OHS Risk Assessment

advertisement

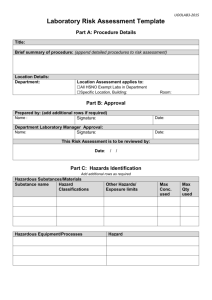

SAMPLE Health & Safety Risk Assessment Guidelines for Wineries Table of Contents 1. Introduction…………………………………………………………………………..1 2. Definitions…………………………………………………………………………… 2 3. Health & Safety Risk Assessment Method……………………………………….3 1. Introduction These guidelines summarize the procedure to be followed when conducting and annual health and safety risk assessment. This methodology is suitable for the assessment of most work tasks. It is not suited to the assessment of complex processing activities. These are assessed using alternative methods such as Hazard and Operability Studies (HAZOP) or Failure Mode Effect Analysis (FMEA). The risk assessment methodology covers all OH&S related hazards. Some legislation, standards and guidance require more detailed risk assessment for specific hazards. The following list (non exhaustive) of specific hazards should be included in the risk assessment however they may also require a more detailed assessment: Manual Handling- Manual Handling Risk Assessment Chemicals- Chemical Use Risk Assessment DSE / VDU - Display Screen Equipment / Visual Display Unit Noise- Noise Risk Assessment Dusts- Atmospheric Hygiene Assessment Explosive Atmospheres Assessment Occupational Health- Occupational Health Risk Assessment (GRMS) Machinery- Machinery Risk Assessment Fire- Fire Risk Assessment Ergonomics- Ergonomic Risk Assessment Legionella Risk Assessment Process Equipment Risk Assessment (HAZOP) Lightning Risk Assessment Work at Heights Risk Assessment Wellbeing Risk Assessment FLT Risk Assessment The guidelines have been developed using the following publications: BS 8800:2004 Occupational Health and Safety Management Systems Guide Boyle, T., (2002) Health and Safety Risk Management, IOSH HSE, (1997) HSG65 Successful Health and Safety Management HSE, (2006) INDG163 5 Steps to risk assessment The risk assessment should be reviewed and updated on an annual basis or due to changes in a process, activity, organization or equipment changes. The risk assessment should also be reviewed if an incident investigation highlights that the risk has not been appropriately assessed. 2. Definitions Hazard Source or situation with a potential for harm (in terms of human injury, ill health or a combination of these). Risk Combination of the likelihood and consequence of a specified hazardous event. A risk always has two components: a. The likelihood of a hazardous event. b. the consequences of the event Where health is concerned the consequence of a hazardous event may be based on a number of events. E.g. repeated exposure to noise on separate occasions may cause noise induced hearing loss. Risk Assessment Process of identifying hazards and evaluating the risks to health and safety arising from these hazards whilst taking account of the existing risk controls. (For planned activities evaluate risk by taking account of the proposed risk controls.) Risk Controls Workplace precautions, for example physical safe guards, containment of airborne contaminants, safe systems of work, training / competency and personal protective equipment. When proposing risk controls to mitigate a hazard due consideration should be given to the hierarchy of control: - First:- If practical eliminate hazard altogether Second:- Try to reduce the risk at source Third:- Reduce the risk through procedures Fourth:- Reduce the risk by providing PPE 3. Health and Safety Risk Assessment Method The 5 steps to risk assessment are: a) b) c) d) e) Determine work activities Identify hazards Identify current risk controls Assess the risk Specify actions to reduce the risk Risk assessment should be conducted by competent people with practical knowledge of the work activities. Risk assessment should be conducted by small teams of individuals who have been trained in the risk assessment methodology. The teams will need access to OHS specialists to conduct the assessment. 3 a. Determine work activities Work activities are listed in a workshop session by considering normal every-day activities and other non-routine activities such as infrequent maintenance tasks, contractor activities and home-working. It is important to consider different operational modes of the activity i.e. normal use, change over or CIP. Work activities can be classified in three ways: a. Geographical areas b. Stages in the production process c. A combination of a. and b. above To obtain the necessary level of detail for risk assessment it will be necessary to decompose activities into tasks, see example below. Process / Area: Bottling line Activity: Automatic labeling machine Tasks: Replenish labels Bottle size change-over Conduct Autonomous Maintenance Replenish liquid glue Relieve blockages Operate machine Clean machine & parts In order to identify the hazards associated