Safe Work Procedure - Faculty of Medicine

advertisement

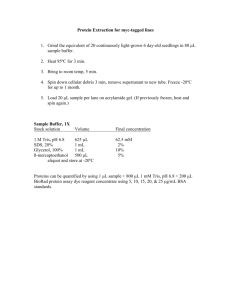

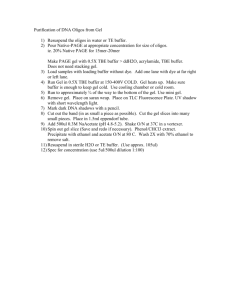

OHS026 Safe Work Procedure Faculty/Division Medicine Document number SOMS GBD SWP 026 School/ Divisional Unit School of Medical Sciences Initial Issue date 13-03-2009 Current version 1.0 Current Version Issue date 20-04-2010 Next review date 20-04-2013 The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form. Safe Work Procedure Title and basic description Title: western blot Description: Using specific antibodies to target signals at protein level Associated risk assessment title and location: RA Poring Acrylamide gel 009, RA SDS page and western 010, RA Western blot gel running and transferring 014, RA Preparation buffer for western blot, RA Develop film 002, RA Waste management 015 located in room 209B ___________________________________________________________________________________________________________ ___________ Page 1 of 4 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 Describe the activity or process Read all MSDS’s before starting experiment Make SDS Polyacrylamide gel: 30% Acrylamide/Low-Bis solution Polyacrylamide – carcinogenic and neurotoxic) 10% Ammonium persulphate (AMPS) N,N,N',N'-Tetramethylethylenediamine (TEMED)Harmful if inhaled or swallowed) Resolving buffer (1.5M Tris.Cl pH 8.8) Stacking buffer (0.5M Tris.Cl pH 6.8) 10% (w/v) Sodium dodecyl sulfate (SDS) Addition of TEMED to acrylamide gel solution should be carried out in a well ventilated area or a fume hood. Take set gel and load into gel running cassette. If only one gel is being run, load a buffer dam in the opposing slot to the gel. Slide cassette into running tank. Pour in ~800ml SDS Running buffer in main chamber, and ~100ml SDS running buffer into cavity between gel, cassette and buffer dam. Pipette in appropriate volumes (30-40ul) of sample in wells within the gel. When finished, affix the lid to the tank, ensuring that the cathodes and anodes are aligned (i.e. red electrode on the lid to red electrode on the tank, black to black). Plug the tank leads (again red to red and black to black) into the BIO-RAD powerpac. Turn the power pac on. Set the powerpac to Volts constant, and adjust the voltage to between 70 – 100V. Hit the “running man” button to initiate current through the gel apparatus. Once gel has finished running, hit the “flat hand” button to stop the current. Turn the powerpac off. Unplug the running tank, and place it in the sink. Remove the gel cassette from within, and place on absorbent material on the adjacent bench. Pour the running buffer from the upper chamber into the main chamber and discard it. Open the gel cassette and remove the gel and buffer dam. Using a “gel releaser”, pry the two pieces of glass encasing the gel apart. Do not use forceps to separate these glass plates, as plates will break. Open the gel transfer cassette, place the black surface down into the cassette well of the transfer tray. Fill the tray halfway with transfer buffer. Thoroughly wet two foam pads in the transfer buffer, place one on top of the black (now bottom) surface of the transfer cassette. Wet one piece of Whatman paper and place on top of the foam pad. Wet the “gel releaser” in transfer buffer, and use it to lift the gel off the glass plate. Place the gel squarely onto the wet piece of Whatman paper. Pour ~40ml Methanol into a small container. Take one cut piece of PVDF and, using flat forceps, immerse it in the methanol for 10 seconds, and then into the transfer buffer in the tray. Place the membrane so that it adheres entirely to the gel. Using a clean, transfer buffer wet 15ml tube; roll out any air bubbles between the gel and the membrane. Wet another cut piece of Whatman paper in transfer buffer, and lay this over the membrane. Again roll out any air bubbles with the 15ml tube. Thoroughly wet another foam pad, and place this on to the now layered Black plastic-Whatman paper-GelMembrane-Whatman paper sandwich. Close the transfer cassette and place into the transfer tank, being careful to align the black side of the cassette with the black side of the transfer tank. Fill the tank with Transfer Buffer (~1.2L), and place a solid ice pack into the transfer tank. Fill a large eski ¼ full with ice, and form a well in the ice large enough for the tank. Place the tank into this well, plug the tank lid on, ensuring the black goes to the black, and plug the lid into the powerpac. Turn the powerpac on. Set the volts constant to 80V, and put the timer on for 120 mins. Hit the “running man” button to start the transfer. 