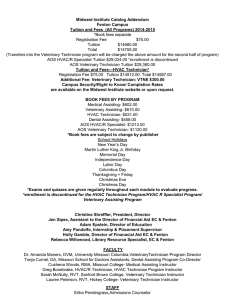

HVAC Systems and Their Role in Infection Control and

advertisement

Presented by: John Martinelli Corporate Director of Healthcare Services Forensic Analytical Consulting Services. Inc. November 14, 2013 – CSHE Orange County Chapter In-Service Webcast Upon completion of this session you will be able to: : ◦ Discuss the impact of HVAC system on infection control and prevention in hospital settings; ◦ Describe the importance of pressure relationships established by the HVAC systems; ◦ Explain how air exchange rates and pressure differentials work together to control and remove airborne contaminants; ◦ List resources available to assist in determining how a room’s HVAC system should perform based on the room use; ◦ Describe the impact of temporary or unplanned changes to the HVAC system’s function can impact the environment; and ◦ Describe methods and tools used to confirm the system is functioning as designed Major Functions of HVAC • • • • Provide fresh air Control temperature and humidity Filter air coming in to the building Control air flow – By creating pressure differentials – Directional supply (laminar flow) – Alignment of supply and exhaust/return • Quickly relocate, dilute and remove airborne contaminants Teamwork Required • Air Exchanges – Calculations based on space volume and total air supplied to the space (20’ x 20’ x 10’ = 400 cubic foot space, with 100 CFM supplied gets one room volume of air exchange every 4 minutes or 15 ACH) • Pressure differentials – Barriers required (walls and doors, ceilings and floors) – Open doors can defeat the design – Amount of air supplied and air removed must be different Air Exchanges What it does • Supplies filtered, fresh air to the space – In with the good • Dilutes and replaces – Out with the bad – CO2, airborne contaminants Presumes no new contaminant being introduced Presumes perfect air mixing Pressure Differential (ΔP) • Positive pressure – More air supplied to space than removed • Examples – Protective Environment (PE) Rooms – Patients at high risk of acquiring infection – Operating Rooms – Wrap and Pack (Clean side) of Sterile Processing Pressure Differential (ΔP) • Negative pressure – More air removed from space than is supplied • Examples – – – – Airborne Infection Isolation Rooms (AIIR’s) Restrooms Scope Wash Decontamination (Dirty side) of Sterile Processing Why Bother? • Required by Code – – – – ANSI/ASHRAE/ASHE Standard 170-2008 (Table 7.1) AIA Guidelines, 2001 FGI Guidelines, 2010 – TJC (EOC Standard) Cal Mechanical Code (Table 4A) - OSHPD • Written Policy/Management Plans • And It Works! – Reduces HAI’s – Provides defensibility Why Bother? • Stepped up enforcement – Joint Commission looking at pressure differentials more closely than ever – OR’s, Endoscopy, SPD/CSP – Findings can be for EOC and Leadership But it was compliant when it was built (So do I have to bring it up to current code?) • Can remain as installed unless: – Change in Room Function (per paragraph 104.3) – Remodel (per paragraph 104.1, minor remodel OK) – Deemed necessary by building official for the general safety and welfare of the occupants and the public (per paragraph 102.6) Per OSHPD Code Application Notice, Can Minor Adjustment = Major Changes • IAQ Complaints – Staff restricting flow, changes things everywhere • Outdoor intakes require inspection and maintenance • Filter replacements – Clogged filters impact air supply (Quantity) • Impact of Construction Projects – Temporary Negative Pressure Areas Impact other Areas ++ ++ How do we know it’s working? • Test and Balance Reports – Measure supply (and exhaust/return) volumes from all registers in all critical spaces – Check Pressure Differentials at all doors and windows – Open windows and doors? – SPD doors open for work flow – Roll up doors at Materials Receiving and doors to hall propped open = ?? How do we know it’s working? Tools to Test • Test and Balance • Pressure Differentials Micromanometer Balometer Rotating Vane Anemometer : ◦ The HVAC system can have a significant positive impact on infection control and prevention in hospital settings; ◦ In addition to making the indoor environment comfortable air exchange rates and pressure differentials work together to control and remove airborne contaminants; ◦ The California Mechanical Code provides tables to show how the HVAC system should perform based on space use; ◦ Temporary or unplanned changes to the HVAC system’s function can impact the environment; and ◦ We can use a variety of tools and specialty vendors to test how well our permanent and temporary ventilation systems are working. Questions?