IEEE Paper Template in A4 (V1)

advertisement

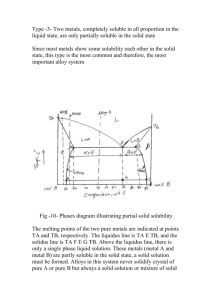

Microstructure and Thermoelectric Properties of n-type Chalcogenide Nanopowders Sintered by ECAE S. Ceresara#1, C. Fanciulli#2, D. Vasilevskiy*3 1-CNR-IENI, Corso Promessi Sposi 29, 23900 Lecco, Italy 1ceresara 2c.fanciulli @tin.it @ieni.cnr.it 2-École Polytechnique de Montréal - Département de Génie Mécanique, H3C 3A7 Montréal, Canada 3dimitri.vasilevskiy@polymtl.ca Abstract— Nanograined powders of Bi1.9Sb0.1Te2.85Se0.15 alloy have been consolidated into bulk ingots by warm ECAE process. Sintering has been achieved after only two ECAE passes at 300 °C, with a total holding time at this temperature of 19 minutes. The morphological characterization of ECAE processed samples, performed by HRTEM, has shown grain sizes varying from 20 to 50 nm. Thermoelectric properties, measured at 300 K show that the thermal conductivity is considerably reduced by the nanostructure, but the value of the Seebeck coefficient is relatively low, due to a non optimized value of the electron concentration. The latter result has been attributed to oxygen contamination. Keywords— thermoelectricity, nanopowders, warm ECAE, low temperature sintering, Bismuth Telluride alloys I. INTRODUCTION Chalchogenides belonging to the (BixSb1-x)2(TeySe1-y)3 family are known as the best TE materials for the temperature range from 0 to 250 °C and are used in most present applications of thermoelectricity. Their dimensionless figure of merit, ZT, has remained around 1 for several decades, until a breakthrough of ZT=2.3 at 300K has been achieved in a Bi2Te3/Sb2Te3 superlattice [1]. The concept of “nanostructured thermoelectricity” has been soon extended to bulk materials: as a consequence, a considerable enhancement of ZT, in a wide temperature range, has been achieved in p-type BixSb2-xTe3, by reducing the crystalline grain size to the nanometer scale [2, 3]. In both papers [2] and [3], nanoparticles were fabricated by ball milling, either starting from alloy ingots [2], or from elemental chunks [3]. In both cases, consolidation of the powders into dense bulk was achieved by hot pressing. From a general point of view, it appears that other consolidation processes, alternative to hot pressing, may help preserving the nanocrystalline grain size. Among these, spark plasma sintering (SPS) is often recommended [4] because of its relatively short sintering time. Another potentially suitable process is represented by equal channel angular extrusion (ECAE), since it allows powder sintering at considerably lower temperature than hot pressing [5]. In this paper we have followed the latter approach to consolidate n-type chalcogenide nanopowders. II. EXPERIMENTAL Nanopowders of Bi1.9Sb0.1Te2.85Se0.15 alloy were prepared from shots of 99.995 % purity Bi, Sb, Te, Se elements by mechanical alloying (M.A.) Attrition milling was performed in argon atmosphere for 10 hours. The average size of the nanograins was estimated as 20-25 nm, both by X-ray peak diffraction broadening and by direct observation at HRTEM [6]. By operating in an Ar filled dry box, the nanoparticles were pressed into pellets 10 mm in diameter and 8 mm in height, by applying a pressure of 500 MPa. A number of pellets were inserted into a Cu can, 25 mm in external diameter and 120 mm in length, with the interposition of a Nb diffusion barrier, 1 mm in thickness. Three composite billets were vacuum sealed and ECAE processed at 300°C, with 2 (sample A), 4 (sample B), and 6 (sample C) passes, respectively. The holding time in temperature was 19, 37, and 50 minutes, for samples A, B, and C, respectively. The principles of warm ECAE have been described in a previous paper [7]. For the present experiments we have used an upgraded equipment which allows processing of billets 25 mm in diameter and 120 mm in length. The true plastic strain after each pass is ε = 0.98. The Harman method has been used to measure the figure of merit, Z, at 300 K, both along the longitudinal (i.e. parallel to the extrusion axis) and the transverse directions. Typical samples, 6 x 6 x 7 mm3, were cut from the centre of the ECAE processed billets. The values of the electric resistivity, ρ, and of the Seebeck coefficient, α, were measured on the same samples; the thermal conductivity, λ, was calculated from the relationship λ=α2/Zρ. Hall measurements, under 0.5 T magnetic field, were performed by the Van der Pauw method on thin (0.6 mm) specimens sliced normal to the