fact sheet:

advertisement

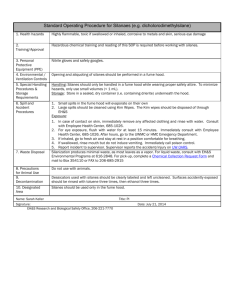

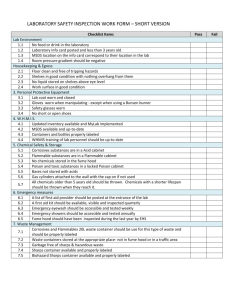

f a c t s h e e t Energy Efficient Fume Hood Management Fume hoods are big contributors to two things in laboratories: safety and energy consumption. Engineered to prevent exposure to hazardous chemicals and gasses, fume hoods are among the most commonly used pieces of engineered safety equipment for conducting chemical research. However, with providing this essential protection to researchers comes a large energy cost due to the air exchange used by the fume hood. Fume hoods function as an engineered safety mechanism by exhausting air through the hood face to the outside of the building, therefore removing any harmful fumes away from the researcher. It is in this design that the energy consumption increases, as energy is used not only to run the equipment, but to also move the air (heated and cooled) from the lab through the hood. In other words, each chemical fume hood used in MIT’s laboratories can use as much energy as 2-3 single family homes. With over 1,100 fume hoods on campus there is a lot of opportunity for energy savings in each lab. Key Facts Fume Hood Issue Resolution: There are approximately 1100 fume hoods between MIT and Lincoln Labs. Of the 1100, 600 are variable air volume (VAV) and 500 are constant air volume (CAV). CAV fume hoods move the same amount of air regardless of the sash position and operate at maximum air exchange at all times. VAV hoods use sensors to calculate the pressure differential necessary to maintain a constant face velocity. Air volume may be adjusted using a closedloop or open-loop control. Closed-loop control uses a small air speed sensor embedded in the hood to measure the face velocity and adjust dampers to change the air volume accordingly. Open-loop control hoods use sash position sensors to calculate the necessary air volume. Venturi air valves are used to control the flow of air between the hood and the exhaust network. Either design drops the air flow through the hood substantially. The hood usually operates at minimum air exchange, if workers properly close the hood when it is not in use. Ventilation plays a key role in the energy consumption as the air that moves through the fume hood is generally heated and cooled for the comfort and safety of the occupants. Department of Facilities – SAPweb Building Service Environment, Health & Safety Office – environment@mit.edu Take Action - SHUT YOUR SASH! Regardless of the type of Fume Hood your lab uses, Shut the Sash Post stickers to Shut the Sash on fume hoods as a reminder Contact Facilities through SAP to report an equipment operating issue and have it repaired GreeningMIT is an initiative of the Campus Energy Task Force. For more information visit or contact: http://web.mit.edu/mitei/ be-green@mit.edu Energy Efficient Fume Hood Management Fact Sheet Page 1 Impact Department of Chemistry Conservation Program A campaign to close fume hood sashes within the Department of Chemistry lead to the following savings: net savings of about $24,000/yr in energy in building 18 $41,000/yr throughout the entire department averted approximately 93 tons of CO2 in building 18 and 160 tons of CO2 department-wide These savings were achieved with approximately $12,000 in initial investment, and minimal continuing cost. Resources & Information Refer to the following websites for more information about energy use from fume hoods in laboratories: MIT’s Closing the Loop: http://sustainability.mit.edu/projects/fume-hoods Labs21 2008 Annual Conference – ‘Constant Flow, Variable Flow, and All the Space Between’ by Jim Coogan, P.E. http://www.i2sl.org/elibrary/coogan2008.html Visit the following website for ‘Shut Your Sash’ posters and stickers for your lab: http://sustainability.mit.edu/resources/tools-and-templates Energy Efficient Fume Hood Management Fact Sheet Page 2

![fume hoods [wp5] - Hamilton Laboratory Solutions](http://s3.studylib.net/store/data/009520146_1-b34781e52d61d12260c6f661c91de251-300x300.png)