Pollution board asks thermal plants to stop spilling fly ash Riyan

advertisement

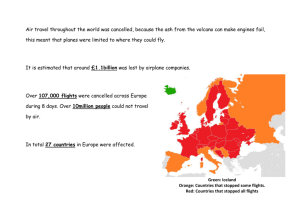

Share on emailShare on printShare on redditMore Sharing ServicesShare on emailShare on Pollution board asks thermal plants to stop spilling fly ash printMore Sharing Services Riyan Ramanath V, TNN Jul 22, 2013, 04.19AM IST Tags: Pollution board| bones| ash BHUBANESWAR: Wary of spilling of fly ash from thermal power plants to nearby water bodies and farm lands, the Orissa State Pollution Control Board (OSPCB) has asked all thermal power plants to follow at least five precautionary measures during monsoon. The OSPCB's directives came in the wake of fly ash pond leakage of Hindalco thermal power plant in Sambalpur district last year, which led to damage of agricultural lands adjacent to the plant. It also contaminated water in the irrigation canal. "At a recent meeting, we discussed the fly ash issue and formulated some measures, which can ensure better management of fly ash generated from captive power plants. I is the look out of industries to effectively follow the guidelines and dispose of fly ash before they spill into water bodies and irrigated lands," said environment director B P Singh. Sources said toxic fly ash from the Hindalco captive power plant is dumped at a site less than 100 metres from the Hirakud reservoir. The site is also close to the irrigation canal that conveys reservoir water to farm lands. "The five steps the industries have been asked ot follow include construction of garland drains around ash disposal area to prevent spilling, proper sloping of the ash mound, erection of a toe wall to keep the ash mound intact and compact, and finally clear demarcation of the disposal path," said environment scientist Dilip Kumar Behera. "Only 54% of the total ash generated from thermal power plants are being utilized or disposed of. About 24 million tonnes of fly ash is generated per annum from the industries generating a total of 11,400 MW power. If the ashes lie unused, it can contaminate ground water in the nearby areas" he said. Fly ash contains at least 22 heavy metals, of which 18 can affect lungs, bones and other diseases. "If the bulk of fly ash is lifted for construction of roads, filling mining void, filling low-lying areas and brick making, hazardous pollutants emanating from it won't affect the environment," said an OSPCB official. Share on emailShare on printShare on redditMore Sharing ServicesShare on emailShare on Pollution board asks thermal plants to stop spilling fly ash printMore Sharing Services Riyan Ramanath V, TNN Jul 22, 2013, 04.19AM IST Tags: Pollution board| bones| ash BHUBANESWAR: Wary of spilling of fly ash from thermal power plants to nearby water bodies and farm lands, the Orissa State Pollution Control Board (OSPCB) has asked all thermal power plants to follow at least five precautionary measures during monsoon. The OSPCB's directives came in the wake of fly ash pond leakage of Hindalco thermal power plant in Sambalpur district last year, which led to damage of agricultural lands adjacent to the plant. It also contaminated water in the irrigation canal. "At a recent meeting, we discussed the fly ash issue and formulated some measures, which can ensure better management of fly ash generated from captive power plants. I is the look out of industries to effectively follow the guidelines and dispose of fly ash before they spill into water bodies and irrigated lands," said environment director B P Singh. Sources said toxic fly ash from the Hindalco captive power plant is dumped at a site less than 100 metres from the Hirakud reservoir. The site is also close to the irrigation canal that conveys reservoir water to farm lands. "The five steps the industries have been asked ot follow include construction of garland drains around ash disposal area to prevent spilling, proper sloping of the ash mound, erection of a toe wall to keep the ash mound intact and compact, and finally clear demarcation of the disposal path," said environment scientist Dilip Kumar Behera. "Only 54% of the total ash generated from thermal power plants are being utilized or disposed of. About 24 million tonnes of fly ash is generated per annum from the industries generating a total of 11,400 MW power. If the ashes lie unused, it can contaminate ground water in the nearby areas" he said. Fly ash contains at least 22 heavy metals, of which 18 can affect lungs, bones and other diseases. "If the bulk of fly ash is lifted for construction of roads, filling mining void, filling low-lying areas and brick making, hazardous pollutants emanating from it won't affect the environment," said an OSPCB official. 111111111111111111111111111111111111111111111111111111111111111111111111 11111111111111111111111111111111111111111111111111111111111111 Share on emailShare on printShare on redditMore Sharing Services o o o Share on emailShare on printMore Sharing Services Thermal plant fly ash to boost greenery Riyan Ramanath V, TNN Sep 9, 2013, 04.27AM IST Tags: Thermal plant| Orissa state pollution control board| Orissa Forest Development Corporation BHUBANESWAR: Fly ash generated from thermal power plants in the state can be used for afforestation. Delhi-based Centre for Fly Ash Research and Management (C-FARM), in collaboration with regional research laboratory (RRL), will guide Orissa State Pollution Control Board (OSPCB) on how to promote fly ash in forestry management. The OSPCB, which opened a resource centre two months ago to facilitate the promotion of fly ash utilization, hopes to adopt the new research and guide the fly ash generating industries and users. Experts said fly ash contains micro-nutrients and it can be helpful in the growth of plants. Fly ash mainly helps increase the fertility of degraded soil. "Fly ash improves the soil texture and increases its water holding capacity, which can ensure survival