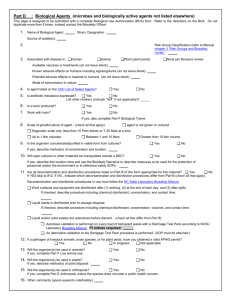

Procedure 1 Safe working with Genetically

advertisement

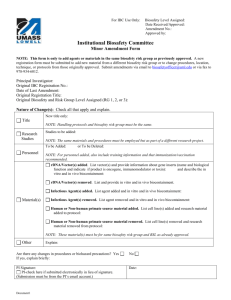

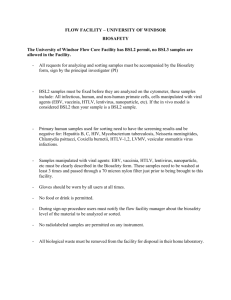

Biosafety Unit, CRISP, FHML, MUMC+ Procedure 1: Guidelines for safe working with Genetically Modified Organisms and cells 1. Subject and application area According to Working Conditions and Environmental Health legislation, working procedures and guidelines have to be written and followed in order to minimize the risk at contamination of employees or the environment with genetically modified organisms. Procedures and guidelines with respect to hygiëne and safety are based on principles of Safe microbiological techniques. The procedures and guidelines depend on the restriction level of the GMO activities, decided by the Ministry of Housing, Spatial planning and Environment (VROM). At Maastricht University and the Academic Hospital, activities under ML-I, ML-II, DM-II and DM-III restriction are allowed. I. These guidelines comprises 9 different aspects of working with GMO’s: 1. preparative activities 2. entrance to restricted area 3. equipment requirements of restricted area’s clothing 4. hygiene and safe working procedures 5. cleaning and disinfection 6. maintenance 7. storage and internal transport 8. incidents,accidents and calamities Furthermore, there are separate procedures for the below mentioned activities, merely still in Dutch; if necessary, please contact the BSO or your supervisor. You will find the forms and procedures on the website: www.crispmaastricht.nl. (The website is partly under construction, but you can at least al necessary forms you need.) DBE: Departmental Biosafety Expert (ABV:Afdelingsdeskundige biologische veiligheid) BSO: Biosafety Officer (BVF: Biologische-veiligheidsfunctionaris) March 2011 Biosafety Unit, CRISP, FHML, MUMC+ RI: Responsible Investigator (VM:Verantwoordelijk medewerker) 3.1 Preparative activities The Responsible Investigator (RI) has to apply for a permit at Buro GGO (part of the Infrastructure and Environment (IenM) see http://www.rijksoverheid.nl/onderwerpen/biotechnologie#ref-vrom Changes in a permit needs an application too; for information, contact the Biosfety Officer. Forms you need to perform a change in the permit can be found on the website www.crispmaastricht.nl The RI will be appointed by the Biosafety Officer and will be informed concerning the duties and responsibilities. The RI has to apply the employees, working under his responsibility to the Biosafety Officer by the form approval as GMO worker Sent the filled-in form to the Biosafety Officer The Biosafety Officer will assess the level of training. The RI has to report the roomnumbers were you want to do the GMO-activities to the Biosafety Officer. In case GMO activities never happened before in a certain laboratory, the Biosafety Officer has to approve a laboratory for GMO-activities 3.2 Entrance to the GMO laboratories Doors and windows must be closed during activities with GMO’s. ML-II Laboratories should be locked when nobody is in the room. Employees, who have a written permission, signed by the Biosafety Officer, stated that they are sufficiently familiar with safe microbiological techniques, and received instructions by the Responsible Investigator are allowed to enter restricted area except to ML-I laboratories, where also Non-GMO activities are allowed. Students, working for a short period of 6 weeks in the laboratories are named in the logbook of the room. These students work under strict guidance of the Responsible investigator. The name if the RI should be mentioned in the logbook too. March 2011 Biosafety Unit, CRISP, FHML, MUMC+ 3.3 Arrangements of GMO-laboratories. ML-I level The entrance door of the laboratory contains: - a lock - superscription: ML-I laboratory - superscription: ‘no entrance for unauthorized people/restricted area - names, roomnumber and tel. numbers of: Principal investigator Departmental biosafety expert Biosafety Officer The walls, floors and working surfaces are finished with non-absorbing At the entrance is located:a sink, a tap, a dispenser with soap and a dispenser materials. with towels . Doors should be closed with a door-closer, a magnet or a sign: Keep the door Inside the lab are clothing racks Inside the laboratory there are no archives and desks with paper work closed. Eating (also chewing gum), drinking, storing food cups, dishes etc. in the laboratory is forbidden. ML-II level The entrance door of the laboratory contains: - a lock - superscription: ML-II laboratory and a biohazard sign - superscription: ‘no entrance for unauthorized people/restricted area - names, roomnumber and tel. numbers of: Principal investigator Departmental biosafety expert