Risk Assessmen Guidelines - Department of Biomedical Engineering

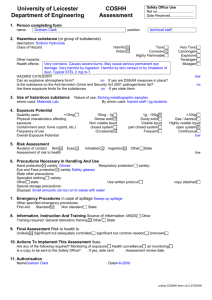

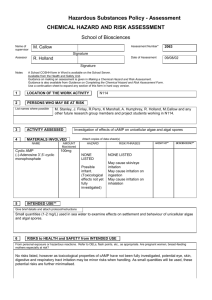

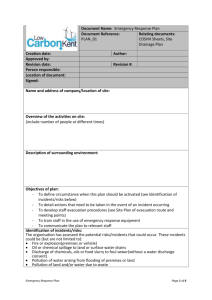

advertisement

Faculty of Engineering List of Experiment / Activity Department: S/N Last updated: 29 Feb 2008 Lab Supervisor Location/Project Work Experiment / Activities (Routine / Non-Routine) Priority Target Date for Assessment Faculty of Engineering Activity Sequence List - Activity or Experiment-Based Risk Assessment Experiment / Activity Steps Department: No. BiE Experiment / Activity Bacteria culture of Bacillus PS3 and Halobacterium Saliinarum Location: E3A 7 floor Laboratory: Nanobioanalytics Workable Sequence/Task Preparation of culture media Autoclave sterilisation of media and labware Bacteria culture in shaking incubator Use of spectrophotometer to track culture progress Centrifuge of bacteria cells/membranes Chemical/detergent treatment and assays of cell membranes and protein Last updated: 29 Feb 2008 Faculty of Engineering Activity or Experiment-Based Risk Assessment Form Department: BIE Name of Experiment/Activity: Bacteria culture (Bacillus PS3 and Halobacterium Salinarum) Location: Nanobioanalytics Lab Name of Person in-charge: Tan Wee Jin Last Review Date: 1 Task Preparation of Hazards Spillage media 2. Risk Evaluation & Control Skin/Eye contact, Existing Risk Control (if any) Lab coat, covered inhalation hand/foot/eyewear, Possible Consequences S L R 1 2 2 2 1 2 2 1 2 , take precautions based on MSDS 2 Autoclave High temperature Skin/eye contact, Lab coat, covered sterilisation and and pressure inhalation, spillage, hand/foot/eyewear, burns follow standard drying of media/labware eqpt operating instructions 3 Dr Dieter Wilhelm Trau Next Review Date: 1. Hazard Identification No. Name of PI: BSL 1 Bacteria Moving parts Skin/eye contact, Lab coat, culture in inhalation, spillage, hand/eye/footwear incubator/shaker glass breakage, protection, follow eqpt malfunction standard operating instructions, perform std decontamination with bleach/ 70% ethanol in case of Last updated: 29 Feb 2008 Additional / New Risk Control S L R Action By Deadline Faculty of Engineering spillage Use of Spillage Spectrophotomet Contamination, Use of protective eqpt malfunction. eqpt, Follow std er 1 1 2 3 1 3 operating and decontamination instructions Use of centrifuge Spillage, high Contamination, Use of protective Check Motor in speed moving parts eqpt malfunction hand/foot/eyewear case of and eqpt, balance suspected all bottles before damage, e.g. in centrifuge, check case rotor falls safe operating onto ground speeds, follow operating instructions Chemical/deterge Spillage Skin/eye/inhalation Use protective nt treatment and contact. Work area wear, proper assays of contamination decontamination membranes/ procedures, follow protein chemical MSDS 1 3 3 Use smaller volumes safety procedures Conducted by: (Name, designation) Approved by: (Name, designation) Signature: Signature: Date: Date: Last updated: 29 Feb 2008 Risk Assessment Matrix Likelihood Severity Minor Moderate Major Remote (1) Occasional (2) Frequent (3) 1 2 3 2 4 6 3 6 9 (1) (2) (3) Severity Categories Level Human (Impact to Physical Being) Biological Impact Environmental Damage Property Damage (S$) (1) Minor No Injury or light injury requiring only first aid treatment (MC < 4 days MC) Any injury/ill health leading to ≥ 4 days MC or ≥ 1 day hospitalisation or leads to temporary disability May not cause human disease, if does, the disease is unlikely to spread to the community and there is usually effective prophylaxis or treatment available; Reversible Up to $5,000 Can cause severe human disease, not ordinarily spread by casual contact from one individual to another; it may spread to the community, but there is usually effective prophylaxis or treatment available Reversible but takes years $5,001 to $50,000 Fatality, permanent Disability or life threatening disease Can cause lethal human disease, may be readily transmitted from one individual to another, or from animal to human or vice-versa directly or indirectly, or casual contact, it may spread to the community; usually no effective prophylaxis or treatment available Irreversible More than $50,000 (2) Moderate (3) Major Likelihood Categories Level (1) Remote (2) Possible (3) Frequent Events Frequency Undesired event which may occur but unlikely, once in 5 years Undesired event which is probable, once in a year Undesired event which probably occur in most circumstances, once or more in a month Risk Level and Acceptability Criteria Risk Score Risk Level Acceptability of Risk <3 Low Risk Acceptable Medium Risk Moderately Acceptable 3–4 Last updated: 29 Feb 2008 Recommended Actions No additional risk control measures required. To continue to monitor to ensure risk do not escalate to higher level. Acceptable to carry out the work activity; however, task need to be reviewed to bring risk level to As Low As Reasonably Practicable. Interim control measures such as administrative controls can be implemented. Supervisory oversight required. Faculty of Engineering Job must not be carried out until risk level is brought to at least medium risk level. >4 High Risk Not Acceptable Risk controls should not be overly dependant on personal protective equipment. Controls measures should focus on Elimination, substitution and engineering controls. Immediate Management intervention required to ensure risk being brought down to at least medium level before work can be commenced. Last updated: 29 Feb 2008