ENG/ Ahmed Abdelmonem Mohamed Abdelgwad

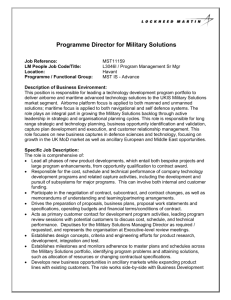

advertisement

ENG/ Ahmed Abdelmonem Mohamed Abdelgwad QA/QC coating engineer and inspector Certified senior painting inspector B.GAS – GRADE (1) BGAS-CSWIP APPROVAL PAINTING INSPECTOR GRADE 1 Certificate no.: 64444 APPROVAL NO: BG 580908 Certified coating and insulation inspector in ARAMCO sap no. 70009234 Alexandria, Egypt .Mobile: +2-01222216762 E-mail: ahmed_abdelmonem3@yahoo.com CAREER OBJECTIVE: Seeking for a reputable position at a petroleum company. PERSONAL INFORMATION: Date of Birth : March 31st, 1981 Gender : Male Marital Status : married Military status: Exempted EDUCATION BACKGROUND: B.Sc. In Nuclear Engineering Department, Alexandria University, 2005 The sciences which we are learned: 40% nuclear sciences 30% electrical sciences ( Circuits, Electronics, Electric Machines and Power) 30% mechanical sciences ( Machine Design, Mechanical Drawing, Heat Transfer, Mechanics, Fluid Mechanics, and Thermal Power Stations) Graduation Project: Robotic system for remote detection of radioactivity Grade : Excellent Supervisor : Prof. Mohammed Yasser khalil (Head of Nuclear Engineering Department) Project brief : Robotic system for remote detection of radioactivity TRANSMIT ITS DATA TO COMPUTERS WIRELESS TRAINING EXPERIENCE: The Ministry Of Energy And Electricity Generation At El DABAA Station Egyptian Atomic Energy Authority The Production and Control Section in Abukir Fertilizers Company Distribution Company of Electricity in Mohrambek Qualifications: QC OF SURFACE PRPARATION&COATING APPLICATION Reading specification and designing the quality control requirements for the project (work procedure & compatibility of products data sheets with specifications) Preparing the daily reports Evaluation tests for proposed coating systems Weekly meeting Destructive &final acceptance tests Documentation Training and/or supervising trainee inspector Preparing for the bidding Overall QC/QA Blasting and painting QC/QA pre-projects Study of Specifications, Standards, and Project Quality Control Plan. Prepare the suitable Inspection Plan compatible with the Project Specifications and quality plan. Check of Quality of Equipments, and Inspection Instruments (Calibration Certificates), as per level of acceptance in Specifications and Standards. Pre job Evaluation Tests for Painting Systems and compatibility to Specifications’ requirements. Reports format, and other activities recording forms. o Subcontractor / Contractor QC personnel prequalification / Certifying. o Pre job meeting for submittals and discussing QC Responsibilities and Authorities, and define of persons in charge. Ongoing -Project: o Daily QC Inspections, Checks and Tests. o Training or/and supervising of junior QC personnel. Updating / revising the Inspection Plan if needed. Updating with the latest revising of Project Specifications or Client’s revising. End -Project: o Final Inspection Tests (New Construction Projects), or Failure analysis ( for maintenance projects). Documentation of Completion of work. Certified senior painting inspector B.GAS – GRADE (1) Certified senior painting inspector B.GAS – GRADE (1) BGAS-CSWIP APPROVAL PAINTING INSPECTOR GRADE 1 Certificate no.: 64444 APPROVAL NO: BG 580908 Certified coating and insulation inspector in ARAMCO sap no. 70009234 WORK EXPERIENCE: E.G.C Company (Engineering group for contracting) FROM JANUARY 2006 TO DEC 2006 I was working as a site engineer at this company which is concerned working in protection of ferrous and non ferrous substrate (St. St., Tanks, Piping, Concrete flooring etc…) using all types of painting materials, wrapping and fire proofing systems with advanced equipment and instruments and updating technology SUMED COMPANY in maintenance for tanks tank no.4&5 and my field of work in blasting and painting (tanks) with several types of coatings like fibreglass for bottoms and all body of tank FROM (15-1-2006 TO 13-3-2006) • working in EL WASTANI PETROLEUM COMPANY (WASCO) field for natural gas From (15-3-2006 to 12-7-2006) : Client : WASCO CONTRACTOR : PRESSON ENERFLIX SUBCONTRACTOR : PETROJET SUB SUBCONTRACTOR: E.G.C Company (Engineering group for contracting) Project : NATURAL GAS STATION Location : NEW DAMITTA Position : Painting Project Engineer and inspector Project items: 1- Blasting and painting ( pipe lines, tanks and steel structure) 2- Thermal insulation for ( pipe lines and all type of equipment) 3- Fire Proofing System 4- Wrapping for underground lines Specifications: PRESSON ENERFLIX SPECS Paint supplier: JOTUN Working like executive Engineer in SOUTH DABAA PETROLEUM COMPANY From (15-7-2006 to 20-12-2006) Client : SOUTH DABAA PERTROLEUM COMPANY CONTRACTOR : PETROJET SUBCONTRACTOR : E.G.C Company (Engineering group for contracting) Project : PETROLEUM STATION Location : EAST DESERT (ELQATTARA SUNK) Position : Painting Project Engineer and inspector Project items : 1- Blasting and painting ( pipe lines, tanks and steel structure) 2- Thermal insulation for ( pipe lines and all type of equipment) 3- Wrapping for underground lines Paint supplier: JOTUN & SIGMA THE PETROLEUM PROJECTS AND TECHNICAL CONSULTATION (PETROJET). Working In PETROJET, Marine Sector, El-Maadia Yard as QA/QC Engineer for Painting & Coating Works. SINCE DEC 2006 TILL MARCH.2007 ( IN PETROJET) Client Project Location Position Project items racks and TSF. Specifications Paint supplier : GUPCO : SAQQARA platform & onshore pipe racks : PETROJET general marine dept.- Maadyia Yard : Painting Project Engineer and inspector : A four legs offshore platform consists of Jacket, Boat landing, Decks, riser guard, pipe : KBR spec's : JOTUN SINCE JANUARY 2007 TILL APRIL 2007 ( IN PETROJET) Client : NOSPCO Project : NORTH OF SINAI Location : PETROJET general marine dept.- Maadyia Yard Position : Painting Project Engineer and inspector Project items : A THREE legs offshore platform consists of Jacket, Boat landing, Decks, Riser and TSF. Specifications : NOSPCO spec's Paint supplier : HEMPLE & SIGMA Duties in the Project : Blasting and painting QC/QA pre-projects Study of Specifications, Standards, and Project Quality Control Plan. Prepare the suitable Inspection Plan compatible with the Project Specifications and quality plan. Check of Quality of Equipments, and Inspection Instruments (Calibration Certificates), as per level of acceptance in Specifications and Standards. . End -Project: o Final Inspection Tests (New Construction Projects), or Failure analysis ( for maintenance projects). Documentation of Completion of work SINCE MARCH 2007 TILL MAY 2007 ( IN PETROJET) Client Project Location Position Project items Specifications Paint supplier Duties in the Project : : P.M.S : STINGER 80 M : PETROJET general marine dept.- Maadyia Yard : Painting Project Engineer and inspector : 20 tanks with different diameter 80 & 60 inch and different items : P.M.S spec's : SAIPES TRANSOCEAN Blasting and painting QC/QA pre-projects Study of Specifications, Standards, and Project Quality Control Plan. Prepare the suitable Inspection Plan compatible with the Project Specifications and quality plan. Check of Quality of Equipments, and Inspection Instruments (Calibration Certificates), as per level of acceptance in Specifications and Standards. . End -Project: o Final Inspection Tests (New Construction Projects), or Failure analysis ( for maintenance projects). Documentation of Completion of work SINCE APRIL 2007 TILL DEC 2007 ( IN PETROJET) Client Project Location Position Project items : BURRULS : SAIPEM PROJECTS : PETROJET general marine dept. - Maadyia Yard. : Painting Project Engineer and inspector. : Manifold, PLETs, Jumpers, UTAs AND Suction Piles . Specifications Paint supplier Duties in the Project : : saipem spec's ACCORDING TO NORSOK M-501. : SIGMA PAINTS. Blasting and painting QC/QA pre-projects Study of Specifications, Standards, and Project Quality Control Plan. Prepare the suitable Inspection Plan compatible with the Project Specifications and quality plan. Check of Quality of Equipments, and Inspection Instruments (Calibration Certificates), as per level of acceptance in Specifications and Standards. Pre job Evaluation Tests