as Microsoft Word

advertisement

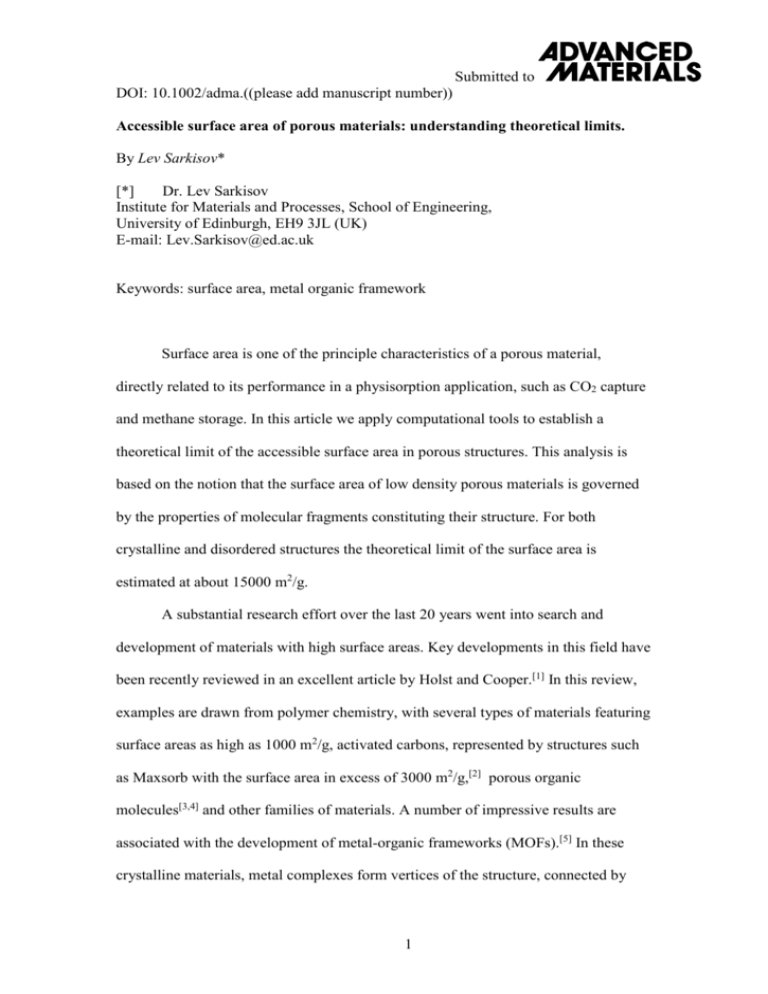

Submitted to DOI: 10.1002/adma.((please add manuscript number)) Accessible surface area of porous materials: understanding theoretical limits. By Lev Sarkisov* [*] Dr. Lev Sarkisov Institute for Materials and Processes, School of Engineering, University of Edinburgh, EH9 3JL (UK) E-mail: Lev.Sarkisov@ed.ac.uk Keywords: surface area, metal organic framework Surface area is one of the principle characteristics of a porous material, directly related to its performance in a physisorption application, such as CO2 capture and methane storage. In this article we apply computational tools to establish a theoretical limit of the accessible surface area in porous structures. This analysis is based on the notion that the surface area of low density porous materials is governed by the properties of molecular fragments constituting their structure. For both crystalline and disordered structures the theoretical limit of the surface area is estimated at about 15000 m2/g. A substantial research effort over the last 20 years went into search and development of materials with high surface areas. Key developments in this field have been recently reviewed in an excellent article by Holst and Cooper.[1] In this review, examples are drawn from polymer chemistry, with several types of materials featuring surface areas as high as 1000 m2/g, activated carbons, represented by structures such as Maxsorb with the surface area in excess of 3000 m2/g,[2] porous organic molecules[3,4] and other families of materials. A number of impressive results are associated with the development of metal-organic frameworks (MOFs).[5] In these crystalline materials, metal complexes form vertices of the structure, connected by 1 Submitted to organic linkers. This architecture allows one, through selection of appropriate linkers, to create extremely sparse materials with record low crystal densities (< 0.25 g/cm3) and ultrahigh surface areas (> 6000 m2/g).[6] Recently, two new materials have been discovered with extraordinary properties. NU-100 is a metal-organic framework, which was predicted using computational modelling and consequently synthesized and characterized.[7] The experimentally measured surface area of NU-100 is 6143 m2/g. PPN-4 is a polymer material with diamondoid framework topology, featuring surface area of 6461 m2/g.[8] What is the highest possible surface area of a porous material? Understanding theoretical limits is important in our efforts to design materials with tailored properties. Traditionally, surface area of a porous material is estimated experimentally from the Brunauer-Emmett-Teller (BET) method, applied to nitrogen adsorption isotherms at 77 K.[9] Within this method adsorption is described as the formation a multilayer on the surface of the material, from which, given the size of the nitrogen molecule, surface area can be derived. This picture, however, may not be valid in very narrow pores (or micropores) and in the systems with substantial structural heterogeneity. As a result, although it has been more than 70 years since the original publication, it is still an ongoing debate on the most consistent way to apply and interpret the BET method.[10] Alternatively, surface area of a porous material can estimated using a computational approach. This approach requires a model structure of the porous material. In case of a crystalline material, the model structure is simply a representative sample of the crystalline network. For disordered materials, the model must be constructed to reflect primary morphological features of the material under consideration. One can envision a surface accessible to spherical probe of a particular 2 Submitted to size as the surface obtained by rolling the probe particle over the atoms of the structure. In the actual simulation, a Monte Carlo procedure is used to construct this surface and to calculate its area.