Anheuser-Busch International, Inc

advertisement

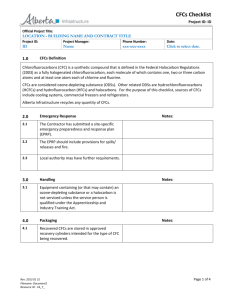

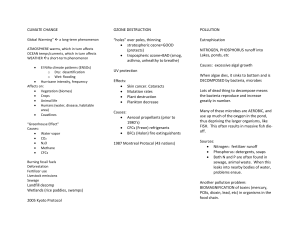

Ecological Cooling: The Fridge from Eastern Germany In March of 1993, mass production of the world’s first refrigerator that works without damaging the earth’s vital ozone layer began in Niederschmiedeberg, the hometown of a small eastern German firm. FORON Domestic Appliances GmbH offers the first “green” refrigerator, completely free of chlorofluorocarbons (CFCs). The road to this achievement, however, was not easy. CFCs and The Montreal Agreement For decades, chlorofluorocarbons (CFCs) were the refrigerants of choice worldwide. They were nontoxic, nonflammable, and energy-efficient. The price of $.57 per pound in 1980 also made CFCs quite inexpensive. Introduced in the 1930s, CFCs by 1985 represented a worldwide market of $1.5 billion a year. Since 1974, scientists had theorized that CFCs would deplete the earth’s ozone layer, which shields the earth from the sun’s harmful ultraviolet rays. As a result of these implications, and due to public pressure, the U.S. government banned the use of CFCs in aerosol propellants in 1978. Due to the nonavailability of reasonable substitutes, however, the use of CFCs in refrigerators and air conditioners continued to be permitted. After scientists observed a hole in the ozone layer over Antarctica, nations from around the world enacted the 1987 Montreal Protocol, which called for a 50 percent cut in CFC use by mid-1998. Given the growing public concern with environmental issues, the protocol was subsequently revised twice: in 1990, it was agreed that the 50 percent reduction in most CFCs was to be achieved by 1995 and the 1992 revision banned all CFC use by 1996. 1 The ban had a chilling effect on the producers of cooling devices since they depended heavily on CFCs. For example, to reduce energy consumption, refrigerators are insulated with polyurethane foam. During manufacture, the foam is saturated with 300 to 600 grams of CFCs. The gas remains in the foam and because it insulates better than air, the gas provides for heat insulation. The disadvantage of CFC-foamed polyurethane is that the CFCs gradually diffuse out of the foam and are replaced by air. The CFC escapes into the atmosphere and destroys the ozone layer. The energy efficiency of the refrigerators also deteriorates considerably over the years due to the CFC-air exchange. CFCs also contribute to the actual refrigeration process. Due to their thermodynamic properties, CFCs are highly temperature responsive to compression and expansion, therefore allowing an efficient cooling process to take place. Even though hermetically sealed, a leaky pipe or uncontrolled disposal can result in the gradual release of up to 250 grams of CFCs. dkk Scharfenstein Deutsche Klima and Kraftmaschinen AG was founded in the German state of Saxony in 1927. The firm concentrated on producing heating and cooling devices together with compressors. In the 1950s the East German communist regime took over the firm as state property and renamed it dkk Scharfenstein. As the only firm in Eastern Europe producing both refrigerators and compressors, dkk Scharfenstein (DKK) soon achieved a leadership position in the region. By 1989, the firm’s 5,200 employees produced more than 1 million refrigerators and 1.5 million compressors. Every apartment built by the East German regime had a refrigerator made by DKK. Ten million East German households had a DKK fridge; 80 percent of households had its freezers. With the fall of the Berlin Wall on November 9, 1989, and the collapse of communism in Eastern Europe, DKK’s markets collapsed as well. Long-term export contracts were rescinded. At the same time, domestic demand declined precipitously as stylish new products from West Germany became available. By 1992, production had declined to 200,000 refrigerators, and employment had shrunk to 1,000. In light of the continuing decline of its business, dkk Scharfenstein was taken over by Germany’s Treuhandanstalt, the German government’s privatization arm. _______________ Source: This case was written by Michael R. Czinkota based on discussions with Dr. Juergen Lembke, head of marketing, FORON GmbH, and reports by German and U.S. media. Financial and logistical support from the U.S. Information Agency (USIA) is gratefully acknowledged. 