT fill the eye with solder. 6 Hook Terminals Connect the hook terminal the same way as the perforated terminal. Use a 180, 270 or 360 loop. Make sure there is sufficient insulation gap. Cup/Pot Terminals The cup/pot terminal requires a different technique to the other types of terminals. First put a twist of solder into the cup. The twist should not protrude above the terminal cup. The wire should be tinned. Heat the terminal until the solder melts, quickly insert the tinned end of the wire and then remove the iron. The wire should be vertical in the cup and should touch the bottom and the back of the cup. COMPONENT TO TERMINAL CONNECTIONS Component leads are usually solid wire and are pre-tinned during manufacture. Putting strain relief bends in the leads protects the components from both vibration and thermal expansion or contraction damage. The leads must always remain straight as they leave the body of the component, so stress relief bends should start no closer than 1/16" (2mm) from the component body. The leads should connect to the terminals with a 180/270 loop. All horizontally mounted components should touch the board. The exceptions to this rule are glass components which should be mounted 1/32" (l mm) above the board surface. Use a heat sink (a metallic clip with a fairly large mass between the component body and the soldering iron) on heat sensitive components. 7 PRINTED CIRCUIT BOARDS Printed circuit boards are made of plastic, fibrous or fibreglass materials. There are three main types of board, single sided, double sided and multi layer. Tracks are the conductors that run between the pads or eyelets to which the components are soldered. The pads and eyelets on double sided and multi layered boards have plated through holes that connect the two (or more) sides/layers together as well as accommodate the component leads. Single sided board Double sided board showing plated through hole Multi layered Board Installing Components. Components must have stress relief bends and most of them should have the leads bent or clinched on the back (solder) side of the board. The components must be mounted from the top (component) side of the board. Correct polarity must be observed on polarized items. Always clip leads to their correct length before soldering. Install colour coded components so they can be read them from left to right or from top to bottom, and components with printed information so the information can be read after installation. Obviously polarity takes precedence over readability. All horizontally mounted components should touch the board, except glass components which should have the required space (1 mm) between the component and the board. COMPONENT TO PCB CONNECTIONS There are 6 basic types of connections: a) Straight Through. This is the simplest connection. The lead or wire is inserted through the board, trimmed and soldered from the bottom (solder) side of the board - never the component side. The solder should flow through the hole to the component side and form a fillet around the lead. On the solder side the lead should protrude approximately 1mm and be covered with solder but the outline should still be visible. b) Bent or Semi clinched. The lead is inserted through the board and bent over slightly. The lead is cut close to the board and then soldered. The bent lead should not be more than 2 mm above the board. Whenever possible bend the lead in the direction of the track. The soldering requirements from a) above apply. c) Fully Clinched. The lead is inserted through the board and bent over completely. It is cut to a maximum length equal to the radius of the pad, and a minimum of ½ the radius. When possible the lead should contact the board in the direction of the track. The soldering requirements from a) above apply. 8 d) Spaded. The lead is inserted through the board and is swaged (pressed flat). This holds the component to the board so that it doesn't move when it is soldered. Usually a special tool is required. The soldering requirements from a) above apply. e) Surface Mounting. The component lead, pre-tinned, rests on a pad which has also been pre-tinned. To solder - hold the lead against the pad and apply light pressure. Touch the top of the lead with the iron until the solder on the pad melts, slide the iron along the lead and remove. Release the pressure when the joint is cooled. f) Offset Pad Mounting. The lead is passed through the hole and bent back for a surface mount. This is often used when a pad is offset from the mounting hole. Bend the lead in the direction of the track or pad and use the same soldering requirements as the surface mount in e) above. General rules/standards for mounting and soldering components are shown in pictorial form on page 11. The key to each component’s non-conformance is on page 12. At right is a cross section of a typical component to PCB solder joint. MOUNTING AND SOLDERING I.C. PACKAGES Dual In-line Packages (DIPs) DIPs are very sensitive to heat and also have a number of leads (legs) that are close together. This means a large amount of heat can be concentrated in one area. The technique used for soldering can reduce the effect of heat, ensuring a functioning I.C. when mounted. One technique follows: 1. Carefully insert the DIP into the PCB taking care not to bend any legs under the body of the chip. 2. Ensure the DIP is level and then clinch two diagonally opposite leads to hold the chip in place. 