extrusion direction. In such a way, the carrier concentration, n, was determined and the mobility, μ=1/neρ, (e = charge of the electron) was calculated. III. RESULTS AND DISCUSSION A. Microstructure characterization The XRD pattern of the nanopowders, reported in Fig.1, confirms the formation of the Bi1.9Sb0.1Te2.85Se0.15 phase by mechanically alloying of the elemental Bi, Sb, Te, Se shots. However, DSC analysis, reported in Fig.2, shows that the powder is not single-phase: as a matter of fact, a small endothermic peak is observed at 410 °C. By considering that the Te-rich eutectic temperature of the Bi-Te binary alloy falls at 413 °C [8], it appears that a small fraction of Te-rich eutectic is also present in the powders, although unrevealed by XRD. It is believed that the eutectic has not affected the sintering of nanopowders, since ECAE has been performed at a temperature far below 410 °C The morphological characterization of ECAE processed samples has been performed by collecting several HRTEM images. Examples are given in Figs. 3, 4, and 5, for samples A, B, and C, respectively. 18000 16000 Bi1.9Sb0.1Te2.85Se0.15 14000 Powders Counts 12000 a = 4.37 A c = 30.36 A 10000 Fig.3 HRTEM image of sample A 8000 6000 4000 2000 0 10 20 30 40 50 60 70 80 90 100 110 120 2 deg Fig. 1 XRD pattern of nanopowders Fig.4 HRTEM image of sample B Fig.2 DSC curve of M.A. nanopowders From the nominal alloy composition and from the lattice parameters obtained from XRD plot refinement and reported in Fig.1, a theoretical density of 7.84 g/cm3 has been calculated. Although such a figure is likely to be slightly incorrect, due to the presence of the eutectic, it may be taken as a reference value for the comparison of the density of the samples in different structural states. The density of the pellets resulted 83% of the full density value, simply by dividing its mass to its geometrical volume. The density of ECAE processed samples were determined by Archimedes’ method and resulted about 96%. The differences in density with the number of ECAE passes were within the reproducibility of the measurements (±0.5%). Fig.5 HRTEM image of sample C In such figures, the nanograins are represented as a selfcontained area consisting of one or more sets of fringes. It appears that in all cases their dimension varies from 20 to 50 nm. XRD measurements performed on the three different samples were also used for a deeper structural analysis. From the diffraction patterns, the Hall-Williamson plot has been obtained and reported in Figs. 6, 7, and 8, for sample A, B, and C, respectively. materials when there is a distribution of grain size, since a small number of large particles gives a relevant contribution to the XRD measurements [9]. B. Thermoelectric properties The thermoelectric properties of the ECAE processed samples are shown in Tab I. For the purpose of comparison, also the results obtained on the same material batch by direct extrusion [6] at 440 °C, in Ar atmosphere, are reported. TABLE I THERMOELECTRIC PROPERTIES AT 300 K OF THE ECAE PROCESSED SAMPLES Fig. 6 Hall-Williamson plot of sample A Sample α ρ λ Z (K-1) n (m-3) μ A (μV/K) (μΏm) (W/Km) x 103 x 10-25 (cm2/Vs) 8.0 55 1.2 331 Longit. -164 11.2 1.45 1.68 Transv. -158 14.2 1.02 1.47 Longit. -147 13.5 1.16 1.37 Transv. -146 15.7 1.08 1.27 Longit. -167 13.7 1.15 1.76 Transv. -159 16.1 1.01 1.55 6.6 59 -178 8.2 1.41 2.74 1.9 401 B C Extruded at 440°C Fig. 7 Hall-Williamson plot of sample B Fig. 8 Hall-Williamson plot of sample C In these plots, the slope of the line obtained by the linear fit of the data is related to the strain of the nanograins. It increases with the number of ECAE passes, from 0.08% in sample A, to 0.21% in sample B, reaching 0.40% in sample C. The intercept of the same line with the Y-axis is related to the grain size, D. From this analysis, D shows tendency to increase with the number of ECAE passes from 64, to 84, up to 160 nm for samples A. B, and C, respectively. Using the Scherrer’s formula to calculate D from the same diffraction patterns, a value of 55 nm is obtained for all the samples. Both analysis of X-ray line profiles indicate a grain size considerably larger than the values directly measured by HRTEM. This result is often observed in nanostructured The most striking result emerging from the analysis of Tab. I is the anomaly of the n values of the ECAE processed samples. To explain this “fuzzy” behaviour of carrier concentration with the number of ECAE passes, we assume