corrosion of Al in Citric

advertisement

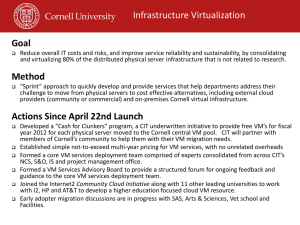

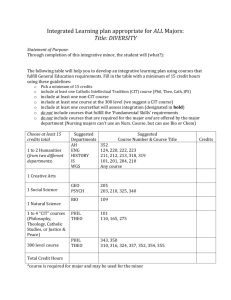

1 Corrosion of Aluminum alloys in Citric acid, W / without sodium chloride Layla Abdulkareem Al Juhaiman King Saud University Chemistry Department, Science College, PO Box 22452 Riyadh, Saudi Arabia, 11495 Fax : + 966 1 4772245 e-mail: ljuhiman@ksu.edu.sa Abdullah Al Mayouf and Abdulaziz Al Suhaybany King Saud University Chemistry Department, Science College, PO Box 2455 Riyadh, Saudi Arabia, 11451 Fax : + 966 1 4675952 e-mail : amayouf @ksu.edu.sa Abstract The corrosion behavior of two aluminum alloys (Al cookware, Al 6063) and pure aluminum in aerated aqueous solutions containing food additives namely citric acid with/without commercial salt were studied. Non electrochemical methods (weight loss and surface study) and electrochemical measurements (Open circuit potential and polarization) were applied. In polarization measurements the effect of pH, temperature, concentration and time were studied. Surface study of Al using Energy Dispersion X-Ray (EDX) showed the high depletion of Fe and Mg from Al6063 surface. In polarization measurements, the values of current density for citric acid increased with increasing pH (except at neutral solutions) and temperature but were not affected by concentration changes of citric acid. The addition of chloride ions to citric acid greatly increased the corrosion rate in acidic and basic medium many folds; the effect was influenced by the aluminum composition. The corrosion rate wasn't affected in citric solution after 60 hours but decreased with time when chloride ions where present. 1. Introduction Aluminum alloys were subjects to wide spectrum of researches because of their possible relation to human health [1-3]. Aluminum is now known to be a neurotoxin agent since 1980 [1,2]. Due to its accumulation in brain, bones and liver, it was associated with some diseases like dialysis encephalopathy, bone disorder and other disorders [1-7]. Thus it is important to shed some light on its dissolution in aqueous solution containing some food additives. The corrosion behavior of aluminum alloys is studied widely in the literature in acidic [8-10], neutral [11-17] and basic medium [18-20]. It is well known that aluminum exhibits a passive behavior in aqueous solutions due to the thin compact oxide film on its surface. The aluminum oxide solubility increases in acidic and basic medium which explain the importance of studying the role of pH as shown by Lampease et al [14]. The object of this paper is to study the corrosion behavior of two aluminum alloys (Al cookware and Al 6063) in aqueous solutions containing food additives namely citric acid (Cit) with/without 2 commercial salt (CS) and compare the results with pure Aluminum in Cit with/without pure NaCl. 2. Experimental methods Two methods were used non electrochemical and electrochemical measurements to study the corrosion rate (CR) of aluminum. Two alloys were used (Aluminum cookware (AlCW) and Al 6063T4) in addition to pure aluminum (99.99% from Good fellow). The composition of Al alloys is listed in Table (1). Non electrochemical measurements include weight loss and surface study. In weight loss the corrosion rate of Al alloys in citric acid (Cit) with/without CS was measured at pH2 and 60ºC ±1 for two hours. Al alloys were used as circular disks with surface area of cm2, 4.93, 5.03 ± 0.10 for AlCW and Al 6063 respectively. Citric acid was AR grade from Merck and distilled water was used to prepare all solutions except for ALCW were tab water was used. The concentration of all solutions was 0.10M. Pure NaCl was added to Cit for pure Al while CS was added to Cit for AlCW and Al 6063. The composition of CS is listed in Table (2). Before measurements the Al surface was polished with 600 and 1200 emery paper, washed with distilled