[11,12] Accessible surface area is a geometric characteristic, it is free of the assumptions involved in the BET theory and, in principle, can be used on its own to systematically describe and compare porous structures to each other. For example, this approach has been recently applied to characterize a variety of porous materials including MOFs and polymers.[13,14] However, a number of recent studies reported a striking agreement between the computed accessible surface areas and those measured using the BET method for a number of materials.[15,16] This is not a chance event and requires a comment. In the analysis of the applicability of the BET method to MOFs, Walton and Snurr explored a series of materials (so called isoreticular MOFs, or IRMOFs[17]) with systematically changed linker geometry and cage size.[16] Computer visualization of nitrogen adsorption in IRMOF-16 (which features cages of size of more than 20 Å, and therefore is not a microporous material) clearly shows formation of a layer of nitrogen on the surface of the organic linkers and in the corners of the structure (Figure 4b in the original publication[16]). Although this layer looks somewhat inhomogeneous, its formation resembles adsorption on a free surface, which is one of the key assumptions in the BET theory. The BET surface area (obtained either from the experimental or simulated isotherm on IRMOF-16) agrees very well with the computed accessible area, suggesting that despite the limitations of the BET method, it correctly captures the extent of the solid surface accessibility. Interestingly, a surprisingly good agreement between the BET and the accessible surface areas has been observed even for ultramicroporous materials, where the BET theory is expected to break down.[18] In this study, however, we are interested in materials with very high surface areas, 3 Submitted to which are expected to be very sparse with densities lower than that of IRMOF-16, and pore sizes larger than that in IRMOF-16. In this regime, concerns associated with the applicability of the BET method to microporous materials are not applicable. One of the principle advantages of the computational approach is that it can be applied to hypothetical structures, including model porous materials and individual molecular fragments. Here we apply this computational method to answer the main question posed in the article. To be consistent with the previous studies and with the experimental measurements we use a single atom of nitrogen as a probe particle, with the parameters of this atom and other details of the calculation provided in the supplemental information file (results from an alternative calculation based on a single site representation of nitrogen and consistent with several earlier studies are also provided there). The high surface area of MOFs to a significant extent is governed by the surface area of organic linkers, constituting the structure. Thus, as has been previously suggested in the analysis by Chae and co-workers,[19] the design of MOFs with extensive surfaces can in principle be reduced to the selection of linkers with the highest possible surface area and ensuring that as much as possible of this surface area is accessible and not obstructed by the neighbouring elements of the structure. What molecules would have the highest surface area? It is illustrative to examine the accessible surface area of simple molecules. For example, as shown in Table 1, a molecule of methane has surface area of about 90000 m2/g, whereas for benzene it is about 26000 m2/g as seen by the probe nitrogen atom. In case of methane, this characteristic can be viewed as the limiting value of the accessible surface area for an organic molecule. 4 Submitted to Consider a series of IRMOFs, where Zn-based metal complexes are linked by chains of aromatic (phenylene) units (one in IRMOF-1, two in IRMOF-10, three in IRMOF-16).