of the plants," said C-FARM advisor Vimal Kumar. He said Odisha generates about 25 million tonnes of fly ash a year and it might go up to 100 million tones in the next seven years. "If the use of fly ash is not promoted in the forestry sector, bulk of fly ash will remain unused, which will pose danger to the environment. In Odisha, we have already experimented the use of fly ash in 75 hectares in Sukinda range under Cuttack forest division for raising a nursery. The Orissa Forest Development Corporation also has been keen on the use of fly ash," said Kumar. After burning of coal in a thermal power plant, fly ash is generated, which contains potassium, phosphorous, nitrogen, said a scientist of RRL. "Under normal circumstances, the survival of plants in case of bulk plantation is low. But the use of fly ash has made wonders. Use of fly ash in plantation can not only check pollution but it can ensure effortless greenery," said the scientist. A recent survey by OSPCB revealed that only 54% of the total ash generated from industries in the state is being utilized. "We have taken several initiatives to promote the use of fly ash. But its use in a massive plantation drive can clear the mess in several fly ash ponds in the industries. Lack of proper use of fly ash not only damages lakhs of acres of farm lands in the state, it is posing danger to water and aquatic life. Fly ash contains at least 22 heavy metals of which 18 are cancerous leading to lungs, bone and other diseases," said senior environmental scientist D K Behera. About 194 million tonnes of fly ash is presently piled up in fly ash ponds of about 40 major thermal power plants in the state. 222222222222222222222222222222222222222222222222222222222222222222222222222222 222222222222222222222222222222222222222222222222222222222222222222222222222222 Volume 2 No.4 July 1999 TECHNOLOGY : Flyash Disposal and Utilization: The Indian Scenario Thermal Power stations using pulverized coal or lignite as fuel generate large quantities of ash as a by-product. There are about 82 power plants in India, which form the major source of flyash in the country. With the commissioning of super thermal power plants and with the increasing use of low grade coal of high ash content, the current production of ash is about 85 million tonnes per year. This figure is likely to go upto 100 million tonnes per year by the year 2000 AD and pose serious ecological problems. Appreciating the overall concern for the environment and the need for the safe disposal and effective utilisation of flyash, Department of Science & Technology (DST) as the nodal agency and Technology Information and Assessment Council (TIFAC) as the implementing agency commissioned a Flyash Mission in 1994. Flyash Mission: a Technology Project in Mission Mode (TPMM) is being implemented with participation of Ministry of Environment & Forest, Ministry of Power, Thermal Power Stations, R&D institutions and Industry. The focus is on demonstration of coal ash related technologies for developing confidence and thus ensuring large scale adoption. A number of projects taken up by the industry, R&D institutions and academia have shown encouraging results. Some of these projects have been completed, multiplier effects have started and other projects are heading towards meaningful completion. A judicious mix of select thrust areas have been taken up for concerted efforts. These include Flyash Characterisation, Hydraulic Structures, Handling and Transportation, Agriculture related studies and Application, Ash Ponds and Dams, Reclamation of Ash Ponds for Human Settlement, Roads and Embankments, Underground Mine Fills and related research projects. Although the scope for use of ash in concrete, brick making, soil-stabilization treatment and other applications has been well recognized, only a small quantity of the total ash produced in India is currently utilized in such applications. Most of the ash generated from the power plants is disposed off in the vicinity of the plant as a waste material covering several hectares of valuable land. The bulk utilization of ash is possible in two areas, namely, ash dyke construction and filling of low-lying areas. Coal ash has been successfully used as structural fills in many developed countries. However, this particular bulk utilization of ash is yet to be implemented in India. Since most of the thermal power plants in India are located in areas where natural materials are either scarce or expensive, the availability of flyash is bound to provide an economic alternative to natural soils. Flyash Characterization and Testing The properties of ash are a function of several variables such as coal source, degree of pulverization, design of boiler unit, loading and firing conditions, handling and storage methods. Thus, it is not surprising that a higher degree of variation can occur in ash, not only between power plants but within a single power plant also. A change in any of the above factors can result in detectable changes in the properties of the ash produced. The degree to which any change affects the utilization potential of ash is a function of the nature and degree of the change and the particular application for which the ash might be used. The physical, geotechnical and chemical parameters to characterize flyash are the same as those for natural soils, e.g., specific gravity, grain size, Atterberg limits, compaction characteristics, permeability coefficient, shear strength parameters and consolidation parameters. The procedures for determination of these parameters are also similar to those for soils. Flyash Disposal in Ash Ponds Primarily, the flyash is disposed off using either dry or wet disposal scheme. In dry disposal, the flyash is transported by truck, chute or conveyor at the site and disposed off by constructing a dry embankment (dyke). In wet disposal, the flyash is transported as slurry through