Composting for increasing the fertilizer value of chicken

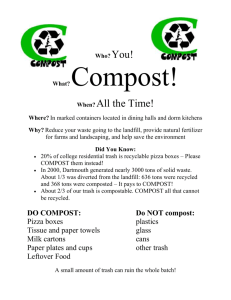

advertisement

3 COMPOSTING FOR INCREASING THE FERTILIZER VALUE OF CHICKEN MANURE: EFFECTS OF FEEDSTOCK ON P AVAILABILITY 4 5 B. Vandecasteele1, B. Reubens1, K. Willekens1, S. De Neve2 1 2 6 1 7 Environment, Burg. van Gansberghelaan 109, B-9820 Merelbeke, Belgium 8 2 9 CONTACT: bart.vandecasteele@ilvo.vlaanderen.be, ILVO, Van Gansberghelaan 109, B-9820 Merelbeke Institute for Agricultural and Fisheries Research (ILVO), Plant Sciences Unit, Crop Husbandry and Ghent University, Dept. Soil Management, Coupure 653, B-9000 Ghent, Belgium 10 11 ABSTRACT 12 The application rate of poultry manure as organic fertilizer is restricted due to its low C/P and N/P ratio. This 13 research was set up to find out optimal feedstock composition for composting chicken manure in order to 14 create a soil improver with a higher value as organic fertilizer, and to assess the effects of this process on P 15 availability in the end products. The research is based on two compost experiments with three treatments 16 each, and the chicken manure composts were compared with the end products of green waste compost used 17 as bedding material in chicken houses, centrally processed chicken manure and a stockpiled mixture of green 18 waste compost and chicken manure. In the first compost trial, feedstock materials were compared for 19 composting with fresh chicken manure. The chicken manure compost with 42.5 vol% bark in the feedstock 20 had the highest quality as soil improver in terms of organic matter content, C/P ratio, C/N ratio and stability. 21 Results of the second compost trial indicate that 10 vol% of fresh chicken manure is the upper limit in small- 22 scale on-farm windrow composting above which nutrient losses become too high and the N/P ratio of the 23 obtained fertilizer becomes too low. Stability of the product (expressed as oxygen uptake rate) had a major 24 effect on P availability in the compost. Blending the chicken manure compost with biochar based on holm 25 oak resulted in a more than proportional decrease in easily available P in the biochar-blended compost. P in 26 poultry manure can be recycled through composting and be applied as an organic fertilizer with optimal 27 nutrient ratio and organic matter content when appropriate feedstock materials are selected and the amount of 28 fresh manure in the feedstock mixture is restricted. 29 1 30 Keywords: organic fertilizer, value-added soil improver, P recycling, wood chips, bedding material, biochar- 31 blended compost, poultry litter 32 33 1 INTRODUCTION 34 For proper application as organic fertilizer it may be necessary to treat raw chicken manure: due to its 35 variable composition, raw chicken manure is difficult to spread in a homogenous way. Storage over a longer 36 period may be necessary as it is not always available at proper time of application in the field. Besides these 37 bottlenecks the application rate of raw poultry manure as organic fertilizer is restricted due to its low C/P and 38 N/P ratio and the risk of N and P losses [1]. To meet fertilization standards for reducing nutrient leaching, the 39 total P and N content of poultry manure limits the application rate [1-3]. Long-term poultry litter application 40 in pasture soil affected the P distribution in soil aggregate size fractions and may lead to P losses [4]. Several 41 options for processing manure were tested previously, e.g. poultry litter granulation [2], composting of 42 manure [1, 3,5-7] or biochar production with chicken manure as feedstock [8]. The process circumstances of 43 biochar production affected the liming effect and nutrient release of different types of biochar based on 44 chicken manure [8]. Application of additives is another option to change the properties of chicken manure: 45 several additives can be supplied to slurries and manures to reduce P availability and leaching [9-10]. 46 Composting of manure [1, 3,5-7] or the solid fraction of the digestate remaining after the anaerobic digestion 47 of cattle slurry constitutes a feasible treatment for reducing the volume for haulage and for the production of 48 composts with an adequate degree of stability and maturity and the presence of value-added properties, such 49 as suitable physical properties [11]. Composting of chicken manure mixed with other feedstock materials 50 may result in a stable product rich in nutrients and organic matter, with a lower risk for P leaching [12] and 51 higher C/P ratio. Compost can be stored for a longer period and is easier to apply in the field than raw 52 chicken manure. Composting of poultry manure might have additional benefits, e.g. further decomposition of 53 veterinary drugs, as recently the uptake of veterinary medicines by plants has been demonstrated for several 54 compounds and plant species when chicken manure was used as fertilizer [13-16]. Composting of manure 55 resulted in faster or stronger degradation of these compounds [17-18]. Increasing the quality and added-value 56 of compost is related to feedstock selection [19] and pre- and post-treatment of the compost, e.g. by 2 57 screening [20] or shredding [21]. Tognetti et al. [21] reported strategies to improve the OM (organic matter) 58 content of composts, but sometimes these strategies also resulted in a decrease in nutrient availability. For 59 some types of manure, adding rice hulls, woody material or straw allows to process the manure into a high 60 quality compost [22]. C-rich materials can be mixed at the onset of composting, or can be added already as 61 bedding material in the stable. The bedding material may affect the compost quality, as shown by Larney et 62 al. [5] for wood chip-bedded and straw-bedded cattle manure. Studies differ in the amount of poultry manure 63 applied in the composting process, the maturity of the composts and the composting system. Higher ratio of 64 poultry manure in the feedstock mixture of composting resulted in higher extractable P [3]. Compost quality 65 is affected by its stability. The biodegradation potential of organic matter may be used as an indicator of 66 compost stability and can be expressed by several indices based on the cell wall components lignin, 67 hemicellulose and/or cellulose [23-28]. Based on the biochemical composition, Gabrielle et al. [23] 68 calculated a biological stability index to predict C and N mineralisation in compost. Francou et al. [24] and 69 Lashermes et al. [25] applied the lignin/holocellulose ratio as an indicator during the composting process. 70 Paradelo et al. [26] reported that the fractionation of organic matter into cellulose, hemicellulose and lignin 71 enabled a better monitoring of the waste decomposition. Chalhoub et al. [28] reported that the compost with 72 the highest (hemicellulose + cellulose)/lignin ratio, i.e., the highest biodegradation potential also resulted in 73 the highest amount of potentially mineralized C in an incubation trial, indicating it was the least mature 74 compost. 