120 mins later when the transfer is finished, turn the power pac off, and remove the tank lid and dispose the used transfer buffer. Remove the Transfer cassette from the tank, place on absorbent material on the bench. Open the cassette, and carefully remove the top foam pad (furthest from the black side), and the Whatman paper nearest it. Using flat forceps, remove the membrane adjacent to the gel, and place into a clean container. Cover the membrane with distilled water. Always discard of polyacrylamide gels in the a closed bag and then in chemical waste bin. Discard the whatman paper in the biohazard bins. Wash the tank, cassette, and foam pads with distilled water and leave to dry. Dispose of eski ice from transfer down the sink. Rinse the blot once with PBS. Prepare 5% skim milk powder (SMP) in PBST. Use 20 mL per blot. Block for 60 min at room temperature with gentle rotation on the platform shaker. During this time, prepare your primary antibody. NB: incubation conditions will vary depending on the supplier of the antibody. Generally for a primary antibody 1 h at room temperature diluted in 20 mL 5% SMP in PBST with gentle rotation. Wash the blot 3 times with PBST (20 mL) with gentle rotation for 10 min, 10 min, and then 10 min. During this time, prepare the secondary antibody (also in 5% SMP in PBST). Incubate blots with the secondary antibody solution for 1 h at room temperature with gentle rotation. Wash the blot 3 times with PBST (20 ml) with gentle rotation for 10min, 10 min, and then 10 min. Make up ECL and pre-incubate membrane in it for 5 mins. Wrap the blot in plastic wrap and place it into an x-ray cassette. Secure with tape to avoid movement. Take film, scissors, membrane, developer and fixative to dark room and expose the film. Turn the red light ON and turn the white light OFF so as not to expose all the film in the box. Open the box of autoradiography film and remove a single sheet, then re-seal the box and put it away. Place the sheet of film over the blot and expose for the desired time. Remove the film from the cassette and place it through film develop machine. Scan the film and quantify protein level. List all resources required including plant, chemicals, personal protective clothing and equipment, etc Suitable PPE Buffer, Acrylamide, SDS, APS, TEMED, loading buffer, methanol Primary and secondary antibodies, ECL, skim milk, fixative, developer Electrophoresis, heating block, PVDF membrane, filter paper, plastic lane combs, cassette, scissors, fume hood, film and film develop machine ___________________________________________________________________________________________________________ ___________ Page 2 of 4 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 List potential hazards and risk controls including specific precautions required Chemicals may be hazardous – Contact and absorption of acrylamide via contact of solution with skin or splashing into eyes and Inhalation of TEMED via vapors. Gloves, Safety goggles and lab coat should be worn when handling acrylamide solutions and TEMED. Making of polyacrylamide gels should be carried out in a well ventilated area, preferably in a fume hood. Potential electrical hazard – do annual inspections of electrical equipment and ensure electrical safety tag is current. Potential aerosol hazard – wear PPE and use a biosafety hood or wear a mask. Potential injury by scissors or heating block – training is required if handling the equipment, make a sign to warn people on heating block. List emergency shutdown instructions Power pack, heating block and file develop machine have “OFF” switch that can be used in emergency. Shut all electrical equipment off at power point in case of emergency. List clean up and waste disposal requirements For chemicals: Clean up with detergent and with water Dispose into chemical waste For sample: Clean up or sock with 70% ethanol Dispose into biological waste List legislation, standards and codes of practice used in the development of the SWP NSW OHS Act 2000 NSW OHS Regulation 2001 Australia Dangerous Goods Code Code of Practice for the Labeling of Workplace Substances AS/NZS 2243.2:2006. Safety in laboratories. Part 2: Chemical aspects Australian Standard AS2243.6-1990. Safety in laboratories. Part 6: Mechanical Aspects. Australian Standard AS2243.7-1991. Safety in laboratories. Part 7: Electrical Aspects. AS/NZS 2161.1:2000 Occupational Protective Gloves – Selection, Use and Maintenance Safe Work Procedure Form (OHS026) UNSW Hazardous Waste Disposal Procedure Supervisory approval, training, and review Supervisor: Prof E Burcher Signature: Plant custodian: Signature List competency required – qualifications, certificates, licencing, training - eg course or instruction: SWP review date: 20-04-2013 Responsibility for SWP review: Fei Shang List all resources required including plant, chemicals, personal protective clothing and equipment, etc ___________________________________________________________________________________________________________ ___________ Page 3 of 4 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 Equipment: Gel Pouring Apparatus Short and Spacer Plates Plastic Lane Combs Plastic Falcon Tubes Fume Hood Chemicals: 30% Acrylamide/Low-Bis solution 10% Ammonium persulphate (AMPS) N,N,N',N'-Tetramethylethylenediamine (TEMED) Resolving buffer (1.5M Tris.Cl pH 8.8) Stacking buffer (0.5M Tris.Cl pH 6.8) 10% (w/v) Sodium dodecyl sulfate (SDS) Personal Protective Equipment: Safety Goggles Lab Coat/Gown Face Mask (for addition of TEMED to acrylamide solution) ___________________________________________________________________________________________________________ ___________ Page 4 of 4 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007