1 Ecological Cooling: The Fridge from Eastern Germany Development of the Eco-Fridge dkk Scharfenstein had been familiar with the ecological problems of CFCs since the mid-eighties. At that time, the firm had considered a switch to hydrofluorocarbon (HFC) 134a. This new chemical did not contain chlorine, but still made use of fluor, which contributes to the greenhouse effect and to global warming. However, these plans were abandoned for two reasons. First, the price of HFC 134a was far more than that of CFC. Second, unlike its Western counterparts, Scharfenstein was unable to obtain the product from Western markets due to export control regulations promulgated by the Multilateral Committee for Export Controls (COCOM). While HFC 134a was available in the Soviet Union, only very limited quantities were offered for sale. After 1990, HFC 134a became freely available in eastern Germany. By that time, however, the Scharfenstein staff already was working on a different project. In conjunction with Professor Harry Rosin, head of the Dortmund Institute for Hygiene, Scharfenstein had focused on a mix of butane and propane gases to cool its refrigerators. The ingredients were environmentally friendly and, with newly designed compressors, the equipment operated with less electrical power. Management presented the new product to Treuhand, in an effort to stave off the liquidation of the firm. Treuhand attempted to interest a consortium consisting of the German firms Bosch and Siemens in acquiring Scharfenstein. After a cursory review, however, both firms decided that the new technology was too radical, unproven, and flammable and withdrew from all discussions. They, like major competitors such as Whirlpool and AEG, would continue to concentrate on HFC 134a research and production. Although expensive, HFC 134a was now competitive because new taxes had increased CFC prices to more than $5 per pound. In addition, major investments had already been made into HFC production. For example, in its race against DuPont and Elf Atochem, the British firm Imperial Chemical Industries PLC alone already had invested nearly $500 million into HFC development. To ensure that retailers would share their perspective, major producers of refrigerators supplied leaflets that warned about the dangers of explosion of fridges filled with propane and butane. Treuhand did not approve the production of the new fridge. In light of mounting losses, an additional 360 Scharfenstein employees were laid off and Treuhand announced plans to liquidate the firm. Facing the shutdown of its operations, Scharfenstein’s management decided to go public with its new product. Information on the CFC-free fridge was sent to all manufacturers of refrigeration equipment, none of whom showed any interest. However, interest did materialize from unexpected quarters: The leadership of the Greenpeace organization. This worldwide nonprofit group quickly recognized the benefits of the new fridge. It commissioned 10 prototype models to be produced, and after finding them satisfactory, mounted a $300,000 advertising campaign in favor of the production of “greenfreeze.” Intense negotiations with retailers brought in orders and options for 70,000 of the refrigerators. The future of Scharfenstein brightened immediately. The German Ministry for the Environment supported a capital infusion of $3 million into the company. Shortly thereafter, Treuhand rescinded the layoffs that had been announced. By 1993, the firm was acquired by a consortium of British, Kuwaiti, and German investors and renamed FORON Household Appliances GmbH. Since then, FORON has received various environmental prizes and labels. The firm was awarded the government’s coveted Blue Angel symbol for environmental friendliness. The German Technical Society awarded its safety seal of approval. The business magazine DM named the fridge its product of the year. The giant German appliance manufacturers, which once scorned the new technology as “impossible, dangerous and too energy-consuming,” now are scrambling to put out their own green refrigerators. Major efforts of CFC-free refrigerators are also being undertaken by U.S. and Japanese manufacturers. In the United States, a group of utilities offered $30 million to the manufacturer that designed the most energy efficient refrigerator without using CFCs. FORON expects to produce more than 160,000 eco-fridges per year and actively is exploring the possibility of exports. Inquiries have been received from China, Japan, the United States, India, Australia, and New Zealand. Even though the product is priced some 5 to 10 percent more than conventional models, the firm believes that “consumers who are environmentally aware will pay the price.” 2