75 Mixing biochar in compost may affect both the compost quality and the biochar characteristics. Borchard et 76 al. [29] concluded that composting increases the surface reactivity of biochars, potentially enhancing nutrient 77 retention in soils. Applying 2 vol% of biochar (made from wood) in the feedstock of chicken manure 78 composting resulted in a compost with better chemical and biochemical characteristics in terms of 79 stabilization indices, the microbial biomass and enzymatic activities related to the C, N and P cycles [7]. 80 Dias et al. [6] mixed chicken manure with biochar (made from wood), coffee husk or sawdust in a 1:1 fresh 81 weight ratio at the beginning of the process. The biochar proved to be a good bulking agent, resulting in 82 intensive humification and reduced N losses in the mature compost. 83 This research was set up to determine the effect of feedstock composition on P content and availability in 84 chicken manure compost and in products from other valorisation strategies for chicken manure. Specific 3 85 research questions are: 1) are chicken manure-based composts good soil improvers (compared to alternative 86 processing), 2) what are the Cd, Zn and Mn concentrations in these products, 3) what is the amount of 87 chicken manure that can be added to the compost in order to obtain quality compost in terms of product 88 stability, 4) what is the effect of composting on P-availability, 5) can addition of biochar further improve 89 compost quality? To assess the effect of biochar on compost properties, one of the composts based on 90 chicken manure was mixed with biochar with a higher C/P ratio than the compost. 91 92 2 METHODOLOGY 93 94 2.1 Compost trials and other applications of chicken manure 95 Composts based on chicken manure (two trials) are compared with other treatment options for chicken 96 manure: mixed storage of chicken manure and green waste, manure treatment in a central processing facility, 97 and application of green waste compost as bedding material in chicken houses (Table 1). All treatments have 98 in common that the chicken manure was ‘mixed’ in one way or another with materials with higher C/P ratios 99 and C/N ratios. In all treatments except the use of green waste compost in chicken houses, the chicken 100 manure was mixed at the onset of the experiment. By mixing the manure with more stable materials, we 101 aimed at reducing N leaching losses and gaseous losses, and producing a value-added organic fertilizer, i.e., 102 a product with optimal properties for the end user. 103 COMPOST TRIAL 1 104 In the first compost trial (Table 2), three alternative feedstock mixtures were compared for composting with 105 fresh chicken manure. The mixture of each of the three treatments consisted of chicken manure, wheat straw 106 and fresh grass clippings. These feedstock materials were completed with a mixture of grass hay and green 107 waste compost for compost A, tree bark for compost B and grass hay for compost C (Table 2). Feedstock 108 mixtures had a C/N content of 30/1, which is generally considered an ideal starting ratio for composting. The 109 mixtures were composted in open air on a site with concrete floor at the experimental farm of ILVO in 110 Merelbeke, in a windrow system with a length of 20m per compost type. The individual feedstock materials 111 used in the composting process (Table 3) and the feedstock mixtures were sampled at the start in four 4 112 replicates (each based on 10 subsamples) and samples were stored in the refrigerator at 4°C. Some feedstock 113 mixtures contain very dry and light materials such as straw and hay (Table 3, Table 4). This is the 114 explanation for the clear differences in composition on DM% base (Table 1) or on vol% base (Table 2). 115 On September 22nd 2010, the three compost piles were set up by arranging the feedstock materials in a 116 windrow with the least dense material (wheat straw and grass hay) below and the most dense material 117 (chicken manure) on top, so as to obtain an ideal, homogeneous mixture after turning with a Tractor-pulled 118 Sandberger ST300 windrow compost turner. Temperature and CO2 levels in the composts were monitored to 119 detect the need for compost turning. The composts were mechanically mixed when too high temperatures (> 120 65°C) or CO2 levels (> 16 vol% CO2) were measured. When the feedstock mixture became too dry water 121 was added to the compost with a drip irrigation system of the “Uniram” type, at an hourly rate of 8 litre 122 water per meter windrow. The windrows were covered with semipermeable fabrics to avoid too high water 123 contents. The need for turning the compost was highest shortly after starting the composting, with 124 temperature peaks over 65°C (Fig. 1). Especially mixture B was highly reactive, and needed to be turned 11 125 times during the trial. Mixture A and C were turned 6 and 10 times, respectively. CO 2 levels were higher for 126 compost A and C than for compost B, especially during the first week (results not shown). Maximum values 127 were 12 to 14% CO2. Compost B needed most additional water, which was supplied during five full days. 128 Compost A and C were supplied with water during one and three days, respectively. After 10 weeks of 129 composting, compost A and C were stored in two piles as the temperature was already below 30°C. These 130 piles and the windrow for compost B were sampled on January 5th 2011, 15 weeks after the composting 131 process started. Four samples per row or pile (each based on 10 subsamples) were taken and sieved over a 20 132 mm mesh and stored in the refrigerator at 4°C. The separate feedstock materials (Table 3) and composts 133 were weighed on a weigh bridge when compost piles were set up and at time of sampling. 134 COMPOST TRIAL 2 135 In the second trial, the effect of the amount of chicken manure in the feedstock mixture was assessed, i.e. 10, 136 17 or 20 vol% (Table 2), but with the same methodology as in the first trial. The tested feedstock materials 137 were wheat straw, grass clippings, poplar bark, willow wood chips, and grass hay (Table 4). The wood chips 138 were harvested in a plot with Salix viminalis in the short rotation coppice plantation of ILVO. The 139 composting started on February 18th 2011. Due to dry weather conditions, intensive follow-up of the process 5 140 (e.g. regular moistening) was necessary. The second composting experiment was characterized by high 141 temperatures over a long period, indicating that the applied feedstock mixture served as a long-term C source 142 for the process (Fig. 2). Irrespective of the continuously high temperatures and activity, the three composts 143 were weighed, sampled and stockpiled on 15th of May 2011. 