water then ultrasonically cleaned for 1 minute in acetone. After performing weight loss the disks were washed thoroughly with distilled water, then (2%Cr2O3 ,5 %H3PO4( then weighed and kept dry for surface study. The surface of Al disks was scanned after 30 days of immersion using Scanning Electron Microscope (SEM) (Joel-JSM-T330A) connected with Energy Dispersion X-Ray (EDX). Electrochemical measurements (Open circuit potential and polarization measurements) were done using a potentiostat /galvanostat connected to a computer. All experiments were carried out using a three electrode cell with saturated calomel as the reference electrode and a platinum electrode as counter electrode. The Al working electrode was in the form of a circular rod. The exposed surface area of the three electrodes used were (1.00 cm2, 0.783 cm2, 0.282 cm2 ± 0.10) for AlCW, Al 6063 and Al pure respectively. The electrode was prepared directly before electrochemical measurements then immersed in solutions to perform open circuit for one hour before polarization measurements. The effect of pH, citric acid concentration, temperature and time was studied. 3. Results and discussion 3.1 Non Electrochemical measurements 3.1.1 Weight loss From weight loss method the corrosion rate (CR) is calculated using the following equation: ∆w A*t Where ∆ w is the weight loss of Al (g); A is the surface area (cm2) and t is the immersion time (days) Corrosion rate (CR) = 3 The CR of AlCW, Al 6063 in Cit w/without CS solutions are listed in Table (3) after two hours of immersion at 60 ºC. It is clear that the CR of AlCW at 60 ºC is greater than that of Al 6063. The addition of CS to Cit increased the CR 4.6 times for AlCW and 23 times for Al6063. These results agree with Tomcsani et al [21] that chloride ions act as partners in the electrochemical reaction. The CR of both alloys is greater than that of pure Al. In addition weight loss from unpublished work [22] for Al6063 at 25 ºC Cit w/without NaCl showed that the CR of Al 6063 increased about ten times when the temperature was raised to 60ºC. 3.1.2 Surface Study SEM images of Al surface after 30 days of immersion in Cit and Cit + NaCl are shown in Figs (1-2) for Al 6063. Local corrosion was clear for Cit acid. For Cit + NaCl in addition to increasing number of bigger pits, the surface was full of cracks with variable depth which is in agreements with the weight loss results. Surface analysis using EDX for Al surface are shown in Table (4). Inspection of Table (4) shows the remarkable decrease in Mg and Fe after immersion in acid solutions with/without chloride ions which explained the high corrosion rate in these acids. This result is in agreements with Brillas et al [23] that the local corrosion of Al alloys increased with increasing amounts of magnesium. It may be attributed to deposition of the phase Mg5Al8 which makes an anodic phase in the aluminium matrix making it an optimum region of dissolution [24]. The role of Fe resembles that of Mg where the presence of the phase FeAl3 is accompanied with local corrosion as mentioned by Seri [13] 3.2 Electrochemical measurements 3.2.1 Open circuit potential measurements They were done for AlCW, Al6063 and pure Al electrodes at 0.10M, 25 ±1ºC and different pH values. The data are shown in Fig (3, 4) for AlCW in Cit, Cit +CS as a representation of the other electrodes. The values of steady state potential, Ess are listed in Table (5). It is known that when open circuit potential goes to increasing potential values it indicates strengthening of the pre-immersion oxide film. It was noticed that Ess values decrease after addition of chloride ions to Cit. In addition Ess values decrease with increasing pH values which indicate thinning of pre-immersion oxide film and agrees with earlier results [25]. 