3. Trim the remaining leads to approximately 1 mm above the board. 4. Solder one leg, ensuring the solder flows through to the top of the board and forms a fillet. 5. Solder another leg at the opposite end and side from the first. 6. Go back and solder the leg next to the one you soldered first. 7. Alternate ends/sides until all legs are soldered. The usual soldering standards apply. It is often preferred to solder a chip holder to the PCB. These holders are not heat sensitive and are usually more robust than a chip. They allow you to ‘plug in’ the chip and make chip replacement very simple. 9 Can type ICs and single Transistors Transistor and can type IC's are mounted in a different manner to DIPs. They can be mounted with or without an insulating spacer between them and the PCB. The leads should be spread outward slightly, stress relief bends are optional if no spacer is used, but mandatory if a spacer is used. Take care to ensure that all leads (legs) are correctly located in the mounting holes. Do not force the component too close to the board as this will stress the legs. Clinch the leads making sure the can is upright. Heat damage can be drastically reduced by once again soldering alternate legs. Vertical Mounting (Axial lead Components – a lead at each end of the component) It is often the case that axial lead components are mounted vertically instead of horizontally. This can be to reduce the overall size of a PCB or because the mounting holes are too close together to accommodate the component. Vertical components should never touch the board or have insulation material in the mounting hole. They should have sufficient space (approximately 2-4 mm) between themselves and the board to allow a heat sink to be used. This space will also provide mandatory stress relief when the lead/component expands and contracts due to heat/cold and allow access to the lead if removing the component. During forming the upper lead must remain straight for several mm as it exits the component body. This prevents stress to the internal connection of the component. Colour codes should read from top to bottom, and the component should be vertical when finally soldered. All normal soldering requirements apply. Vertical mounting of axial components Approx 2-4 mm 10 11 KEY TO PCB RESISTOR MOUNTING DIAGRAM Examples A, B, C and D are all correct. Example E: Component is mounted at an angle and is therefore NOT touching the board. All horizontal components, except glass bodied, should be mounted flush to the board unless specified otherwise by Drawing or Engineering Change Order. (ECO). See example A for correct mounting. Example F: Leads are cut too short and do not protrude through the pad/eyelet on the solder side of the PCB. All non-clinched leads must protrude 1 to 3 mm. See example B. Example G: The distance between pads/eyelet’s is insufficient to accommodate the component resulting in the leads being formed too close to the body of the resistor. This can cause damage to the internal connection of the lead, and does not give sufficient stress relief. See example C for correct lead forming. Example H: The colour coding is at the bottom making it difficult to see if components are close together. Although this does not present any physical problem, it does not improve ‘inspectability’ if colour codes are not in the same orientation. See example D. Example I: Component is not touching the board. See example A. Example J: Leads are clipped too long and can be accidentally bent over to produce a short circuit to adjacent pads/tracks. See example B. Example K: Leads poorly formed and show evidence of multiple bends. Strong possibility that the leads have suffered metal fatigue and will fracture. See example A. Example L: Component is offset from center giving insufficient room to correctly form the lead on the closer side. Possibility of internal stress/damage as in example G. See example A. Example M: Leads clipped too long and will probably produce a short circuit or solder bridge to adjacent pads/tracks. Clinched leads should be clipped off at a point between half and full radius of the pad and should not ‘overhang’. See example A. Example N: Component not vertical, and upper lead is formed too close to body of resistor. Possibility of internal stress/damage as in example G. See example D. Example O: Component mounted flush to board giving zero stress relief. All vertical components should be mounted proud of the board by sufficient distance to allow for a heat sink and