[17] As has been noted by Schnobrich and co-workers as the number of rings in the linker is increased, the role of the metal complex vertices is diminished and the surface area of the porous material should approach that of the poly(pphenylene) estimated at 10577 m2/g.[20] To complement this result, here we evaluate the surface area of polyacene (a chain of linearly fused aromatic rings) to be about 10224 m2/g. Yet, even higher specific (in other words per gram of material) surface area is possible. Cumulene (=C=C=)n and polyyne (−C≡C−)n have been observed and characterized in several studies,[21,22] although the existence and stability of very long fragments of these molecules has been received with some scepticism.[23] These polymeric chains are based on carbon atoms only and have no hydrogen atoms. The accessible surface area of these structures is calculated here to be 14936.9 m2/g and this is the highest possible specific surface area of a polymeric chain, or any porous material, either ordered or disordered, based on this chain as a building block. This can be compared to the highest surface areas observed for porous polymers (PAF-1, BET surface area 5600 m2/g[24] and PPN-4, BET surface area 6461 m2/g[8]) and MOFs (NU-100[7], BET surface area 6143 m2/g). In the first case, the polymer structure is based on a diamond-like network, where carbon-carbon bonds are replaced with phenylene rings. In the second case, the structure of the metal-organic framework is based on branched linkers, which involve interchanging phenylene and alkyne (−C≡C−) groups. This study suggests that, although it is unlikely to create materials based solely on polyyne linkers, higher proportion of alkyne groups in the linker structure should lead to further increase in the surface area, with the theoretical limit determined above. 5 Submitted to In case of disordered porous structures the situation is more complex. As has been already discussed, these materials require a model representing their structure, and construction and validation of appropriate models of disordered materials, such as activated carbons, has been a substantial research challenge in itself.[25-27] It has been widely accepted that the basic structural unit of activated carbon is a fragment of a carbon sheet, or several fragments stacked together.[25] Experimental studies suggest that for typical non-graphitizing porous carbon materials these fragments range between 1 and 5 nm in diameter.[28] Models where these fragments are represented as disks or platelets and the whole structure of the material is based on a random packing of these platelets, have proven to be an accurate representation of several classes of porous carbon materials, such as BPL.[29,30] Even more sophisticated models of disordered carbons started to emerge based on curved and fullerene-like fragments and models, imitating the actual process of carbon material formation.[28, 31-34] Here we also recognize that smaller structural units have higher proportion of edges exposed per unit mass or per carbon atom and thus have higher specific surface area. In fact, it is this idea that allowed Kaneko and co-workers to put forward a plausible explanation of high surface areas, exceeding that of a single graphitic layer (2630 m2/g) and observed for several activated carbons.[35] Therefore, here we base our model on the smallest platelet consistent with the experimental observations. This platelet corresponds to the molecule of coronene and is shown in Table 1. The diameter of this molecule is about 1 nm and the surface area is 12274.1 m2/g. As a model of carbon material we consider a random packing of these platelets. Analysis of the geometric and BET surface areas in carbon models based on packings of carbon fragments has been recently performed by Gauden et al.[34] In their work the fragments were larger and of more complex geometry, compared to this 6 Submitted to study. Interestingly, using these models, Gauden and co-workers concluded that if anything, the BET method underestimates the surface area of activated carbons and not overestimates it as is often assumed for microporous materials.