for Painting Systems and compatibility to Specifications’ requirements. Reports format, and other activities recording forms. o Subcontractor / Contractor QC personnel prequalification / Certifying. o Pre job meeting for submittals and discussing QC Responsibilities and Authorities, and define of persons in charge. Ongoing -Project: o Daily QC Inspections, Checks and Tests. o Training or/and supervising of junior QC personnel. Updating / revising the Inspection Plan if needed. Updating with the latest revising of Project Specifications or Client’s revising. End -Project: o Final Inspection Tests (New Construction Projects), or Failure analysis ( for maintenance projects). Documentation of Completion of work SINCE JUNE 2007 TILL JANUARY 2008 ( IN PETROJET) Client : ELKHAFGY Project : ELKHAFGY PROJECTS Location : PETROJET general marine dept. - Maadyia Yard Position : QA/QC coating Engineer and inspector Project items : A four legs offshore platform consists of 6 Jackets, 6 Boat landing, 6 Decks, 6 riser guard and field joint coating for sub sea spools (cold wrap tape and H.S.S coating as a repair material ) Specifications : ARAMCO spec's Paint supplier : SIGMA PAINTS Duties in the Project : Blasting and painting QC/QA pre-projects Study of Specifications, Standards, and Project Quality Control Plan. Prepare the suitable Inspection Plan compatible with the Project Specifications and quality plan. Check of Quality of Equipments, and Inspection Instruments (Calibration Certificates), as per level of acceptance in Specifications and Standards. Pre job Evaluation Tests for Painting Systems and compatibility to Specifications’ requirements. Reports format, and other activities recording forms. o Subcontractor / Contractor QC personnel prequalification / Certifying. o Pre job meeting for submittals and discussing QC Responsibilities and Authorities, and define of persons in charge. Ongoing -Project: o Daily QC Inspections, Checks and Tests. o Training or/and supervising of junior QC personnel. Updating / revising the Inspection Plan if needed. Updating with the latest revising of Project Specifications or Client’s revising. End -Project: o Final Inspection Tests (New Construction Projects), or Failure analysis ( for maintenance projects). Documentation of Completion of work SINCE JANUARY 2008 TILL FEBRUARY 2009 (IN PETROJET) Client : ARAMCO Project : YANBU GAS PLANT EXPANSION Location : PETROJET SAUDIA ARABIA BRANCH (YANBU) Position : QA/QC coating Engineer and inspector Project items : Blasting and painting (pipe lines, tanks and steel structure) Thermal insulation for (pipe lines and all type of equipment) Wrapping for underground lines Specifications : ARAMCO spec's Paint supplier : HEMPEL PAINTS Duties in the Project : Blasting and painting QC/QA pre-projects Study of Specifications, Standards, and Project Quality Control Plan. Prepare the suitable Inspection Plan compatible with the Project Specifications and quality plan. Check of Quality of Equipments, and Inspection Instruments (Calibration Certificates), as per level of acceptance in Specifications and Standards. Pre job Evaluation Tests for Painting Systems and compatibility to Specifications’ requirements. Reports format, and other activities recording forms. o Subcontractor / Contractor QC personnel prequalification / Certifying. o Pre job meeting for submittals and discussing QC Responsibilities and Authorities, and define of persons in charge. Ongoing -Project: o Daily QC Inspections, Checks and Tests. o Training or/and supervising of junior QC personnel. Updating / revising the Inspection Plan if needed. Updating with the latest revising of Project Specifications or Client’s revising. End -Project: o Final Inspection Tests (New Construction Projects), or Failure analysis ( for maintenance projects). Documentation of Completion of work SINCE MARCH 2009 TILL NOVEMBER 2010 ON SHORE AND OFF SHORE (IN PETROJET) Client : ELKHAFGY Project : ELKHAFGY PROJECTS Location : PETROJET SAUDIA ARABIA BRANCH ELKHAFGY SAUDIA ARABIA (off shore ) Position : QA/QC COATING ENGINEER AND INSPECTOR Project