Biosafety Officer Near the exit is a sink with an elbow-tap, a soap dispenser and a towel dispenser. A ML-II laboratory contains a Biosafety Cabinet Class II, with an extra valve in the gas pipe. Fridges and storage places for Genetic Modified Organisms carry the Biohazard sign and are explosion safe The walls, floors and working surfaces are finished with non-absorbing materials. March 2011 Biosafety Unit, CRISP, FHML, MUMC+ At the entrance is located:a sink, a tap, a dispenser with soap and a dispenser with towels . Doors should be closed with a door-closer and a sign a sign: Keep the door closed. Inside the lab are clothing racks. Inside the laboratory there are no archives and desks with paper work Eating (also chewing gum), drinking, storing food cups, dishes etc. in the laboratory is forbidden. Radiators are easy to clean. All places of the floor can be cleaned easily. There are no waste pipes in the floor. Windows in the laboratory can’t be openend. No central vacuumsystem. The laboratory will be cleaned by the employees themselves. ML-III level There are additional guidelines for an ML-III laboratory, but at the moment no ML-III laboratory is in use at Maastricht University. When you want some information about ML-III labs, please contact the Biosafety Officer DM-II level On the door of the room is the superscription - biohazard sign - DM-I, DM-II or DM-III - No entrance for unauthorized people - Name and tel. nr. of Departmental Biosafety expert and Biosafety Officer Floor, walls, doors and ceilings are easy to clean and to disinfect. Windows can’t be opened. Near the exit is a sink with an elbow-tap, a soap dispenser and a towel dispenser. Drain pipes and ventilators are covered with a fine gauze. While working, wear a labcoat, which needs to stay in the room when the experimentator leaves. Before washing, labcoats needs to be autoclaved. The workbench must be disinfected after the activities are completed. Spill must be disinfected immediately There is a supply to avoid escape of the animals, e.g a partition at the door. Animals are housed and kept in a way that unintended mating is impossible. At the outside of the door is clear that the door can’t be openend during some handlings, for instance when the cage is opened. DM-III level March 2011 Biosafety Unit, CRISP, FHML, MUMC+ Entrance only possible by a sluice with a sink In the laboratory is underpressure and the exhaust is equipped with a HEPA filter The laboratory can be disinfected with gasses, e.g. H2O2 Urine and faeces of larger animals can be collected in a special tank with a purging with HEPA filter. The content of the tank can be disinfected before disposal. There needs to be an autoclave en suite When performing a DM-III experiment, it is not allowed to have animals from other experiments in the same room. 3.4 Clothing Laboratory coats with long sleeves and a green collar or a green mark on the breast pocket must be worn at all times in the laboratory. The labcoats must be worn closed. It is not allowed to wear these labcoats outside the laboratory. The labcoats should be hanged on the clothing racks inside the laboratory. Coats, worn in a ML-II or DM-II/DM-III laboratories must be autoclaved always (4min/134oC), prior to washing. Contaminated coats from an ML-I lab must be decontaminated by autoclaving prior to washing. Personal belongings (clothing, bags etc.) must be kept outside the GMO laboratory or stored in a closet. 3.5 Hygiëne and safe working procedures Eating, drinking, food storage or smoking is forbidden in a GMO laboratory. While working in the GMO labs, do not wear rings, bracelets and wristwatches. Personal belongings must be kept outside the laboratory. Before the activities begin, a sufficient quantity of disinfectant must be readily. Avoid touching your face and your hair with your hands. Avoid manipulation of contact lenses and use disposable tissues in stead of cloth handkerchiefs. Hands should be washed regularly and always before leaving the laboratory. Mouth pipetting is forbidden. Use a pipetting balloon or a pipetman. Prevent the formation of aerosols by March 2011 Biosafety Unit, CRISP, FHML, MUMC+ - centrifugation and mixing in closed tubes - drying of wet needles, prior to flaming them or use disposable oses. - do not take fluid-filled pipettes into a flame - Let the tip of a pipette carefully flow out to the inner wall of a tube - avoid the use of injection needles or be extremely carefully. - do not throw away used Pasteur pipettes with a push - equipment that easily produces aerosols like a sonicator, to be placed in a safety cabinet class II. Try to avoid disturbance of the air-flow in the cabinet by careful handling. 