144 Besides the second compost trial, a 50:50 dry matter ratio mixture of green waste compost and fresh chicken 145 manure was stockpiled during the same period (February 18th until May 9th) and sampled after 3 and 7 146 months. Temperature increased within the stockpiled mixture of chicken manure and green waste compost, 147 but never exceeded the temperatures measured in the compost windrows (Fig. 2). At time of sampling, four 148 samples per windrow or pile (each based on 10 subsamples) were taken and sieved over a 20 mm mesh and 149 stored in the refrigerator at 4°C. 150 OTHER TREATMENTS WITH CHICKEN MANURE 151 We furthermore tested the effect of two other treatments of chicken manure on the chemical properties of the 152 end product. A fresh weight mixture of 73.5% chicken manure + 21% green waste compost + 5.5% horse 153 manure was processed for hygienisation (10 hours >70°C) at a central manure processing facility (Compofert 154 Plant Kallo (Belgium), Op de Beeck Group) with active tunnel aeration (7 days), followed by storage (closed 155 system, NH3 recirculation with NH3 stripping). The processed material was sampled directly after the active 156 tunnel aeration: four samples (each based on 10 subsamples) were taken from the pile and sieved over a 20 157 mm mesh and stored in the refrigerator at 4°C. 158 A 30 cm layer of green waste compost was used as bedding material in a chicken house with 3000 laying 159 hens during 5.5 months. The compost was applied on a surface of 26 x 3.6m, this was half of the stable area. 160 The compost bedding material was wetted regularly with an irrigation system, and homogenized with a 161 cultivator. After four months low amounts of chipped straw were added as C source at a rate of ± 200 kg FW 162 / month. The bedding material in the chicken house was sampled after 2 and 5.5 months. At each sampling 163 event, four samples were taken, each composed of 10 subsamples, sieved over a 20 mm mesh and stored in 164 the refrigerator at 4°C. Analysis methods are listed in Table 5. 165 6 166 2.2 Effect of mixing biochar in compost based on chicken manure 167 Compost E was sampled on July 3th 2012 (after 13 months of storage). the fraction < 8mm was mixed with 168 10% biochar on a fresh weight base in four replicates. The biochar (fraction < 2 mm) was provided by 169 Proininso Inc. (Málaga, Spain), for which holm oak was used as feedstock for pyrolysis at 650°C. The 170 mixtures were stored during five days at 20°C and then sampled for analysis. Analysis methods are listed in 171 Table 5. 172 173 2.3 Data processing and statistics 174 Twelve compost products were sampled in this study: three chicken manure compost products in each of 175 both compost trials, the bedding compost sampled after 2 and 5.5 months, the centrally processed chicken 176 manure, the green waste compost used in the experiment with the stockpiled compost/chicken manure 177 mixture, and the stockpiled green waste compost/chicken manure mixture sampled after 3 and 7 months. For 178 these products, the relationship between total and NH4 acetate extractable P and other compost 179 characteristics were investigated by correlation analysis of the average of the four measurements per product 180 and per sampling event. Based on the fractions determined according to Van Soest et al. [30], the 181 biodegradation 182 %cellulose)/%lignin. potential was calculated as the holocellulose/lignin ratio: (%hemicellulose + 183 184 3 RESULTS & DISCUSSION 185 3.1 186 Products were assessed for their value as soil improver and organic fertilizer. A high organic matter content 187 combined with a high C/P ratio is beneficial for the product quality. Mineral N is preferentially in nitrate 188 form, as it indicates aerobic conditions in the product. Low OUR (oxygen uptake rate) values are typical for 189 stable products [31]; a high stability in combination with a high portion NO3-N in the mineral N pool 190 indicates that no N immobilization in the soil will occur at time of field application. High EC values indicate 191 high salt contents, which may limit plant growth when compost is mixed with soil. Based on these chemical 192 characteristics, the chicken manure compost with 42.5 vol% bark in the feedstock (compost B) had the Quality as soil improver and organic fertilizer 7 193 highest quality as soil improver, i.e. the highest OM content (on DM base), lowest EC, lowest OUR and 194 highest C/N and C/P ratio (Table 6, Table 7). 195 The highest stability is found for chicken manure compost E: it has the lowest OUR value and the highest 196 NO3 concentration. Compost D has a higher OM content and a higher N/P and C/P ratio than compost E and 197 F (Table 6). These results indicate that 10 vol% of fresh chicken manure is the upper limit in small-scale on- 198 farm windrow composting above which nutrient losses become too high and the N/P ratio of the obtained 199 fertilizer becomes too low (Table 6). The stockpiled mixture was characterised by high NH4-N 200 concentrations and high OUR values after 3 months of storage, indicating the instable nature of the mixture 201 (Table 7). 202 The C/P ratio was low for the stockpiled mixture of green waste compost and chicken manure. For this 203 product, a low C/P ratio and the low OM content indicate that the mixed storage of high doses of chicken 204 manure with green waste compost is not a good way for processing chicken manure. It might be a better 205 option to mix green waste compost and chicken manure just before application in the field, as mixed storage 206 of high doses of chicken manure resulted in high mass and nutrient losses in this study. 207 After 5.5 months, the bedding material was rich in mineral N, had a favorably high C/P ratio (even higher 208 than for the composts based on chicken manure) but both the OUR and the NH4-N/NO3-N ratio indicate that 209 the product is not fully stable yet (Table 7). As fresh chicken manure is added during the whole period to the 210 bedding material, stabilization in the chicken house will be a slow process. The high C/P ratio for the 211 compost-bedded chicken manure illustrates the positive effect of the applied compost. In future research it 212 should be tested if this product can be further stabilized by composting after removal from the chicken 213 houses, as was reported by Larney et al. [5] for beef cattle feedlot manure. Storage of the bedding material 214 after removal may result in high N losses, as shown above for the storage of the green waste compost and 215 chicken manure mixture. 216 Chicken manure compost B, D, the processed chicken manure and the bedding material were characterized 217 by higher C/P ratios and higher OM contents (Table 7), making them suitable products for application in the 218 field. Due to this higher C/P ratio, these products can be applied in a higher dose than fresh chicken manure 219 without exceeding the fertilization standards [1-3]. The latter two products still had high NH4-N 220 concentrations, which may result in N losses during application. As the compost used as bedding material 8 221 initially was characterized by a C/P ratio > 100, the resulting product had the highest C/P ratio of the 222 products tested in this study (Table 7). Two of the 12 products were characterised by high NH4-N 223 concentrations, high OUR values and high NH4-N/NO3-N ratios (Table 7), indicative for the not fully mature 224 state of these products: the stockpiled mixture of poultry manure and green waste compost after 3 months 225 storage, and the centrally processed manure. The stockpiled manure was still not mature after 7 months of 226 storage, as illustrated by the OUR determination (Table 7). Feedstock selection is a means to create value- 227 added compost, as was reported previously by Tognetti et al. [21] and Leconte et al. [22]. Based on the 228 temperature progress during the processing, only the composts A to E and the centrally processed manure 229 had a sufficient degree of hygienisation. The temperatures >60°C in these products may result in faster or 230 stronger degradation of undesired substances such as veterinary drugs [17-18], reducing the risk of plant 231 uptake in case of field application of chicken manure [13-16]. 