for expansion/contraction stress relief, unless specified otherwise by drawing or ECO. On temperature induced contraction, the lead will ‘pull out’ of the component. Also, the colour code is at the bottom. See example D. Example P: Leads are ‘pulled tight’ giving no stress relief resulting in same temperature induced problem as example O above. See example A. Example Q: Everything is correct except that the colour coding is reversed. Although this does not present any physical problem, it does not improve ‘inspectability’ if colour codes are not in the same orientation. See example A. 12 SURFACE MOUNT PCBs Many of today’s PCBs are made up of completely surface mounted components. These are extremely small and can reduce the size of a PCB or increase the ‘population’ of the PCB by a considerable amount. The pictures below show the size of some components (resistors at left, capacitors middle and transistors at right) compared to a typical ½ watt through mount resistor. As the name implies, surface mount components are not mounted in ‘through holes’ but soldered directly to pads on the surface of the board. Their size and accuracy of placement require a completely different technique to the through mount technology. Most commercially produced surface mount PCBs use special ‘pick and place’ computer controlled robotic machines to choose the right components and place them in the correct position on the board. Prior to placement a special paste (a combination of flux/solder/glue) has been applied to the mounting pads or to the mounting surface of the component. This ensures the components remain in place until soldered. The actual soldering process can also differ greatly from through mount soldering. Hot air is often used to heat the area of the mounting pad until the solder melts and forms a fillet with the pre-tinned component mounting area. Amateur or hobby surface mount production can be accomplished by far less sophisticated methods. The solder/flux paste can be applied by a hypodermic syringe, components can be placed using tweezers and soldering can actually be accomplished with a small tipped soldering iron or even a toaster oven. (Yes, a toaster oven). 13 STATIC ELECTRICITY Many components require special protection against static electricity. During Winter months or in dry environments static charges of 40,000 Volts are not unusual. These voltages can easily damage static sensitive components, and although many components have internal protective devices built in they still require special precautions. Anti-static lab coats and mats, special anti-static floors, wrist straps, anti-static packaging and leather soled shoes are some of the precautionary measures taken to prevent static damage. If you work at a static protected work station, here are some of the procedures you must follow: 1) 2) 3) ALWAYS wear a wrist strap. NEVER wear the wrist strap over clothing - be sure it is on the skin. ALWAYS ‘discharge’ your hands before you begin work by placing them on the anti-static work table mat. 4) ALWAYS wear leather soled shoes. 5) ALWAYS button up your anti-static lab coat. 6) NEVER slide components on any surface. 7) NEVER have plastic, styro-foam cups or any unnecessary objects on your work bench. 8) NEVER comb your hair at the work station. 9) ALWAYS pick up devices only by the body – try not to touch the leads. 10) ALWAYS transport static sensitive components in static shielding packages, containers or bags that protect the device from static electricity. 11) ALWAYS keep other components, assemblies and work sheets in their packages as much as possible. 14 Test your knowledge of solder/soldering Answer True (T) or False (F) 1. 2. 3. 4. Solder works like a glue. Solder is an alloy of tin and lead. Wetting action creates a new alloy. The "plastic" range is the temperature range between solder starting to melt and becoming completely liquid. 5. Moving a joint when it is in the plastic range is acceptable. 6. Eutectic solder has a very small plastic range. 7. If a copper surface looks clean it is ready for soldering. 8. Flux removes the oxides. 9. One size soldering iron is good for all jobs. 10. A solder bridge is extra flux. 11. A large mass needs a small tip. 12. Do not tin a soldering iron. 13. You should clean the work with solvent after soldering. 14. "60/40" solder is 60% lead and 40% tin. 15. When soldering the connection, put the solder on the iron tip. Answer the questions with complete sentences. 1. 2. 3. 4. 5. 6. What is flux? What does flux do? What is flux cored solder? Why is it important when hand soldering to use solder with a plastic range? What determines the size or wattage of soldering iron to be used? When soldering, where do you put the soldering iron tip and where do you put the solder? 7. What is the ideal time to hold the iron on a connection? 8. What chemicals can you use for cleaning solder joints? 9. What is ‘tinning’? 10. What does a solder bridge do? Prepared by Mike Crompton 15