3.2.2 Polarization measurements They were studied at different concentrations, pH, temperatures and times for the AlCW, Al 6063 electrodes in Cit and Cit + CS and pure Al in Cit and Cit + NaCl. To study the effect of concentration the temperature was kept at 25 ±1ºC and the concentration of Cit was changed from 0.01M-0.50M. The results are shown in Table (6) for Al 6063 only. It is clear that corrosion current density values (Icorr) were almost constant which means that this factor doesn't play a significant role in corrosion control. To study the effect of pH the concentration was kept constant at 0.10M, the temperature was kept at 25 ±1ºC and the pH values were changed from 2-9.5. Polarization curves are shown in Figs (5, 6) for AlCW in Cit and Cit + CS. The electrochemical parameters of the three electrodes in Cit with/without NaCl at different pH values are listed in Table (7a ,7b). It is clear from these polarization results that: 4 Corrosion potential, Ecorr decreased with increasing pH which is in agreements with open circuit potential results [25]. For Cit Icorr decreased with increasing pH until it reached its minimum at pH 6.5 then started to increase to reach its maximum at pH 9.5 For Cit, Cit +CS the trend for Icorr values was :AlCW > Al 6063 > Al pure The addition of NaCl to carboxylic acids increased greatly Icorr values in acidic medium only but it didn't affect the neutral and alkaline medium. These results are combatable with the surface isoelectric point of native air-formed oxide film determined by McCafferty and Wightman [26]. The isoelectric point of Al of 9.5 makes the Al surface positive below pH 9.5 and allows for penetration of Cl- ions whereas when the pH is ≥ 9.5 the Al surface would be negative which will prevent the penetration of Cl- ions. The removal of surface defects by incorporation of chloride ions was experimentally verified by Lee & Pyun using Auger Analysis [27]. A previous model by McCaferty [28] was extended to consider that penetration of Cl- ions can occur by film dissolution or by migration through oxygen vacancies [29]. Our results agree also with another recent study by Kolice et al [17] where they have shown using XPS studies that the amount of Cl- ions taken up by the passive film on Al surface varied with pH and the minimum concentration of surface chloride occurred at a pH near pH9.5. To study the effect of temperature the concentration was kept constant at 0.10M, and the temperature was changed from (10-60ºC). The electrochemical parameters of the three electrodes in Cit, Cit + NaCl are listed in Table (8a, 8b). In general increasing the temperature shift Ecorr to the negative direction which means thinning of the aluminium oxide film and correlate with increasing Icorr values. It is clear from Table (8a,8b) that: In general corrosion current density values increase with increasing temperature but not largely maybe because the dominant reduction reaction is reduction of oxygen whose concentration decrease with increasing temperature. It is clear that the effect of temperatures was less severe than the effect of pH. For Cit the trend for Icorr values was :AlCW > Al 6063 > Al pure For Cit + NaCl the general trend for Icorr values was :Al 6063 >AlCW > Al pure The high values of Icorr for Al 6063 reflect the effect of alloying elements. The effect of time was studied at pH4.5 after 60 hour and compared to that after one hour for Al 6063 only; the results are listed in Table (9). It is obvious that Icorr for Al 6063 in Cit wasn't affected by time while that of Al 6063 in Cit +CS decreased 22% after 60 hours. This strange result seems to be related to the presence of chloride ions. To validate this result the same measurements were done for Al 6063 in solutions containing 0.10M Cit+NaCl , CS and pure NaCl and the same trend was found. The low Icorr in presence of chloride ions may be explained by the findings of Foley [30] and Pyun [31] where they found that the presence