232 Chicken manure is rich in K, Ca and Mg in relation to the other feedstock materials (Table 3, Table 4). Grass 233 hay and grass clippings may also have high K concentrations (Table 3, Table 4). The lower the amount of 234 chicken manure in the feedstock mixture and the lower the mass reduction during the compost process, the 235 lower are the K, Ca and Mg concentrations in the composts. This is illustrated by the lower K, Ca and Mg 236 concentrations in compost B versus compost A and C (due to lower mass reduction), and in compost D 237 versus compost E and F (lower amount of chicken manure in the feedstock mixture) (Table 6). 238 239 3.2 Cd, Zn and Mn concentrations 240 High heavy metal concentrations may reduce the quality of the chicken manure-based products in terms of 241 applicability as soil improver or organic fertilizer. Concentrations of Cd, Zn and Mn in the compost are 242 affected both by concentrations in the feedstock mixture and by the mass reduction during composting. In the 243 first compost trial, Cd concentrations were relatively high in the poplar bark (Table 3), leading to higher 244 concentrations in compost B than for compost A and C. In the second compost trial, Cd concentrations were 245 high in the poplar bark and the wood chips (Table 4), leading to high Cd concentrations in all composts 246 (Table 6). The wood chips were harvested from a plot with Salix viminalis in the short rotation coppice 247 plantation of ILVO, and higher Cd concentrations for this species were observed previously in bark and 248 wood compared to other species [32]. Higher Cd concentrations in the compost due to the use of bark or 9 249 wood chips did not result in higher risk of Cd leaching [32]. Zn and Mn concentrations were high in the 250 chicken manure, especially in the second compost trial (Table 3, Table 4). The Cd concentrations in the 251 composts exceed the legal criterion of 2 mg Cd/ kg DM compost in compost D, E and F, while the legal 252 criterion of 400 mg Zn/ kg DM compost is exceeded for compost E and F (Table 6). Legal criteria for Mn 253 concentrations in compost do not currently exist. Increasing the amount of wood chips or bark in the 254 feedstock mixture allowed to increase the quality of the composts in terms of C/P ratio and OM (Table 7), 255 but this also resulted in higher Cd and Zn concentrations (Table 6), thus reducing the quality in terms of 256 heavy metal concentrations. 257 258 3.3 Mass reduction, biodegradation potential and product stability 259 The feedstock mixture of compost B had a lower biodegradation potential, which is reflected in a lower mass 260 reduction than for the other two composts (Table 8). After composting, a lower biodegradation potential was 261 measured for compost B than for compost A and C (Table 8). 262 The mass reduction for the three composts of trial 2 was clearly higher than for those of trial 1, while a low 263 mass reduction was observed for the stockpiled manure (Table 8). The second composting experiment was 264 characterized by high temperatures over a long period (Fig. 2), indicating that the applied feedstock mixture 265 served as a long-term C source for the process. 266 The feedstock mixtures of the three windrows in the second composting experiment and the feedstock 267 mixture for the stockpile experiment had a comparable biodegradation potential (Table 8). The 268 biodegradation potential for the feedstock mixtures in the second composting experiment were clearly lower 269 than for feedstock mixture of compost A and C. This indicates that the biodegradability of chicken manure 270 and grass clippings were similar. After three months of storage, the stockpiled mixture of green waste 271 compost and chicken manure had a higher biodegradation potential than the composts based on chicken 272 manure (Table 8), and after 7 months the biodegradation potential was still higher than for chicken manure 273 compost B, D, E and F (Table 8). 274 The biodegradation potential was found to be a useful indicator for comparing feedstock mixtures and end 275 products. Within compost trial 1, mass reduction during composting was related to biodegradation potential 276 of the feedstock mixture (Table 8). Blanco & Almendros [27] reported a clear decrease in holocellulose 10 277 content and an increase in the lignin content during composting of urea-amended wheat straw with 5% dry 278 weight horse manure. During this process, the holocellulose/lignin ratio decreased from 5.0 to 1.6 [27]. We 279 found a similar decrease in our compost trials (Table 8). A good positive correlation was found between 280 OUR (Table 7) and the biodegradation potential (Table 8) for the samples of the two compost trials and the 281 green waste compost and the end product of the storage trial (R2 = 0.76, n = 8, p < 0.01). Our results confirm 282 that the biodegradation potential is a useful indicator in monitoring decomposition processes during 283 composting and storage as reported previously [23-28]. 284 285 3.4 Total and available P 286 Chicken manure was the main source of P in compost trial 1 and 2. For compost trial 1, chicken manure 287 accounted for 72, 79 and 75% of the P in the feedstock mixture for compost A, B en C, respectively. In 288 compost trial 2, 83, 90 and 92% of the P originated from the manure for compost D, E and F, respectively. 289 The amount of P supplied by chicken manure in the stockpiled mixture of chicken manure and green waste 290 compost was 86% of the total amount of P. Total P concentrations were higher in the chicken manure 291 composts than in the initial feedstock mixtures (Fig. 3) due to the mass reduction during composting [12]. 292 0.25M NaOH-extractable P concentrations were higher in the chicken manure composts than in the initial 293 feedstock mixtures (Fig. 3), but the 0.25M NaOH-extractable P concentrations were relatively lower for the 294 chicken manure composts than for the feedstock mixtures (Fig. 3), pointing at P stabilisation during 295 composting, as was observed previously by Felton et al. [12] based on a decrease in water-soluble P during 296 the process. 297 NH4-acetate, CaCl2/DTPA and 0.25M NaOH-extractable P concentrations were lower for compost B than for 298 the other two chicken manure composts (Fig. 3). The lower P availability is related to the lower P content 299 due to the lower mass reduction for compost B, as illustrated by the lower biodegradation potential for 300 compost B than for compost A and C (Table 8). 