items : A four legs offshore platform consists of 6 Jackets, 6 Boat landing, 6 Decks, 6 riser guard and field joint coating for sub sea spools (cold wrap tape and H.S.S coating as a repair material ) Specifications : ARAMCO spec's Paint supplier Duties in the Project : : SIGMA PAINTS Blasting and painting QC/QA pre-projects Study of Specifications, Standards, and Project Quality Control Plan. Prepare the suitable Inspection Plan compatible with the Project Specifications and quality plan. Check of Quality of Equipments, and Inspection Instruments (Calibration Certificates), as per level of acceptance in Specifications and Standards. Pre job Evaluation Tests for Painting Systems and compatibility to Specifications’ requirements. Reports format and other activities recording forms. o Subcontractor / Contractor QC personnel prequalification / Certifying. o Pre job meeting for submittals and discussing QC Responsibilities and Authorities, and define of persons in charge. Ongoing -Project: o Daily QC Inspections, Checks and Tests. o Training or/and supervising of junior QC personnel. Updating / revising the Inspection Plan if needed. Updating with the latest revising of Project Specifications or Client’s revising. End -Project: o Final Inspection Tests (New Construction Projects), or Failure analysis ( for maintenance projects). Documentation of Completion of work SINCE NOVEMER 2010 TILL NOVEMBER 2011 Client : BURRULS Project : TECHNIP PROJECTS Location: PETROJET general marine dept. - Maadyia Yard. Position: QA/QC coating Engineer and inspector Project items: Manifold, PLETs, Jumpers, UTAs AND Suction Piles . and field joint coating for sub sea spools (cold wrap tape and H.S.S coating as a repair material ) Specifications: technip spec's ACCORDING TO NORSOK M-501. Paint supplier : SIGMA PAINTS Duties in the Project : Blasting and painting QC/QA pre-projects Study of Specifications, Standards, and Project Quality Control Plan. Prepare the suitable Inspection Plan compatible with the Project Specifications and quality plan. Check of Quality of Equipments, and Inspection Instruments (Calibration Certificates), as per level of acceptance in Specifications and Standards. Pre job Evaluation Tests for Painting Systems and compatibility to Specifications’ requirements. Reports format and other activities recording forms. o Subcontractor / Contractor QC personnel prequalification / Certifying. o Pre job meeting for submittals and discussing QC Responsibilities and Authorities, and define of persons in charge. Ongoing -Project: o Daily QC Inspections, Checks and Tests. o Training or/and supervising of junior QC personnel. Updating / revising the Inspection Plan if needed. Updating with the latest revising of Project Specifications or Client’s revising. End -Project: o Final Inspection Tests (New Construction Projects), or Failure analysis ( for maintenance projects). Documentation of Completion of work SINCE 5- 2011 TILL 12-.2011 (IN PETROJET) Client : GPC Project : AMER 8 platform Location : PETROJET general marine dept.- Maadyia Yard Position : QA/QC coating Engineer and inspector Project items : A four legs offshore platform consists of Jacket, Boat landing, Decks, riser guard, pipe racks and TSF. Specifications : ennpi specs Paint supplier : SIGMA Duties in the Project : Blasting and painting QC/QA pre-projects Study of Specifications, Standards, and Project Quality Control Plan. Prepare the suitable Inspection Plan compatible with the Project Specifications and quality plan. Check of Quality of Equipments, and Inspection Instruments (Calibration Certificates), as per level of acceptance in Specifications and Standards. Pre job Evaluation Tests for Painting Systems and compatibility to Specifications’ requirements. Reports format, and other activities recording forms. o Subcontractor / Contractor QC personnel prequalification / Certifying. o Pre job meeting for submittals and discussing QC Responsibilities and Authorities, and define of persons in charge. Ongoing -Project: o Daily QC Inspections, Checks and Tests. o Training or/and supervising of