01025 Bid Document "Indoor Air Quality (IAQ) Management Plan"

advertisement

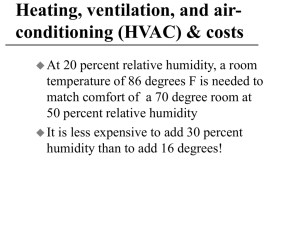

SECTION 01025 INDOOR AIR QUALITY (IAQ) MANAGEMENT PLAN PART 1 - GENERAL 1.1 SUMMARY A. Per the requirements for LEED EQ C031.1, and as specified in Section 01022- Environmental Procedures and in this section, the Contractor shall prepare and submit an IAQ Management Plan. B. The IAQ Management Plan shall highlight the five requirements of the Sheet Metal and Air Conditioning National Design/Builders Association (SMACNA), IAQ Guidelines for Occupied Buildings Under Construction, 1995, Chapter 3 and shall embody the principles and practices set forth hereinafter. C. Provide submittals as specified in Section 01022 – Environmental Procedures and in Table A of the same section. The LEED-QC Manager shall sign all submittals. D. Subcontractors and their employees shall be provided instruction and training in the IAQ Management Plan. 1.2 SOURCE CONTROL A. Protect against moisture exposure. Building materials shall be kept dry to avoid the introduction of moisture into the building interior. B. Avoid the use of moisture-damaged materials. Any porous materials that have been wetted shall be dried thoroughly before installation. Any porous materials that have been damaged, remained wet longer than 48 hours, or show signs of visible mold shall be discarded. C. Ensure that the construction process will not result in moisture intrusion. In the event of rain or groundwater gaining entry to the building interior during construction, notify the City Engineer. D. Avoid tracking pollutants into work areas. Once the framing and mechanical system installation starts, access to the building interior shall be controlled to minimize the tracking in of contaminants. Material deliveries and construction waste removal shall be routed via the most direct route to the building exterior of the building rather than through the space. Provide rough track-off grates or matting at the entryway to remove moisture and contaminants from workers shoes. Prevent the ingress of rodents and pests. No smoking inside the building. 1.3 HVAC PROTECTION A. Store HVAC equipment in a clean, dry location. Until HVAC equipment (ducting, registers, air handler components, fans, and motors) has been installed, it shall be kept covered with plastic film or in a location where it will not be exposed to moisture, dust, or other contaminants. B. Seal all HVAC inlets and outlets. Use of the HVAC system shall be avoided during construction until drywall construction is complete. Temporary ventilation may be installed to remove contaminants. All air inlets and outlets shall be sealed during construction. These include CITYWIDE PUBLIC SAFETY BOND PROGRAM RAMPART REPLACEMENT STATION INDOOR AIR QUALITY (IAQ) MANAGEMENT PLAN 01025-1 outside air inlets, grilles, diffusers, supply ducts, return ducts, ceiling plenums, VAV (variable-air volume) plenum intakes, and window ventilator or air conditioning units. Openings shall be sealed with plastic film and tape that can be removed cleanly. C. Seal HVAC components during installation. For ducting runs that require several days to install, sections shall be sealed off as they are completed. Seals shall be removed prior to continuing the ducting run. Other components of the HVAC system shall be subjected to the same requirements to protect them from contamination. D. Use temporary filtration media. If the HVAC system is to be used while construction work is being done, temporary filtration media shall be installed on all intakes. Such filtration media shall have a minimum filtration efficiency (Minimum Efficiency Reporting Value-MERV per ASHRAE 52.2) OF 8. For air intakes into parts of a building that are very sensitive to dust contamination, such as computer rooms, filtration media with a MEJRV rating of 13 or higher is required. New filtration with a MERV rating of 1.3 shall be installed after construction. E. Inspect filters regularly. When the HVAC system is being used during construction and temporary filters are installed, filters shall be inspected weekly and replaced as needed. F. Avoid contaminated air entry into enclosed parts of the building. When outdoor construction activities generate dust, combustion emissions, or other contaminants, operable windows and outside air supplies to enclosed portions of the building shall be closed. 1.4 HOUSEKEEPING A. Minimize accumulation of dust and other contaminants. Construction practices shall be used that minimize the production of dust and other contaminants from construction activities. Use integral dust-collection systems on drywall sanders, cut-off saws, and routers. Confine dustgeneration activities to areas where clean-up can be carried out easily and contaminants will not be tracked to other areas. B. Suppress Dirt. Wetting agents or sweeping compounds shall be used to deep dust from becoming airborne. C. Clean up dust. Wet clothes, damp mops, and vacuum cleaners with high-efficiency particulate (HEPA) filters shall be used to clean up dust generated by construction activities. Cleaning frequency shall be increased when dust accumulation is noted. D. Clean up spills. All spills and excess applications of solvent-containing products should be cleaned up using approved methods as soon as practicable. Water spills shall be mopped up promptly. E. Keep work area dry. The entire area shall be kept as dry as practicable by promptly repairing any leaks that allow rainwater entry and mopping up any water accumulation. Use dehumidification if necessary for prompt drying of wetted spaces. Unvented combustion (e.g., propane of diesel “salamander” space heaters) shall not be used. F. Seal containers containing volatile liquids. Containers of fuel, paints, finishes, and solvents shall be kept tightly sealed and preferably stored outside of the building when not in use. CITYWIDE PUBLIC SAFETY BOND PROGRAM RAMPART REPLACEMENT STATION INDOOR AIR QUALITY (IAQ) MANAGEMENT PLAN 01025-2 1.5 SEQUENCING AND SCHEDULING A. Schedule the installation of porous materials only after closing in building. Porous materials, such as insulation, fireproofing, and drywall shall not be installed in a building until the envelope is fully weather light. B. Provide for a minimum of two-week building flush-out period with new filtration media at 100% outside air at the end of each phase of construction and prior to occupancy. C. Install furnishing after interior finishes have cured. Furnishing shall not be installed until interior finishes (paints, stains and sealants) have been applied and have fully cured. D. Provide adequate ventilation during curing period. To aid in curing of interior finishes and other products used during construction and to remove pollutants after drywall installation is complete, provide adequate ventilation with 100% outside air, and proper filtration. In humid periods or when very high-moisture materials are present, supplementary dehumidification may be required during this curing period. END OF SECTION CITYWIDE PUBLIC SAFETY BOND PROGRAM RAMPART REPLACEMENT STATION INDOOR AIR QUALITY (IAQ) MANAGEMENT PLAN 01025-3