301 NH4-acetate and CaCl2/DTPA -extractable P concentrations were lower in the composts D, E and F than in 302 the stockpiled mixture of chicken manure and green waste compost (Fig. 3), pointing at a stabilisation of P in 303 the composting process. With exception of the samples of the stockpiled mixture with poultry manure, a 304 positive relationship between total and NH4-Acetate extractable P was observed (Fig. 4). For the stockpiled 11 305 chicken manure after three months of storage and the centrally processed manure, both the high OUR and the 306 high NH4-N/NO3-N ratio point at an incomplete composting and partly anaerobic circumstances (Table 5). In 307 partly anaerobic conditions NO3-N can be transformed to NH4-N due to redox reactions. After 7 months of 308 storage, the OUR value was lower, indicating a higher stability of the mixture, but NO3-N concentrations 309 were still small, especially in comparison with the high NH4-N concentrations in the mixtures (Table 7). 310 311 Inorganic P was found to be the most important form of P in a range of composts and other biosolids [33-34]. 312 Inorganic P can be both apatite inorganic P (form associated with Ca) and non-apatite inorganic P (forms 313 associated with oxides and hydroxides of Al, Fe and Mn). For the feedstock materials used to produce the 12 314 compost products, no clear relationship between total Ca and P concentration was observed. Regarding the 315 Ca/P ratio in the feedstock materials, three groups could be distinguished: tree bark with an average Ca/P 316 ratio of 25.6 and an average content of 26.0 g Ca/kg DM, poultry manure with an average Ca/P ratio of 4.2 317 and an average content of 82.0g Ca/kg DM, and the other feedstock materials with an average Ca/P ratio of 318 2.8 and average content of 4.9g Ca/kg DM. In contrast to the feedstock materials, a clear positive 319 relationship between total Ca and P was detected in the compost products, with exception of the centrally 320 processed manure. For the other 11 products, a positive correlation (R2 = 0.92, p < 0.001) between both 321 parameters was found. The pHH2O of the 12 products ranged between 7.68 (green waste compost used in the 322 storage trial) and 8.75. We also observed a strong positive correlation (R2 = 0.81 (p < 0.001, n=12) and 0.96 323 (p < 0.001, n=11) with and without the centrally processed manure, respectively) between NH4-Acetate 324 extractable P and the NH4-Acetate extractable Ca (Fig. 4). These results indicate that P binding and 325 availability in the products after processing is related to Ca, and that apatite P is the dominant P form in the 326 studied products. 327 Although Ca concentrations in the NH4-Acetate extract were 100x higher than Fe and Mn concentrations 328 (Fig. 4), Mn and Fe can give an indication on the effect of anaerobic conditions on P availability. In general, 329 we found a clear positive relationship between NH4-Acetate extractable P and the NH4-Acetate extractable 330 Fe or Mn (Fig. 4), but the unstable products (centrally processed manure and stockpiled manure/compost 331 mixture) deviated from this linear relationship. The availability of Mn and Fe is known to increase in 332 anaerobic conditions [35], and these products also had higher OUR and a higher NH4-N/NO3-N ratio, as 12 333 discussed above. Availability of Mn and Fe increases when oxygen levels decrease due to decomposition 334 activity, and these changes affect the P availability in the products. 335 P availability in the compost will change when compost is applied to the soil. Gagnon et al. [33] reported that 336 compost application resulted in lower labile P but comparable total inorganic P than when pure KH2PO4 was 337 added to the soil. Composting of poultry litter mixed with hardwood chips or pine sawdust did not change P 338 availability in soil in comparison with fresh poultry litter [1]. 339 3.5 340 As the applied biochar had a higher C/P ratio than the chicken manure compost (Table 9), blending the 341 compost with biochar resulted in a product with a higher C/P ratio, a higher OM content and a lower P 342 content (Table 7). The main effect was a more than proportional decrease in easily available P in the biochar- 343 blended compost, both as water extractable and CaCl2/DTPA extractable P (Table 9). 344 P in the biochar-blended compost can be bound by Ca, or by Fe, Al and Mn. Total Ca content in the biochar 345 (65g/kg DM) is clearly higher than the total Al (<0.1g/kg DM), Fe (0.3g/kg DM) and Mn (0.4g/kg DM) 346 content. As pHH20 and NH4-acetate extractable Ca are increasing by biochar amendment while NH4-acetate 347 extractable Fe and Mn are decreasing (Table 9), this indicates that the easily available P in the chicken 348 manure compost is bound by Ca when blending the compost with biochar. 349 Addition of biochar is an option to increase C/P ratio and OM content while reducing the leaching risk of P 350 from compost: amending biochar resulted in lower easily available P concentrations, thus reducing the water- 351 extractable P prone to leaching [11]. As biochar is mainly organic matter, blending compost with biochar 352 may not result in long-term fixation of P in the compost-amended soil. Application of other immobilizing 353 agents (e.g. gypsum [9], Al- and Fe-rich materials [10]) may lead to irreversible or long-term P 354 immobilization. More research on effects of biochar type and/or dose is necessary to further elucidate this 355 potential application. The effect of biochar on P availability in compost might also be affected by the 356 moment of biochar application, i.e. at the start of the composting process [6, 7] or in the mature compost. Effect of mixing biochar in compost based on chicken manure 357 13 358 4 CONCLUSIONS 359 Several valorisation strategies for chicken manure were tested on their value as soil improver. Total P 360 concentration in the chicken manure compost was found to be the result of P in the feedstock mixture and 361 mass reduction during composting, which is driven by the biodegradation potential of the feedstock. The 362 latter is found to be a useful method for screening the value of feedstock mixtures for composting. Results 363 point at a stabilisation of P during the composting process. In order to reduce nutrient losses and achieve a 364 fertilizer with a sufficiently high C/P ratio, we conclude that for small-scale on-farm windrow composting of 365 chicken manure a sufficient amount of wood chips or bark should be combined with a maximum of 10 vol% 366 of fresh chicken manure. Changing the feedstock composition in the composting process allowed to increase 367 the value of chicken manure as soil improver. 