[34] The model considered here can be viewed as the limiting case of the model by Gauden et al.[34] As an additional constraint, we impose a condition that the platelets in the packing must form a percolated self-supporting network, or cluster. Two platelets belong to the same cluster if any two atoms of the platelets touch each other or slightly overlap. Whether the platelets form a percolated cluster based on this criterion is determined using the computational tools described in our previous publication.[12] We start with a dense packing of platelets (obtained using a simple Monte Carlo protocol, with parameters ensuring some small overlap between the atoms. See the supporting information for more detail). Some of the platelets are then gradually removed. Within each new configuration generated in this process the largest cluster of platelets is identified and analysed. If it spans the simulation cell in all three dimensions, in other words is percolated, it is then considered as a model structure and its accessible surface area is calculated. The process continues until the percolation threshold is reached, beyond which any further removal of the platelets leads to disconnected structures. Packings near the threshold correspond to the percolated clusters with the highest surface area. Figure 1 shows an example of the starting packing configuration and a typical sparse cluster just before the percolation threshold. Accessible surface area for this model of activated carbon averaged over several realizations of percolated cluster is given in Table 1. This result shows that the theoretically possible accessible surface area of a model activated carbon substantially exceeds the current record values (BET surface area 3800 m2/g).[36] Even higher experimental BET surface area of 5100 m2/g 7 Submitted to for a carbon structure was observed in an earlier study, but it was dismissed as unrealistic.[37] This work suggests that these values of surface areas in disordered carbon materials are not impossible after all, with the surface area of the presented model exceeding 6000 m2/g. Clearly, this theoretical estimate is not a rigorous limit, as it depends on the simulation protocol and parameters employed in the model. (Alternative protocols to prepare these packings and resulting implications on the characteristics of the packings are briefly discussed in the supporting information file). For a more rigorous estimate, a configuration of freely floating platelets, each of them fully accessible to the probe atom, can be considered. This structure should have exactly the same specific surface area as a single platelet (12274.1 m2/g). This is highest possible area for a system based on particular platelet geometry, although obviously it is not a realistic picture. In conclusion, it is important to emphasize that the structures considered here are not likely to be attainable in the experiments due to stability issues and synthetic challenges. Instead, the outlined theoretical limits of the accessible surface area of molecular structures should serve as a guideline in our efforts to create evermore porous materials. Acknowledgements L.S. would like to thank Prof. Randy Snurr and Prof. Andrew Cooper for some useful comments and acknowledge EPSRC grant EP/G062129/1 “Innovative Gas Separations for Carbon Capture” for financial support. Received: ((will be filled in by the editorial staff)) Revised: ((will be filled in by the editorial staff)) Published online: ((will be filled in by the editorial staff)) [1] J. R. Holst, A. I. Cooper, Adv. Mater. 2010, 22, 5212. [2] T. Otowa, R. Tanibata, M. Itoh, Gas Separation & Purification 1993, 7, 241. 