pipe and disposed off in impoundment called "ash pond". Most of the power plants in India use wet disposal system, and when the lagoons are full, four basic options are available: (a) constructing new lagoons using conventional constructional material, (b) hauling of flyash from the existing lagoons to another disposal site, (c) raising the existing dyke using conventional constructional material, and (d) raising the dyke using flyash excavated from the lagoon ("ash dyke"). The option of raising the existing dyke is very cost effective because any fly ash used for constructing dyke would, in addition to saving the earth filling cost, enhance disposal capacity of the lagoon. The constructional methods for an ash dyke can be grouped into three broad categories: (a) Upstream method, (b) Downstream method and (c) Centerline method. Fig.1 shows typical configurations of embankments constructed using the different methods. The construction procedure of an ash dyke includes surface treatment of lagoon ash, spreading and compaction, benching and soil cover. Upstream Method Downstream Method Centreline Method Fig. 1 Typical ash dyke raising configurations An important aspect of design of ash dykes is the internal drainage system. The seepage discharge from internal surfaces must be controlled with filters that permit water to escape freely and also to hold particles in place and the piezometric surface on the downstream of the dyke. The internal drainage system consists of construction of rock toe, 0.5m thick sand blanket and sand chimney. After completion of the final section including earth cover the turfing is developed from sod on the downstream slope. Flyash as Fill Material Large scale use of ash as a fill material can be applied where (a) flyash replaces another material and is therefore in direct competition with that material, (b) flyash itself is used by the power generating company producing the flyash to improve the economics of the overall disposal of surplus flyash; and (c) at some additional cost, flyash disposal is combined with the rehabilitation and reclamation of land areas desecrated by other operations. Fills can be constructed as structural fills where the flyash is placed in thin lifts and compacted. Structural flyash fills are relatively incompressible and are suitable for the support of buildings and other structures. Non-structural flyash fill can be used for the development of parks, parking lots, playgrounds and other similar lightly loaded facilities. One of the most significant characteristics of flyash in its use as a fill material is its strength. Well-compacted flyash has strength comparable to or greater than soils normally used in earth fill operations. In addition, lignite flyash possesses self-hardening properties which can result in the development of shear strengths. The addition of illite or cement can induce hardening in bituminous flyash which may not self-harden alone. Significant increases in shear strength can be realized in relatively short periods of time and it can be very useful in the design of embankments. Environmental Considerations The environmental aspects of ash disposal aim at minimizing air and water pollution. Directly related to these concerns is the additional environmental goal of aesthetically enhancing ash disposal facilities. The ash produced in thermal power plants can cause all three environmental risks - air, surface water and groundwater pollution. The pathways of pollutant movement through all these modes are schematically represented in Fig.2. Fig.2 Pathways of Pollutant Movement around Ash Disposal Facility Air pollution is caused by direct emissions of toxic gases from the power plants as well as windblown ash dust from ash mound/pond. The air-borne dust can fall in surface water system or soil and may contaminate the water/soil system. The wet system of disposal in most power plants causes discharge of particulate ash directly into the nearby surface water system. The long storage of ash in ponds under wet condition and humid climate can cause leaching of toxic metals from ash and contaminate the underlying soil and ultimately the groundwater system. However, most of these environmental problems can be minimised by incorporating engineering measures in the design of ash ponds and continuous monitoring of surface and groundwater water systems. Flyash Expertise at IIT Kanpur IIT Kanpur has pioneered the development of the ash dyke design in India. A number of ash disposal facilities across the country have been designed at this Institute. Currently, a major technology demonstration project on Ash Dyke Design: Raising, Maintenance and Monitoring sponsored by Flyash Mission with active support from NTPC is being executed at the Department of Civil Engineering. As a part of this project, a detailed manual on ash disposal practice has been prepared to standardize the procedures for ash disposal across the country. Another Flyash Mission sponsored project involving detailed geotechnical and environmental investigation of an ashfill site near Badarpur, New Delhi, is nearing completion. Based on field and laboratory investigations, detailed guidelines have been prepared for constructing ashfills and possibility of groundwater pollution through leaching of toxic metals examined. A national conference, Flyash Disposal and Deposition: Beyond 2000 AD, organised at the Institute in February 1999, looked into areas such as design of ash disposal facility, reclamation of ash ponds, structural filling of low-lying areas by flyash and the environmental aspects of ash disposal. The problems related to flyash are complex and huge, requiring a national effort and commitment. The expertise available at different institutions has to be fully harnessed to develop technologies for large scale eco-friendly utilization of flyash. Rajiv Sinha Department of Civil Engineering IIT Kanpur