368 The results indicate that apatite P is the dominant P form in the studied products and that P binding and 369 availability after processing is related to Ca. P availability was affected by stability and redox circumstances 370 in the chicken manure products. P availability increased in case of anoxic conditions in the product. The 371 mixed storage of high doses of chicken manure and green waste compost seemed not to be efficient. The end 372 products of applying green waste compost as bedding material and of the central processed manure had a 373 high C/P ratio and a high OM content, making them suitable as soil improver and organic fertilizer. The 374 results indicate a high potential for using green waste compost as bedding material in chicken houses. Wood- 375 based biochar was found to be a potential solution to increase the C/P ratio and reduce the amount of easily 376 available P in chicken manure compost. This should be further tested. 377 378 5 ACKNOWLEDGEMENTS 379 We wish to thank the lab and field technicians of ILVO for their help during the composting trials, and for 380 executing the chemical analyses. This research was partly financially supported by the Flemish Government 381 - Sustainable Agricultural Development Division (ADLO), and partly executed within the FERTIPLUS 382 project. The project FERTIPLUS (Grant Agreement N° 289853) is co-funded by the European Commission, 383 Directorate General for Research & Innovation, within the 7th Framework Programme of RTD, Theme 2 – 384 Biotechnologies, Agriculture & Food. The views and opinions expressed in this paper are purely those of the 14 385 writers and may not in any circumstances be regarded as stating an official position of the European 386 Commission. We are grateful to Jos Arits and the Op de Beeck group for their logistic support, and to 387 Antonio Quero Alba from PROININSO S.A. for providing the biochar based on holm oak. 388 15 389 REFERENCES 390 [1] Preusch, P.L., Adler, P.R., Sikora, L.J., Tworkoski, T.J.: Nitrogen and phosphorus availability in 391 composted and uncomposted poultry litter. J. Environ. Qual. 31, 2051-2057 (2002) 392 [2] Toor, G. S., Haggard, B. E.: Phosphorus and trace metal dynamics in soils amended with poultry litter 393 and granulates. Soil Use Manage. 25, 409–418 (2009) 394 [3] Leconte, M.C., Mazzarino, M.J., Satti, P., Crego, M.P.: Nitrogen and phosphorus release from poultry 395 manure composts: the role of carbonaceous bulking agents and compost particle sizes. Biol. Fert. Soils 47, 396 897-906 (2011) 397 [4] Ranatunga, T.D., Seshadri, S.R., Taylor, R.W.: Phosphorus distribution in soil aggregate size fractions in 398 a poultry litter applied soil and potential environmental impacts. Geoderma 192, 446-452 (2013) 399 [5] Larney, F.J., Olson, A.F., Miller, J.J., DeMaere, P.R., Zvomuya, F., McAllister, T.A.: Physical and 400 chemical changes during composting of wood chip-bedded and straw-bedded beef cattle feedlot manure. 401 J.Environ. Qual. 37, 725-735 (2008) 402 [6] Dias, B.O., Silva, C.A., Higashikawa, F.S., Roig, A., Sanchez-Monedero, M.A.: Use of biochar as 403 bulking agent for the composting of poultry manure: Effect on organic matter degradation and humification. 404 Bioresour. Technol. 101, 1239-1246 (2010) 405 [7] Jindo, K., Suto, K., Matsumoto, K., Garcia, C., Sonoki, T., Sanchez-Monedero, M.A.: Chemical and 406 biochemical characterisation of biochar-blended composts prepared from poultry manure. Bioresour. 407 Technol. 110, 396-404 (2012) 408 [8] Hass, A., Gonzalez, J.M., Lima, I.M., Godwin, H.W., Halvorson, J.J., Boyer, D.G.: Chicken Manure 409 Biochar as Liming and Nutrient Source for Acid Appalachian Soil. J. Environ. Qual. 41, 1096-1106 (2012) 410 [9] Mishra, A., Cabrera, M. L., Rema, J. A.: Phosphorus fractions in poultry litter as affected by flue-gas 411 desulphurization gypsum and litter stacking. Soil Use Manage. 28, 27-34 (2012) 412 [10] Brennan, R.B., Fenton, O., Rodgers, M., Healy, M.G.: Evaluation of chemical amendments to control 413 phosphorus losses from dairy slurry. Soil Use Manage. 27, 238–246 (2011) 414 [11] Bustamante, M.A., Alburquerque, J.A., Restrepo, A.P., de la Fuente, C., Paredes, C., Moral, R;, Bernal, 415 M.P.: Co-composting of the solid fraction of anaerobic digestates, to obtain added-value materials for use in 416 agriculture. Biomass Bioenerg. 43, 26-35 (2012) 16 417 [12] Felton G. K., Carr, L.E., Prigge, C.E., Bouwkamp J.C.: Nitrogen and phosphorous dynamics in 418 cocomposted yard trimmings and broiler litter. Compost Sci. Util. 12, 349-355 (2004) 419 [13] Boxall, A.B., Johnson, P., Smith, E.J., Sinclair, C.J., Stutt, E., Levy, L.S.: Uptake of veterinary 420 medicines from soils into plants. J. Agric. Food Chem. 54, 2288−2297 (2006) 421 [14] Jones-Lepp, T.L., Sanchez, C.A., Moy, T., Kazemi, R.: Method development and application to 422 determine potential plant uptake of antibiotics and other drugs in irrigated crop production systems. J. Agric. 423 Food Chem. 2010, 58, 11568−11573 (2010) 424 [15] Dolliver, H., Kumar, K., Gupta, S.: Sulfamethazine uptake by plants from manure-amended soil. J. 425 Environ. Qual. 36, 1224−1230 (2007) 426 [16] Broekaert, N., Daeseleire, E., Delezie, E., B. Vandecasteele, B., T. De Beer, T., Van Poucke, C.: Can 427 the Use of Coccidiostats in Poultry Breeding Lead to Residues in Vegetables? An Experimental Study. J. 428 Agric. Food Chem. DOI: 10.1021/jf304149d 429 [17] Dolliver, H., Gupta, S., Noll, S.: Antibiotic degradation during manure composting. J. Environ. Qual. 430 37, 1245-1253 (2008) 431 [18] Ramaswamy, J., Prasher, S.O., Patel, R.M., Hussain, S.A., Barrington, S.F.: The effect of composting 432 on the degradation of a veterinary pharmaceutical. Bioresour. Technol. 101, 2294-2299 (2010) 433 [19] Steel, H., Vandecasteele, B., Willekens, K., Sabbe, K., Moens, T., Bert, W. Nematode communities and 434 macronutrients in composts and compost-amended soils as affected by feedstock composition. Appl. Soil 435 Ecol. 61, 100-112 (2012) 436 [20] Frederickson, J., Howell, G., Hobson, A.M.: Effect of pre-composting and vermicomposting on 437 compost characteristics. Eur. J. Soil Biol. 43, S320-S326 (2007) 438 [21] Tognetti, C., Mazzarino, M.J., Laos, F.: Compost of municipal organic waste: Effects of different 439 management practices on degradability and nutrient release capacity. Soil Biol. Biochem. 40, 2290-2296 440 (2008) 441 [22] Leconte, M.C., Mazzarino, M.J., Satti, P., Iglesias, M.C., Laos, F.: Co-composting rice hulls and/or 442 sawdust with poultry manure in NE Argentina. Waste Manage., 29, 2446-2453 (2009) 443 [23] Gabrielle, B., Da-Silveira, J., Houot, S., Francou, C.: Simulating urban waste compost effects on carbon 444 and nitrogen dynamics using a biochemical index. J. Environ. Qual. 33, 2333-2342 (2004) 17 445 [24] Francou, C., Linères, M., Derenne, S., Villio-Poitrenaud, M.L., Houot, S.: Influence of green waste, 446 biowaste and paper-cardboard initial ratios on organic matter transformations during composting. Bioresour. 447 Technol. 99, 8926-8934 (2008) 448 [25] Lashermes, G., Barriuso, E., Le Villio-Poitrenaud, M., Houot, S. Composting in small laboratory pilots: 449 Performance and reproducibility. Waste Manage 32, 271-277 (2012). 450 [26] Paradelo, R., Moldes, A.B., Barral, M.T.: Evolution of organic matter during the mesophilic composting 451 of lignocellulosic winery wastes. J. Environ. Manage. 