IAQ Regulatory Recap

advertisement

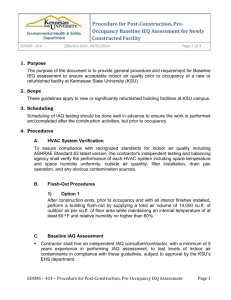

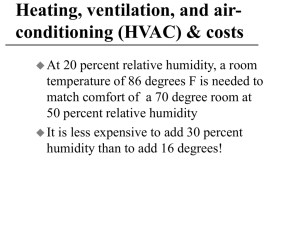

Indoor Air Quality Presented by: Mark Wilson Summit Project Management IAQ Regulatory Recap • EPA - Promulgating regulations and recommendations • OSHA - Federal and State OSHA requirements • NIOSH – Personal Protective Equipment • ADA – Bio Chemically Handicapped • STATE – Title 24 (California) • IGRA – Compliance for Public Health & Safety / OSHA • NIGC - Ensures Regulatory Compliance to above Codes and Standards • • • • • • • IBC/IMC International Building Code – International Mechanical Code State Laws, Codes and Standards BOCA Building Officials and Code Administrators State Codes Adopted or Amended from ICC / UBC IMC/UBC International Mechanical Code / Uniform Mechanical Code ASHRAE American Society of Heating, Refrigeration and Air Conditioning Engineers SMACNA Sheet Metal and Air Conditioning National Contractors Association IAQ Recognized Standards • ASHRAE Standard 62.1-2007 Ventilation for Acceptable Indoor Air Quality • ASHRAE Standard 52.2-1999 Method of Testing General Ventilation Air Cleaning Devices for Removal Efficiency by Particle Size • ANSI/ASHRAE Addenda 62t and 62w, Addenda to ANSI/ASHRAE Standard 62.1-2007, Ventilation for Acceptable Indoor Air Quality • EPA document # 402-F-91-102 Building Air Quality • SMACNA IAQ Guidelines for Occupied Buildings Under Construction • Tribal Lands should consider adopting codes and standards to improve IAQ. – Referenced Standards in ICC framework, International Mechanical Code – CFR Requirements for Federal Compliance • CFR 559.5 – Licensing Requirements for Gaming Facilities – State and Local Codes and Standards may required compliance due to Compact requirements Prevention Strategies • The best strategy to avoid most all forms of building contaminates are a result of proper design, construction and maintenance of the facility. • Without emphasis on design and construction, containment and maintenance efforts are more difficult to undertake and achieve similar results Causes of Contamination • More commonly cited sources: – – – – – – – – – Dust & Mold CO2 Volatile Organic Compounds (VOC’s) Stuffy, Stale, Moisture or excessively Dry Air Tobacco Smoke Exhaust from combustion (internal and external) Radon, Sewer Gas, Methane Biological contaminates Pesticides End Result – Poor IAQ • • • • • • • Sick Building Syndrome (SBS) Building Related Illness (BRI) Multiple Chemical Sensitivity (MCS) Loss of Productivity for employees Increased health care costs Loss of income from patrons Increased Maintenance Costs Avoiding Poor Filtration & Airflow • Contract Document Language • IAQ Design Standard • IAQ Requirements incorporated into Specifications • Clarification of Scope to assure who will conduct IAQ Plans and requirements Contract Documents • Owner’s Representative/ Program Manager Agreement • Architects Agreement • CM/ General Contractor Agreement • General Conditions • Specifications • Drawings, Addenda, RFI, Change Orders CSI MasterFormat® • Construction Specification Institute’s MasterFormat is the most widely recognized and implemented specification standard in use today. • CSI Specifications should be amended to incorporate project specific goals and standards to achieve optimal IAQ. Facility Construction Subgroup • • • • • • • • Division 07 — Thermal and Moisture Protection Division 08 — Openings Division 09 — Finishes Division 10 — Specialties Division 11 — Equipment Division 12 — Furnishings Division 23 — Heating Ventilation and Air Conditioning Division 44 — Pollution Control Equipment Drawings • The architect will either be responsible for the entire design which will result in drawings, or outline specific elements as Design Build, Design Assist or as a Design Specification. • Specific details or requirements in the specifications for windows, doors, penetrations, openings, shaft enclosures, shall be detailed or specified in accordance with codes, standards or best practices for IAQ. • Plan check review should have an IAQ emphasis from a qualified professional with IAQ experience. CM/GC Agreements • Contract language that details responsibilities for the CM/GC as included services will need to be incorporated. • Specific Codes and Standards for construction incorporated into contract language. • Specifications, and associated drawings, addenda etc. should be referenced in contract for clarity. Division 01 — General Requirements • General Requirements for cleanup • Coordination of Commissioning and IAQ Plan implementation • Requirements for the enclosure of building envelope during construction to prevent moisture contamination / mold prevention • Construction Sequencing and Monitoring IAQ Design Goals • Provide thermal comfort • Distribute adequate amounts of outdoor air to meet ventilation needs of all building occupants • Isolate and remove odors and contaminants through