8 [3] Submitted to S. Jiang, J. T. A. Jones, T. Hasell, C. E. Blythe, D. J. Adams, A. Trewin, A. I. Cooper, Nature Comm. 2011, 2, 207. [4] T. Hasell, S. Y. Chong, K. E. Jelfs, D. J. Adams, A. I. Cooper, J. Am. Chem. Soc. 2012, 134, 588. [5] G. Ferey, Chem. Soc. Rev. 2008, 37, 191. [6] H. Furukawa, N. Ko, Y. B. Go, N. Aratani, S. B. Choi, E. Choi, A. O. Yazaydin, R. Q. Snurr, M. O'Keeffe, J. Kim, O. M. Yaghi, Science 2010, 329, 424. [7] O. K. Farha, A. O. Yazaydin, I. Eryazici, C. D. Malliakas, B. G. Hauser, M. G. Kanatzidis, S. T. Nguyen, R. Q. Snurr, J. T. Hupp, Nature Chem. 2010, 2, 944. [8] D. Yuan, W. Lu, D. Zhao, H. C. Zhou, Adv. Mater. 2011, 23, 3723. [9] S. Brunauer, P. H. Emmett, E. Teller, J. Am. Chem. Soc. 1938, 60, 309. [10] J. Rouquerol, P. Llewellyn, F. Rouquerol, Studies in Surface Science and Catalysis 2007, 160, 8. [11] L. D. Gelb, K. E. Gubbins, Langmuir 1998, 14, 2097. [12] L. Sarkisov, A. Harrison, Mol. Sim. 2011, 37, 1248. [13] T. Duren, L. Sarkisov, O. M. Yaghi, R. Q. Snurr, Langmuir 2004, 20, 2683. [14] C. Herdes, L. Sarkisov, Langmuir 2009, 25, 5352. [15] T. Duren, F. Millange, G. Ferey, K. S. Walton, R. Q. Snurr, Journal of Physical Chemistry C 2007, 111, 15350. [16] K. S. Walton, R. Q. Snurr, J. Am. Chem. Soc. 2007, 129, 8552. [17] M. Eddaoudi, J. Kim, N. Rosi, D. Vodak, J. Wachter, M. O'Keeffe, O. M. Yaghi, Science 2002, 295, 469. [18] Y. S. Bae, A. O. Yazaydin, R. Q. Snurr, Langmuir 2010, 26, 5475. [19] H. K. Chae, D. Y. Silberio-Perez, J. Kim, Y. B. Go, M. Eddaoudi, A. J. Matzger, M. O’Keeffe, O. M. Yaghi, Nature 2004, 427, 523. 9 [20] Submitted to J. K. Schnobrich, K. Koh, K. N. Sura, A. J. Matzger, Langmuir 2010, 26, 5808. [21] R. B. Heimann, J. Kleiman, N. M. Salansky, Carbon 1984, 22, 147. [22] W. A. Chalifoux, R. R. Tykwinski, Nat. Chem. 2010, 2, 967. [23] H. Kroto, Chem. World 2010, 7, 37. [24] T. Ben, H. Ren, S. Ma, D. Cao, J. Lan, X. Jing, W. Wang, J. Xu, F. Deng, J. M. Simmons, S. Qiu, G. Zhu, Angew. Chem. Int. Ed. Engl. 2009, 48, 9457. [25] T. J. Bandosz, M. J. Biggs, K. E. Gubbins, Y. Hattori, T. Iiyama, K. Kaneko, J. Pikunic, K. T. Thomson, in Chemistry and Physics of Carbon, Vol. 28 (Ed: L. R. Radovic), Marcel Dekker, Inc, New York, USA 2003, Ch. 2. [26] M. J. Biggs, A. Buts, D. Williamson, Langmuir 2004, 20, 7123. [27] M. J. Biggs, A. Buts, Q. Cai, N. A. Seaton, Studies in Surface Science and Catalysis 2006, 160, 79. [28] P. J. F. Harris, S. C. Tsang, Philos. Mag. A-Phys. Condens. Matter Struct. Defect Mech. Prop. 1997, 76, 667. [29] E. I. Segarra, E. D. Glandt, Chem. Eng. Science 1994, 49, 2953. [30] J. C. Liu, P. A. Monson, Adsorption-J. Int. Ads. Soc. 2005, 11, 5. [31] K. T. Thomson, K. E. Gubbins, Langmuir 2000, 16, 5761. [32] A. Kumar, R. F. Lobo, N. J. Wagner, Carbon 2005, 43, 3099. [33] A. Kumar, R. F. Lobo, N. J. Wagner, AIChE Journal 2011, 56, 1496. [34] P. A. Gauden, A. P. Terzyk, S. Furmaniak, P. J. F. Harris, P. Kowalczyk Appl. Surf. Sci. 2010, 256, 5204. [35] K. Kaneko, C. Ishii, M. Ruike, H. Kuwabara, Carbon 1992, 30, 1075. [36] M. Jordá-Beneyto, F. Suárez-García, D. Lozano-Castelló, D. Cazorla-Amorós, A. Linares-Solano, Carbon 2007, 45, 293. 10 [37] Submitted to T. G. Lamond, H. Marsh, Carbon 1964, 1, 293. Figure 1. Left panel: A typical configuration of a dense random packing of coronene platelets. Right panel: a typical configuration of a fully percolated cluster of platelets obtained by random removal of some of the platelets from a dense configuration. Note, that some of the platelets that seem to be detached from the cluster are connected to it over the periodic boundary conditions, delineated with the black box. Table 1. Accessible surface areas of molecules and platelet packings. Molecular object Methane Structure Surface area [m2/g] 88893.9 11 Submitted to Benzene 26182.1 Coronene 12274.1 Random packing of platelets 6403.0±204.9 12 Submitted to A random packing of platelets as a model of an activated carbon material. Keyword: surface area, metal organic framework L. Sarkisov* Accessible surface area of porous materials: understanding theoretical limits. ToC figure ((55 mm broad, 50 mm high, or 110 mm broad, 20 mm high)) 13