116, 18-26 (2013). 452 [27] Blanco, M.-J., Almendros, G.: Chemical transformation, phytotoxicity and nutrient availability in 453 progressive composting stages of wheat straw. Plant Soil 196, 15-25 (1997) 454 [28] Chalhoub, M., Garnier, P., Coquet, Y., Mary, B., Lafolie, F., Houot, S.: Increased nitrogen availability 455 in soil after repeated compost applications: Use of the PASTIS model to separate short and long-term effects. 456 Soil Biol. Biochem. 65, 144-157 (2013) 457 [29] Borchard, N., Prost, K., Kautz, T., Moeller, A., Siemens, J.: Sorption of copper (II) and sulphate to 458 different biochars before and after composting with farmyard manure. Eur. J. Soil Sci. 63, 399- 409 (2012) 459 [30] Van Soest, P.J., Robertson, J.B., Lewis, B.A.: Methods for Dietary Fiber, Neutral Detergent Fiber, and 460 Nonstarch Polysaccharides in Relation to Animal Nutrition. J. Dairy Sci. 74, 3583-3597 (1991) 461 [31] Grigatti, M., Dios Perez, M., Blok, W., Ciavatta, C., Veeken, A.: A standardized method for the 462 determination of the intrinsic carbon and nitrogen mineralization capacity of natural organic matter 463 sources. Soil Biol. Biochem., 39, 1493-1503 (2007) 464 [32] Vandecasteele, B., Willekens, K., Zwertvaegher, A., Degrande, L., Tack, F.M.G., Du Laing, G.: Effect 465 of composting on the Cd, Zn and Mn content and fractionation in feedstock mixtures with wood chips from a 466 short-rotation coppice and bark. Waste Manage., 10.1016/j.wasman.2013.06.014. 467 [33] Gagnon, B., Demers, I., Ziadi, N., Chantigny, M. H., Parent, L.-E., Forge, T. A., Larney, F. J., Buckley, 468 K. E.: Forms of phosphorus in composts and in compost-amended soils following incubation. Can. J. Soil 469 Sci. 92, 711-721 (2012) 470 [34] Garcia-Albacete, M., Martin, A., Cartagena, M.C.: Fractionation of phosphorus biowastes: 471 Characterisation and environmental risk. Waste Manage. 32, 1061-1068 (2012) 18 472 [35] Du Laing, G., Bontinck, A., Samson, R., Vandecasteele, B., Vanthuyne, D.R.J., Meers, E., Lesage, E., 473 Tack, F.M.G., Verloo, M.G.: Effect of decomposing litter on the mobility and availability of metals in the 474 soil of a recently created floodplain. Geoderma 147, 34-46 (2008) 475 19 476 477 478 479 FIGURE 1 Temperature evolution during composting for the three composts (A: circles, B: squares, C: triangles) in compost trial 1. 480 20 481 482 483 484 FIGURE 2 Temperature evolution during composting for the three composts (D: circles, E: squares, F: triangles) in compost trial 2, and the stockpiled mixture of compost and chicken manure (S: crosses). 485 21 486 487 FIGURE 3 P concentrations in 4 extracts for feedstock mixtures (FM) and composts of the three composts (A-B-C) in 488 compost trial 1, the three composts (D-E-F) in trial 2, and the stockpiled mixture of compost and chicken 489 manure after 3 months of storage (S). Data are average values of 4 separately analysed samples. 490 22 491 492 493 FIGURE 4 Relationship between NH4-Acetate extractable P concentrations in 12 products based on chicken manure, 494 and total P concentrations or NH4-Acetate extractable Fe and Mn concentrations. S3 and S7: stockpiled 495 mixture of compost and chicken manure sampled after 3 and 7 months, respectively, CP: centrally 496 processed chicken manure, AC: acetate. Each point is the average of 4 analysed samples per product. 497 23 498 499 TABLE 1 Details on the experimental set-up of trials on chicken manure processing: feedstock materials, samplings, 502 Treatment Initial material Mass reduction and degree of biodegradation compost). % Chicken manure in initial mixture (DM base) 501 End product sampled after # days amount of chicken manure in the initial mixture and analyses (DM: dry matter, GW compost: green waste Intermediate sampling after # days 500 chicken manure compost A Chicken manure, wheat straw, grass clippings, grass hay, GW compost no 97 19 x chicken manure compost B Chicken manure, wheat straw, grass clippings, poplar bark no 97 22 x chicken manure compost C Chicken manure, wheat straw, grass clippings, grass hay no 97 28 x chicken manure compost D Chicken manure, wheat straw, grass clippings, grass hay, poplar bark, wood chips no 81 30 x chicken manure compost E Chicken manure, wheat straw, grass clippings, grass hay, poplar bark, wood chips no 81 42 x chicken manure compost F Chicken manure, wheat straw, grass clippings, grass hay, poplar bark, wood chips no 81 47 x x Storage Chicken manure, GW compost 80 222 47 Central processing green waste compost, horse manure, chicken manure no 7 79 Bedding material green waste compost 72 174 0 503 504 24 505 506 507 TABLE 2 Feedstock composition (vol%) of the three composts (A-B-C) in trial 1 and the three composts (D-E-F) in trial 2 Compost trial Compost 1 A B C 2 D E F Chicken manure 10% 7.5% 7.5% 10% 17% 20% wheat straw 30% 30% 30% 15% 12% 13% grass clippings 15% 20% 20% 21% 17% 13% poplar bark 42.5% 27% 27% 27% wood chips 18% 18% 18% grass hay compost 25% 42.5% 9% 9% 9% 20% - 508 509 25 510 511 TABLE 3 Chemical properties of the feedstock materials used in compost trial 1 (OM: organic matter, DM: dry matter, Ntot: total nitrogen). Values are averages ± standard deviation of 4 samples per feedstock 512 Variable grass hay C grass hay A Chicken grass manure clippings poplar bark OM (%/DM) 95.1 ± 0.3 92.4 ± 0.5 91.2 ± 2.7 90.3 ± 0.5 42.8 ± 1.9 88.2 ± 0.6 DM (%) 36.8 ± 3.4 63.5 ± 5.8 16.8 ± 3.3 46.5 ± 1.9 62.7 ± 0.6 8.9 ± 0.7 73 ± 0 27 ± 0 55 ± 0 205 ± 2 533 ± 20 80 ± 0 Cd (mg/kg DM) 0.15 ± 0.02 0.11 ± 0.02 0.17 ± 0.05 1.72 ± 0.18 0.31 ± 0.01 0.12 ± 0.01 Zn (mg/kg DM) 26 ± 9 40 ± 2 64 ± 10 222 ± 8 244 ± 209 70 ± 29 Mn (mg/kg DM) 15 ± 1 117 ± 12 125 ± 54 62 ± 9 225 ± 135 77 ± 2 C/N (-) 117 ± 7 51 ± 3 34 ± 11 58 ± 8 8.25 ± 0.75 24 ± 1 N/P (-) 7.61 ± 0.7 5.13 ± 0.84 5.93 ± 0.4 7.07 ± 0.65 1.94 ± 0.56 4.94 ± 0.08 C/P (-) 901 ± 128 264 ± 31 203 ± 67 410 ± 59 15.87 ± 3.28 120 ± 4 Ntot (g/kg DM) 4.52 ± 0.26 10.00 ± 0.60 16.02 ± 4.90 8.80 ± 1.07 29.03 ± 3.52 20.28 ± 0.53 P (g/kg DM) 0.60 ± 0.09 1.98 ± 0.22 2.70 ± 0.74 1.25 ± 0.17 15.51 ± 2.59 4.10 ± 0.12 K (g/kg DM) 2.6 ± 0.1 17.6 ± 1.7 11.9 ± 3.5 6.6 ± 0.3 21.7 ± 0.4 35.4 ± 0.8 Ca (g/kg DM) 2.9 ± 0.3 4 ± 0.3 6.5 ± 1.2 26.6 ± 1.4 73.9 ± 3.4 4.8 ± 0.3 Mg (g/kg DM) 0.70 ± 0.01 1.17 ± 0.11 1.50 ± 0.28 1.74 ± 0.23 4.86 ± 0.03 1.71 ± 0.05 bulk density (g/l) 513 wheat straw 514 515 26 516 517 TABLE 4 Chemical properties of the feedstock materials used in compost trial 2 and the stockpiled mixture of 518 chicken manure and green waste compost (OM: organic matter, DM: dry matter, Ntot: total nitrogen, GW: 519 green waste). Values are averages ± standard deviation of 4 samples per feedstock Variable wheat straw grass hay poplar bark wood chips OM (%/DM) 93.9 ± 0.7 85.9 ± 3.3 87.5 ± 0.7 96.7 ± 1.8 59.1 ± 0.6 84.8 ± 3.4 22.83 ± 4.32 DM (%) 15.7 ± 1.5 25.4 ± 4.0 32.3 ± 1.5 46.9 ± 5.1 49.9 ± 1.2 15.2 ± 2.3 56.0 ± 1.6 99 ± 2 147 ± 14 335 ± 18 291 ± 12 551 ± 6 133 ± 11 624 ± 11 Cd (mg/kg DM) 0.13 ± 0.01 0.18 ± 0.04 3.91 ± 0.56 3.01 ± 0.27 0.30 ± 0.01 0.27 ± 0.04 0.58 ± 0.05 Zn (mg/kg DM) 27 ± 6 116 ± 36 190 ± 8 150 ± 10 589 ± 21 73 ± 15 146 ± 13 Mn (mg/kg DM) 24 ± 3 174 ± 18 75 ± 32 59 ± 6 469 ± 9 162 ± 56 261 ± 68 C/N (-) 82 ± 5 24 ± 4 64 ± 4 85 ± 7 9.4 ± 0.2 17 ± 1 12.88 ± 2.01 N/P (-) 9.86 ± 1.00 5.49 ± 0.46 8.94 ± 1.09 6.75 ± 0.70 2.48 ± 0.02 7.64 ± 0.43 4.76 ± 0.57 C/P (-) 818 ± 120 136 ± 28 575 ± 60 575 ± 19 23.5 ± 0.8 132 ± 4 60.88 ± 4.87 Ntot (g/kg DM) 6.38 ± 0.33 19.80 ± 2.22 7.63 ± 0.53 6.35 ± 0.61 34.88 ± 0.75 25.03 ± 3.42 9.88 ± 0.95 P (g/kg DM) 0.65 ± 0.08 3.64 ± 0.66 0.86 ± 0.08 0.94 ± 0.02 14.07 ± 0.42 3.3 ± 0.57 2.09 ± 0.22 K (g/kg DM) 2.8 ± 0.6 26.8 ± 7.5 7.0 ± 0.8 2.8 ± 0.1 24.6 ± 0.9 18.6 ± 7.5 4.0 ± 1.0 Ca (g/kg DM) 3.1 ± 0.1 10.2 ± 2.2 25.4 ± 1.8 7.5 ± 0.2 86.6 ± 4.8 4.6 ± 0.6 17.1 ± 1.5 Mg (g/kg DM) 0.87 ± 0.08 2.36 ± 0.53 1.46 ± 0.08 0.58 ± 0.01 7.31 ± 0.43 1.85 ± 0.33 3.1 ± 0.46 bulk density (g/l) 520 Chicken manure grass clippings GW compost 27 521 522 TABLE 5 Analysed parameters, methods and references. Parameter Method and reference Sample preparation EN 13040 Dry matter (DM) content EN 13040 Laboratory compacted bulk density EN 13040 pH-H2O 1:5 (v/v) soil to water suspension, EN 13037 Electrical conductivity (EC) 1:5 (v/v) soil to water suspension, EN 13038 Organic matter (OM) content EN 13039 Water extractable NO3-N 1:5 v/v extraction in water (EN 13652), Dionex DX-600 IC ion chromatograph Water extractable NH4-N 1:5 v/v extraction in water (EN 13652), Foss Fiastar 5000 continuous flow analyser NH4 Acetate extractable Ca, K, Mg, P, Mn, Fe 1:5 v/v extraction in NH4 acetate buffered at pH 4.65, measured by Varian VISTA-PRO ICP-OES CaCl 2/DTPA-extractable P 1:5 (v/v) 0.01M CaCl2 + 0.002M DTPA extract (EN 13651), measured by Varian VISTA-PRO ICP-OES Total N Dumas Method (EN 13654-2), Thermo Flash 4000 shaking 20g fresh compost (<1cm) in 200ml buffered nutrient solution during 5 days in a closed Oxitop Oxygen uptake rate (OUR) respirometer (Grigatti et al. [31]) 523 Total concentrations for Cd, Zn, Mn, K, Mg, Ca and P ashing, digestion with HNO3 (p.a. 65%), measured by Varian VISTA-PRO ICP-OES 0.25 M NaOH and 0.05 M Na2-EDTA extractable P 1:20 (w:v) in 0.25 M NaOH/0.05 M Na2-EDTA, 16h shaking at 22°C, measured by Varian VISTA-PRO ICP-OES Neutral detergent fibre (NDF) content Ankom220 Fiber Analyzer extraction unit, Van Soest et al. [30] Acid detergent fibre (ADF) content Ankom220 Fiber Analyzer extraction unit, Van Soest et al. [30] Acid detergent lignin (ADL) content Ankom220 Fiber Analyzer extraction unit, Van Soest et al. [30] 28 524 525 TABLE 6 Chemical properties of the produced composts and the stockpiled mixture. Values are averages ± 526 standard deviation of 4 samples per product. Compost trial 1: compost A, B and C; compost trial 2: 527 compost D, E and F, S: stockpiled mixture of chicken manure and green waste compost after 3 (‘3m’) and 528 7 (‘7m’) months Variable A B C D E F S (3m) S (7m) pH-H2 O (-) 8.56 ± 0.14 8.59 ± 0.06 8.31 ± 0.05 8.7 ± 0.1 8.7 ± 0.1 8.6 ± 0.1 8.7 ± 0.1 8.3 ± 0.3 EC (μS/cm) 3385 ± 323 945 ± 109 2453 ± 217 801 ± 163 1404 ± 73 804 ± 151 5450 ± 227 1654 ± 605 DM (%) 37.5 ± 1.5 34.5 ± 0.6 36.0 ± 1.9 37.0 ± 0.3 42.1 ± 1.1 34.3 ± 0.5 52.5 ± 0.4 50.6 ± 0.6 bulk density (g/l) 544 ± 15 568 ± 4 553 ± 11 502 ± 5 487 ± 7 642 ± 9 528 ± 4 734 ± 32 0.72 ± 0.06 1.14 ± 0.07 0.35 ± 0.08 2.92 ± 0.17 2.44 ± 0.06 2.42 ± 0.15 0.42 ± 0.03 0.42 ± 0.02 Zn (mg/kg DM) 341 ± 7 280 ± 30 303 ± 54 372 ± 16 513 ± 31 456 ± 23 367 ± 49 393 ± 31 Mn (mg/kg DM) 489 ± 47 231 ± 10 339 ± 77 340 ± 53 426 ± 32 512 ± 89 369 ± 32 426 ± 31 19.65 ± 1.23 16.38 ± 2.75 15.90 ± 1.92 19.58 ± 0.34 22.23 ± 0.70 19.53 ± 1.17 15.48 ± 1.96 15.03 ± 0.95 11.25 ± 0.8 9.61 ± 0.55 13.46 ± 1.78 12.03 ± 0.81 10.6 ± 0.71 11.72 ± 0.91 Cd (mg/kg DM) N (g/kg DM) 529 P (g/kg DM) 12.09 ± 1.26 7.55 ± 1.08 K (g/kg DM) 28.5 ± 2.3 11.8 ± 0.4 26 ± 6.2 16.7 ± 0.5 20.4 ± 0.7 14.2 ± 0.8 16.5 ± 1.5 11.7 ± 2.0 Ca (g/kg DM) 68.7 ± 1.1 51 ± 1.4 60.6 ± 9.5 52.9 ± 2.2 73.9 ± 5.0 73.7 ± 1.9 53.1 ± 5.9 52.7 ± 6.8 Mg (g/kg DM) 7.31 ± 0.29 4.8 ± 0.14 6.05 ± 0.23 4.94 ± 0.16 6.28 ± 0.36 5.83 ± 0.27 4.99 ± 0.29 5.22 ± 1.44 530 531 29 532 533 TABLE 7 Chemical properties of the products based on chicken manure at different stages during processing (S: 534 start, I: intermediate, E: end). Values are averages of 4 samples per compost (OM: organic matter, OUR: 535 oxygen uptake rate, “-“: not assessed). 536 Trial Treatment Step NO3-N NH4-N (mg/l compost) Compost trial 1 Compost trial 2 storage trial Central processing Bedding material 537 OM OUR (%/DM) (mmol/kg OM/h) C/N N/P C/P (-) (-) (-) Chicken manure S - - 59 - 9.4 2.5 23.5 A E 114 46 37 7 10.4 1.6 17.2 B E 41 <5 51 4 17.7 2.2 38.4 C E 57 15 31 11 10.9 1.4 15.4 D E 18 <5 65 7 18.5 2.0 38.0 E E 134 <5 59 5 14.8 1.7 24.9 F E 43 <5 56 6 16.0 1.6 26.1 Green waste compost S 113 <5 23 3 12.9 4.8 60.9 3 months storage I 17 1092 28 54 10.2 1.5 14.9 7 months storage E <5 210 23 14 8.6 1.3 11.0 Compost S <5 <5 55 - 20.0 6.6 131.0 Chicken manure S - - 41 - 8.6 2.0 17.6 processed manure E <5 1160 59 60 9.3 2.9 27.1 Compost start S <5 <5 - 55 20.0 6.6 131.0 grid manure S - - 58 - 9.7 2.0 19.5 After 2 months I 34 312 53 7 14.0 4.0 57.0 After 5.5 months E 546 301 62 12 14.0 4.0 55.0 538 539 30 540 TABLE 8 Biodegradation potential (Values are averages ± standard deviation of 4 samples) and dry matter (DM) 541 mass reduction for feedstock mixtures and composts of the three composts (A-B-C) in trial 1, the three 542 composts (D-E-F) in trial 2 and the stockpiled mixture of compost and chicken manure (S). The green 543 waste compost used in the stockpiled mixture was analysed as well (GW compost: green waste compost, 544 NA: not assessed) 545 Compost trial 1 2 546 Treatment Biodegradation potential % DM Mass reduction Start End A 5.7 ± 0.2 1.5 ± 0.1 24% B 2.8 ± 0.4 1.2 ± 0.1 9% C 7.3 ± 0.3 1.8 ± 0.2 21% D 3.1 ± 0.1 1.3 ± 0.1 40% E 3.1 ± 0.1 1.3 ± 0.1 36% F 3.2 ± 0.1 1.3 ± 0.1 47% GW compost (S) 1.0 ± 0.1 S (3 months) 3.3 ± 0.6 2.4 ± 0.2 10% S (7 months) 2.4 ± 0.2 1.6 ± 0.2 NA 547 31 548 549 TABLE 9 Effect on compost characteristics of mixing biochar at a 10% fresh weight ratio in the 0-8 mm fraction of 550 mature compost based on chicken manure (Values are averages ± standard deviation of 4 samples) and 551 properties of the applied biochar. Extractant is indicated in brackets. Values in bold are significantly 552 different (p<0.01) according to the two-sided t-test. 553 554 Variable Unit Biochar Compost Biochar-blended compost % change Dry Matter %/fresh 69.4 39.4 (0.3) 42.7 (0.5) +8 Org. Matter %/DM 76.7 47.0 (0.5) 50.2 (1.1) +7 total N %/DM 2.4 (0.1) 2.1 (0.1) -12 total P g/kg DM 16.1 (0.3) 15.0 (0.1) -7 pH-H20 - 8.0 (0.1) 8.4 (0.1) +6 P (CaCl 2/DTPA) mg/l fresh compost 329 (21) 225 (11) -32 P (H2O) mg/l fresh compost 37.1 (1.7) 26.3 (2.4) -29 P (NH4 Acetate) mg/l fresh compost 1736 (173) 1592 (95) -8 Ca (NH4 Acetate) mg/l fresh compost 6521 (658) 7386 (433) +13 Fe (NH4 Acetate) mg/l fresh compost 10.3 (0.3) 7.9 (0.6) -23 Mn (NH4 Acetate) mg/l fresh compost 41.4 (3.9) 41.0 (2.5) -1 NH4-N (H2O) mg/l fresh compost <5 <5 - NO3-N (H2O) mg/l fresh compost 330 (25) 296 (39) -10 2.8 32