ACTIVITY #1 - Plastics Identification

advertisement

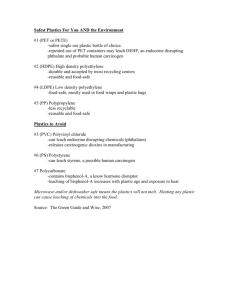

Plastics Identification Introduction: A tremendous variety of plastics have become commonplace in contemporary society. Unknown in 1950, plastics represent an enormous portion of the packaging industry in the 21st century. The plastics are tailored to provide properties related to their use. The compositions vary accordingly. Unlike many discarded materials, most plastics in common use do not biodegrade. Instead of biodegrading, plastics will photodegrade. Photodegradation is a process whereby sunlight breaks plastics into progressively smaller pieces, all of which are still plastic polymers. In fact, the degradation eventually yields individual molecules of plastic, but these are still too tough for most anything—even such indiscriminate consumers as bacteria—to digest. It turns out the each composition has a range of densities. Thus, measuring the density of a scrap of plastic gives insight about the plastic's composition. The densities suggest something very straightforward. For example, polypropylene, low density polyethylene, and high density polyethylene are expected to float on water while polystyrene, polyvinyl chloride, and polyethylene terephthalate are expected to sink under water. Consider the following values: Table 1 Name Abbrev Density g/mL Polypropylene PP 0.90-0.91 Low density polyethylene LDPE 0.92-0.94 High density Polyethylene HDPE 0.95-0.97 Polystyrene PS 1.05-1.07 Polyvinyl chloride V 1.18-1.65 Polyethylene terephthalate PETE 1.38-1.39 1 Objective: Samples of plastic can be distinguished on the basis of floating or sinking in solvents of known density. Materials: 5 test tubes per lab group Test tube rack (one per lab group) Masking tape & markers for labeling test tubes Colored Plastic samples 5 types of solvent Toothpicks 5 plastic disposable transfer pipettes per lab group Safety: The ethanol is flammable. Keep open flames and spark sources away from the solvents. Know the location of the fire equipment; review use of that equipment before beginning work. Wear goggles and apron. Wash spills with water. Avoid ingesting the chemicals. Wash hands after the experiment. Procedure: 1. Label 5 test tubes with the name of each solvent being used. See table 3 to properly label each test tube with the name of the solvent. 2. Use a different disposable plastic transfer pipettes to fill each labeled test tube 2/3’s full with the density solvents. 3. Place small samples of the colored plastics, one of each color, into each tube. HINT: Each colored plastic sample has been numbered. Refer to Table 4. 4. Surface tensions will cause all of the plastics to float until each is "wetted" and submerged. Use a toothpick to poke at the plastics until they are submerged. Be sure no bubbles are trapped by the plastic chips. 5. Note and RECORD in table 3 which plastics FLOAT, and which SINK on a solvent by solvent basis. 6. Repeat for each plastic sample. 7. After all plastics have been tested and recorded in data table 3, determine 2 Results: Table 2 Color of Plastic Sample Green Blue Gold Yellow White Red Number 1 2 3 4 5 6 Table 3 Test Tube Number solvent density g/mL 1 sat MgCl2 1.34 2 10% NaCl in water 1.08 3 water 1.00 4 1:1 ethanol:water 0.94 5 4:3 ethanol: water 0.92 3 Float (plastic #) Sink (plastic #) Table 4 Plastic Type Density of Plastic PP 0.90-0.91 g/ml LDPE 0.92-0.94 g/mL HDPE 0.95-0.97 g/mL PS 1.05-1.07 g/mL V 1.18-1.30 g/mL PETE 1.38-1.39 g/mL Color Questions: 1. An unknown plastic floats on water but sinks under 10% NaCl. Suggest the composition of this plastic. 2. The same principles used here are used by gas station attendants to check antifreeze. Explain what is done and the basis for the procedure. Image: http://www.mindfully.org/Plastic/Plasticizers/Out-Of-DietPG5nov03.htm 4