pressure control, filtration, and exhaust fans and specialized equipment 8 Key Design Strategies to improve IAQ • • • • • • Manage the process to achieve good IAQ Control moisture in building assemblies Limit entry of outdoor contaminants Control moisture & contaminants in mechanical systems Limit contaminants from indoor sources Contain and exhaust contaminants from equipment & activities • Reduce concentrations through ventilation and air cleaning • Apply more advanced ventilation approaches Design Considerations • • • • • • • High Standards in design for IAQ Integrated Design Team Approach Facility placement on site Intake and exhaust grille placement Zone configuration to prevent cross contamination Integrated Design Approach Interiors Selection to minimize VOC’s Design Team Coordination • Integrated Design should be employed to capture all trades input. • Architect, Owner’s Representation or PreConstruction Management should coordinate all IAQ efforts among Design Team. • Best Practices from ASHRAE Advanced Energy Design Guide(s) Construction IAQ Plan • Construction IAQ Management Plan SMACNA IAQ Guidelines for Occupied Buildings Under Construction, Ch 3 (2007). • ASHRAE 52.2-2007: Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size. Pre-Occupancy IAQ Plan • Construction IAQ Management Plan Review • After construction ends and prior to occupancy conduct a minimum two-week building flush-out with new Minimum Efficiency Reporting Value (MERV) 13 filtration media at 100% outside air. After the flush out, replace the filtration media with new MERV 13 filtration media, except the filters solely processing outside air. -OR• Conduct a baseline indoor air quality testing procedure consistent with the United States Environmental Protection Agency’s current Protocol for Environmental Requirements, Baseline IAQ and Materials, for the Research Triangle Park Campus, Section 01445. Heating & Cooling Equipment Making up the most important functional element of design are the HVAC functional components that will be implemented to heat and cool the building. The selection of the right system for the application is critical in ensuring appropriate IAQ. HVAC System Types Dedicated Outdoor Air Systems Ground Source Heat Pump (GSHP) Displacement Ventilation Systems Energy Recovery Ventilation Systems Package Rooftop Systems Ductless Split System Evaporative Cooling System Chilled Water Plants Baseboard Heating System Hydronic Ceiling Panel System Unit Ventilator System VAV Reheat System Under floor Systems (UFAD) Evaporatively Precooled Condenser Dedicated Outside Air Systems Example Supplemental Equipment Strategies • • • • • • • • Electrostatic Air Cleaners Humidification / Dehumidification Radiant Heating Systems ERV – Energy Recovery Wheels Air-to-Air, Fixed-Plate Heat Exchanger Features Desiccant Dehumidification HEPA Filtration Monitoring Monitoring Equipment • Of utmost importance is the integration of monitoring equipment into the building management system for not only temperature but for humidity, CO2 and VOC’s. With properly placed sensors and integration, HVAC system performance and efficiency can be monitored for not only compliance to standards but to improve energy efficiency, comfort and improve maintenance monitoring. • In addition, this equipment can help set a baseline and provide historical trend analysis tools to help monitor system performance • Lastly, monitoring equipment can help isolate and troubleshoot areas of concern. HVAC Commissioning Plan • • • • • Commissioning plan development. Documentation of design intent. Design review. Submittals review. Inspections and system functional performance testing. • Enhanced operating and maintenance documentation, including hands-on training of the staff • Operating and maintaining the equipment. • Post-occupancy testing and operation evaluation. Combustion Air Openings • • • • International Mechanical Code Sized in accordance with code Installed in accordance with code Combustion Air Systems – Utilized to help improve IAQ – Improved rodent control – Confined or Unconfined Spaces requirements Intake & Exhaust Design Considerations Source HS3: ASHRAE 62 Guidelines Chimney Connector Pass throughs • Installed in accordance with IBC or adopted, Chapter 8 Chimneys & Vents and Appendix A • Installed in accordance with IMC and NFPA 211 • Properly detailed in Construction Documents • Rated Assemblies and penetrations need to meet of exceed building, fire and mechanical codes • Uniformity and guidance found in NFPA 97 • Chimney Connector Heat Reclaimers • Gas Vent Connectors • Direct Vent • Fuel Fired Appliances IAQ and Chimney Connectors • Properly installed to exhaust harmful gasses to the atmosphere to prevent buildup of harmful gasses • What You Should Know About Combustion Appliances and Indoor Air Pollution – EPA Clean Indoor Air Design Concerns • Stack Effect • Back Drafting • Monitoring Systems