junior QC personnel. Updating / revising the Inspection Plan if needed. Updating with the latest revising of Project Specifications or Client’s revising. End -Project: o Final Inspection Tests (New Construction Projects), or Failure analysis ( for maintenance projects). Documentation of Completion of work SINCE NOVEMER 2011 TILL JUNE 2012 Client : BURRULS Project : SAIPEM PROJECTS Location: PETROJET general marine dept. - Maadyia Yard. Position: QA/QC coating Engineer and inspector Project items: Manifold, PLETs, Jumpers, UTAs AND Suction Piles . and field joint coating for sub sea spools (cold wrap tape and H.S.S coating as a repair material ) Specifications: SAIPEM spec's ACCORDING TO NORSOK M-501 Paint supplier Duties in the Project : SIGMA PAINTS : Blasting and painting QC/QA pre-projects Study of Specifications, Standards, and Project Quality Control Plan. Prepare the suitable Inspection Plan compatible with the Project Specifications and quality plan. Check of Quality of Equipments, and Inspection Instruments (Calibration Certificates), as per level of acceptance in Specifications and Standards. Pre job Evaluation Tests for Painting Systems and compatibility to Specifications’ requirements. Reports format, and other activities recording forms. o Subcontractor / Contractor QC personnel prequalification / Certifying. o Pre job meeting for submittals and discussing QC Responsibilities and Authorities, and define of persons in charge. Ongoing -Project: o Daily QC Inspections, Checks and Tests. o Training or/and supervising of junior QC personnel. Updating / revising the Inspection Plan if needed. Updating with the latest revising of Project Specifications or Client’s revising. End -Project: o Final Inspection Tests (New Construction Projects), or Failure analysis ( for maintenance projects). Documentation of Completion of work SINCE MARCH 2012 TILL JUNE 2013 Client : GUPCO Project : HILAL PLATFORM Location: PETROJET general marine dept. - Maadyia Yard. Position: QA/QC coating Engineer and inspector Project items: A four legs offshore platform consists of Jacket, Boat landing, Decks, riser guard, pipe racks and TSF. and field joint coating for sub sea spools (cold wrap tape and H.S.S coating as a repair material ) Specifications: GUPCO AND ENNPI SPECS Paint supplier Duties in the Project : JOTUN PAINTS : Blasting and painting QC/QA pre-projects Study of Specifications, Standards, and Project Quality Control Plan. Prepare the suitable Inspection Plan compatible with the Project Specifications and quality plan. Check of Quality of Equipments, and Inspection Instruments (Calibration Certificates), as per level of acceptance in Specifications and Standards. Pre job Evaluation Tests for Painting Systems and compatibility to Specifications’ requirements. Reports format, and other activities recording forms. o Subcontractor / Contractor QC personnel prequalification / Certifying. o Pre job meeting for submittals and discussing QC Responsibilities and Authorities, and define of persons in charge. Ongoing -Project: o Daily QC Inspections, Checks and Tests. o Training or/and supervising of junior QC personnel. Updating / revising the Inspection Plan if needed. Updating with the latest revising of Project Specifications or Client’s revising. End -Project: o Final Inspection Tests (New Construction Projects), or Failure analysis ( for maintenance projects). Documentation of Completion of work SINCE MAY 2012 TILL PRESENT Client : PHPC (PHARONIC PETROLEUM COMPANY) Project : W PHPC PROJECT Location: PETROJET WESTREN dept. – port saied Position: QA/QC coating Engineer and inspector Project items: PIPING AND STRUCTURES Specifications: PHPC AND ENNPI SPECS Paint supplier Duties in the Project : JOTUN PAINTS : Blasting and painting QC/QA pre-projects Study of Specifications, Standards, and Project Quality Control Plan. Prepare the suitable Inspection Plan compatible with the Project Specifications and quality plan. Check of Quality of Equipments, and Inspection Instruments (Calibration Certificates), as per level of acceptance in Specifications and Standards. Pre