3.6 Cleaning and disinfection Disinfect surfaces of working tables at the end of each day and after spilling with water containing 0,1% active chlorine (for E. Coli K12 300 ppm, for viruses and bacteriophages:1000 ppm) or with 70% ethanol. Remove the disinfectants with water after 5 minutes disinfection time. Spill can be disinfected and removed by covering the Spill with tissues, drenched in a 0,1% active chlorine solution. (e.g. 1 tablet SumaTab D4 in 1,5 liter water or 1 tablet Stafilex in 1,5 liter water (around 30 oC) and let this act on the spill for 5-10 minutes Clean thereafter with a sufficient amount of water. Tissues should go to the GGO-waste bin (green bin) ML-II labs shall be cleaned weekly by departmental employees. Contaminated glassware and other reusable waste must be chemical decontaminated or autoclaved prior to washing. 3.7 Maintenance Defects and failure of equipment has to be reported immediately to the maintenance department. The ventilation system, -80 freezers and the safety cabinets are controlled by the building-control-system (GBS) -80 freezers and safety cabinets are also connected to an emergency-power system. The technical engineer reports the planned operations to the departmental safety expert or by absence or to the RI in charge or to the BSO. Outside working hours, the BSO is called up in case of calamities or defects. March 2011 Biosafety Unit, CRISP, FHML, MUMC+ 3.8 Storage outside the GMO Laboratories, internal transport Storage places outside GMO Laboratories should be reported to the BSO. This needs to be written in the central administration system and on the plan of the buildings. - Register the characteristics of the stored GMO’s and the location of storage, like it is written in this form: storage GMOs Register the GGO-number of the permit, the host, the vector, the insert results of control on purity and identity of GMO’s GMO’s should be stored in a closed, intact double unbreakable container, free of leakage. In the same storage place, e.g. a drawer in a fridge or freezer, GMO’s and non- GMO’s must be packed separately. The outer container must be labeled with “GMO” and in case of an ML-II organism: also a biohazard sign. Containers with contaminated material needs to be disinfected prior to transport. Glass ware and other open materials with GMO’s must be transported in tightly closed intact containers, free of leakage. Transport of GMO’s with an ML-II restriction needs to go in an outer container with a biohazard sign. When you use a vacuum suction, use a first bottle with a small amount of soap and 0.1% active chlorine. Connect this bottle to a second one with 1 M. NaOH, in order to neutralize the chlorine vapour. When the suction bottle is filled, or after one week, disconnect the bottle in the evening, place it in a hood and add a chlorine tablet. Keep the inactivation of the waste overnight and discard the waste the next day in the sink. 3.9 Incidents, accidents and calamities Experiments with special risks should be reported beforehand at the Biosafety Officer. When a situation can not be controlled by the employee, or his/her colleagues, the general calamity plan will start. The Responsible Investigator or the Departmental biosafety expert needs to be called up. If necessary, the BSO can be called up. Tel. nrs are on the door of the restricted area’s. March 2011 Biosafety Unit, CRISP, FHML, MUMC+ It is allowed to enter the restricted area again after the BSO has inspected the room and gives the permission. All incidents, near incidents and calamities must be registered in the logbook of the room. Always contact the Biosafety Officer. 3.10 Further remarks If the information in 3.1 to 3.9 is not sufficient, please contact the Biosafety Officer. Since there are a lot of unknown consequences to calamities in a GMO laboratory, much of efford is to be taken to avoid such calamities. Therefore the below mentioned regulations are concerned: - Closed doors supply fire compartmentalization - Floor drains do not enter the sewer directly. - Flamable organic solvents (up to 25 l. are stored in a closed safety cupboard or in an explosion-free fridge. Larger amounts go into a Safety cupboard. Consult the company doctor when you have questions regarding he GMOactivities in relation to your health. References (Dutch) Arbo-informatieblad nr. 18, laboratoria. SDU Uitgevers, Den Haag, 5 druk, 2010. Integrale versie van de regeling Genetisch Gemodificeerde Organismen en het Besluit GGO, IenM, sept. 2010. Leidraad voor een handboek GGO ingeperkt gebruikt, BVF-platform, december 2006 Information For further information, please contact the Biosafety Officers: Natasja Kisters, 043-3881137 e-mail: n.kisters@maastrichtuniversity.nl Marjanne Markerink, tel. 043-3882986 e-mail: m.markerink@maastrichtuniversity.nl March 2011