with a task those conducting the risk assessment should have an understanding of the following: - The duration, frequency - Scope for hazardous interaction with other activities Who carries out the tasks Others who are affected by the task (maintenance, cleaners, contractors) Existing procedures relating to execution of the task Permit-to work systems in place Manufacturers instructions (in the case of work equipment) Substances / Chemicals used The weight / size / shape of materials manually handled during the task Accident / incident records relating to the task For certain unplanned tasks e.g. the repair of a burst pipe, it is unlikely that this task would have been risk assessed using this methodology as its occurrence would not have been anticipated by the risk assessment team. These activities are risk assessed in a different manner. If the task is being completed by a contractor it should be risk assessed in the task specific method statement prepared by the contractor prior to commencement of works. In other instances a permit to work checklist forms the basis of a risk assessment. 3 b. Identify Hazards Identify the hazards associated with each task. When identifying the hazards consider the following: Is there a source of harm? Who or what could be harmed? How could harm occur? Consider the following physical, chemical, biological & psychological hazards (not exhaustive): PHYSICAL Slippery or uneven ground leading to slips / falls Work at heights leading to falls Equipment falling from a height causing injury Inadequate space e.g. low headroom leading to head injury Poor ergonomics leading to RSI Manual handling leading to back injury Moving parts causing trapping /entanglement injuries Hot surfaces or substances causing burns e.g. glue / steam Poor housekeeping leading to fire Ionizing radiation leading to health effects Violence to staff Harmful energy sources e.g. electricity, pneumatic energy, compressed air, hydraulic energy Noise leading to hearing defects Confined spaces with hazardous atmospheres BIOLOGICAL Inhalation, ingestion or contact with bodily fluids causing illness CHEMICAL Inhalation, ingestion, contact with a chemical which causes injury PSYCHOLOGICAL Workplace stress leading to health issues Physical violence leading to injury The list above is by no way exhaustive and should only be used to guide thinking. Care must be taken to ensure all other hazardous scenarios are documented. 3 c. Identify current risk controls For each identified hazard existing control measures should be specified. 3 d. Determine the Risk Risk is determined by estimating the potential severity of harm and the likelihood harm will occur for a given hazard. To estimate the severity of harm consider: How the person is likely to be affected? What harm will result? Severity of harm is categorized into the following levels, see table overleaf: Harm Category Low Medium High Health Nuisance and irritation, temporary ill health leading to discomfort Partial hearing loss, dermatitis, asthma, WRULD, ill health leading to permanent minor disability Acute fatal diseases, severe life shortening diseases, permanent substantial disability Safety Superficial injuries, minor Lacerations, burns, Fatal injuries, amputations, cuts and bruises, eye irritation from dust concussion, serious sprains, minor fractures multiple injuries, major fractures Next consider the likelihood that a hazardous event actually results in harm. Likelihood is categorized into the following levels: Likelihood of Harm Category Low Medium High Typical Occurrence Typically experienced once during the lifetime of an individual Typically experienced once every five years by an individual Typically experienced at least once every six months by an individual Risk level is estimated using the business risk footprint below. (D) medium (G) high (I) CR IT MEDIUM SEVERITY HIGH (B) low (E) medium (H) high (A) low (C) low (F) medium IC AL LOW LIKELIHOOD LOW MEDIUM HIGH 3 e. Specify Control Measures Control measures are specified for each hazard along with owners and completion dates. Control measures should reduce the hazard to an acceptable risk level. The table below should be considered in determining the level of action required to mitigate a given hazard. Risk Level MATRIX SECTOR ACTION REQUIRED LOW A, B, C No additional controls required unless they can be implemented with minimal effort in terms of cost and human resource. Actions to mitigate these hazards are low priority. MEDIUM D, E, F Action is required to move this hazard to a lower risk level. These actions should be progressed within one month. HIGH G, H, I Substantial efforts should be made to reduce the risk. Consideration should be given to suspending the activity until additional controls have been implemented. These actions should be progressed within one week.