of chloride ions in basic medium increased the resistance of the oxide layer due to incorporation of chloride 5 ions in the defected sites where they form compounds like AlCl3, Al(OH)2Cl and Al(OH)Cl2. Our findings are also in agreements with Taprizi et al [32] and Kolice et al [15, 17]. This was experimentally verified by Pyun and Lee [33] using Augar Analysis where they found that the ''number of available pit initiation sites was noticeably reduced by pre immersion in 1M NaCl solution, which is due to occurrence of metastable pitting'' [33]. This explains the complexity of adsorption of these ions and proves that some adsorption reactions on Aluminum may need longer times as some researchers prove [6, 33, and 34]. Although the previous results about the role of chloride ions in forming defect repairing oxide films were in the neutral and alkaline media, our results show that they may play the same role in acidic medium at long immersion times. 4. Conclusion The corrosion behavior of Al alloys in food additives depends on pH, chloride ion, temperature, time and alloying elements. The dietary sources of aluminum are food and water. The increase in CR of aluminum in carboxylic acids and chloride ions needs more elaborate studies to determine the dissolution of aluminum from cooking utensil and compare them with the daily allowed amount assigned from World Health Organization (WHO). Acknowledgment The authors wish to thank King Abdulaziz City for Science and Technology for their valuable financial support of this study. 6 Table (1) Composition of Al alloys Element Al Zn Ti Cr Al 6063 AlCW 97.5098.35 97.62 0.10 -- 0.1 0 -- 0.10 -- Table (2) Composition of CS Compound NaCl CaSO4 % 99.8 Si Fe Mg Mn Cu Other 0.200.60 -- 0.35 0.450.90 -- 0.10 0.10 0.15 0.045 0.023 Sn= 0.95 1.366 Mg SO4 0.07 MgCl2 I2 Additives 0.03 0.05 MgCO3 Additive s 0.0070.010 Table (3) CR (g/cm2.days) of Al from weight loss at pH 2, 60 ºC, two hours Solution Cit Cit + NaCl AlCW Al 6063, Al pure 6.61exp -4 2.01exp-4 1.41 exp-4 28.12 exp -4 23.92 exp-4 4.45 exp-4 Table (4) Surface analysis of Al 6063 in test solutions after 30 days [22] Al Si Fe Mg Mn Uncorroded sample 97.13 1.4 0.21 0.94 0.38 Cit 98.19 1.69 0.01 0.05 0.16 Cit +NaCl 98.22 1.89 0.08 ---- 0.29 0.25 7 Table (5) Open circuit potential of Al electrodes in acid solutions at 0.10M, 25ºC and different pH pH AlCW , Cit Al 6063 , Cit Al Pure , Cit 2.0 -503 -496 -487 4.5 -490 -692 -614 6.6 -452 -731 -739 9.5 -1396 -1365 -1745 pH AlCW, Cit +CS Al 6063, Cit +CS Al Pure, Cit+NaCl 2.0 -676 -760 -685 4.5 -666 -763 -712 6.6 -697 -770 -792 9.5 -1374 -1477 -1754 Table (6) Electrochemical parameters of Al 6063 in different concentrations of Cit at 25ºC [Cit] ,M pH Ecorr Icorr , mV μA /cm2 0.01 2.7 -366 0.36 0.05 2.4 -364 0.39 0.10 2.0 -446 0.50 0.20 2.1 -370 0.38 0.50 1.9 -396 0.38 8 Table (7a) Electrochemical parameters of Al alloys in Cit w/without CS solutions at 0.10M, 25ºC and different pH Solution pH AlCW Al 6063 Cit Cit + CS Ecorr , mV Icorr μA /cm2 Ecorr , mV Icorr μA /cm2 2.0 -483 4.84 -446 0.50 4.5 -512 1.92 -700 0.40 6.5 -446 0.67 -755 0.16 9.5 -1396 56.68 -1365 53.55 2.0 -674 13.24 -714 19.91 4.5 -662 4.64 -703 3.30 6.5 -734 0.25 -776 0.067 9.5 -1418 62.70 -1392 54.8 Table (7b) Electrochemical parameters of Al pure in Cit w/without NaCl solutions at 0.10M, 25ºC and different pH Pure Al Solution pH Cit Cit + NaCl 2.0 Ecorr , mV -462 Icorr μA /cm2 0.45 4.5 -584 0.33 6.5 -718 0.16 9.5 -1727 19.44 2.0 -679 6.91 4.5 -702 0.39 6.5 -786 0.20 9.5 -1768 18.83 9 Table (8a) Electrochemical parameters of Al alloys in Cit w/without CS solutions at 0.10 M, pH 2.0, and different temperature Solution Cit Cit + CS T ,°C AlCW Al 6063 Ecorr , mV Icorr μA /cm2 Ecorr , mV Icorr μA /cm2 10 -461 2.77 -392 0.28 25 -483 4.84 -446 0.50 45 -443 7.65 -489 1.58 60 -455 8.42 -520 5.23 10 -660 9.63 -699 12.10 25 -674 13.24 -714 19.90 45 -687 14.93 -661 45.50 60 -695 17.50 -766 52.32 Table (8b) Electrochemical parameters of Al pure in Cit w/without NaCl solutions at 0.10 M, pH 2.0, and different temperature Pure Al Solution T ,°C Cit Cit + NaCl 10 Ecorr , mV -495 Icorr μA /cm2 0.10 25 -462 0.45 45 -580 1.47 60 -560 4.42 10 -687 2.38 25 -679 6.91 45 -686 11.59 60 -675 20.26 10 Table (9) Electrochemical parameters of Al 6063 in different solutions at 0.10 M, pH4.5, 25ºC and different times Solution Time Ecorr , Icorr , ,hr mV μA /cm2 1 -700 0.40 Cit Cit +CS CS NaCl, [22] Cit+NaCl , [22] 60 -590 0.44 1 -703 3.30 60 -651 0.72 1 -700 1.06 60 -867 0.10 1 -674 1.32 60 -729 0.18 1 -724 10.0 60 -663 3.59 11 Fig (1) SEM of Al 6063 in Cit after 30 days of immersion, [22] Fig (2) SEM of Al6063 in Cit + NaCl after 30 days of immersion ,[22] 12 Fig(3) Open circuit potential of AlCW in Cit at 0.10M and different pH Fig (4) Open circuit potential of AlCW in Cit + CS at 0.10M and different pH 13 Fig (5) Polarization curves of AlCW in Cit at 0.10M and different pH Fig (6) Polarization curves of AlCW in Cit +CS at 0.10M and different pH 14 5. References [1] H.J. Gitelman, “Aluminum and Health”, a critical review, Marcel Dekker, Inc. (1989) [2]A.Lion , Food Chem. Toxico.,Vol.21,No.1,pp.103-109,(1983) [3]K.Winship, Adverse Drugs React. Toxicol. Rev., Vol.11, No.2, pp.123 –141, (1992) [4] A.Bard “Encyclopedia of the Elements” Vol.VI, (1976) [5]D.V.Brown, “Metallurgy Basics”, Van Nostrand Reinhold Company Inc., (1983) [6] A.Martel , R.Motekaitis and R.Smith, Polyhedron,Vol.9,No.2/3 ,pp.171-182 ,(1990) [7] P.Slanina andY.Falkeborn , Fd.Chem.Toxic.,Vol.22 , No.5 , pp.391-397 ,(1984) [8]A.A.Al-Suhybani, Corrosion Prevention &Control, Vol.6, pp.71-77, (1989) [9]B.Mǜller, Corr. Sc. ,46 ,159(2004) [10]M.N.Desai ,G.Shah ,D. Shah and M.Gandi , Anti-Corrosion, Vol.3 , pp.1619,(1972) [11]D.Zhu ,W.Ooij, Corr. Sc., 45,2163 (2003) [12]M.Abdulhay and A.A.Al-Suhybani , International Journal of Chemistry ,Vol.4, No.3 , pp.97-109,(1993) [13] O.Seri , Corrosion Science ,Vol.36, No.10 , pp.1789-1803,(1994) [14] N.Lampease , and P. Koutsokos , Corrosion Science ,Vol.36, No.6 , pp.10111025,(1994) [15] A.Kolice , J.C.Polkinghorne and A.Wieckoski , Electrochimca Acta ,Vol.43 ,No.18 , pp.2605-2618 ,(1998) [16]V.Guillaumin and G.Mankoski , Corrosion Science ,Vol.41, pp.421-438,(1999) [17]A.Kolice, A.S.BEsing, P.Baradlai, R.Haasch, A.Weickowski,'' Effect of thickness and ion content of the oxide film on Al in NaCl media'' J. Electrochem. Soc.,148, 251 (2001) [18]A.A.Al-Suhaybani , Mat.Wiss.Werkstofftech ,Vol.22,pp.301-307 ,(1991) [19]K.Wong & R.Alkire , J. Electrochemical Society ,Vol.137, No.10, pp.3010-3015, (1990) [20]M.BÖRÖCZ-SZABó , Acta Alimentaria,Vol.6 , No.4, pp.341-353, (1977) [21]L.Tomcsanyi , K.Varga,I.Bartik ,G.Horani and E.Maleczki , Electrochimca Acta ,Vol. 34 , No.6 , pp.855-859, (1989) [22] A. Al Mayouf, L. Al Juhaiman and A. Suhaybani ,"Corrosion of Aluminum in ascorbic, Citric and Tartaric acids with /without sodium chloride '' under publication [23]E. Brillas, P. L. Cabot, F. Centellas, J. A. Carrido, E. Parez and R M. Rodfiques. Electrochim. Acta, Vol.43 ,p.799,(1998) [24]G.M.Scamans,N.Jholroyd,And C.D.Tuck, Corrosion Sci.,Vol.27 ,pp. 329 (1987) 15 [25] A. Al Mayouf, L. Al Juhaiman and A. Suhaybani , Journal of Saudi Chemical Society, pp365-384( 2000) [26] E.McCafferty, J.P.Wightman, J.Colloid Interface Sci.,194,344(1997) [27] W.Lee , S. Pyun, Elecrochim.Acta.,45, (No.12)1901(2000) [28]. McCafferty, Corr. Sc., 37(No.3), 481(1995) [29]E. McCafferty, Corr. Sc., 45, 1421(2003) [30]Foley,R., Corrosion, Vol. 42,No.5, pp.277(1986) [31]S.Pyun, Corrosion Science, Vol.4, p.653(1999) [32]M.Taprizi,S.B.Lyon ,G.E.Thompson &J.M.Ferguson ,Corrosion Science ,Vol.32,No.1,pp.733-742 (1991) [33]S.Pyun,W.Lee, '' Corr. Sc., 43, 353(2001) [34]Lars-Ölof Ohman &Staffan Sjöberg J.Chec,Soc, Dalton Trans, pp.2513(1983)