Historic Preservation Industrial Reconnaissance Survey

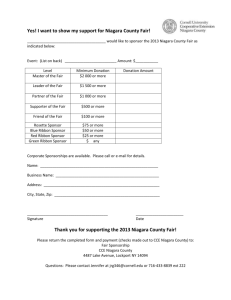

advertisement