that the vacuum sealing system of the composite billet has failed to fully protect the powder from oxygen contamination. Under this hypothesis, when the contamination is feeble (samples A and C), oxygen dissolves in the alloy, introducing donor levels [10] and increasing the n value. When the oxygen contamination is more important (sample B), the formation of Bi oxides is likely to occur at 300 °C. In such a situation, the cation sub-lattice is under-stoichiometric and Bi vacancies are created. Ionization of the latter, according to the reaction vBix → vBi'''+3h• [11], causes a drop in the n carrier concentration. The non optimized electron concentration accounts for the low values of α and, consequently, of Z. In previous experiments on ECAE processed chalcogenides [7], the maximum value of Z was observed along the plane of intersection of the entry and exit channel (at 45° to the extrusion direction in our equipment). This was explained by the specific texture assumed by the material, with the basal (00l) planes of the hexagonal crystal cell preferentially oriented parallel to such a shear deformation plane. This rule has been confirmed also in present case. As a matter of fact, measurements of sample B along a plane at 45° to the extrusion direction have shown a value of Z = 1.76 x 10 -3 K-1, namely 28% higher than in the longitudinal direction. The positive note emerging from the analysis of tab. I is represented by the low values of λ, which well compare with those obtained in p-type nanostructured (BixSb1-x)2Te3 alloys [2, 3]. IV. CONCLUSIONS Results of the present investigation confirm the validity of the warm ECAE process in the consolidation of the nanograined powders. Sintering by ECAE has been achieved after only two passes at 300 °C, with a total holding time at this temperature of 19 minutes. Further investigation is needed to improve the thermoelectric properties of ECAE processed nanopowders. In particular, oxygen contamination has to be avoided, for instance by operating in an Ar atmosphere; in addition, the starting nanograined powder has to be a stoichiometric single phase alloy. ACKNOWLEDGMENT The authors are thankful to Mr. E. Bassani for technical assistance in ECAE experiments. [2] [3] [4] [5] [6] [7] [8] [9] [10] REFERENCES [1] R. Venkatasubramanian, E. Sivola, T. Colpitts, B. O’Quinn, “Thin-film thermoelectric devices with. high room-temperature figures of merit,” Nature, Vol.413, pp. 597–602, Oct.2001 [11] B. Poudel, Q. Hao, Y. Ma, Y. Lan, A. Minnich, B. Yu, X. Yan, D. Wang, A. Muto, D. Vashaee, X. Chen, J. Liu, M.S. Dresselhaus, G. Chen, Z. Ren, “High-Thermoelectric Performance of Nanostructured Bismuth Antimony Telluride Bulk Alloy,” Science, Vol. 320, pp. 634–638, May 2008. Y. Ma, Q. Hao, B. Poudel, Y. Lan, B.Yu, D. Wang, G. Chen, Z. Ren, “Enhanced Thermoelectric Figure-of-Merit in p-Type Nanostructured Bismuth Antimony Tellurium Alloys Made from Elemental Chunks,” Nano Lett., Vol.8, pp. 2580–2584, Aug. 2008 M. Scheele, A. Kornowski, C. Klinke, H. Weller, N. Oeschler, K. Meier, “Synthesis and thermoelectric characterization of Bi2Te3 nanoparticles,” Adv. Funct. Mat., Vol. 19, pp. 3476–3483, Nov. 2009 A. Kaushik, I. Karaman, A.R. Srinivasa, “Simulation of Powder Compaction using Equal Channel Angular Extrusion at Room Temperature: Comparison of Two Constitutive Theories,” IJSCS, Vol.1, pp. 211–226, Dec. 2009 D. Vasilevskiy, M.S. Dawood, J.-P. Masse, S. Turenne, R.A. Masut, “Generation of Nanosized Particles during Mechanical Alloying and their Evolution through the Hot Extrusion Process in Bismuth Telluride Based Alloys”, JEM, Vol. 39, Issue 9, p. 1890, 2010 S. Ceresara, G. Giunchi. N. Ripamonti, “Warm ECAE: a Novel Deformation Process for Optimizing Mechanical and Thermoelectric Properties of Chalcogenides,” in Proceeding of 25th ICT, Vienna, Aug. 2006, paper K4 H. Okamoto, L.E. Tanner, “Bi-Te (Bismuth-Tellurium),” in Binary Alloy Phase Diagram, 2nd ed., Ed. T.B. Massalski, ASM International, Materials Park,. Ohio, 1990, Vol.1, p. 800. D.B. Cullity, S.R. Stock, Elements of X-Ray Diffraction, 3rd ed., Ed. New York : Prentice Hall, 2001 J.M. Schultz, J.P. McHugh, W.A. Tiller, “Effect of Heavy Deformation and Annealing on the Electrical Properties of Bi2Te3,” J Appl. Phys., Vol. 33, pp. 2443–2450, Aug. 1962 H.Sherrer, S. Sherrer, “Thermoelectric Properties of Bismuth Antimony Telluride Sold Solutions” in Thermoelectrics Handbook: Macro to Nano, Ed. D.M. Rowe, Taylor & Francis, Boca Raton, 2006, Chapter 27