job Evaluation Tests for Painting Systems and compatibility to Specifications’ requirements. Reports format, and other activities recording forms. o Subcontractor / Contractor QC personnel prequalification / Certifying. o Pre job meeting for submittals and discussing QC Responsibilities and Authorities, and define of persons in charge. Ongoing -Project: o Daily QC Inspections, Checks and Tests. o Training or/and supervising of junior QC personnel. Updating / revising the Inspection Plan if needed. Updating with the latest revising of Project Specifications or Client’s revising. End -Project: o Final Inspection Tests (New Construction Projects), or Failure analysis ( for maintenance projects). Documentation of Completion of work SINCE JUNE 2013 TILL PRESENT Client : BURRULS PH 9A Project : SAIPEM PROJECTS Location: PETROJET general marine dept. - Maadyia Yard. Position: QA/QC coating Engineer and inspector Project items: Manifold, PLETs, Jumpers, UTAs AND Suction Piles . and field joint coating for sub sea spools (cold wrap tape and H.S.S coating as a repair material ) Specifications: saipem spec's ACCORDING TO NORSOK M-501. Paint supplier : Duties in the Project : Blasting and painting QC/QA pre-projects Study of Specifications, Standards, and Project Quality Control Plan. Prepare the suitable Inspection Plan compatible with the Project Specifications and quality plan. Check of Quality of Equipments, and Inspection Instruments (Calibration Certificates), as per level of acceptance in Specifications and Standards. Pre job Evaluation Tests for Painting Systems and compatibility to Specifications’ requirements. Reports format and other activities recording forms. o Subcontractor / Contractor QC personnel prequalification / Certifying. o Pre job meeting for submittals and discussing QC Responsibilities and Authorities, and define of persons in charge. Ongoing -Project: o Daily QC Inspections, Checks and Tests. o Training or/and supervising of junior QC personnel. Updating / revising the Inspection Plan if needed. Updating with the latest revising of Project Specifications or Client’s revising. End -Project: o Final Inspection Tests (New Construction Projects), or Failure analysis ( for maintenance projects). Documentation of Completion of work Training Courses Attended: Course title Date and location Corrosion: causes and types + cathodes protection methods Higher Institute of Technology in Egypt MAY 2012 CSWIP in painting grade 1 27TH OF APRIL 2012 GRADE 1 AT TWI Negotiation skills JUNE 2011 At AUC Safety orientation completion ARAMCO (YANBU GAS PLANT DEPARTMENT) Date Of Issue 19/1/2009 Date Of Expiry 19/1/2011 Corrosion: causes and types and precautionary methods and finally test for aramco approval ARMCO (YANBU) Certified coating and insulation inspector in ARAMCO sap no. 70009234 CSWIP in painting 27TH OF OCTOBER 2007 AND MY GRADE IN IT WAS GRADE 2 at Society of mechanical Eng. Management training program Career development & consultation academy 4-8 November 2007 MANAGEMENT TRAINING PROGRAM CAREER DEVELOPMENT & CONSULTIONS ACADEMY FROM 4 TO 8 NOVEMBER 2007 Microsoft word In international computer ceneter from 1 to 5 june 2005 Excel level 1 & 2 In international computer ceneter from 3 to 30 march 2005 Computer Skills: Ms Office. Windows 3.x, Windows 9X WIN 95 , WIN 98 ,WIN ME, WIN XP, MS, WIN7 .WIN 8 Office, Internet. Programs of windows and hardware: very good Excellent in treatment and maintenance with all programs of computers And all hardware Language Skills: Arabic English : Mother Tongue : very good (spoken, writing and reading) Soft Skills: Interactive fast enough to learn new technologies and sciences. High ability for communication and presentation skills. Ability to work in a group or individually according to the job requirements. Ability to set and achieve goals and to work under pressure. Hard worker, don’t mind working for long hours / weekends. HOBBIES: Computer, Reading, sports and internet And I’m enthusiastic to learn more in any new creation comes out in connection with my career. REFERENCES: Available Upon Request